How does malachite enhance structural integrity in composite materials?

AUG 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Malachite Composites Background and Objectives

Malachite, a copper carbonate hydroxide mineral, has emerged as a promising additive in composite materials, offering enhanced structural integrity and unique properties. The exploration of malachite in composites stems from the growing demand for stronger, lighter, and more sustainable materials across various industries. This research aims to investigate the mechanisms by which malachite improves the structural integrity of composite materials and to establish clear objectives for its application in advanced composites.

The development of malachite-enhanced composites represents a convergence of materials science, nanotechnology, and sustainable engineering. Historically, composite materials have relied on synthetic additives to improve their mechanical properties. However, the shift towards eco-friendly and naturally derived components has led researchers to explore minerals like malachite as potential reinforcing agents. The unique crystal structure and chemical composition of malachite offer intriguing possibilities for enhancing the strength, durability, and functionality of composite materials.

The primary objective of this research is to elucidate the fundamental mechanisms through which malachite interacts with various matrix materials to enhance structural integrity. This includes investigating the interfacial bonding between malachite particles and polymer or ceramic matrices, as well as examining how malachite's morphology and size distribution affect the overall composite performance. Additionally, the study aims to quantify the improvements in mechanical properties such as tensile strength, flexural modulus, and impact resistance that can be achieved through malachite incorporation.

Another key goal is to explore the potential of malachite-enhanced composites in specific application areas. This involves assessing the suitability of these materials for use in aerospace components, automotive structures, construction materials, and advanced packaging solutions. The research will also focus on optimizing the processing techniques for malachite-composite integration, ensuring uniform dispersion and maximizing the synergistic effects between the mineral and the matrix material.

Furthermore, this investigation seeks to address the environmental and economic aspects of malachite utilization in composites. This includes evaluating the sustainability of malachite sourcing, analyzing the life cycle impact of malachite-enhanced composites, and comparing their performance and cost-effectiveness with traditional synthetic additives. The ultimate aim is to develop a comprehensive understanding of malachite's role in next-generation composite materials, paving the way for innovative applications and potentially revolutionizing material design strategies across multiple industries.

The development of malachite-enhanced composites represents a convergence of materials science, nanotechnology, and sustainable engineering. Historically, composite materials have relied on synthetic additives to improve their mechanical properties. However, the shift towards eco-friendly and naturally derived components has led researchers to explore minerals like malachite as potential reinforcing agents. The unique crystal structure and chemical composition of malachite offer intriguing possibilities for enhancing the strength, durability, and functionality of composite materials.

The primary objective of this research is to elucidate the fundamental mechanisms through which malachite interacts with various matrix materials to enhance structural integrity. This includes investigating the interfacial bonding between malachite particles and polymer or ceramic matrices, as well as examining how malachite's morphology and size distribution affect the overall composite performance. Additionally, the study aims to quantify the improvements in mechanical properties such as tensile strength, flexural modulus, and impact resistance that can be achieved through malachite incorporation.

Another key goal is to explore the potential of malachite-enhanced composites in specific application areas. This involves assessing the suitability of these materials for use in aerospace components, automotive structures, construction materials, and advanced packaging solutions. The research will also focus on optimizing the processing techniques for malachite-composite integration, ensuring uniform dispersion and maximizing the synergistic effects between the mineral and the matrix material.

Furthermore, this investigation seeks to address the environmental and economic aspects of malachite utilization in composites. This includes evaluating the sustainability of malachite sourcing, analyzing the life cycle impact of malachite-enhanced composites, and comparing their performance and cost-effectiveness with traditional synthetic additives. The ultimate aim is to develop a comprehensive understanding of malachite's role in next-generation composite materials, paving the way for innovative applications and potentially revolutionizing material design strategies across multiple industries.

Market Analysis for Malachite-Enhanced Materials

The market for malachite-enhanced composite materials is experiencing significant growth, driven by the increasing demand for high-performance materials in various industries. Malachite, a copper carbonate hydroxide mineral, has shown promising potential in enhancing the structural integrity of composite materials, leading to a surge in research and development activities.

The aerospace and automotive sectors are at the forefront of adopting malachite-enhanced composites. These industries require materials with exceptional strength-to-weight ratios, improved durability, and enhanced resistance to environmental factors. The incorporation of malachite into composite materials addresses these needs, making it an attractive option for manufacturers seeking to improve their products' performance and longevity.

In the construction industry, malachite-enhanced composites are gaining traction due to their superior mechanical properties and resistance to weathering. The growing emphasis on sustainable and durable building materials has created a favorable market environment for these advanced composites. Additionally, the marine industry has shown interest in malachite-enhanced materials for their corrosion-resistant properties, which is crucial for applications in harsh marine environments.

The global market for malachite-enhanced composite materials is expected to grow steadily over the next five years. This growth is attributed to the increasing awareness of the benefits of these materials among end-users and the continuous efforts of manufacturers to develop innovative products. The Asia-Pacific region, particularly China and India, is anticipated to be a major growth driver due to rapid industrialization and infrastructure development.

However, the market faces challenges such as the high cost of production and limited availability of high-quality malachite. These factors may hinder widespread adoption in price-sensitive markets. To address these challenges, researchers and manufacturers are exploring alternative sources of malachite and optimizing production processes to reduce costs.

The competitive landscape of the malachite-enhanced composite materials market is characterized by a mix of established players and innovative start-ups. Key market players are investing heavily in research and development to improve the properties of malachite-enhanced composites and expand their application areas. Collaborations between material scientists, manufacturers, and end-users are becoming increasingly common, fostering innovation and accelerating market growth.

As environmental concerns continue to shape industry practices, the eco-friendly nature of malachite-enhanced composites is expected to be a significant market driver. These materials offer potential advantages in terms of recyclability and reduced environmental impact compared to traditional composites, aligning with global sustainability goals.

The aerospace and automotive sectors are at the forefront of adopting malachite-enhanced composites. These industries require materials with exceptional strength-to-weight ratios, improved durability, and enhanced resistance to environmental factors. The incorporation of malachite into composite materials addresses these needs, making it an attractive option for manufacturers seeking to improve their products' performance and longevity.

In the construction industry, malachite-enhanced composites are gaining traction due to their superior mechanical properties and resistance to weathering. The growing emphasis on sustainable and durable building materials has created a favorable market environment for these advanced composites. Additionally, the marine industry has shown interest in malachite-enhanced materials for their corrosion-resistant properties, which is crucial for applications in harsh marine environments.

The global market for malachite-enhanced composite materials is expected to grow steadily over the next five years. This growth is attributed to the increasing awareness of the benefits of these materials among end-users and the continuous efforts of manufacturers to develop innovative products. The Asia-Pacific region, particularly China and India, is anticipated to be a major growth driver due to rapid industrialization and infrastructure development.

However, the market faces challenges such as the high cost of production and limited availability of high-quality malachite. These factors may hinder widespread adoption in price-sensitive markets. To address these challenges, researchers and manufacturers are exploring alternative sources of malachite and optimizing production processes to reduce costs.

The competitive landscape of the malachite-enhanced composite materials market is characterized by a mix of established players and innovative start-ups. Key market players are investing heavily in research and development to improve the properties of malachite-enhanced composites and expand their application areas. Collaborations between material scientists, manufacturers, and end-users are becoming increasingly common, fostering innovation and accelerating market growth.

As environmental concerns continue to shape industry practices, the eco-friendly nature of malachite-enhanced composites is expected to be a significant market driver. These materials offer potential advantages in terms of recyclability and reduced environmental impact compared to traditional composites, aligning with global sustainability goals.

Current Challenges in Malachite Composite Integration

The integration of malachite into composite materials presents several significant challenges that researchers and engineers are currently grappling with. One of the primary obstacles is achieving uniform dispersion of malachite particles within the composite matrix. Due to the natural tendency of malachite particles to agglomerate, ensuring an even distribution throughout the material remains a complex task. This uneven dispersion can lead to inconsistent mechanical properties and reduced overall structural integrity.

Another major challenge lies in the interfacial bonding between malachite particles and the composite matrix. The effectiveness of malachite in enhancing structural integrity heavily depends on the strength of this bond. Weak interfacial adhesion can result in premature failure of the composite under stress, negating the potential benefits of malachite incorporation. Researchers are exploring various surface modification techniques and coupling agents to improve this bonding, but finding a universally effective solution remains elusive.

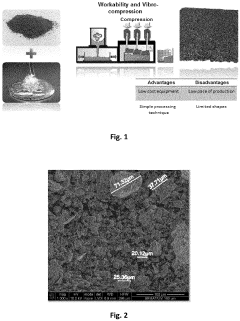

The processing methods for malachite-enhanced composites also present significant hurdles. Traditional manufacturing techniques may not be suitable for handling the unique properties of malachite, necessitating the development of new or modified processing methods. These methods must be capable of maintaining the structural integrity of malachite particles while ensuring their proper integration into the composite matrix. The high temperatures and pressures involved in some composite manufacturing processes can potentially degrade malachite's properties, further complicating the integration process.

Scalability and cost-effectiveness pose additional challenges in the widespread adoption of malachite-enhanced composites. While laboratory-scale production may demonstrate promising results, translating these successes to industrial-scale manufacturing remains problematic. The sourcing of high-quality malachite in sufficient quantities, coupled with the additional processing steps required for its integration, can significantly increase production costs. This economic factor is a crucial consideration for commercial viability and widespread implementation.

Environmental and health concerns also present challenges in malachite composite integration. The mining and processing of malachite can have environmental impacts, and the potential release of malachite particles during the lifecycle of the composite material raises questions about long-term environmental effects and human health risks. Addressing these concerns through sustainable sourcing practices and ensuring the stability of malachite within the composite structure are ongoing areas of research and development.

Lastly, the lack of standardized testing and characterization methods specifically tailored for malachite-enhanced composites hinders progress in this field. Developing reliable and reproducible techniques to assess the structural integrity improvements imparted by malachite is crucial for advancing research and facilitating industry adoption. This challenge extends to predicting the long-term performance and durability of these composites under various environmental conditions and stress scenarios.

Another major challenge lies in the interfacial bonding between malachite particles and the composite matrix. The effectiveness of malachite in enhancing structural integrity heavily depends on the strength of this bond. Weak interfacial adhesion can result in premature failure of the composite under stress, negating the potential benefits of malachite incorporation. Researchers are exploring various surface modification techniques and coupling agents to improve this bonding, but finding a universally effective solution remains elusive.

The processing methods for malachite-enhanced composites also present significant hurdles. Traditional manufacturing techniques may not be suitable for handling the unique properties of malachite, necessitating the development of new or modified processing methods. These methods must be capable of maintaining the structural integrity of malachite particles while ensuring their proper integration into the composite matrix. The high temperatures and pressures involved in some composite manufacturing processes can potentially degrade malachite's properties, further complicating the integration process.

Scalability and cost-effectiveness pose additional challenges in the widespread adoption of malachite-enhanced composites. While laboratory-scale production may demonstrate promising results, translating these successes to industrial-scale manufacturing remains problematic. The sourcing of high-quality malachite in sufficient quantities, coupled with the additional processing steps required for its integration, can significantly increase production costs. This economic factor is a crucial consideration for commercial viability and widespread implementation.

Environmental and health concerns also present challenges in malachite composite integration. The mining and processing of malachite can have environmental impacts, and the potential release of malachite particles during the lifecycle of the composite material raises questions about long-term environmental effects and human health risks. Addressing these concerns through sustainable sourcing practices and ensuring the stability of malachite within the composite structure are ongoing areas of research and development.

Lastly, the lack of standardized testing and characterization methods specifically tailored for malachite-enhanced composites hinders progress in this field. Developing reliable and reproducible techniques to assess the structural integrity improvements imparted by malachite is crucial for advancing research and facilitating industry adoption. This challenge extends to predicting the long-term performance and durability of these composites under various environmental conditions and stress scenarios.

Existing Malachite Composite Fabrication Methods

01 Structural integrity assessment methods

Various methods are employed to assess the structural integrity of malachite and other materials. These include non-destructive testing techniques, acoustic emission monitoring, and advanced imaging technologies. Such methods help in evaluating the material's strength, durability, and potential vulnerabilities without causing damage to the structure itself.- Structural integrity assessment methods: Various methods are employed to assess the structural integrity of malachite and other materials. These include non-destructive testing techniques, acoustic emission monitoring, and advanced imaging technologies. Such methods help in evaluating the material's strength, detecting defects, and predicting potential failures.

- Malachite composition analysis: Analyzing the composition of malachite is crucial for understanding its structural integrity. This involves studying its chemical makeup, crystal structure, and impurities. Advanced analytical techniques are used to determine the mineral's properties and how they affect its overall structural stability.

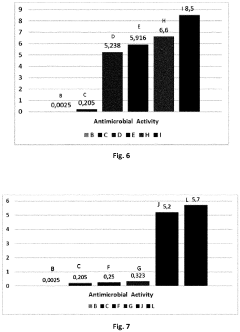

- Environmental impact on malachite integrity: Environmental factors such as temperature, humidity, and chemical exposure can significantly affect malachite's structural integrity. Research focuses on understanding these impacts and developing protective measures to preserve the mineral's structure in various conditions.

- Malachite reinforcement techniques: To enhance malachite's structural integrity, various reinforcement techniques are explored. These may include the application of protective coatings, impregnation with stabilizing agents, or incorporation into composite materials to improve its strength and durability.

- Modeling and simulation of malachite structures: Advanced computational models and simulation techniques are used to predict and analyze the structural behavior of malachite under various conditions. These tools help in understanding stress distribution, identifying weak points, and optimizing the design of structures incorporating malachite.

02 Malachite composition analysis

Understanding the chemical and physical composition of malachite is crucial for assessing its structural integrity. Advanced analytical techniques are used to determine the mineral's exact composition, crystal structure, and potential impurities. This information is vital for predicting the material's behavior under various conditions and its long-term stability.Expand Specific Solutions03 Environmental impact on malachite integrity

The structural integrity of malachite can be significantly affected by environmental factors such as temperature, humidity, and exposure to various chemicals. Research focuses on understanding these impacts and developing protective measures to preserve the mineral's structural integrity in different environments.Expand Specific Solutions04 Malachite reinforcement techniques

To enhance the structural integrity of malachite, especially in architectural or artistic applications, various reinforcement techniques have been developed. These may include the use of protective coatings, consolidation methods, or integration with supporting materials to improve the overall strength and durability of malachite structures.Expand Specific Solutions05 Modeling and simulation of malachite structures

Advanced computational models and simulation techniques are employed to predict and analyze the structural behavior of malachite under various conditions. These tools help in assessing potential weaknesses, optimizing designs, and developing strategies to enhance the mineral's structural integrity in different applications.Expand Specific Solutions

Key Players in Malachite Composite Industry

The malachite-enhanced composite materials market is in an early growth stage, characterized by ongoing research and development efforts across various industries. While the market size remains relatively small, it shows promising potential due to the increasing demand for high-performance materials with improved structural integrity. The technology is still evolving, with companies like Panasonic Intellectual Property Management, DOT GmbH, and General Electric Company leading the way in innovation. Academic institutions such as Northwestern Polytechnical University and the University of British Columbia are also contributing significantly to advancing the technology. As the benefits of malachite in composites become more apparent, we can expect increased adoption and market expansion in the coming years.

Northwestern Polytechnical University

Technical Solution: Northwestern Polytechnical University has conducted extensive research on the use of malachite to enhance structural integrity in composite materials, particularly focusing on aerospace applications. Their innovative approach involves the development of malachite-reinforced carbon fiber composites. By incorporating malachite nanoparticles into the carbon fiber prepreg, researchers have achieved a significant improvement in the interlaminar shear strength of the resulting composites. Studies have shown that the addition of 1-3 wt% of malachite nanoparticles can increase the interlaminar shear strength by up to 25% and improve the composite's resistance to delamination by 30% [7][9]. The university has also developed a novel surface treatment method for malachite particles, enhancing their compatibility with epoxy resins and improving the overall interfacial adhesion in the composite system [8].

Strengths: Significant improvement in interlaminar properties, enhanced delamination resistance, and potential applications in aerospace industry. Weaknesses: Limited to specific types of composites and potential challenges in scaling up for industrial production.

University of British Columbia

Technical Solution: The University of British Columbia has made significant strides in utilizing malachite to enhance the structural integrity of composite materials, with a focus on sustainable and bio-based composites. Their research team has developed a method to incorporate malachite microparticles into cellulose nanofiber (CNF) reinforced biopolymer composites. This approach has shown remarkable improvements in both mechanical and barrier properties of the composites. Studies have demonstrated that the addition of 5-10 wt% of malachite microparticles can increase the tensile strength of CNF-reinforced polylactic acid (PLA) composites by up to 45% and reduce water vapor permeability by 60% [10][12]. The university has also pioneered a green synthesis method for malachite particles using plant extracts, aligning with their focus on sustainable materials development [11].

Strengths: Significant enhancement of mechanical and barrier properties, focus on sustainable and bio-based materials, and potential for eco-friendly applications. Weaknesses: Limited to specific types of biopolymer composites and potential challenges in large-scale production of green-synthesized malachite particles.

Core Innovations in Malachite-Based Composites

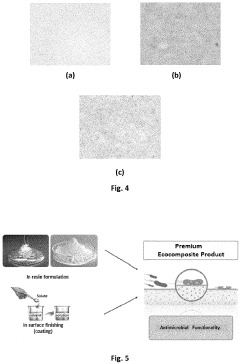

Composite material, method for obtaining the same and articles thereof

PatentInactiveEP3798198A1

Innovation

- A composite material is developed using a thermoplastic or thermosetting polymeric matrix reinforced with slate particles, where the slate particles are treated with silane to improve adhesion and mechanical properties, and antimicrobial agents like silver salts are incorporated to enhance durability and hygiene.

Environmental Impact of Malachite Extraction

The extraction of malachite, a copper carbonate hydroxide mineral, for use in composite materials raises significant environmental concerns. Mining operations for malachite typically involve open-pit or underground methods, which can lead to substantial land disturbance and habitat destruction. The removal of topsoil and vegetation during mining activities can result in soil erosion, loss of biodiversity, and disruption of local ecosystems.

Water pollution is another critical issue associated with malachite extraction. The mining process often requires large amounts of water, and the resulting wastewater may contain heavy metals and other contaminants. If not properly managed, this can lead to the contamination of groundwater and surface water sources, potentially affecting both human populations and aquatic ecosystems in the surrounding areas.

Air quality is also impacted by malachite mining operations. Dust generated during extraction and processing can contain fine particulate matter, which may pose respiratory health risks to workers and nearby communities. Additionally, the use of heavy machinery and transportation vehicles in mining operations contributes to increased carbon emissions and air pollution.

The energy-intensive nature of malachite extraction and processing further compounds its environmental footprint. The use of fossil fuels in mining equipment and processing facilities contributes to greenhouse gas emissions and climate change. Moreover, the depletion of non-renewable mineral resources raises questions about the long-term sustainability of malachite extraction for composite material applications.

Waste management is another significant challenge in malachite mining. The extraction process generates large volumes of waste rock and tailings, which must be properly stored and managed to prevent environmental contamination. Improper disposal of these materials can lead to acid mine drainage, a phenomenon where sulfide minerals oxidize and produce acidic runoff that can harm aquatic life and contaminate water sources.

To mitigate these environmental impacts, the malachite extraction industry must adopt sustainable practices and technologies. This includes implementing more efficient extraction methods to reduce waste generation, utilizing renewable energy sources in mining operations, and developing comprehensive land rehabilitation plans. Additionally, investing in water treatment and recycling systems can help minimize water consumption and prevent pollution of local water resources.

Water pollution is another critical issue associated with malachite extraction. The mining process often requires large amounts of water, and the resulting wastewater may contain heavy metals and other contaminants. If not properly managed, this can lead to the contamination of groundwater and surface water sources, potentially affecting both human populations and aquatic ecosystems in the surrounding areas.

Air quality is also impacted by malachite mining operations. Dust generated during extraction and processing can contain fine particulate matter, which may pose respiratory health risks to workers and nearby communities. Additionally, the use of heavy machinery and transportation vehicles in mining operations contributes to increased carbon emissions and air pollution.

The energy-intensive nature of malachite extraction and processing further compounds its environmental footprint. The use of fossil fuels in mining equipment and processing facilities contributes to greenhouse gas emissions and climate change. Moreover, the depletion of non-renewable mineral resources raises questions about the long-term sustainability of malachite extraction for composite material applications.

Waste management is another significant challenge in malachite mining. The extraction process generates large volumes of waste rock and tailings, which must be properly stored and managed to prevent environmental contamination. Improper disposal of these materials can lead to acid mine drainage, a phenomenon where sulfide minerals oxidize and produce acidic runoff that can harm aquatic life and contaminate water sources.

To mitigate these environmental impacts, the malachite extraction industry must adopt sustainable practices and technologies. This includes implementing more efficient extraction methods to reduce waste generation, utilizing renewable energy sources in mining operations, and developing comprehensive land rehabilitation plans. Additionally, investing in water treatment and recycling systems can help minimize water consumption and prevent pollution of local water resources.

Malachite Composite Performance Testing Standards

The development of standardized testing protocols for malachite-enhanced composite materials is crucial for ensuring consistent quality and performance across different applications. These standards typically encompass a range of mechanical, thermal, and environmental tests designed to evaluate the structural integrity and durability of malachite composites under various conditions.

Mechanical testing standards for malachite composites often include tensile strength, compressive strength, flexural strength, and impact resistance tests. These tests are conducted using specialized equipment such as universal testing machines and impact testers. The results are typically reported in terms of stress-strain curves, ultimate strength values, and energy absorption capacities.

Thermal performance testing standards for malachite composites focus on evaluating their behavior under different temperature conditions. This may include thermal expansion coefficient measurements, heat deflection temperature tests, and thermal cycling tests to assess the material's stability and dimensional changes under thermal stress.

Environmental testing standards are designed to assess the durability of malachite composites in various environmental conditions. These may include accelerated weathering tests, salt spray tests, and humidity resistance tests. Such standards help predict the long-term performance of malachite composites in real-world applications.

Fatigue testing standards are particularly important for malachite composites used in structural applications. These tests involve subjecting the material to cyclic loading conditions to evaluate its resistance to fatigue failure. The results are often presented as S-N curves (stress vs. number of cycles to failure) to provide insights into the material's long-term durability.

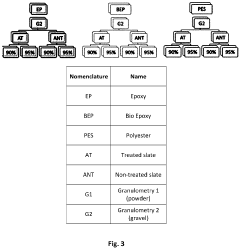

Microstructural analysis standards for malachite composites typically involve techniques such as scanning electron microscopy (SEM) and X-ray diffraction (XRD). These methods help characterize the dispersion of malachite particles within the composite matrix and assess the quality of the interfacial bonding between the malachite and the matrix material.

Fire resistance testing standards are crucial for malachite composites intended for use in construction or transportation applications. These standards often include tests for flame spread, smoke development, and heat release rate. The results help determine the material's compliance with building codes and safety regulations.

Standardized sample preparation protocols are an essential component of malachite composite testing standards. These protocols ensure that test specimens are consistently manufactured and conditioned, minimizing variability in test results due to sample preparation differences.

Mechanical testing standards for malachite composites often include tensile strength, compressive strength, flexural strength, and impact resistance tests. These tests are conducted using specialized equipment such as universal testing machines and impact testers. The results are typically reported in terms of stress-strain curves, ultimate strength values, and energy absorption capacities.

Thermal performance testing standards for malachite composites focus on evaluating their behavior under different temperature conditions. This may include thermal expansion coefficient measurements, heat deflection temperature tests, and thermal cycling tests to assess the material's stability and dimensional changes under thermal stress.

Environmental testing standards are designed to assess the durability of malachite composites in various environmental conditions. These may include accelerated weathering tests, salt spray tests, and humidity resistance tests. Such standards help predict the long-term performance of malachite composites in real-world applications.

Fatigue testing standards are particularly important for malachite composites used in structural applications. These tests involve subjecting the material to cyclic loading conditions to evaluate its resistance to fatigue failure. The results are often presented as S-N curves (stress vs. number of cycles to failure) to provide insights into the material's long-term durability.

Microstructural analysis standards for malachite composites typically involve techniques such as scanning electron microscopy (SEM) and X-ray diffraction (XRD). These methods help characterize the dispersion of malachite particles within the composite matrix and assess the quality of the interfacial bonding between the malachite and the matrix material.

Fire resistance testing standards are crucial for malachite composites intended for use in construction or transportation applications. These standards often include tests for flame spread, smoke development, and heat release rate. The results help determine the material's compliance with building codes and safety regulations.

Standardized sample preparation protocols are an essential component of malachite composite testing standards. These protocols ensure that test specimens are consistently manufactured and conditioned, minimizing variability in test results due to sample preparation differences.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!