How Geometric Isomers Influence Crystallization in Solid-State Chemistry

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Geometric Isomers and Crystallization: Background and Objectives

Geometric isomers, molecules with the same molecular formula but different spatial arrangements of atoms, have long been a subject of fascination in the field of solid-state chemistry. The study of how these isomers influence crystallization processes has gained significant traction in recent years, driven by the growing demand for precise control over material properties in various industries, including pharmaceuticals, electronics, and advanced materials.

The evolution of this field can be traced back to the early 20th century when the concept of molecular symmetry and its impact on physical properties began to emerge. However, it wasn't until the advent of advanced analytical techniques, such as X-ray crystallography and nuclear magnetic resonance spectroscopy, that researchers could truly delve into the intricacies of geometric isomerism and its effects on crystal formation.

Over the past few decades, the interplay between geometric isomers and crystallization has become increasingly relevant in drug development, where polymorphism – the ability of a compound to crystallize in multiple forms – can significantly impact a drug's efficacy and bioavailability. This has spurred intensive research into understanding and controlling the crystallization behavior of geometric isomers in pharmaceutical compounds.

The primary objective of current research in this field is to elucidate the fundamental mechanisms by which geometric isomers influence crystal nucleation, growth, and morphology. This understanding is crucial for developing predictive models and control strategies for crystal engineering, which has far-reaching implications across multiple industries.

Another key goal is to explore the potential of geometric isomerism as a tool for tailoring material properties. By manipulating the spatial arrangement of atoms in molecules, researchers aim to create crystals with enhanced performance characteristics, such as improved solubility, stability, or optical properties.

Furthermore, there is a growing interest in leveraging geometric isomerism to develop novel functional materials. This includes the design of smart materials that can undergo reversible structural changes in response to external stimuli, opening up possibilities for applications in sensors, actuators, and responsive coatings.

As we look to the future, the field is poised to benefit from emerging technologies such as artificial intelligence and machine learning. These tools promise to accelerate the discovery and optimization of new materials by predicting crystal structures and properties based on molecular geometry. The integration of computational methods with experimental techniques is expected to drive significant advancements in our ability to control and exploit the influence of geometric isomers on crystallization processes.

The evolution of this field can be traced back to the early 20th century when the concept of molecular symmetry and its impact on physical properties began to emerge. However, it wasn't until the advent of advanced analytical techniques, such as X-ray crystallography and nuclear magnetic resonance spectroscopy, that researchers could truly delve into the intricacies of geometric isomerism and its effects on crystal formation.

Over the past few decades, the interplay between geometric isomers and crystallization has become increasingly relevant in drug development, where polymorphism – the ability of a compound to crystallize in multiple forms – can significantly impact a drug's efficacy and bioavailability. This has spurred intensive research into understanding and controlling the crystallization behavior of geometric isomers in pharmaceutical compounds.

The primary objective of current research in this field is to elucidate the fundamental mechanisms by which geometric isomers influence crystal nucleation, growth, and morphology. This understanding is crucial for developing predictive models and control strategies for crystal engineering, which has far-reaching implications across multiple industries.

Another key goal is to explore the potential of geometric isomerism as a tool for tailoring material properties. By manipulating the spatial arrangement of atoms in molecules, researchers aim to create crystals with enhanced performance characteristics, such as improved solubility, stability, or optical properties.

Furthermore, there is a growing interest in leveraging geometric isomerism to develop novel functional materials. This includes the design of smart materials that can undergo reversible structural changes in response to external stimuli, opening up possibilities for applications in sensors, actuators, and responsive coatings.

As we look to the future, the field is poised to benefit from emerging technologies such as artificial intelligence and machine learning. These tools promise to accelerate the discovery and optimization of new materials by predicting crystal structures and properties based on molecular geometry. The integration of computational methods with experimental techniques is expected to drive significant advancements in our ability to control and exploit the influence of geometric isomers on crystallization processes.

Market Demand for Controlled Crystallization

The market demand for controlled crystallization in solid-state chemistry has been steadily growing, driven by the increasing need for high-performance materials in various industries. The ability to manipulate and control the crystallization process, particularly through the influence of geometric isomers, has become crucial in developing advanced materials with specific properties and functionalities.

In the pharmaceutical industry, controlled crystallization plays a vital role in drug formulation and delivery. The arrangement of molecules in crystal structures can significantly impact drug solubility, bioavailability, and stability. As the demand for more effective and targeted drug delivery systems rises, pharmaceutical companies are investing heavily in research and development to understand and control the crystallization process. This has led to a growing market for technologies and methodologies that can precisely manipulate geometric isomers during crystallization.

The electronics industry also presents a substantial market for controlled crystallization techniques. With the continuous miniaturization of electronic components and the push for higher performance, there is an increasing demand for materials with specific crystal structures. Geometric isomers can influence the electronic and optical properties of materials, making their control essential in the development of advanced semiconductors, display technologies, and energy storage devices.

In the field of materials science, the ability to control crystallization through geometric isomers has opened up new possibilities for creating novel materials with tailored properties. This has led to a surge in demand from industries such as aerospace, automotive, and energy, where high-performance materials are critical. The market for lightweight, strong, and heat-resistant materials continues to expand, driving research into controlled crystallization techniques.

The growing focus on sustainable and environmentally friendly materials has also contributed to the market demand for controlled crystallization. By manipulating geometric isomers during the crystallization process, researchers can develop materials with improved recyclability, biodegradability, and reduced environmental impact. This aligns with the increasing consumer and regulatory pressure for more sustainable products across various industries.

Furthermore, the food and beverage industry has shown significant interest in controlled crystallization techniques. The texture, stability, and sensory properties of many food products are directly influenced by their crystal structure. As consumers demand higher quality and more diverse food experiences, manufacturers are turning to advanced crystallization control methods to improve product characteristics and shelf life.

As the market for controlled crystallization continues to expand, there is a parallel growth in demand for specialized equipment, analytical tools, and software for studying and manipulating geometric isomers in solid-state chemistry. This has created opportunities for companies specializing in scientific instrumentation and computational modeling to develop and market advanced solutions for researchers and industries working in this field.

In the pharmaceutical industry, controlled crystallization plays a vital role in drug formulation and delivery. The arrangement of molecules in crystal structures can significantly impact drug solubility, bioavailability, and stability. As the demand for more effective and targeted drug delivery systems rises, pharmaceutical companies are investing heavily in research and development to understand and control the crystallization process. This has led to a growing market for technologies and methodologies that can precisely manipulate geometric isomers during crystallization.

The electronics industry also presents a substantial market for controlled crystallization techniques. With the continuous miniaturization of electronic components and the push for higher performance, there is an increasing demand for materials with specific crystal structures. Geometric isomers can influence the electronic and optical properties of materials, making their control essential in the development of advanced semiconductors, display technologies, and energy storage devices.

In the field of materials science, the ability to control crystallization through geometric isomers has opened up new possibilities for creating novel materials with tailored properties. This has led to a surge in demand from industries such as aerospace, automotive, and energy, where high-performance materials are critical. The market for lightweight, strong, and heat-resistant materials continues to expand, driving research into controlled crystallization techniques.

The growing focus on sustainable and environmentally friendly materials has also contributed to the market demand for controlled crystallization. By manipulating geometric isomers during the crystallization process, researchers can develop materials with improved recyclability, biodegradability, and reduced environmental impact. This aligns with the increasing consumer and regulatory pressure for more sustainable products across various industries.

Furthermore, the food and beverage industry has shown significant interest in controlled crystallization techniques. The texture, stability, and sensory properties of many food products are directly influenced by their crystal structure. As consumers demand higher quality and more diverse food experiences, manufacturers are turning to advanced crystallization control methods to improve product characteristics and shelf life.

As the market for controlled crystallization continues to expand, there is a parallel growth in demand for specialized equipment, analytical tools, and software for studying and manipulating geometric isomers in solid-state chemistry. This has created opportunities for companies specializing in scientific instrumentation and computational modeling to develop and market advanced solutions for researchers and industries working in this field.

Current Challenges in Isomer-Influenced Crystallization

The field of solid-state chemistry faces several significant challenges when it comes to understanding and controlling the influence of geometric isomers on crystallization processes. One of the primary obstacles is the complexity of predicting and manipulating the spatial arrangements of molecules during crystal formation. Geometric isomers, with their identical molecular formulas but different spatial orientations, can dramatically affect the final crystal structure, leading to variations in physical properties and chemical reactivity.

A major challenge lies in the precise control of isomer ratios during crystallization. Even slight variations in the proportion of different geometric isomers can result in substantial changes to the crystal lattice, affecting properties such as solubility, melting point, and stability. Researchers struggle to develop reliable methods for selectively crystallizing specific isomers or maintaining consistent isomer ratios throughout the crystallization process.

Another significant hurdle is the lack of comprehensive understanding of the kinetics and thermodynamics governing isomer-influenced crystallization. The energy landscapes associated with different geometric isomers can be intricate, with multiple local minima and complex transition pathways. This complexity makes it difficult to predict and control the crystallization outcomes, especially in systems with multiple components or polymorphic tendencies.

The characterization of isomer-influenced crystal structures presents its own set of challenges. Traditional X-ray diffraction techniques may struggle to distinguish between closely related isomeric forms, particularly when dealing with subtle differences in molecular packing. Advanced analytical methods, such as solid-state NMR spectroscopy and computational modeling, are often required to fully elucidate the structural nuances, but these techniques can be time-consuming and resource-intensive.

Furthermore, the scalability of isomer-controlled crystallization processes remains a significant obstacle for industrial applications. Techniques that work well at the laboratory scale may not translate effectively to large-scale production, where factors such as heat and mass transfer become increasingly important. Developing robust and scalable methods for isomer-influenced crystallization is crucial for the practical implementation of this knowledge in fields such as pharmaceuticals and materials science.

Lastly, the environmental and processing conditions play a critical role in isomer-influenced crystallization, yet their effects are often poorly understood. Factors such as temperature, pressure, solvent choice, and the presence of impurities or additives can all impact the preferential crystallization of specific isomers. Unraveling these complex relationships and developing predictive models that account for these variables remains a formidable challenge in the field.

A major challenge lies in the precise control of isomer ratios during crystallization. Even slight variations in the proportion of different geometric isomers can result in substantial changes to the crystal lattice, affecting properties such as solubility, melting point, and stability. Researchers struggle to develop reliable methods for selectively crystallizing specific isomers or maintaining consistent isomer ratios throughout the crystallization process.

Another significant hurdle is the lack of comprehensive understanding of the kinetics and thermodynamics governing isomer-influenced crystallization. The energy landscapes associated with different geometric isomers can be intricate, with multiple local minima and complex transition pathways. This complexity makes it difficult to predict and control the crystallization outcomes, especially in systems with multiple components or polymorphic tendencies.

The characterization of isomer-influenced crystal structures presents its own set of challenges. Traditional X-ray diffraction techniques may struggle to distinguish between closely related isomeric forms, particularly when dealing with subtle differences in molecular packing. Advanced analytical methods, such as solid-state NMR spectroscopy and computational modeling, are often required to fully elucidate the structural nuances, but these techniques can be time-consuming and resource-intensive.

Furthermore, the scalability of isomer-controlled crystallization processes remains a significant obstacle for industrial applications. Techniques that work well at the laboratory scale may not translate effectively to large-scale production, where factors such as heat and mass transfer become increasingly important. Developing robust and scalable methods for isomer-influenced crystallization is crucial for the practical implementation of this knowledge in fields such as pharmaceuticals and materials science.

Lastly, the environmental and processing conditions play a critical role in isomer-influenced crystallization, yet their effects are often poorly understood. Factors such as temperature, pressure, solvent choice, and the presence of impurities or additives can all impact the preferential crystallization of specific isomers. Unraveling these complex relationships and developing predictive models that account for these variables remains a formidable challenge in the field.

Existing Methods for Controlling Geometric Isomers

01 Selective crystallization of geometric isomers

Geometric isomers can be separated through selective crystallization techniques. This process involves manipulating conditions such as temperature, solvent, and concentration to promote the crystallization of one isomer over another. The method exploits differences in solubility and crystal structure between geometric isomers to achieve separation.- Separation of geometric isomers through crystallization: Crystallization techniques can be employed to separate geometric isomers. This process exploits differences in solubility and crystal structure between isomers, allowing for their selective crystallization and subsequent separation. The method can be optimized by controlling factors such as temperature, solvent choice, and cooling rate to enhance the purity and yield of the desired isomer.

- Selective crystallization of specific geometric isomers: Certain techniques can be used to preferentially crystallize one geometric isomer over another. This may involve the use of specific solvents, additives, or seeding crystals that promote the formation of a particular isomer. By carefully controlling the crystallization conditions, it's possible to enhance the yield and purity of the desired geometric isomer.

- Fractional crystallization for isomer purification: Fractional crystallization can be used to purify geometric isomers. This method involves multiple crystallization steps, each time separating the crystals from the mother liquor and recrystallizing. The process can be repeated to progressively increase the purity of the desired isomer, taking advantage of slight differences in solubility between the isomers.

- Use of chiral resolving agents in crystallization: Chiral resolving agents can be employed in the crystallization process to separate geometric isomers. These agents form diastereomeric complexes with the isomers, which have different solubilities and crystallization properties. This technique can be particularly useful for separating enantiomers or other challenging isomer pairs.

- Temperature-controlled crystallization for isomer separation: Temperature control during the crystallization process can be crucial for separating geometric isomers. By carefully manipulating the temperature profile, it's possible to exploit differences in the crystallization behavior of different isomers. This method can involve precise cooling rates, temperature cycling, or maintaining specific temperature ranges to promote selective crystallization.

02 Use of seeding in isomer crystallization

Seeding is a technique used to initiate and control the crystallization of specific geometric isomers. By introducing small crystals of the desired isomer, the process can be directed towards preferential crystallization of that form. This method is particularly useful for separating isomers with similar physicochemical properties.Expand Specific Solutions03 Solvent selection for isomer crystallization

The choice of solvent plays a crucial role in the crystallization of geometric isomers. Different solvents can affect the solubility and crystal formation of isomers differently, allowing for selective crystallization. Careful selection of solvents or solvent mixtures can enhance the separation efficiency of geometric isomers.Expand Specific Solutions04 Temperature control in isomer crystallization

Temperature manipulation is a key factor in controlling the crystallization of geometric isomers. By carefully adjusting the temperature during the crystallization process, it is possible to favor the formation of one isomer over another. This technique can be used in combination with other methods to optimize the separation of geometric isomers.Expand Specific Solutions05 Purification of geometric isomers post-crystallization

After initial crystallization, further purification steps may be necessary to obtain high-purity geometric isomers. These steps can include recrystallization, washing, or other separation techniques to remove impurities or traces of the undesired isomer. The purification process is crucial for obtaining isomers with high optical purity.Expand Specific Solutions

Key Players in Solid-State Chemistry Research

The field of geometric isomers' influence on crystallization in solid-state chemistry is in a mature stage of development, with significant research conducted by academic institutions and pharmaceutical companies. The market size is substantial, driven by applications in drug development and materials science. Companies like Pfizer, AbbVie, and Janssen Pharmaceutica are at the forefront, leveraging advanced crystallization techniques to optimize drug formulations. Research institutions such as Dana-Farber Cancer Institute and The Broad Institute contribute to fundamental understanding, while specialized firms like Eikonizo Therapeutics focus on novel small molecule design. The technology's maturity is evident in its widespread adoption across the pharmaceutical industry, with ongoing refinements aimed at enhancing drug efficacy and manufacturing processes.

Pfizer Inc.

Technical Solution: Pfizer has developed advanced techniques for controlling geometric isomerism in drug crystallization. They utilize a combination of computational modeling and experimental approaches to predict and manipulate crystal structures. Their method involves using molecular dynamics simulations to understand how different geometric isomers interact during nucleation and crystal growth[1]. They have also implemented a high-throughput screening platform that allows rapid assessment of crystallization conditions for various geometric isomers[3]. This platform integrates robotics, microfluidics, and advanced imaging techniques to analyze thousands of crystallization conditions simultaneously. Pfizer's approach has led to significant improvements in drug bioavailability and stability through optimized crystal forms[5].

Strengths: Comprehensive approach combining computational and experimental methods, high-throughput screening capabilities. Weaknesses: High cost of implementation, may be less effective for complex molecular systems.

AbbVie, Inc.

Technical Solution: AbbVie has developed a novel approach to controlling geometric isomerism in solid-state chemistry, focusing on pharmaceutical applications. Their method involves the use of tailored co-crystals and salt forms to manipulate the arrangement of geometric isomers during crystallization[2]. They employ advanced spectroscopic techniques, including synchrotron X-ray diffraction and solid-state NMR, to characterize the resulting crystal structures at an atomic level[4]. AbbVie has also pioneered the use of supramolecular synthons to direct the assembly of specific geometric isomers in the solid state, leading to more predictable and controllable crystallization outcomes[6]. This approach has been particularly successful in improving the solubility and bioavailability of drugs with complex isomeric structures.

Strengths: Innovative use of co-crystals and supramolecular chemistry, advanced characterization capabilities. Weaknesses: May be limited to certain classes of molecules, potential scalability issues for large-scale production.

Core Innovations in Isomer-Driven Crystallization

Compounds and uses thereof

PatentPendingUS20230145003A1

Innovation

- Development of specific compounds that modulate the BAF complex by inhibiting BRG1 and/or BRM activity, which can be used alone or in combination with other pharmaceutically active agents to treat disorders like cancer.

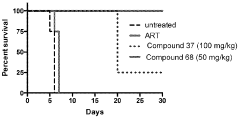

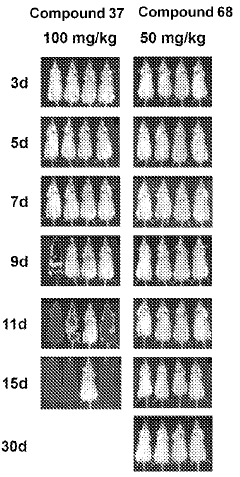

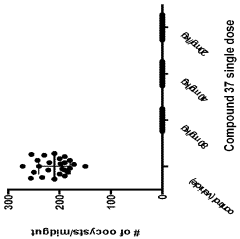

Compounds and methods for the treatment of malaria

PatentInactiveIN202118043692A

Innovation

- Development of specific compounds, such as those represented by Formula I and listed in Table 1, which offer new structural features and functional groups to target malaria parasites effectively, including those resistant to existing drugs.

Environmental Impact of Crystallization Processes

The crystallization processes in solid-state chemistry, particularly those influenced by geometric isomers, can have significant environmental implications. These processes are widely used in various industries, including pharmaceuticals, agrochemicals, and materials science, and their environmental impact must be carefully considered.

Crystallization often involves the use of solvents, which can be a major source of environmental concern. The choice of solvent and the efficiency of the crystallization process can greatly affect the amount of waste generated. When geometric isomers are involved, the complexity of the crystallization process may increase, potentially leading to higher solvent consumption and waste production. This increased waste can contribute to air and water pollution if not properly managed.

Energy consumption is another critical environmental factor in crystallization processes. The formation of different crystal structures by geometric isomers may require specific temperature and pressure conditions, which can be energy-intensive. The need for precise control over these parameters to achieve desired crystal forms can result in increased energy usage, contributing to greenhouse gas emissions and climate change if non-renewable energy sources are used.

The polymorphism exhibited by geometric isomers in crystallization can also impact the environmental footprint of the final product. Different crystal forms may have varying solubility, stability, and bioavailability, which can affect their environmental persistence and potential ecological impacts. For instance, a more soluble polymorph might be more readily absorbed by organisms or dispersed in the environment, potentially leading to unintended consequences in ecosystems.

Furthermore, the purification and separation of geometric isomers during crystallization may require additional processing steps, such as recrystallization or chromatography. These additional steps can increase the overall environmental burden of the process through increased resource consumption and waste generation.

However, understanding the influence of geometric isomers on crystallization can also lead to more environmentally friendly processes. By optimizing crystallization conditions for specific isomers, it may be possible to reduce solvent use, improve yield, and minimize waste. This knowledge can be applied to develop more sustainable manufacturing processes, potentially reducing the environmental impact of chemical production.

In conclusion, the environmental impact of crystallization processes involving geometric isomers is multifaceted, encompassing issues of waste generation, energy consumption, and potential ecological effects. As research in this field progresses, it is crucial to consider these environmental aspects and strive for more sustainable crystallization methods that minimize negative impacts while maintaining product quality and efficiency.

Crystallization often involves the use of solvents, which can be a major source of environmental concern. The choice of solvent and the efficiency of the crystallization process can greatly affect the amount of waste generated. When geometric isomers are involved, the complexity of the crystallization process may increase, potentially leading to higher solvent consumption and waste production. This increased waste can contribute to air and water pollution if not properly managed.

Energy consumption is another critical environmental factor in crystallization processes. The formation of different crystal structures by geometric isomers may require specific temperature and pressure conditions, which can be energy-intensive. The need for precise control over these parameters to achieve desired crystal forms can result in increased energy usage, contributing to greenhouse gas emissions and climate change if non-renewable energy sources are used.

The polymorphism exhibited by geometric isomers in crystallization can also impact the environmental footprint of the final product. Different crystal forms may have varying solubility, stability, and bioavailability, which can affect their environmental persistence and potential ecological impacts. For instance, a more soluble polymorph might be more readily absorbed by organisms or dispersed in the environment, potentially leading to unintended consequences in ecosystems.

Furthermore, the purification and separation of geometric isomers during crystallization may require additional processing steps, such as recrystallization or chromatography. These additional steps can increase the overall environmental burden of the process through increased resource consumption and waste generation.

However, understanding the influence of geometric isomers on crystallization can also lead to more environmentally friendly processes. By optimizing crystallization conditions for specific isomers, it may be possible to reduce solvent use, improve yield, and minimize waste. This knowledge can be applied to develop more sustainable manufacturing processes, potentially reducing the environmental impact of chemical production.

In conclusion, the environmental impact of crystallization processes involving geometric isomers is multifaceted, encompassing issues of waste generation, energy consumption, and potential ecological effects. As research in this field progresses, it is crucial to consider these environmental aspects and strive for more sustainable crystallization methods that minimize negative impacts while maintaining product quality and efficiency.

Regulatory Framework for Solid-State Chemistry

The regulatory framework for solid-state chemistry plays a crucial role in ensuring the safety, efficacy, and quality of crystalline materials used in various industries. In the context of geometric isomers and their influence on crystallization, regulatory bodies have established guidelines and standards to address the unique challenges posed by these molecular structures.

The U.S. Food and Drug Administration (FDA) has implemented specific regulations for solid-state chemistry in pharmaceutical development. These regulations require manufacturers to thoroughly characterize and control the crystalline forms of active pharmaceutical ingredients (APIs) and excipients. The FDA's guidance on polymorphism emphasizes the importance of understanding how geometric isomers can affect crystal structure, stability, and bioavailability of drug products.

In Europe, the European Medicines Agency (EMA) has developed guidelines for the investigation of chiral active substances, which include considerations for geometric isomers. These guidelines outline the requirements for demonstrating the purity, stability, and consistency of crystalline forms in drug development and manufacturing processes.

The International Conference on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human Use (ICH) has established guidelines that address solid-state chemistry aspects, including Q6A on specifications and Q1A(R2) on stability testing. These guidelines provide a framework for assessing the impact of geometric isomers on crystallization and product quality across different regulatory jurisdictions.

Regulatory agencies also require manufacturers to implement robust quality control measures to ensure consistent crystalline forms throughout the production process. This includes the use of validated analytical methods to detect and quantify different geometric isomers and their potential impact on crystal structure and properties.

In the field of materials science, regulatory bodies such as the American Society for Testing and Materials (ASTM) have developed standards for characterizing and testing crystalline materials. These standards often include considerations for geometric isomers and their influence on material properties and performance.

As the understanding of geometric isomers and their role in crystallization continues to evolve, regulatory frameworks are adapting to incorporate new scientific knowledge. This includes the development of more sophisticated analytical techniques and computational models to predict and control crystallization behavior in the presence of geometric isomers.

Regulatory agencies are also increasingly focusing on the environmental impact of solid-state chemistry processes. This has led to the implementation of guidelines for green chemistry practices, which encourage the development of more sustainable crystallization methods that consider the influence of geometric isomers on process efficiency and waste reduction.

The U.S. Food and Drug Administration (FDA) has implemented specific regulations for solid-state chemistry in pharmaceutical development. These regulations require manufacturers to thoroughly characterize and control the crystalline forms of active pharmaceutical ingredients (APIs) and excipients. The FDA's guidance on polymorphism emphasizes the importance of understanding how geometric isomers can affect crystal structure, stability, and bioavailability of drug products.

In Europe, the European Medicines Agency (EMA) has developed guidelines for the investigation of chiral active substances, which include considerations for geometric isomers. These guidelines outline the requirements for demonstrating the purity, stability, and consistency of crystalline forms in drug development and manufacturing processes.

The International Conference on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human Use (ICH) has established guidelines that address solid-state chemistry aspects, including Q6A on specifications and Q1A(R2) on stability testing. These guidelines provide a framework for assessing the impact of geometric isomers on crystallization and product quality across different regulatory jurisdictions.

Regulatory agencies also require manufacturers to implement robust quality control measures to ensure consistent crystalline forms throughout the production process. This includes the use of validated analytical methods to detect and quantify different geometric isomers and their potential impact on crystal structure and properties.

In the field of materials science, regulatory bodies such as the American Society for Testing and Materials (ASTM) have developed standards for characterizing and testing crystalline materials. These standards often include considerations for geometric isomers and their influence on material properties and performance.

As the understanding of geometric isomers and their role in crystallization continues to evolve, regulatory frameworks are adapting to incorporate new scientific knowledge. This includes the development of more sophisticated analytical techniques and computational models to predict and control crystallization behavior in the presence of geometric isomers.

Regulatory agencies are also increasingly focusing on the environmental impact of solid-state chemistry processes. This has led to the implementation of guidelines for green chemistry practices, which encourage the development of more sustainable crystallization methods that consider the influence of geometric isomers on process efficiency and waste reduction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!