How Coating Technologies Improve Solenoid Valve Corrosion Resistance

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Coating Evolution and Objectives

Solenoid valve coating technologies have undergone significant evolution over the past decades, driven by the increasing demand for enhanced corrosion resistance in various industrial applications. The primary objective of these advancements has been to extend the operational lifespan of solenoid valves, particularly in harsh environments where corrosive substances are prevalent.

Initially, solenoid valves were primarily constructed from uncoated metals, leaving them vulnerable to corrosion and degradation. As industries expanded into more challenging operational environments, the need for protective coatings became apparent. The first generation of coatings focused on basic barrier protection, utilizing simple paint-based solutions or rudimentary electroplating techniques.

The evolution of coating technologies progressed rapidly with the introduction of more sophisticated materials and application methods. Epoxy-based coatings emerged as a significant improvement, offering better adhesion and chemical resistance. This was followed by the development of powder coatings, which provided a more uniform and durable protective layer.

A major milestone in solenoid valve coating technology was the advent of advanced polymer coatings. These materials, such as polytetrafluoroethylene (PTFE) and fluoropolymers, offered exceptional chemical resistance and low friction properties, greatly enhancing the valve's performance in corrosive environments.

The introduction of nanotechnology marked another significant leap forward. Nanocoatings, with their ability to form ultra-thin yet highly effective protective layers, revolutionized the field. These coatings not only provided superior corrosion resistance but also improved the overall efficiency of the solenoid valves by reducing friction and enhancing flow characteristics.

Recent developments have focused on multi-layer coating systems, combining the benefits of different materials to create a synergistic protective effect. For instance, a base layer might provide excellent adhesion to the metal substrate, while subsequent layers offer chemical resistance and self-healing properties.

The current objectives in solenoid valve coating technology are multifaceted. Researchers and engineers are striving to develop coatings that not only provide superior corrosion resistance but also contribute to energy efficiency, extend maintenance intervals, and comply with increasingly stringent environmental regulations. There is a growing emphasis on creating eco-friendly coating solutions that maintain high performance standards while reducing the environmental impact of manufacturing and disposal processes.

Looking ahead, the field is moving towards smart coatings that can adapt to changing environmental conditions or even self-repair when damaged. The integration of sensors within coating layers to monitor valve health and predict maintenance needs is another area of active research, aligning with the broader trend of industrial IoT and predictive maintenance strategies.

Initially, solenoid valves were primarily constructed from uncoated metals, leaving them vulnerable to corrosion and degradation. As industries expanded into more challenging operational environments, the need for protective coatings became apparent. The first generation of coatings focused on basic barrier protection, utilizing simple paint-based solutions or rudimentary electroplating techniques.

The evolution of coating technologies progressed rapidly with the introduction of more sophisticated materials and application methods. Epoxy-based coatings emerged as a significant improvement, offering better adhesion and chemical resistance. This was followed by the development of powder coatings, which provided a more uniform and durable protective layer.

A major milestone in solenoid valve coating technology was the advent of advanced polymer coatings. These materials, such as polytetrafluoroethylene (PTFE) and fluoropolymers, offered exceptional chemical resistance and low friction properties, greatly enhancing the valve's performance in corrosive environments.

The introduction of nanotechnology marked another significant leap forward. Nanocoatings, with their ability to form ultra-thin yet highly effective protective layers, revolutionized the field. These coatings not only provided superior corrosion resistance but also improved the overall efficiency of the solenoid valves by reducing friction and enhancing flow characteristics.

Recent developments have focused on multi-layer coating systems, combining the benefits of different materials to create a synergistic protective effect. For instance, a base layer might provide excellent adhesion to the metal substrate, while subsequent layers offer chemical resistance and self-healing properties.

The current objectives in solenoid valve coating technology are multifaceted. Researchers and engineers are striving to develop coatings that not only provide superior corrosion resistance but also contribute to energy efficiency, extend maintenance intervals, and comply with increasingly stringent environmental regulations. There is a growing emphasis on creating eco-friendly coating solutions that maintain high performance standards while reducing the environmental impact of manufacturing and disposal processes.

Looking ahead, the field is moving towards smart coatings that can adapt to changing environmental conditions or even self-repair when damaged. The integration of sensors within coating layers to monitor valve health and predict maintenance needs is another area of active research, aligning with the broader trend of industrial IoT and predictive maintenance strategies.

Market Demand for Corrosion-Resistant Solenoid Valves

The market demand for corrosion-resistant solenoid valves has been steadily increasing across various industries due to the critical role these components play in fluid control systems. Solenoid valves are widely used in applications ranging from industrial processes to automotive systems, where exposure to corrosive environments is common. As a result, there is a growing need for valves that can withstand harsh conditions and maintain long-term reliability.

In the oil and gas industry, corrosion-resistant solenoid valves are essential for offshore platforms, refineries, and pipelines where exposure to saltwater, chemicals, and extreme temperatures is constant. The market in this sector is driven by the need to reduce maintenance costs and prevent costly shutdowns due to valve failures. Similarly, the chemical processing industry requires valves that can resist a wide range of corrosive substances, leading to increased demand for advanced coating technologies.

The automotive sector represents another significant market for corrosion-resistant solenoid valves. With the rise of electric and hybrid vehicles, there is a growing need for valves that can withstand the unique challenges posed by new coolant systems and battery technologies. Additionally, the trend towards lightweight materials in vehicle construction has increased the importance of corrosion protection for critical components.

In the water treatment and management sector, the demand for corrosion-resistant valves is driven by the need for reliable operation in both freshwater and wastewater applications. Municipalities and industrial water treatment facilities require valves that can withstand chlorine, ozone, and other corrosive chemicals used in water purification processes.

The aerospace industry also contributes to the market demand, as aircraft systems require highly reliable and corrosion-resistant components to ensure safety and longevity. The extreme conditions experienced during flight, including rapid temperature changes and exposure to various fluids, necessitate advanced coating technologies for solenoid valves used in hydraulic and pneumatic systems.

Market analysts project that the global demand for corrosion-resistant solenoid valves will continue to grow as industries seek to improve equipment reliability and reduce maintenance costs. This trend is further supported by stringent regulations regarding safety and environmental protection, which often require the use of more durable and corrosion-resistant components in critical systems.

As a result of these market dynamics, manufacturers are investing in research and development of innovative coating technologies to meet the increasing demand for corrosion-resistant solenoid valves. This has led to the emergence of new materials and coating processes designed to provide superior protection against a wide range of corrosive environments, ultimately driving the evolution of the solenoid valve market towards more durable and reliable products.

In the oil and gas industry, corrosion-resistant solenoid valves are essential for offshore platforms, refineries, and pipelines where exposure to saltwater, chemicals, and extreme temperatures is constant. The market in this sector is driven by the need to reduce maintenance costs and prevent costly shutdowns due to valve failures. Similarly, the chemical processing industry requires valves that can resist a wide range of corrosive substances, leading to increased demand for advanced coating technologies.

The automotive sector represents another significant market for corrosion-resistant solenoid valves. With the rise of electric and hybrid vehicles, there is a growing need for valves that can withstand the unique challenges posed by new coolant systems and battery technologies. Additionally, the trend towards lightweight materials in vehicle construction has increased the importance of corrosion protection for critical components.

In the water treatment and management sector, the demand for corrosion-resistant valves is driven by the need for reliable operation in both freshwater and wastewater applications. Municipalities and industrial water treatment facilities require valves that can withstand chlorine, ozone, and other corrosive chemicals used in water purification processes.

The aerospace industry also contributes to the market demand, as aircraft systems require highly reliable and corrosion-resistant components to ensure safety and longevity. The extreme conditions experienced during flight, including rapid temperature changes and exposure to various fluids, necessitate advanced coating technologies for solenoid valves used in hydraulic and pneumatic systems.

Market analysts project that the global demand for corrosion-resistant solenoid valves will continue to grow as industries seek to improve equipment reliability and reduce maintenance costs. This trend is further supported by stringent regulations regarding safety and environmental protection, which often require the use of more durable and corrosion-resistant components in critical systems.

As a result of these market dynamics, manufacturers are investing in research and development of innovative coating technologies to meet the increasing demand for corrosion-resistant solenoid valves. This has led to the emergence of new materials and coating processes designed to provide superior protection against a wide range of corrosive environments, ultimately driving the evolution of the solenoid valve market towards more durable and reliable products.

Current Coating Technologies and Challenges

Coating technologies have become increasingly crucial in enhancing the corrosion resistance of solenoid valves. Currently, several advanced coating methods are employed to protect these vital components from harsh environmental conditions and corrosive media. The most prevalent coating technologies include electroplating, physical vapor deposition (PVD), chemical vapor deposition (CVD), and thermal spraying.

Electroplating remains a widely used technique, offering a cost-effective solution for applying thin metallic coatings. This process involves the deposition of metals such as nickel, chrome, or zinc onto the valve surface through electrolysis. While effective for general corrosion protection, electroplating may struggle in extremely aggressive environments.

PVD coatings have gained significant traction due to their excellent wear resistance and ability to form dense, uniform layers. These coatings, typically composed of nitrides or carbides, are applied through processes like sputtering or evaporation. PVD coatings offer superior hardness and can significantly extend the lifespan of solenoid valves in corrosive settings.

CVD technology allows for the deposition of high-purity materials with excellent adhesion to the substrate. This method is particularly effective for applying diamond-like carbon (DLC) coatings, which provide exceptional corrosion and wear resistance. However, the high temperatures often required in CVD processes can limit its applicability for certain valve materials.

Thermal spraying techniques, such as plasma spraying and high-velocity oxy-fuel (HVOF) coating, are utilized for applying thick, protective layers. These methods are particularly useful for large valve components and can deposit a wide range of materials, including ceramics and metal alloys.

Despite these advancements, several challenges persist in the field of coating technologies for solenoid valves. One significant issue is the difficulty in achieving uniform coating thickness on complex valve geometries, particularly in internal passages and small crevices. This can lead to inconsistent protection and potential weak points in the coating.

Another challenge lies in balancing coating hardness with flexibility. While harder coatings generally offer better wear resistance, they may be prone to cracking or delamination under the cyclic stresses experienced by solenoid valves. Developing coatings that maintain integrity under repeated mechanical and thermal stresses remains an ongoing research focus.

The adhesion of coatings to various substrate materials used in solenoid valves also presents a challenge. Poor adhesion can result in coating failure, exposing the underlying material to corrosive agents. Improving surface preparation techniques and developing better interlayer technologies are crucial areas of development.

Furthermore, the increasing demand for environmentally friendly coating processes poses both a challenge and an opportunity for innovation. Traditional methods often involve hazardous materials or generate significant waste. Developing green coating technologies that maintain or exceed current performance standards is a key focus for future advancements in the field.

Electroplating remains a widely used technique, offering a cost-effective solution for applying thin metallic coatings. This process involves the deposition of metals such as nickel, chrome, or zinc onto the valve surface through electrolysis. While effective for general corrosion protection, electroplating may struggle in extremely aggressive environments.

PVD coatings have gained significant traction due to their excellent wear resistance and ability to form dense, uniform layers. These coatings, typically composed of nitrides or carbides, are applied through processes like sputtering or evaporation. PVD coatings offer superior hardness and can significantly extend the lifespan of solenoid valves in corrosive settings.

CVD technology allows for the deposition of high-purity materials with excellent adhesion to the substrate. This method is particularly effective for applying diamond-like carbon (DLC) coatings, which provide exceptional corrosion and wear resistance. However, the high temperatures often required in CVD processes can limit its applicability for certain valve materials.

Thermal spraying techniques, such as plasma spraying and high-velocity oxy-fuel (HVOF) coating, are utilized for applying thick, protective layers. These methods are particularly useful for large valve components and can deposit a wide range of materials, including ceramics and metal alloys.

Despite these advancements, several challenges persist in the field of coating technologies for solenoid valves. One significant issue is the difficulty in achieving uniform coating thickness on complex valve geometries, particularly in internal passages and small crevices. This can lead to inconsistent protection and potential weak points in the coating.

Another challenge lies in balancing coating hardness with flexibility. While harder coatings generally offer better wear resistance, they may be prone to cracking or delamination under the cyclic stresses experienced by solenoid valves. Developing coatings that maintain integrity under repeated mechanical and thermal stresses remains an ongoing research focus.

The adhesion of coatings to various substrate materials used in solenoid valves also presents a challenge. Poor adhesion can result in coating failure, exposing the underlying material to corrosive agents. Improving surface preparation techniques and developing better interlayer technologies are crucial areas of development.

Furthermore, the increasing demand for environmentally friendly coating processes poses both a challenge and an opportunity for innovation. Traditional methods often involve hazardous materials or generate significant waste. Developing green coating technologies that maintain or exceed current performance standards is a key focus for future advancements in the field.

Existing Corrosion-Resistant Coating Solutions

01 Metal-based protective coatings

Metal-based coatings, such as zinc, aluminum, or their alloys, are applied to surfaces to provide corrosion resistance. These coatings act as sacrificial anodes, protecting the underlying material from corrosive environments. The application methods may include hot-dip galvanizing, thermal spraying, or electroplating, depending on the specific requirements and substrate material.- Metal-based protective coatings: Metal-based coatings, such as zinc, aluminum, or their alloys, are applied to surfaces to provide corrosion resistance. These coatings act as sacrificial anodes, protecting the underlying material from corrosive environments. The application methods may include hot-dip galvanizing, thermal spraying, or electroplating, depending on the specific requirements and substrate material.

- Polymer and composite coatings: Polymer-based and composite coatings offer excellent corrosion resistance by forming a protective barrier against corrosive agents. These coatings can include epoxy resins, polyurethanes, or fluoropolymers, often enhanced with additives or nanoparticles to improve their performance. They are applied through various methods such as spray coating, dip coating, or powder coating.

- Surface treatment and conversion coatings: Surface treatment techniques and conversion coatings are used to enhance corrosion resistance by modifying the surface properties of the material. These methods include phosphating, chromating, anodizing, and chemical or electrochemical surface modifications. The treated surface forms a protective layer that inhibits corrosion and improves adhesion for subsequent coatings.

- Advanced coating technologies: Advanced coating technologies, such as plasma electrolytic oxidation, atomic layer deposition, and sol-gel coatings, are employed to create highly corrosion-resistant surfaces. These methods allow for precise control of coating composition and thickness, resulting in superior protection against corrosive environments. They are particularly useful for complex geometries and specialized applications.

- Self-healing and smart coatings: Self-healing and smart coatings represent innovative approaches to corrosion protection. These coatings contain active components that can repair damage or respond to environmental changes, providing long-term corrosion resistance. Examples include coatings with encapsulated healing agents, stimuli-responsive materials, or corrosion inhibitors that are released upon detection of corrosive conditions.

02 Polymer-based protective coatings

Polymer-based coatings, including epoxy, polyurethane, and fluoropolymers, are used to create a barrier against corrosive elements. These coatings offer excellent chemical resistance and durability. They can be applied through various methods such as spray coating, dip coating, or powder coating, providing a uniform and protective layer on the substrate surface.Expand Specific Solutions03 Ceramic and glass-based coatings

Ceramic and glass-based coatings provide superior corrosion resistance in high-temperature and aggressive environments. These coatings are typically applied using thermal spray techniques or sol-gel processes. They form a dense, impermeable layer that protects the underlying material from oxidation and chemical attack, making them suitable for applications in industries such as aerospace and petrochemicals.Expand Specific Solutions04 Nanostructured and composite coatings

Nanostructured and composite coatings combine multiple materials or incorporate nanoparticles to enhance corrosion resistance. These advanced coatings can provide improved barrier properties, self-healing capabilities, and increased durability. The incorporation of nanoparticles or the creation of nanostructured surfaces can significantly improve the coating's performance in various corrosive environments.Expand Specific Solutions05 Surface treatment and pretreatment technologies

Surface treatment and pretreatment technologies are crucial for enhancing the adhesion and performance of protective coatings. These processes may include chemical etching, plasma treatment, or the application of conversion coatings. Proper surface preparation ensures better bonding between the coating and the substrate, leading to improved corrosion resistance and longer-lasting protection.Expand Specific Solutions

Key Players in Solenoid Valve Coating Industry

The coating technologies for improving solenoid valve corrosion resistance are in a mature development stage, with a growing market driven by increasing demand for durable and efficient valves across industries. The global solenoid valve market is expected to reach significant size in the coming years, propelled by automation trends. Leading players like Robert Bosch GmbH, Aisan Industry Co., Ltd., and Mitsubishi Heavy Industries, Ltd. are investing in advanced coating solutions to enhance valve performance and longevity. These companies, along with specialized coating firms such as BASF Coatings GmbH and Henkel AG & Co. KGaA, are continuously innovating to develop more effective and environmentally friendly coating technologies, indicating a competitive and technologically progressive landscape.

Robert Bosch GmbH

Technical Solution: Bosch has developed proprietary coating technologies to enhance the corrosion resistance of solenoid valves used in their automotive and industrial systems. Their approach includes the use of advanced electroplating techniques to apply zinc-nickel alloy coatings, which provide excellent corrosion protection[10]. Bosch also employs plasma-enhanced chemical vapor deposition (PECVD) to create thin, uniform coatings of materials like diamond-like carbon (DLC) on valve components, improving both corrosion resistance and wear resistance[11]. For solenoid valves used in fuel systems, Bosch has developed specialized fluoropolymer coatings that offer superior chemical resistance and anti-sticking properties[12].

Strengths: Extensive experience in automotive and industrial applications, in-house coating development tailored to specific solenoid valve requirements. Weaknesses: Coating technologies may be primarily optimized for Bosch's own products, potentially limiting broader market application.

GM Global Technology Operations LLC

Technical Solution: GM has invested in developing coating technologies to improve the corrosion resistance of solenoid valves used in their vehicles. Their approach includes the use of multi-layer coating systems that combine different materials to provide comprehensive protection. One such system involves a zinc-rich base layer for cathodic protection, followed by a chromate conversion coating for enhanced corrosion resistance, and topped with an organic sealant for additional barrier protection[13]. GM has also explored the use of nanocomposite coatings, incorporating nanoparticles into polymer matrices to create coatings with improved corrosion resistance and durability[14]. For solenoid valves in critical systems, GM employs advanced PVD coatings, such as titanium nitride (TiN), which offer excellent corrosion resistance and wear properties[15].

Strengths: Coatings developed and tested for real-world automotive applications, potential for integration with other GM technologies. Weaknesses: Coating technologies may be primarily focused on automotive applications, potentially limiting versatility for other industries.

Innovative Coating Materials and Techniques

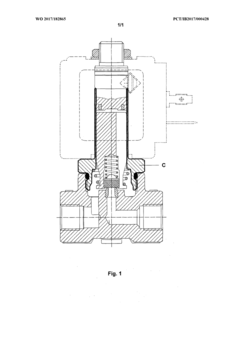

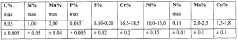

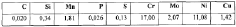

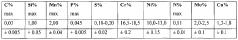

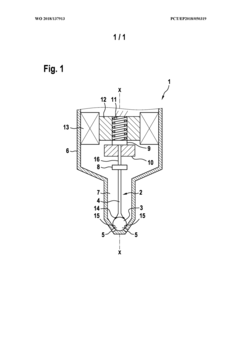

Solenoid valve with special steel components

PatentWO2017182865A1

Innovation

- The use of chrome-nickel-molybdenum austenitic stainless steel with low carbon content, specifically EN 1.4598, for the inner sleeve of solenoid valves, which offers high corrosion resistance, improved machinability, and compliance with safety standards, reducing manufacturing costs and preventing corrosion-related failures.

Solenoid valve, internal combustion engine comprising a solenoid valve, and method for producing a solenoid valve

PatentWO2018137913A1

Innovation

- The solenoid valve uses austenitic steel for at least one surface of the valve needle and optionally the entire needle head and shaft, with a DLC coating to enhance mechanical properties, and the valve housing is also made of austenitic steel to improve corrosion resistance and mechanical stability.

Environmental Impact of Coating Technologies

The environmental impact of coating technologies used to improve solenoid valve corrosion resistance is a critical consideration in the development and application of these protective measures. These coatings, while essential for enhancing the longevity and performance of solenoid valves, can have both positive and negative effects on the environment throughout their lifecycle.

One of the primary environmental benefits of coating technologies is the extended lifespan of solenoid valves. By improving corrosion resistance, these coatings reduce the frequency of valve replacement, thereby decreasing the overall consumption of raw materials and energy required for manufacturing new components. This reduction in material usage and production processes contributes to lower carbon emissions and resource depletion.

However, the production of coating materials and their application processes can have adverse environmental effects. Many coating technologies involve the use of volatile organic compounds (VOCs) and other potentially harmful chemicals. These substances can contribute to air pollution, ozone depletion, and the formation of smog when released into the atmosphere during the coating process or through evaporation.

Water-based coating systems have been developed as a more environmentally friendly alternative to solvent-based coatings. These systems significantly reduce VOC emissions and minimize the risk of air and water pollution. However, they may require more energy for drying and curing, potentially offsetting some of their environmental benefits.

The disposal of coated solenoid valves at the end of their lifecycle presents another environmental challenge. Some coating materials may contain heavy metals or other toxic substances that can leach into soil and water systems if not properly managed. This necessitates careful consideration of end-of-life disposal methods and the development of recycling processes that can safely separate and recover coating materials.

Advancements in nanotechnology have led to the development of more efficient and environmentally friendly coating solutions. Nanostructured coatings can provide superior corrosion resistance with thinner layers, reducing material usage and potentially lowering the environmental impact of both production and disposal processes.

The energy consumption associated with coating application and curing processes is another important environmental factor. High-temperature curing methods, often required for certain coating types, can contribute significantly to the carbon footprint of the manufacturing process. Research into low-temperature curing technologies and energy-efficient application methods is ongoing to address this issue.

In conclusion, while coating technologies for solenoid valve corrosion resistance offer significant environmental benefits through extended product lifespans, their production, application, and disposal processes present complex environmental challenges. Ongoing research and development in this field are focused on creating more sustainable coating solutions that balance performance requirements with environmental stewardship.

One of the primary environmental benefits of coating technologies is the extended lifespan of solenoid valves. By improving corrosion resistance, these coatings reduce the frequency of valve replacement, thereby decreasing the overall consumption of raw materials and energy required for manufacturing new components. This reduction in material usage and production processes contributes to lower carbon emissions and resource depletion.

However, the production of coating materials and their application processes can have adverse environmental effects. Many coating technologies involve the use of volatile organic compounds (VOCs) and other potentially harmful chemicals. These substances can contribute to air pollution, ozone depletion, and the formation of smog when released into the atmosphere during the coating process or through evaporation.

Water-based coating systems have been developed as a more environmentally friendly alternative to solvent-based coatings. These systems significantly reduce VOC emissions and minimize the risk of air and water pollution. However, they may require more energy for drying and curing, potentially offsetting some of their environmental benefits.

The disposal of coated solenoid valves at the end of their lifecycle presents another environmental challenge. Some coating materials may contain heavy metals or other toxic substances that can leach into soil and water systems if not properly managed. This necessitates careful consideration of end-of-life disposal methods and the development of recycling processes that can safely separate and recover coating materials.

Advancements in nanotechnology have led to the development of more efficient and environmentally friendly coating solutions. Nanostructured coatings can provide superior corrosion resistance with thinner layers, reducing material usage and potentially lowering the environmental impact of both production and disposal processes.

The energy consumption associated with coating application and curing processes is another important environmental factor. High-temperature curing methods, often required for certain coating types, can contribute significantly to the carbon footprint of the manufacturing process. Research into low-temperature curing technologies and energy-efficient application methods is ongoing to address this issue.

In conclusion, while coating technologies for solenoid valve corrosion resistance offer significant environmental benefits through extended product lifespans, their production, application, and disposal processes present complex environmental challenges. Ongoing research and development in this field are focused on creating more sustainable coating solutions that balance performance requirements with environmental stewardship.

Cost-Benefit Analysis of Advanced Coatings

The implementation of advanced coating technologies for solenoid valves presents a complex cost-benefit scenario that requires careful analysis. Initial investment in high-performance coatings can be substantial, often increasing the production cost of solenoid valves by 15-25%. This includes expenses for specialized coating materials, equipment upgrades, and potential modifications to manufacturing processes.

However, the long-term benefits of these advanced coatings can significantly outweigh the upfront costs. Improved corrosion resistance extends the operational lifespan of solenoid valves by an estimated 30-50%, depending on the specific coating technology and application environment. This longevity translates to reduced replacement frequency and associated labor costs, potentially saving end-users 20-35% in maintenance expenses over the valve's lifetime.

Enhanced performance is another key benefit. Advanced coatings can improve the valve's efficiency by reducing friction and wear, leading to energy savings of 5-10% in some applications. This is particularly valuable in high-cycle or critical operations where even small improvements in efficiency can result in significant cost savings over time.

The reduction in downtime due to corrosion-related failures is a crucial factor. In industrial settings, unexpected valve failures can lead to production stoppages costing thousands of dollars per hour. Advanced coatings can reduce the frequency of such incidents by up to 40%, resulting in substantial savings and improved operational reliability.

Environmental considerations also play a role in the cost-benefit analysis. Many advanced coatings are more environmentally friendly than traditional corrosion prevention methods, potentially reducing disposal costs and environmental impact. This can lead to savings in regulatory compliance and improved corporate sustainability profiles, which, while difficult to quantify directly, can provide long-term financial benefits through enhanced reputation and market positioning.

When evaluating the return on investment, it's essential to consider the specific application and operating conditions. In harsh environments or critical systems, the benefits of advanced coatings are more pronounced, often providing a return on investment within 2-3 years. In less demanding applications, the payback period may extend to 4-5 years but still offers long-term cost advantages.

Overall, while the initial cost increase for advanced coatings in solenoid valves is significant, the long-term benefits in terms of extended lifespan, improved performance, reduced maintenance, and environmental advantages present a compelling case for their adoption in many industrial applications.

However, the long-term benefits of these advanced coatings can significantly outweigh the upfront costs. Improved corrosion resistance extends the operational lifespan of solenoid valves by an estimated 30-50%, depending on the specific coating technology and application environment. This longevity translates to reduced replacement frequency and associated labor costs, potentially saving end-users 20-35% in maintenance expenses over the valve's lifetime.

Enhanced performance is another key benefit. Advanced coatings can improve the valve's efficiency by reducing friction and wear, leading to energy savings of 5-10% in some applications. This is particularly valuable in high-cycle or critical operations where even small improvements in efficiency can result in significant cost savings over time.

The reduction in downtime due to corrosion-related failures is a crucial factor. In industrial settings, unexpected valve failures can lead to production stoppages costing thousands of dollars per hour. Advanced coatings can reduce the frequency of such incidents by up to 40%, resulting in substantial savings and improved operational reliability.

Environmental considerations also play a role in the cost-benefit analysis. Many advanced coatings are more environmentally friendly than traditional corrosion prevention methods, potentially reducing disposal costs and environmental impact. This can lead to savings in regulatory compliance and improved corporate sustainability profiles, which, while difficult to quantify directly, can provide long-term financial benefits through enhanced reputation and market positioning.

When evaluating the return on investment, it's essential to consider the specific application and operating conditions. In harsh environments or critical systems, the benefits of advanced coatings are more pronounced, often providing a return on investment within 2-3 years. In less demanding applications, the payback period may extend to 4-5 years but still offers long-term cost advantages.

Overall, while the initial cost increase for advanced coatings in solenoid valves is significant, the long-term benefits in terms of extended lifespan, improved performance, reduced maintenance, and environmental advantages present a compelling case for their adoption in many industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!