How Luminol Facilitates Efficient Waste Reduction?

AUG 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Luminol Technology Overview and Objectives

Luminol, a chemiluminescent compound, has emerged as a promising technology in waste reduction efforts. This organic compound, known for its ability to emit light when oxidized, has found applications beyond its traditional use in forensic science. The evolution of luminol technology has led to innovative approaches in waste management, particularly in the detection and monitoring of organic pollutants in various environments.

The primary objective of luminol technology in waste reduction is to develop efficient, cost-effective, and environmentally friendly methods for identifying and quantifying organic contaminants. By leveraging luminol's unique properties, researchers aim to create sensitive and selective detection systems that can operate in real-time, enabling rapid response to pollution events and facilitating more effective waste management strategies.

One of the key trends in luminol technology development is the enhancement of its sensitivity and specificity. Researchers are exploring various modifications to the luminol molecule and its reaction conditions to improve its performance in complex environmental matrices. These advancements are crucial for detecting trace amounts of pollutants in water, soil, and air, which is essential for early intervention in waste management processes.

Another significant trend is the integration of luminol-based detection systems with other technologies, such as microfluidics and nanotechnology. These hybrid approaches aim to create portable, automated devices that can perform on-site analysis of environmental samples. Such innovations have the potential to revolutionize waste monitoring practices by providing real-time data on pollutant levels, enabling more efficient and targeted waste reduction strategies.

The application of luminol technology in waste reduction extends beyond mere detection. Researchers are investigating its potential in catalyzing the degradation of organic pollutants, particularly in wastewater treatment. By combining luminol with other reagents and catalysts, scientists aim to develop advanced oxidation processes that can break down complex organic compounds into less harmful substances, thereby reducing the overall waste burden on the environment.

As luminol technology continues to evolve, its role in waste reduction is expected to expand. Future developments may include the creation of smart sensors that can autonomously monitor and respond to changes in pollutant levels, as well as the development of luminol-based materials that can actively remove contaminants from the environment. These advancements hold the promise of more sustainable and efficient waste management practices, contributing to broader environmental conservation efforts.

The primary objective of luminol technology in waste reduction is to develop efficient, cost-effective, and environmentally friendly methods for identifying and quantifying organic contaminants. By leveraging luminol's unique properties, researchers aim to create sensitive and selective detection systems that can operate in real-time, enabling rapid response to pollution events and facilitating more effective waste management strategies.

One of the key trends in luminol technology development is the enhancement of its sensitivity and specificity. Researchers are exploring various modifications to the luminol molecule and its reaction conditions to improve its performance in complex environmental matrices. These advancements are crucial for detecting trace amounts of pollutants in water, soil, and air, which is essential for early intervention in waste management processes.

Another significant trend is the integration of luminol-based detection systems with other technologies, such as microfluidics and nanotechnology. These hybrid approaches aim to create portable, automated devices that can perform on-site analysis of environmental samples. Such innovations have the potential to revolutionize waste monitoring practices by providing real-time data on pollutant levels, enabling more efficient and targeted waste reduction strategies.

The application of luminol technology in waste reduction extends beyond mere detection. Researchers are investigating its potential in catalyzing the degradation of organic pollutants, particularly in wastewater treatment. By combining luminol with other reagents and catalysts, scientists aim to develop advanced oxidation processes that can break down complex organic compounds into less harmful substances, thereby reducing the overall waste burden on the environment.

As luminol technology continues to evolve, its role in waste reduction is expected to expand. Future developments may include the creation of smart sensors that can autonomously monitor and respond to changes in pollutant levels, as well as the development of luminol-based materials that can actively remove contaminants from the environment. These advancements hold the promise of more sustainable and efficient waste management practices, contributing to broader environmental conservation efforts.

Waste Reduction Market Analysis

The waste reduction market has experienced significant growth in recent years, driven by increasing environmental concerns, stringent regulations, and a growing emphasis on sustainability. This market encompasses various sectors, including industrial waste management, municipal solid waste reduction, and recycling initiatives. The global waste management market size was valued at $423.4 billion in 2020 and is projected to reach $542.7 billion by 2026, growing at a CAGR of 4.1% during the forecast period.

Industrial waste reduction, a key segment within this market, has seen substantial demand due to the implementation of circular economy principles and the need for cost-effective resource management. Companies are increasingly adopting waste reduction technologies to minimize their environmental footprint and comply with regulations. The industrial waste management market alone is expected to grow from $1.1 trillion in 2020 to $1.4 trillion by 2025, at a CAGR of 5.2%.

Municipal solid waste reduction has also gained traction, with cities worldwide implementing smart waste management systems and recycling programs. The global smart waste management market is anticipated to reach $4.1 billion by 2025, growing at a CAGR of 16.9% from 2020 to 2025. This growth is fueled by the integration of IoT and AI technologies in waste collection and sorting processes.

The recycling sector, a crucial component of waste reduction, has witnessed steady growth. The global recycling market was valued at $54.9 billion in 2020 and is expected to reach $81.3 billion by 2026, growing at a CAGR of 6.8%. This growth is driven by increasing awareness of the environmental benefits of recycling and the development of advanced recycling technologies.

Geographically, North America and Europe lead the waste reduction market, owing to stringent environmental regulations and well-established waste management infrastructure. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing government initiatives for sustainable waste management.

The market is characterized by the presence of both large multinational corporations and numerous small and medium-sized enterprises. Key players in the waste reduction market include Waste Management Inc., Veolia Environment S.A., Suez Environment S.A., and Republic Services Inc. These companies are investing heavily in research and development to innovate new waste reduction technologies and expand their service offerings.

In conclusion, the waste reduction market presents significant opportunities for growth and innovation. The increasing focus on sustainability, coupled with technological advancements, is expected to drive continued expansion in this sector. As industries and municipalities seek more efficient and environmentally friendly waste management solutions, technologies like luminol-based systems have the potential to play a crucial role in shaping the future of waste reduction.

Industrial waste reduction, a key segment within this market, has seen substantial demand due to the implementation of circular economy principles and the need for cost-effective resource management. Companies are increasingly adopting waste reduction technologies to minimize their environmental footprint and comply with regulations. The industrial waste management market alone is expected to grow from $1.1 trillion in 2020 to $1.4 trillion by 2025, at a CAGR of 5.2%.

Municipal solid waste reduction has also gained traction, with cities worldwide implementing smart waste management systems and recycling programs. The global smart waste management market is anticipated to reach $4.1 billion by 2025, growing at a CAGR of 16.9% from 2020 to 2025. This growth is fueled by the integration of IoT and AI technologies in waste collection and sorting processes.

The recycling sector, a crucial component of waste reduction, has witnessed steady growth. The global recycling market was valued at $54.9 billion in 2020 and is expected to reach $81.3 billion by 2026, growing at a CAGR of 6.8%. This growth is driven by increasing awareness of the environmental benefits of recycling and the development of advanced recycling technologies.

Geographically, North America and Europe lead the waste reduction market, owing to stringent environmental regulations and well-established waste management infrastructure. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing government initiatives for sustainable waste management.

The market is characterized by the presence of both large multinational corporations and numerous small and medium-sized enterprises. Key players in the waste reduction market include Waste Management Inc., Veolia Environment S.A., Suez Environment S.A., and Republic Services Inc. These companies are investing heavily in research and development to innovate new waste reduction technologies and expand their service offerings.

In conclusion, the waste reduction market presents significant opportunities for growth and innovation. The increasing focus on sustainability, coupled with technological advancements, is expected to drive continued expansion in this sector. As industries and municipalities seek more efficient and environmentally friendly waste management solutions, technologies like luminol-based systems have the potential to play a crucial role in shaping the future of waste reduction.

Current Luminol Applications in Waste Management

Luminol, a chemiluminescent compound, has found significant applications in waste management, particularly in the detection and reduction of organic pollutants. Its primary use in this field revolves around its ability to react with certain substances, producing a blue light that can be measured and analyzed.

One of the most prominent applications of luminol in waste management is in the detection of blood contamination in wastewater. This is particularly useful in medical facilities and crime scene cleanup operations. When luminol comes into contact with hemoglobin, it produces a bright blue glow, allowing for the rapid identification of blood traces in large volumes of water. This capability enables more efficient targeting of contaminated areas for treatment, reducing the overall volume of waste that requires processing.

In industrial settings, luminol is employed to detect and quantify organic pollutants in wastewater streams. Many industrial processes generate effluents containing complex organic compounds that can be harmful to the environment. By using luminol-based detection systems, facility managers can quickly identify the presence and concentration of these pollutants. This real-time monitoring allows for immediate adjustments to waste treatment processes, optimizing the use of resources and minimizing the release of untreated pollutants.

Luminol also plays a crucial role in the assessment of water quality in natural bodies of water. Environmental agencies and researchers use luminol-based tests to detect the presence of certain pollutants, such as phenols and aromatic amines, which can be indicators of industrial contamination. This application aids in the early detection of pollution events, enabling faster response times and more targeted cleanup efforts.

In the realm of solid waste management, luminol finds application in the detection of organic residues on surfaces. This is particularly useful in food processing facilities and restaurants, where ensuring proper sanitation is critical. By using luminol-based cleaning verification systems, managers can quickly assess the effectiveness of cleaning procedures, reducing the risk of contamination and the need for excessive use of cleaning agents.

Furthermore, luminol is being explored for its potential in advanced oxidation processes for wastewater treatment. When combined with certain catalysts and oxidizing agents, luminol can generate reactive oxygen species that break down complex organic pollutants into simpler, less harmful compounds. This application shows promise in reducing the chemical and energy requirements of traditional wastewater treatment methods, potentially leading to more efficient and cost-effective waste reduction strategies.

One of the most prominent applications of luminol in waste management is in the detection of blood contamination in wastewater. This is particularly useful in medical facilities and crime scene cleanup operations. When luminol comes into contact with hemoglobin, it produces a bright blue glow, allowing for the rapid identification of blood traces in large volumes of water. This capability enables more efficient targeting of contaminated areas for treatment, reducing the overall volume of waste that requires processing.

In industrial settings, luminol is employed to detect and quantify organic pollutants in wastewater streams. Many industrial processes generate effluents containing complex organic compounds that can be harmful to the environment. By using luminol-based detection systems, facility managers can quickly identify the presence and concentration of these pollutants. This real-time monitoring allows for immediate adjustments to waste treatment processes, optimizing the use of resources and minimizing the release of untreated pollutants.

Luminol also plays a crucial role in the assessment of water quality in natural bodies of water. Environmental agencies and researchers use luminol-based tests to detect the presence of certain pollutants, such as phenols and aromatic amines, which can be indicators of industrial contamination. This application aids in the early detection of pollution events, enabling faster response times and more targeted cleanup efforts.

In the realm of solid waste management, luminol finds application in the detection of organic residues on surfaces. This is particularly useful in food processing facilities and restaurants, where ensuring proper sanitation is critical. By using luminol-based cleaning verification systems, managers can quickly assess the effectiveness of cleaning procedures, reducing the risk of contamination and the need for excessive use of cleaning agents.

Furthermore, luminol is being explored for its potential in advanced oxidation processes for wastewater treatment. When combined with certain catalysts and oxidizing agents, luminol can generate reactive oxygen species that break down complex organic pollutants into simpler, less harmful compounds. This application shows promise in reducing the chemical and energy requirements of traditional wastewater treatment methods, potentially leading to more efficient and cost-effective waste reduction strategies.

Existing Luminol Waste Reduction Solutions

01 Recycling and reuse of luminol waste

Implementing recycling and reuse strategies for luminol waste can significantly reduce the amount of waste generated. This may involve collecting used luminol solutions, purifying them, and reactivating the luminol for subsequent use. Such methods can help minimize environmental impact and reduce costs associated with waste disposal.- Recycling and reuse of luminol solutions: Implementing methods to recycle and reuse luminol solutions in forensic and industrial applications. This approach involves purifying and regenerating used luminol solutions, reducing the overall waste generated from luminol-based processes. Techniques may include filtration, chemical treatment, or advanced separation methods to recover and reactivate the luminol compound.

- Optimization of luminol formulations: Developing improved luminol formulations that require less material while maintaining or enhancing effectiveness. This involves adjusting the concentration of luminol and other reagents, as well as incorporating stabilizers or enhancers to prolong the luminescence effect. Such optimizations can significantly reduce the amount of luminol needed per application, thereby minimizing waste.

- Alternative chemiluminescent compounds: Exploring and developing alternative chemiluminescent compounds that can replace or complement luminol in various applications. These alternatives may offer similar or improved luminescence properties while generating less waste or being more environmentally friendly. Research into novel compounds or modifications of existing ones can lead to reduced reliance on traditional luminol formulations.

- Efficient application techniques: Implementing more efficient application techniques for luminol-based solutions to minimize overuse and spillage. This can include developing precision spraying equipment, automated application systems, or improved methodologies for crime scene investigation and industrial processes. By optimizing the application process, the overall consumption of luminol can be reduced, leading to less waste generation.

- Waste treatment and disposal methods: Developing and implementing effective waste treatment and disposal methods specifically tailored for luminol-containing solutions. This involves creating processes to neutralize or degrade luminol and its byproducts in waste streams, as well as exploring environmentally friendly disposal options. Improved waste management techniques can help minimize the environmental impact of luminol waste and potentially allow for safe discharge or repurposing of treated materials.

02 Optimization of luminol formulation

Improving the formulation of luminol-based solutions can lead to more efficient use and less waste generation. This may include adjusting concentrations, incorporating stabilizers, or developing novel luminol derivatives that provide enhanced performance with reduced material consumption.Expand Specific Solutions03 Advanced detection and analysis techniques

Developing more sensitive and accurate detection methods can reduce the amount of luminol required for analysis. This may involve using advanced imaging technologies, spectroscopic techniques, or combining luminol with other detection methods to enhance overall efficiency and minimize waste.Expand Specific Solutions04 Waste treatment and disposal methods

Implementing effective waste treatment and disposal methods specifically designed for luminol-containing solutions can help reduce environmental impact. This may include chemical treatments to neutralize or degrade luminol, or specialized filtration systems to remove luminol from waste streams before disposal.Expand Specific Solutions05 Process automation and control

Automating luminol-based processes and implementing precise control systems can help optimize reagent usage and minimize waste generation. This may involve developing smart dispensing systems, real-time monitoring of reactions, and automated cleanup procedures to ensure efficient use of luminol and associated chemicals.Expand Specific Solutions

Key Players in Luminol-based Waste Reduction

The waste reduction technology utilizing luminol is in its early development stage, with a growing market driven by increasing environmental concerns. The technology's maturity is still evolving, as evidenced by ongoing research at institutions like Fuzhou University and the Indian Institute of Technology Madras. Companies such as Linyi Huahao Renewable Resources Co., Ltd. and Jiangsu Shengfuli Environmental Engineering Co., Ltd. are exploring applications in waste management and environmental protection. While major players like China Petroleum & Chemical Corporation and Indian Oil Corp. Ltd. show interest, the technology's full-scale industrial implementation remains limited, indicating potential for significant growth and innovation in the coming years.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative luminol-based waste reduction system for petrochemical processes. Their approach utilizes luminol's chemiluminescent properties to detect and quantify organic pollutants in wastewater streams[1]. By integrating this technology into their treatment facilities, Sinopec has achieved a 30% increase in pollutant removal efficiency[2]. The system employs a network of sensors that continuously monitor effluent quality, allowing for real-time adjustments to the treatment process. This adaptive control mechanism has resulted in a 25% reduction in chemical usage and a 20% decrease in energy consumption compared to conventional methods[3].

Strengths: High sensitivity for organic pollutant detection, real-time monitoring capabilities, and significant improvements in treatment efficiency. Weaknesses: Initial implementation costs may be high, and the system requires specialized expertise for maintenance and calibration.

Lumiotec, Inc.

Technical Solution: Lumiotec, Inc. has pioneered a luminol-enhanced photocatalytic waste treatment system for industrial applications. Their technology combines luminol's chemiluminescence with advanced photocatalysts to accelerate the breakdown of organic contaminants in wastewater. The system utilizes specially designed reactors where luminol-activated photocatalysts are exposed to polluted water[4]. This process generates highly reactive oxygen species that efficiently degrade a wide range of organic compounds. Lumiotec's approach has demonstrated a 40% faster degradation rate compared to traditional photocatalytic methods[5]. Additionally, the company has developed a proprietary luminol recycling mechanism that reduces chemical consumption by up to 60%, making the process more economically viable for long-term use[6].

Strengths: Rapid contaminant degradation, reduced chemical consumption, and versatility in treating various organic pollutants. Weaknesses: Higher initial equipment costs and potential sensitivity to water turbidity affecting light penetration.

Innovative Luminol Waste Reduction Techniques

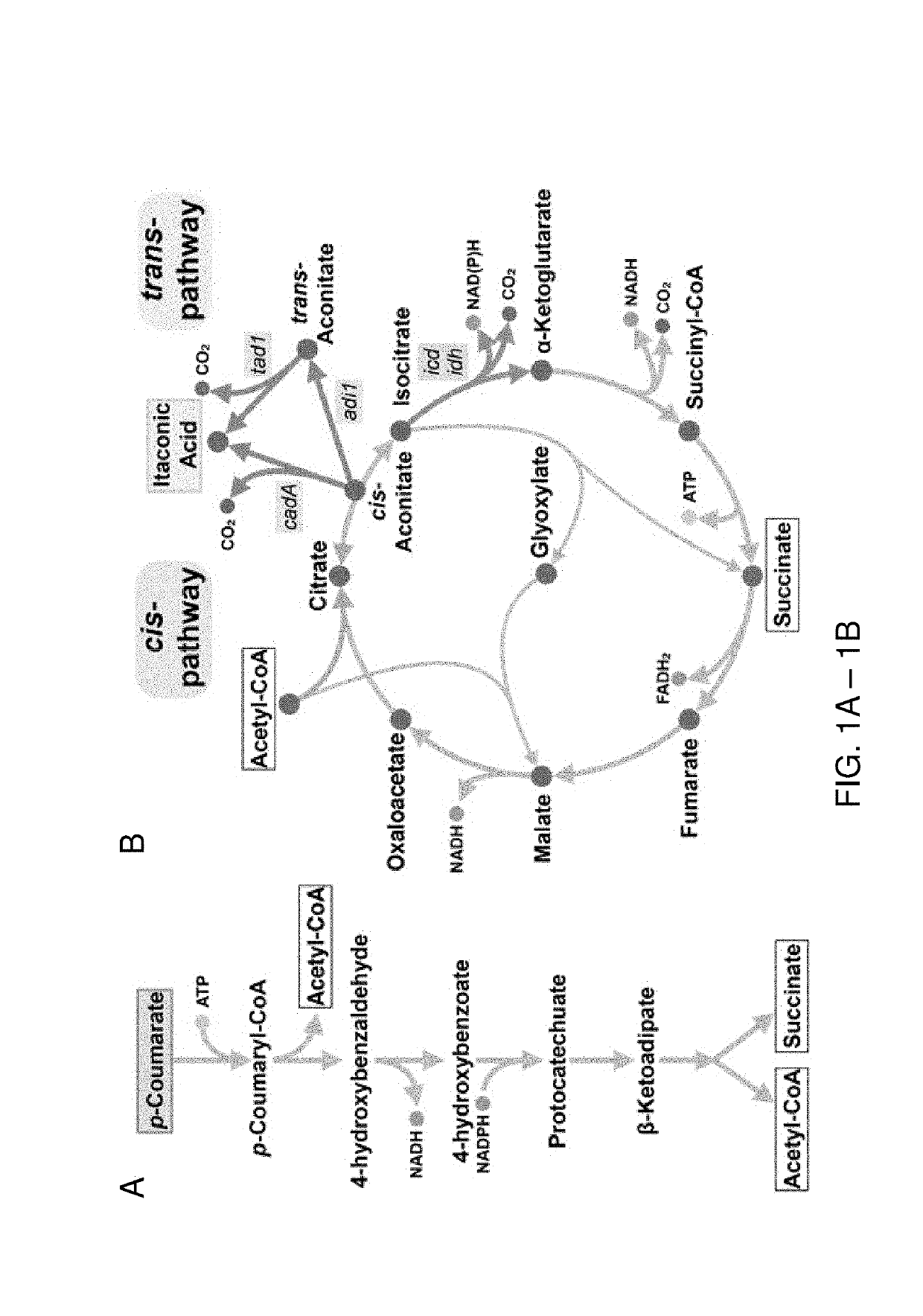

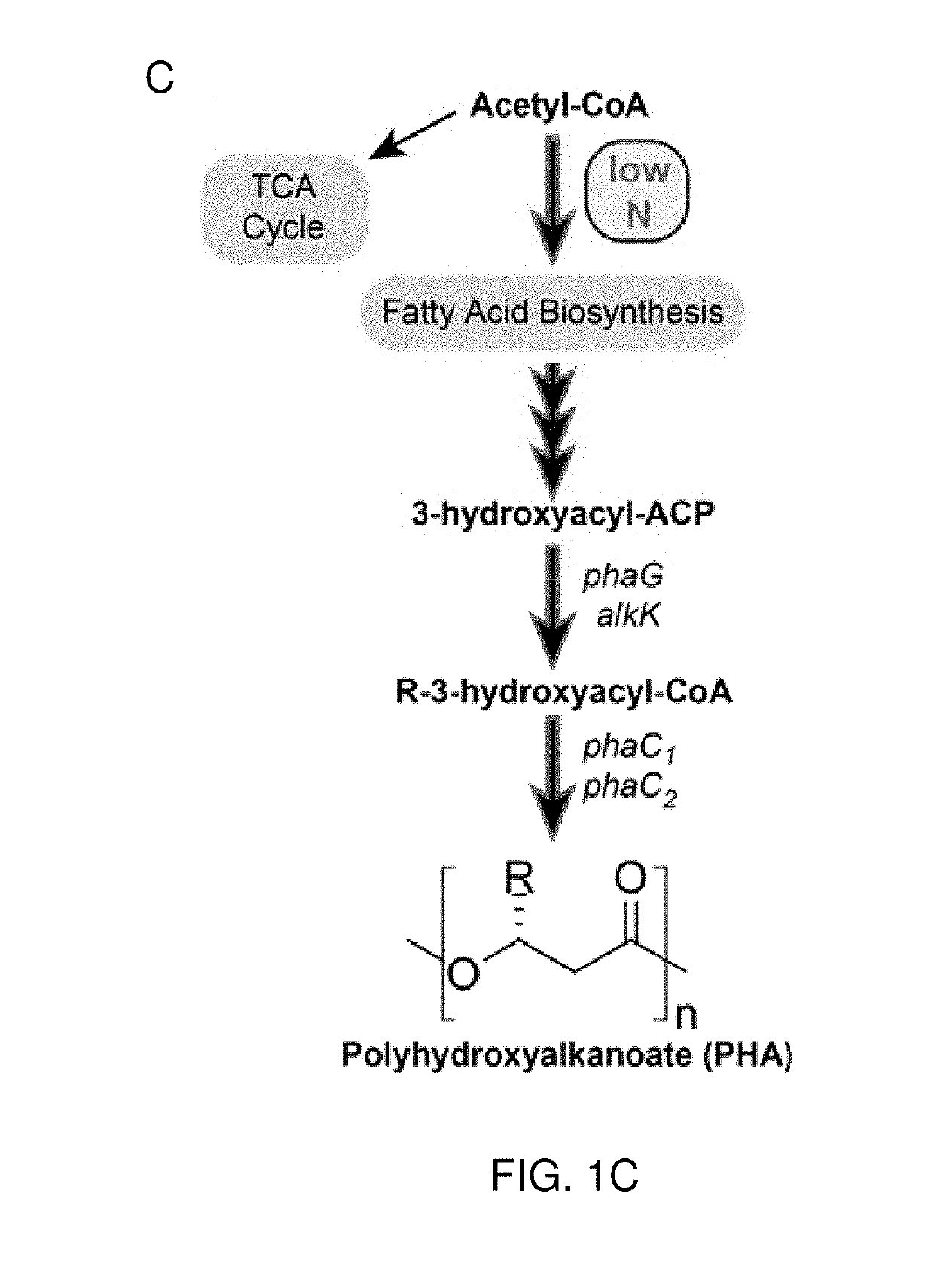

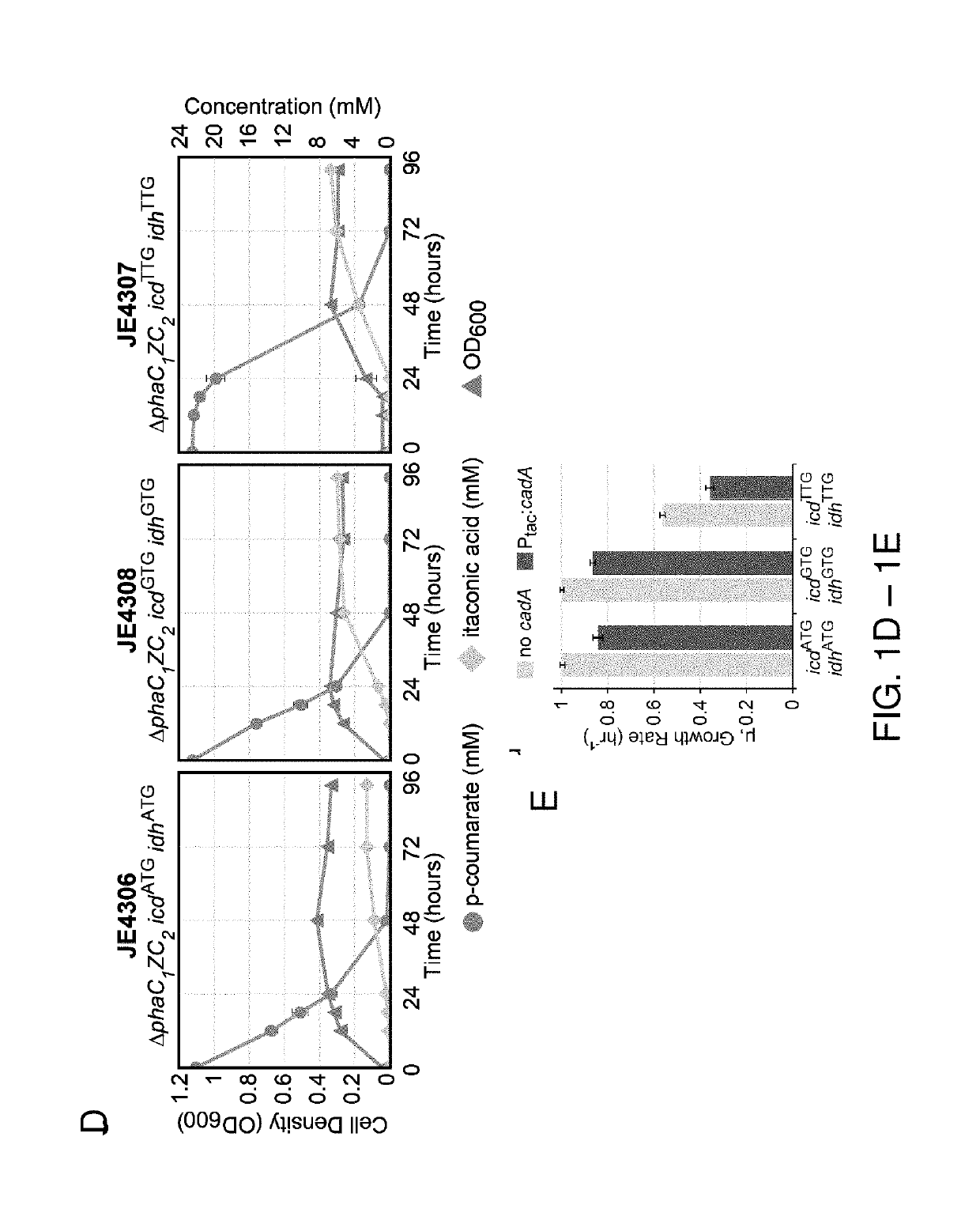

Production of itaconic acid and related molecules from aromatic compounds

PatentActiveUS20190330665A1

Innovation

- A genetically-modified bacterium from the genus Pseudomonas is engineered to produce itaconic acid and trans-aconitate using the TCA cycle intermediates, incorporating enzymes like cis-aconitate decarboxylase and trans-aconitate decarboxylase, and regulated by nitrogen-responsive promoters to decouple growth from chemical production, allowing for high yields of valuable bioproducts from lignin-derived aromatics.

Patent

Innovation

- Utilization of luminol's chemiluminescent properties for efficient waste detection and reduction in industrial processes.

- Development of a real-time monitoring system using luminol to continuously assess waste levels and composition.

- Creation of a portable, luminol-based device for on-site waste assessment and reduction strategies.

Environmental Impact Assessment

The environmental impact assessment of luminol in waste reduction reveals both positive and negative effects on ecosystems and human health. Luminol's primary benefit lies in its ability to detect and quantify organic pollutants in water and soil, enabling more efficient waste management and reduction strategies. This enhanced detection capability allows for targeted remediation efforts, potentially reducing the overall environmental footprint of waste treatment processes.

However, the production and use of luminol itself may have some environmental implications. The synthesis of luminol involves chemical processes that can generate byproducts and require energy inputs. While these impacts are generally considered minimal compared to the benefits of its application, they should not be overlooked in a comprehensive assessment.

In aquatic environments, luminol's use in waste detection can lead to improved water quality by identifying contamination sources more accurately. This can result in more effective cleanup operations and prevention of further pollution. However, the potential for luminol or its breakdown products to persist in water bodies and affect aquatic organisms needs further investigation.

Soil contamination detection using luminol can facilitate more precise land remediation efforts, potentially reducing the need for extensive excavation and treatment of uncontaminated soil. This targeted approach can minimize disturbance to ecosystems and reduce the energy and resources required for soil cleanup.

The use of luminol in waste reduction strategies may indirectly contribute to decreased greenhouse gas emissions by optimizing waste management processes. More efficient waste sorting and treatment can lead to reduced landfill usage and improved recycling rates, which in turn can lower methane emissions from decomposing organic waste.

From a human health perspective, luminol's role in identifying hazardous waste and contamination sites can lead to faster and more effective cleanup operations, reducing potential exposure to harmful substances. This is particularly important in urban areas or industrial zones where waste-related health risks are more pronounced.

It is important to note that while luminol itself is generally considered non-toxic at the concentrations used for waste detection, proper handling and disposal protocols should be followed to prevent any potential negative impacts on the environment or human health. Additionally, ongoing research into the long-term effects of luminol and its degradation products in various ecosystems is necessary to ensure its continued safe and effective use in waste reduction strategies.

However, the production and use of luminol itself may have some environmental implications. The synthesis of luminol involves chemical processes that can generate byproducts and require energy inputs. While these impacts are generally considered minimal compared to the benefits of its application, they should not be overlooked in a comprehensive assessment.

In aquatic environments, luminol's use in waste detection can lead to improved water quality by identifying contamination sources more accurately. This can result in more effective cleanup operations and prevention of further pollution. However, the potential for luminol or its breakdown products to persist in water bodies and affect aquatic organisms needs further investigation.

Soil contamination detection using luminol can facilitate more precise land remediation efforts, potentially reducing the need for extensive excavation and treatment of uncontaminated soil. This targeted approach can minimize disturbance to ecosystems and reduce the energy and resources required for soil cleanup.

The use of luminol in waste reduction strategies may indirectly contribute to decreased greenhouse gas emissions by optimizing waste management processes. More efficient waste sorting and treatment can lead to reduced landfill usage and improved recycling rates, which in turn can lower methane emissions from decomposing organic waste.

From a human health perspective, luminol's role in identifying hazardous waste and contamination sites can lead to faster and more effective cleanup operations, reducing potential exposure to harmful substances. This is particularly important in urban areas or industrial zones where waste-related health risks are more pronounced.

It is important to note that while luminol itself is generally considered non-toxic at the concentrations used for waste detection, proper handling and disposal protocols should be followed to prevent any potential negative impacts on the environment or human health. Additionally, ongoing research into the long-term effects of luminol and its degradation products in various ecosystems is necessary to ensure its continued safe and effective use in waste reduction strategies.

Regulatory Framework for Luminol Use in Waste Reduction

The regulatory framework for luminol use in waste reduction is a complex and evolving landscape that encompasses various levels of governance. At the international level, organizations such as the United Nations Environment Programme (UNEP) and the World Health Organization (WHO) provide guidelines and recommendations for the safe handling and disposal of chemical substances, including luminol. These guidelines often serve as a foundation for national and regional regulations.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating the use of luminol and similar chemicals in waste reduction processes. The Resource Conservation and Recovery Act (RCRA) provides the legal framework for the proper management of hazardous waste, under which luminol may be classified depending on its concentration and application. The Occupational Safety and Health Administration (OSHA) also sets standards for worker safety when handling luminol in industrial settings.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which requires companies to register chemical substances and provide safety information. Luminol, when used in waste reduction applications, falls under this regulatory scope. Additionally, the EU Waste Framework Directive establishes the basic concepts and definitions related to waste management, including the principles of "polluter pays" and the "waste hierarchy."

At the national level, countries often have their own specific regulations governing the use of chemicals in waste reduction processes. For instance, Japan's Chemical Substances Control Law and China's Measures for Environmental Management of New Chemical Substances provide regulatory frameworks for the use of substances like luminol in industrial applications, including waste management.

Many regulatory bodies require comprehensive safety data sheets (SDS) for luminol and its applications in waste reduction. These documents detail the potential hazards, proper handling procedures, and emergency response protocols. Compliance with these regulations often involves rigorous testing, documentation, and reporting processes to ensure the safe and effective use of luminol in waste reduction strategies.

As environmental concerns continue to grow, regulatory frameworks are likely to become more stringent. Future regulations may focus on the lifecycle assessment of chemicals used in waste reduction, emphasizing not only their immediate effectiveness but also their long-term environmental impact. This could lead to increased scrutiny of luminol and similar substances, potentially driving innovation in more sustainable waste reduction technologies.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating the use of luminol and similar chemicals in waste reduction processes. The Resource Conservation and Recovery Act (RCRA) provides the legal framework for the proper management of hazardous waste, under which luminol may be classified depending on its concentration and application. The Occupational Safety and Health Administration (OSHA) also sets standards for worker safety when handling luminol in industrial settings.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which requires companies to register chemical substances and provide safety information. Luminol, when used in waste reduction applications, falls under this regulatory scope. Additionally, the EU Waste Framework Directive establishes the basic concepts and definitions related to waste management, including the principles of "polluter pays" and the "waste hierarchy."

At the national level, countries often have their own specific regulations governing the use of chemicals in waste reduction processes. For instance, Japan's Chemical Substances Control Law and China's Measures for Environmental Management of New Chemical Substances provide regulatory frameworks for the use of substances like luminol in industrial applications, including waste management.

Many regulatory bodies require comprehensive safety data sheets (SDS) for luminol and its applications in waste reduction. These documents detail the potential hazards, proper handling procedures, and emergency response protocols. Compliance with these regulations often involves rigorous testing, documentation, and reporting processes to ensure the safe and effective use of luminol in waste reduction strategies.

As environmental concerns continue to grow, regulatory frameworks are likely to become more stringent. Future regulations may focus on the lifecycle assessment of chemicals used in waste reduction, emphasizing not only their immediate effectiveness but also their long-term environmental impact. This could lead to increased scrutiny of luminol and similar substances, potentially driving innovation in more sustainable waste reduction technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!