Technological advancements in AMOLED screen printing.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AMOLED Printing Evolution

The evolution of AMOLED printing technology has been a remarkable journey, marked by significant advancements and innovations. Initially, AMOLED displays were primarily manufactured using vacuum thermal evaporation techniques, which were costly and limited in scalability. However, the industry's pursuit of more efficient and cost-effective production methods led to the exploration of printing technologies.

In the early 2000s, researchers began investigating the potential of inkjet printing for OLED fabrication. This marked the first significant step towards printable AMOLED displays. The initial attempts faced challenges such as poor resolution and inconsistent film formation, but they laid the groundwork for future developments.

By the mid-2000s, screen printing emerged as a promising alternative for AMOLED production. This technique offered advantages in terms of material efficiency and the ability to create larger displays. Early screen-printed AMOLED prototypes demonstrated the feasibility of the approach, although they still struggled with issues like uniformity and pixel definition.

The late 2000s and early 2010s saw rapid advancements in AMOLED printing technologies. Researchers focused on developing specialized inks and improving printing processes to enhance display quality. Nozzle-printing techniques were refined, allowing for more precise deposition of organic materials. This period also witnessed the introduction of roll-to-roll printing concepts for AMOLED displays, promising high-volume production capabilities.

From 2015 onwards, the industry has seen a convergence of various printing technologies for AMOLED production. Hybrid approaches combining screen printing, inkjet printing, and other deposition methods have emerged. These integrated solutions aim to leverage the strengths of each technique while mitigating their individual limitations.

Recent years have brought about significant improvements in printing resolution and color accuracy. Advanced screen printing techniques now allow for the creation of high-resolution AMOLED displays with pixel densities comparable to those achieved through traditional evaporation methods. The development of new organic materials specifically designed for printing processes has further enhanced the performance of printed AMOLED displays.

Looking ahead, the evolution of AMOLED printing technology is expected to continue at a rapid pace. Research is ongoing into novel printing techniques such as electrohydrodynamic jet printing and micro-contact printing, which promise even greater precision and efficiency. Additionally, efforts are being made to develop fully solution-processed AMOLED displays, which could revolutionize the manufacturing process and enable new form factors and applications.

In the early 2000s, researchers began investigating the potential of inkjet printing for OLED fabrication. This marked the first significant step towards printable AMOLED displays. The initial attempts faced challenges such as poor resolution and inconsistent film formation, but they laid the groundwork for future developments.

By the mid-2000s, screen printing emerged as a promising alternative for AMOLED production. This technique offered advantages in terms of material efficiency and the ability to create larger displays. Early screen-printed AMOLED prototypes demonstrated the feasibility of the approach, although they still struggled with issues like uniformity and pixel definition.

The late 2000s and early 2010s saw rapid advancements in AMOLED printing technologies. Researchers focused on developing specialized inks and improving printing processes to enhance display quality. Nozzle-printing techniques were refined, allowing for more precise deposition of organic materials. This period also witnessed the introduction of roll-to-roll printing concepts for AMOLED displays, promising high-volume production capabilities.

From 2015 onwards, the industry has seen a convergence of various printing technologies for AMOLED production. Hybrid approaches combining screen printing, inkjet printing, and other deposition methods have emerged. These integrated solutions aim to leverage the strengths of each technique while mitigating their individual limitations.

Recent years have brought about significant improvements in printing resolution and color accuracy. Advanced screen printing techniques now allow for the creation of high-resolution AMOLED displays with pixel densities comparable to those achieved through traditional evaporation methods. The development of new organic materials specifically designed for printing processes has further enhanced the performance of printed AMOLED displays.

Looking ahead, the evolution of AMOLED printing technology is expected to continue at a rapid pace. Research is ongoing into novel printing techniques such as electrohydrodynamic jet printing and micro-contact printing, which promise even greater precision and efficiency. Additionally, efforts are being made to develop fully solution-processed AMOLED displays, which could revolutionize the manufacturing process and enable new form factors and applications.

Market Demand Analysis

The AMOLED screen printing market has experienced significant growth in recent years, driven by the increasing demand for high-quality displays in various electronic devices. The global AMOLED market size was valued at $25.5 billion in 2020 and is projected to reach $73.4 billion by 2027, growing at a CAGR of 16.2% during the forecast period. This robust growth is primarily attributed to the rising adoption of AMOLED displays in smartphones, tablets, and televisions.

Consumer electronics, particularly smartphones, remain the largest application segment for AMOLED screen printing technology. The smartphone industry's shift towards bezel-less designs and foldable devices has further accelerated the demand for flexible AMOLED displays. Major smartphone manufacturers like Samsung, Apple, and Huawei have been incorporating AMOLED screens into their flagship devices, driving market growth.

The automotive sector is emerging as a promising market for AMOLED displays, with increasing integration of advanced infotainment systems and digital dashboards in vehicles. The automotive AMOLED display market is expected to grow at a CAGR of 19.8% from 2021 to 2026, indicating substantial opportunities for screen printing technology in this sector.

Wearable devices, including smartwatches and fitness trackers, represent another rapidly growing segment for AMOLED displays. The global wearable display market is projected to reach $4.9 billion by 2025, with AMOLED technology playing a crucial role in this growth due to its energy efficiency and flexibility.

Geographically, Asia Pacific dominates the AMOLED screen printing market, accounting for over 60% of the global market share. This is primarily due to the presence of major display manufacturers and smartphone producers in countries like South Korea, China, and Japan. North America and Europe follow as key markets, driven by the adoption of AMOLED displays in high-end consumer electronics and automotive applications.

The demand for larger AMOLED displays in televisions and monitors is also on the rise, with the market for AMOLED TVs expected to grow at a CAGR of 15.2% from 2021 to 2026. This trend is fueled by consumers' increasing preference for superior picture quality and thinner form factors in their home entertainment systems.

As technological advancements continue to improve the efficiency and reduce the cost of AMOLED screen printing, the market is expected to expand into new application areas such as augmented reality (AR) and virtual reality (VR) devices. The AR and VR market is projected to reach $72.8 billion by 2024, presenting significant opportunities for AMOLED display technologies.

Consumer electronics, particularly smartphones, remain the largest application segment for AMOLED screen printing technology. The smartphone industry's shift towards bezel-less designs and foldable devices has further accelerated the demand for flexible AMOLED displays. Major smartphone manufacturers like Samsung, Apple, and Huawei have been incorporating AMOLED screens into their flagship devices, driving market growth.

The automotive sector is emerging as a promising market for AMOLED displays, with increasing integration of advanced infotainment systems and digital dashboards in vehicles. The automotive AMOLED display market is expected to grow at a CAGR of 19.8% from 2021 to 2026, indicating substantial opportunities for screen printing technology in this sector.

Wearable devices, including smartwatches and fitness trackers, represent another rapidly growing segment for AMOLED displays. The global wearable display market is projected to reach $4.9 billion by 2025, with AMOLED technology playing a crucial role in this growth due to its energy efficiency and flexibility.

Geographically, Asia Pacific dominates the AMOLED screen printing market, accounting for over 60% of the global market share. This is primarily due to the presence of major display manufacturers and smartphone producers in countries like South Korea, China, and Japan. North America and Europe follow as key markets, driven by the adoption of AMOLED displays in high-end consumer electronics and automotive applications.

The demand for larger AMOLED displays in televisions and monitors is also on the rise, with the market for AMOLED TVs expected to grow at a CAGR of 15.2% from 2021 to 2026. This trend is fueled by consumers' increasing preference for superior picture quality and thinner form factors in their home entertainment systems.

As technological advancements continue to improve the efficiency and reduce the cost of AMOLED screen printing, the market is expected to expand into new application areas such as augmented reality (AR) and virtual reality (VR) devices. The AR and VR market is projected to reach $72.8 billion by 2024, presenting significant opportunities for AMOLED display technologies.

Technical Challenges

AMOLED screen printing technology has made significant strides in recent years, yet it still faces several technical challenges that hinder its widespread adoption and further advancement. One of the primary obstacles is achieving consistent and uniform deposition of organic materials across large-area substrates. The precision required for depositing multiple layers of organic compounds, each only a few nanometers thick, poses significant difficulties in maintaining uniformity and preventing defects.

Another major challenge lies in the development of stable and efficient blue OLED emitters. While red and green OLED materials have achieved satisfactory performance levels, blue OLEDs continue to lag behind in terms of efficiency and longevity. This imbalance affects the overall color reproduction and lifespan of AMOLED displays, necessitating ongoing research into novel blue emitting materials and device architectures.

The encapsulation of OLED devices remains a critical issue, as organic materials are highly sensitive to moisture and oxygen. Current encapsulation techniques, while effective, add complexity and cost to the manufacturing process. Developing more efficient and cost-effective encapsulation methods is crucial for improving device reliability and reducing production expenses.

Scaling up production while maintaining high yield rates presents another significant challenge. As display sizes increase and pixel densities become higher, the complexity of the manufacturing process grows exponentially. Ensuring consistent quality across large production batches requires advanced process control and monitoring systems, as well as innovative approaches to defect detection and correction.

The thermal management of AMOLED displays, particularly in high-brightness applications, poses ongoing challenges. As display brightness increases, so does the heat generated by the organic materials, potentially leading to decreased efficiency and shortened device lifetimes. Developing more efficient thermal management solutions and heat-resistant materials is essential for expanding the application range of AMOLED technology.

Furthermore, the industry faces challenges in reducing the overall cost of AMOLED production. While prices have decreased over time, AMOLED displays remain more expensive than their LCD counterparts. This cost differential is partly due to the complexity of the manufacturing process and the high-purity materials required. Innovations in production techniques and materials science are necessary to bridge this cost gap and make AMOLED technology more accessible across various market segments.

Lastly, the environmental impact of AMOLED production and disposal presents growing concerns. The use of rare and potentially harmful materials in some OLED compounds, coupled with the challenges of recycling complex display structures, necessitates research into more sustainable materials and manufacturing processes. Developing eco-friendly alternatives and improving recycling technologies are becoming increasingly important as the adoption of AMOLED displays continues to grow globally.

Another major challenge lies in the development of stable and efficient blue OLED emitters. While red and green OLED materials have achieved satisfactory performance levels, blue OLEDs continue to lag behind in terms of efficiency and longevity. This imbalance affects the overall color reproduction and lifespan of AMOLED displays, necessitating ongoing research into novel blue emitting materials and device architectures.

The encapsulation of OLED devices remains a critical issue, as organic materials are highly sensitive to moisture and oxygen. Current encapsulation techniques, while effective, add complexity and cost to the manufacturing process. Developing more efficient and cost-effective encapsulation methods is crucial for improving device reliability and reducing production expenses.

Scaling up production while maintaining high yield rates presents another significant challenge. As display sizes increase and pixel densities become higher, the complexity of the manufacturing process grows exponentially. Ensuring consistent quality across large production batches requires advanced process control and monitoring systems, as well as innovative approaches to defect detection and correction.

The thermal management of AMOLED displays, particularly in high-brightness applications, poses ongoing challenges. As display brightness increases, so does the heat generated by the organic materials, potentially leading to decreased efficiency and shortened device lifetimes. Developing more efficient thermal management solutions and heat-resistant materials is essential for expanding the application range of AMOLED technology.

Furthermore, the industry faces challenges in reducing the overall cost of AMOLED production. While prices have decreased over time, AMOLED displays remain more expensive than their LCD counterparts. This cost differential is partly due to the complexity of the manufacturing process and the high-purity materials required. Innovations in production techniques and materials science are necessary to bridge this cost gap and make AMOLED technology more accessible across various market segments.

Lastly, the environmental impact of AMOLED production and disposal presents growing concerns. The use of rare and potentially harmful materials in some OLED compounds, coupled with the challenges of recycling complex display structures, necessitates research into more sustainable materials and manufacturing processes. Developing eco-friendly alternatives and improving recycling technologies are becoming increasingly important as the adoption of AMOLED displays continues to grow globally.

Current Printing Solutions

01 AMOLED display panel manufacturing

Various techniques for manufacturing AMOLED display panels, including methods for improving pixel structure, enhancing display quality, and optimizing production processes. These advancements aim to increase the efficiency and performance of AMOLED screens.- AMOLED display panel manufacturing: Various techniques for manufacturing AMOLED display panels, including methods for improving pixel structure, enhancing display quality, and optimizing production processes. These advancements aim to increase the efficiency and performance of AMOLED screens.

- Driving circuits for AMOLED displays: Development of driving circuits specifically designed for AMOLED displays, focusing on improving image quality, reducing power consumption, and enhancing overall display performance. These circuits address issues such as non-uniformity and aging of OLED pixels.

- AMOLED screen printing techniques: Innovative screen printing methods for AMOLED displays, including techniques for depositing organic materials, patterning electrodes, and creating fine-pitch pixel structures. These methods aim to improve the resolution, color accuracy, and uniformity of AMOLED screens.

- AMOLED display device structures: Novel structural designs for AMOLED display devices, including improvements in pixel layout, substrate configuration, and encapsulation techniques. These advancements aim to enhance display performance, increase durability, and enable flexible or foldable AMOLED screens.

- AMOLED color management and calibration: Methods and systems for managing color reproduction and calibrating AMOLED displays, focusing on improving color accuracy, consistency, and longevity. These techniques address issues such as color shift, burn-in, and variations in OLED material degradation over time.

02 Screen printing techniques for AMOLED

Specialized screen printing methods developed for AMOLED displays, focusing on precise deposition of organic materials and conductive elements. These techniques aim to improve the uniformity and resolution of printed layers in AMOLED screens.Expand Specific Solutions03 Driving circuits for AMOLED displays

Innovative driving circuit designs for AMOLED displays, including pixel driving circuits and compensation techniques. These circuits aim to enhance display performance, reduce power consumption, and improve overall image quality.Expand Specific Solutions04 AMOLED touch integration

Methods for integrating touch functionality into AMOLED displays, including in-cell and on-cell touch technologies. These approaches aim to reduce display thickness, improve touch sensitivity, and enhance overall user experience.Expand Specific Solutions05 AMOLED color management and calibration

Techniques for color management and calibration in AMOLED displays, including methods for improving color accuracy, consistency, and brightness. These advancements aim to enhance the visual quality and longevity of AMOLED screens.Expand Specific Solutions

Key Industry Players

The AMOLED screen printing technology market is in a growth phase, with increasing demand driven by the proliferation of smartphones, wearables, and other electronic devices. The global market size is expanding rapidly, expected to reach billions of dollars in the coming years. Technologically, AMOLED screen printing is advancing, with key players like Samsung Electronics, BOE Technology, and TCL China Star Optoelectronics leading innovation. These companies, along with others like Tianma Microelectronics and Everdisplay Optronics, are investing heavily in R&D to improve efficiency, color accuracy, and flexibility of AMOLED displays. The competition is intense, with Chinese manufacturers rapidly catching up to Korean and Japanese counterparts in terms of technological capabilities and production capacity.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has made significant advancements in AMOLED screen printing technology. They have developed a high-resolution fine metal mask (FMM) process that enables the production of displays with pixel densities exceeding 600 PPI [1]. This technology utilizes precise laser-cut metal masks to deposit organic materials accurately. BOE has also introduced inkjet printing for AMOLED production, which allows for more efficient material usage and reduced production costs [2]. Their latest Gen 6 flexible AMOLED production line incorporates advanced evaporation techniques and in-situ encapsulation technology, improving display quality and durability [3].

Strengths: High-resolution capabilities, cost-effective production, and flexible display technology. Weaknesses: Potential yield issues with new technologies and competition from established players.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has pioneered several advancements in AMOLED screen printing. They have developed a proprietary Fine Metal Mask (FMM) technology that allows for ultra-high-resolution OLED deposition, achieving pixel densities over 1000 PPI [4]. Samsung has also introduced a revolutionary Quantum Dot (QD) OLED technology, which combines OLED with quantum dot color conversion layers, resulting in improved color volume and energy efficiency [5]. Additionally, they have made progress in inkjet printing for OLED displays, potentially reducing production costs and enabling larger screen sizes [6].

Strengths: Industry-leading resolution, innovative QD-OLED technology, and established production capabilities. Weaknesses: High production costs and potential oversaturation in the high-end market.

Innovative Techniques

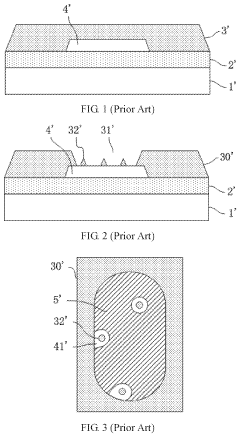

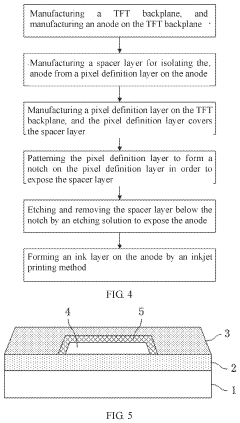

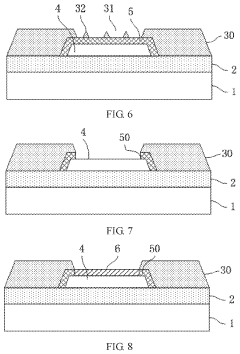

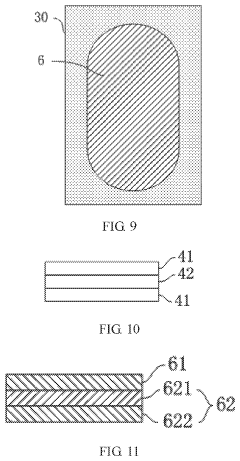

Manufacturing method for an inkjet printing amoled display panel

PatentActiveUS20190371871A1

Innovation

- A manufacturing method involving a spacer layer etched by an etching solution to remove residual PDL material, allowing even inkjet printing without damaging the surface structure or causing thickness/line width loss, comprising steps like forming a TFT backplane, patterning a pixel definition layer, and etching the spacer layer below the notch to expose the anode for improved ink spreadability.

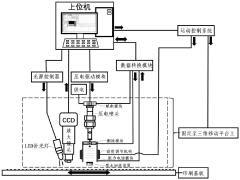

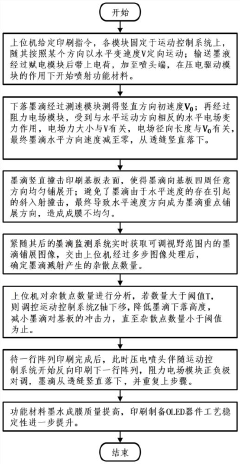

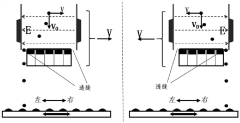

Piezoelectric control system and method for printing high-quality OLED display film layer

PatentInactiveCN113211984A

Innovation

- Using a piezoelectric control system, including a host computer, piezoelectric drive system, motion control system, horizontal ink calming system and ink drop monitoring system, the piezoelectric nozzle moves on the printed substrate and uses the horizontal ink calming system to eliminate the initial speed of the ink droplets , spreading it evenly on the substrate, and adjusting the number of stray dots in real time through the ink droplet monitoring system.

Material Advancements

Material advancements in AMOLED screen printing technology have been pivotal in enhancing the performance and efficiency of displays. Recent years have witnessed significant progress in the development of organic materials, particularly in the realm of emissive layers and charge transport materials.

One of the key areas of improvement has been in the development of phosphorescent emitters. These materials have demonstrated superior efficiency compared to their fluorescent counterparts, allowing for reduced power consumption and extended device lifetimes. Iridium-based complexes have been at the forefront of this advancement, with researchers fine-tuning their molecular structures to achieve optimal color purity and quantum efficiency.

Advancements in hole transport materials (HTMs) and electron transport materials (ETMs) have also played a crucial role in enhancing AMOLED performance. Novel HTMs with high hole mobility and appropriate energy levels have been synthesized, facilitating more efficient charge injection and transport. Similarly, ETMs with improved electron mobility and stability have been developed, contributing to better overall device performance.

The introduction of thermally activated delayed fluorescence (TADF) emitters represents another significant breakthrough in AMOLED materials. These materials can harvest both singlet and triplet excitons, potentially achieving 100% internal quantum efficiency without the need for expensive rare-earth metals. Ongoing research in this area focuses on developing blue TADF emitters with long operational lifetimes, addressing one of the major challenges in OLED technology.

Nanoparticle-based materials have also emerged as a promising avenue for AMOLED screen printing. Quantum dots (QDs), in particular, have garnered significant attention due to their tunable optical properties and high color purity. Efforts are underway to develop solution-processable QD emitters that can be directly integrated into the printing process, potentially simplifying manufacturing and reducing costs.

Advancements in host materials have been equally important, with researchers developing new compounds that offer improved thermal stability and charge balance. These materials play a crucial role in supporting the emissive dopants and ensuring efficient energy transfer within the device structure.

Lastly, the development of flexible and stretchable materials has opened up new possibilities for AMOLED applications. Polymer-based substrates and electrodes that can withstand bending and stretching without compromising electrical performance have been successfully demonstrated, paving the way for next-generation flexible and wearable displays.

One of the key areas of improvement has been in the development of phosphorescent emitters. These materials have demonstrated superior efficiency compared to their fluorescent counterparts, allowing for reduced power consumption and extended device lifetimes. Iridium-based complexes have been at the forefront of this advancement, with researchers fine-tuning their molecular structures to achieve optimal color purity and quantum efficiency.

Advancements in hole transport materials (HTMs) and electron transport materials (ETMs) have also played a crucial role in enhancing AMOLED performance. Novel HTMs with high hole mobility and appropriate energy levels have been synthesized, facilitating more efficient charge injection and transport. Similarly, ETMs with improved electron mobility and stability have been developed, contributing to better overall device performance.

The introduction of thermally activated delayed fluorescence (TADF) emitters represents another significant breakthrough in AMOLED materials. These materials can harvest both singlet and triplet excitons, potentially achieving 100% internal quantum efficiency without the need for expensive rare-earth metals. Ongoing research in this area focuses on developing blue TADF emitters with long operational lifetimes, addressing one of the major challenges in OLED technology.

Nanoparticle-based materials have also emerged as a promising avenue for AMOLED screen printing. Quantum dots (QDs), in particular, have garnered significant attention due to their tunable optical properties and high color purity. Efforts are underway to develop solution-processable QD emitters that can be directly integrated into the printing process, potentially simplifying manufacturing and reducing costs.

Advancements in host materials have been equally important, with researchers developing new compounds that offer improved thermal stability and charge balance. These materials play a crucial role in supporting the emissive dopants and ensuring efficient energy transfer within the device structure.

Lastly, the development of flexible and stretchable materials has opened up new possibilities for AMOLED applications. Polymer-based substrates and electrodes that can withstand bending and stretching without compromising electrical performance have been successfully demonstrated, paving the way for next-generation flexible and wearable displays.

Environmental Impact

The environmental impact of AMOLED screen printing technology has become an increasingly important consideration in the electronics industry. As advancements in this field continue to progress, it is crucial to assess both the positive and negative effects on the environment throughout the entire lifecycle of AMOLED displays.

One of the primary environmental benefits of AMOLED technology is its potential for energy efficiency. AMOLED screens typically consume less power than traditional LCD displays, particularly when displaying darker content. This reduced energy consumption can lead to longer battery life in portable devices and lower electricity usage in larger displays, potentially decreasing overall energy demand and associated carbon emissions.

However, the production process of AMOLED screens presents several environmental challenges. The manufacturing of these displays often involves the use of rare earth elements and precious metals, which can lead to resource depletion and environmental degradation in mining areas. Additionally, the production of AMOLED screens requires various chemicals and solvents, some of which may be hazardous or contribute to air and water pollution if not properly managed.

The disposal and recycling of AMOLED screens also pose significant environmental concerns. As consumer electronics continue to have shorter lifespans, the volume of e-waste containing AMOLED displays is increasing. Many of these devices end up in landfills, where they can leach harmful substances into the soil and groundwater. Proper recycling of AMOLED screens is complex due to the intricate layering of materials, making it challenging to separate and recover valuable components.

Recent technological advancements in AMOLED screen printing have focused on addressing some of these environmental issues. Researchers are exploring more sustainable materials and production methods, such as using organic compounds derived from renewable sources. Some manufacturers are also developing more efficient recycling processes to recover valuable materials from discarded AMOLED displays.

The industry is also making strides in improving the durability and lifespan of AMOLED screens, which could help reduce e-waste generation. Innovations in screen protection technologies and more robust organic materials are contributing to longer-lasting displays, potentially decreasing the frequency of device replacements.

As AMOLED technology continues to evolve, there is a growing emphasis on adopting circular economy principles in the design and production of these displays. This approach aims to minimize waste and maximize resource efficiency throughout the product lifecycle, from manufacturing to end-of-life management.

One of the primary environmental benefits of AMOLED technology is its potential for energy efficiency. AMOLED screens typically consume less power than traditional LCD displays, particularly when displaying darker content. This reduced energy consumption can lead to longer battery life in portable devices and lower electricity usage in larger displays, potentially decreasing overall energy demand and associated carbon emissions.

However, the production process of AMOLED screens presents several environmental challenges. The manufacturing of these displays often involves the use of rare earth elements and precious metals, which can lead to resource depletion and environmental degradation in mining areas. Additionally, the production of AMOLED screens requires various chemicals and solvents, some of which may be hazardous or contribute to air and water pollution if not properly managed.

The disposal and recycling of AMOLED screens also pose significant environmental concerns. As consumer electronics continue to have shorter lifespans, the volume of e-waste containing AMOLED displays is increasing. Many of these devices end up in landfills, where they can leach harmful substances into the soil and groundwater. Proper recycling of AMOLED screens is complex due to the intricate layering of materials, making it challenging to separate and recover valuable components.

Recent technological advancements in AMOLED screen printing have focused on addressing some of these environmental issues. Researchers are exploring more sustainable materials and production methods, such as using organic compounds derived from renewable sources. Some manufacturers are also developing more efficient recycling processes to recover valuable materials from discarded AMOLED displays.

The industry is also making strides in improving the durability and lifespan of AMOLED screens, which could help reduce e-waste generation. Innovations in screen protection technologies and more robust organic materials are contributing to longer-lasting displays, potentially decreasing the frequency of device replacements.

As AMOLED technology continues to evolve, there is a growing emphasis on adopting circular economy principles in the design and production of these displays. This approach aims to minimize waste and maximize resource efficiency throughout the product lifecycle, from manufacturing to end-of-life management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!