Luminol Synthesis Techniques for Enhanced Sensitivity

AUG 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Luminol Evolution

Luminol, a chemiluminescent compound, has undergone significant evolution since its discovery in the early 20th century. Initially synthesized by German chemist Albrecht Schmidt in 1902, luminol's unique properties were not fully understood or utilized until decades later.

The 1920s marked a crucial turning point in luminol's development when H. O. Albrecht recognized its potential for forensic applications. This discovery laid the foundation for luminol's widespread use in crime scene investigations, particularly for detecting trace amounts of blood.

Throughout the 1930s and 1940s, researchers focused on optimizing luminol's synthesis and enhancing its chemiluminescent properties. The introduction of various catalysts and oxidizing agents significantly improved the intensity and duration of luminol's light emission, expanding its potential applications beyond forensics.

The 1950s and 1960s saw a surge in luminol-related research, with scientists exploring its molecular structure and reaction mechanisms. This period was characterized by the development of more efficient synthesis methods and the identification of key factors influencing luminol's sensitivity, such as pH levels and the presence of specific metal ions.

In the 1970s and 1980s, luminol's evolution took a new direction with the advent of analytical techniques like high-performance liquid chromatography (HPLC) and mass spectrometry. These advancements allowed for more precise control over luminol synthesis and purity, leading to enhanced sensitivity in various applications.

The late 20th and early 21st centuries witnessed a shift towards developing luminol derivatives and analogues. Researchers aimed to create compounds with improved stability, increased light output, and tailored spectral properties. This era also saw the integration of luminol-based systems with emerging technologies, such as microfluidics and nanotechnology, further expanding its analytical capabilities.

Recent years have focused on enhancing luminol's sensitivity through innovative synthesis techniques. Scientists have explored novel catalysts, reaction conditions, and molecular modifications to push the limits of detection. The development of luminol-functionalized nanoparticles and the incorporation of luminol into advanced sensor platforms have opened new avenues for ultra-sensitive detection in fields ranging from environmental monitoring to medical diagnostics.

The ongoing evolution of luminol synthesis techniques continues to drive improvements in sensitivity, specificity, and versatility. As researchers delve deeper into the molecular intricacies of luminol and its reactions, new opportunities emerge for its application in cutting-edge scientific and technological domains, promising even greater advancements in the future.

The 1920s marked a crucial turning point in luminol's development when H. O. Albrecht recognized its potential for forensic applications. This discovery laid the foundation for luminol's widespread use in crime scene investigations, particularly for detecting trace amounts of blood.

Throughout the 1930s and 1940s, researchers focused on optimizing luminol's synthesis and enhancing its chemiluminescent properties. The introduction of various catalysts and oxidizing agents significantly improved the intensity and duration of luminol's light emission, expanding its potential applications beyond forensics.

The 1950s and 1960s saw a surge in luminol-related research, with scientists exploring its molecular structure and reaction mechanisms. This period was characterized by the development of more efficient synthesis methods and the identification of key factors influencing luminol's sensitivity, such as pH levels and the presence of specific metal ions.

In the 1970s and 1980s, luminol's evolution took a new direction with the advent of analytical techniques like high-performance liquid chromatography (HPLC) and mass spectrometry. These advancements allowed for more precise control over luminol synthesis and purity, leading to enhanced sensitivity in various applications.

The late 20th and early 21st centuries witnessed a shift towards developing luminol derivatives and analogues. Researchers aimed to create compounds with improved stability, increased light output, and tailored spectral properties. This era also saw the integration of luminol-based systems with emerging technologies, such as microfluidics and nanotechnology, further expanding its analytical capabilities.

Recent years have focused on enhancing luminol's sensitivity through innovative synthesis techniques. Scientists have explored novel catalysts, reaction conditions, and molecular modifications to push the limits of detection. The development of luminol-functionalized nanoparticles and the incorporation of luminol into advanced sensor platforms have opened new avenues for ultra-sensitive detection in fields ranging from environmental monitoring to medical diagnostics.

The ongoing evolution of luminol synthesis techniques continues to drive improvements in sensitivity, specificity, and versatility. As researchers delve deeper into the molecular intricacies of luminol and its reactions, new opportunities emerge for its application in cutting-edge scientific and technological domains, promising even greater advancements in the future.

Market Applications

Luminol synthesis techniques for enhanced sensitivity have found widespread applications across various market sectors, driving innovation and improving analytical capabilities. In the field of forensic science, these advanced luminol formulations have revolutionized crime scene investigations. Law enforcement agencies and forensic laboratories utilize enhanced luminol to detect trace amounts of blood, even in cases where traditional methods fall short. This increased sensitivity allows investigators to uncover crucial evidence that might otherwise go unnoticed, leading to more accurate crime scene reconstructions and improved case resolution rates.

The healthcare industry has also embraced luminol synthesis techniques with enhanced sensitivity for diagnostic purposes. Medical laboratories employ these advanced formulations in immunoassays and other biochemical tests to detect specific proteins, hormones, or disease markers at lower concentrations. This capability enables earlier disease detection, more precise monitoring of treatment efficacy, and improved patient outcomes. Additionally, pharmaceutical companies leverage enhanced luminol in drug discovery processes, allowing for more sensitive screening of potential drug candidates and accelerating the development of new therapeutic compounds.

Environmental monitoring and water quality assessment represent another significant market application for luminol synthesis techniques with enhanced sensitivity. Environmental agencies and research institutions utilize these advanced formulations to detect and quantify trace amounts of pollutants, heavy metals, and other contaminants in water sources. The increased sensitivity enables more accurate monitoring of water quality in rivers, lakes, and groundwater, facilitating early detection of potential environmental hazards and supporting more effective conservation efforts.

In the food and beverage industry, luminol synthesis techniques with enhanced sensitivity play a crucial role in ensuring product safety and quality control. Food manufacturers and regulatory bodies employ these advanced formulations to detect contaminants, allergens, and microbial presence in food products with greater accuracy. This application helps prevent foodborne illnesses, reduces product recalls, and enhances overall consumer safety in the food supply chain.

The agricultural sector has also found valuable applications for luminol synthesis techniques with enhanced sensitivity. Researchers and agrochemical companies utilize these advanced formulations to detect and quantify pesticide residues on crops and in soil samples. This capability allows for more precise monitoring of pesticide use, ensuring compliance with regulatory standards and promoting sustainable farming practices. Additionally, enhanced luminol techniques contribute to the development of more effective and environmentally friendly pest control solutions.

The healthcare industry has also embraced luminol synthesis techniques with enhanced sensitivity for diagnostic purposes. Medical laboratories employ these advanced formulations in immunoassays and other biochemical tests to detect specific proteins, hormones, or disease markers at lower concentrations. This capability enables earlier disease detection, more precise monitoring of treatment efficacy, and improved patient outcomes. Additionally, pharmaceutical companies leverage enhanced luminol in drug discovery processes, allowing for more sensitive screening of potential drug candidates and accelerating the development of new therapeutic compounds.

Environmental monitoring and water quality assessment represent another significant market application for luminol synthesis techniques with enhanced sensitivity. Environmental agencies and research institutions utilize these advanced formulations to detect and quantify trace amounts of pollutants, heavy metals, and other contaminants in water sources. The increased sensitivity enables more accurate monitoring of water quality in rivers, lakes, and groundwater, facilitating early detection of potential environmental hazards and supporting more effective conservation efforts.

In the food and beverage industry, luminol synthesis techniques with enhanced sensitivity play a crucial role in ensuring product safety and quality control. Food manufacturers and regulatory bodies employ these advanced formulations to detect contaminants, allergens, and microbial presence in food products with greater accuracy. This application helps prevent foodborne illnesses, reduces product recalls, and enhances overall consumer safety in the food supply chain.

The agricultural sector has also found valuable applications for luminol synthesis techniques with enhanced sensitivity. Researchers and agrochemical companies utilize these advanced formulations to detect and quantify pesticide residues on crops and in soil samples. This capability allows for more precise monitoring of pesticide use, ensuring compliance with regulatory standards and promoting sustainable farming practices. Additionally, enhanced luminol techniques contribute to the development of more effective and environmentally friendly pest control solutions.

Synthesis Challenges

The synthesis of luminol presents several significant challenges that researchers and manufacturers must overcome to enhance its sensitivity for various applications. One of the primary difficulties lies in achieving high purity levels during the synthesis process. Impurities can significantly affect the chemiluminescent properties of luminol, leading to reduced sensitivity and inconsistent results in forensic and analytical applications.

Another major challenge is the optimization of reaction conditions to maximize yield while maintaining product quality. The synthesis of luminol typically involves multiple steps, each requiring precise control of temperature, pH, and reagent concentrations. Slight variations in these parameters can result in side reactions or incomplete conversions, affecting the overall efficiency of the synthesis process.

The scalability of luminol synthesis techniques also poses a considerable challenge. While laboratory-scale production may be well-established, scaling up to industrial levels often introduces new complexities. These can include heat transfer issues, mixing inefficiencies, and the need for specialized equipment capable of handling larger volumes while maintaining the required precision.

Environmental concerns and regulatory compliance add another layer of complexity to luminol synthesis. Traditional methods often involve the use of harsh chemicals and generate significant waste. Developing greener synthesis routes that reduce environmental impact while maintaining or improving product quality is an ongoing challenge for researchers in this field.

The stability of synthesized luminol is another critical issue. The compound can be sensitive to light, heat, and certain chemical environments, which can lead to degradation over time. Improving the stability of luminol without compromising its chemiluminescent properties is essential for enhancing its shelf life and reliability in various applications.

Furthermore, the development of novel synthesis techniques to produce luminol derivatives with enhanced properties presents its own set of challenges. These may include difficulties in introducing specific functional groups, controlling the regiochemistry of reactions, and maintaining the core luminol structure while modifying its periphery to achieve desired characteristics such as increased solubility or stronger chemiluminescence.

Lastly, the cost-effectiveness of luminol synthesis remains a significant consideration, particularly for large-scale production. Balancing the use of high-quality reagents and sophisticated synthesis techniques with economic viability is crucial for the widespread adoption of enhanced luminol in various industries.

Another major challenge is the optimization of reaction conditions to maximize yield while maintaining product quality. The synthesis of luminol typically involves multiple steps, each requiring precise control of temperature, pH, and reagent concentrations. Slight variations in these parameters can result in side reactions or incomplete conversions, affecting the overall efficiency of the synthesis process.

The scalability of luminol synthesis techniques also poses a considerable challenge. While laboratory-scale production may be well-established, scaling up to industrial levels often introduces new complexities. These can include heat transfer issues, mixing inefficiencies, and the need for specialized equipment capable of handling larger volumes while maintaining the required precision.

Environmental concerns and regulatory compliance add another layer of complexity to luminol synthesis. Traditional methods often involve the use of harsh chemicals and generate significant waste. Developing greener synthesis routes that reduce environmental impact while maintaining or improving product quality is an ongoing challenge for researchers in this field.

The stability of synthesized luminol is another critical issue. The compound can be sensitive to light, heat, and certain chemical environments, which can lead to degradation over time. Improving the stability of luminol without compromising its chemiluminescent properties is essential for enhancing its shelf life and reliability in various applications.

Furthermore, the development of novel synthesis techniques to produce luminol derivatives with enhanced properties presents its own set of challenges. These may include difficulties in introducing specific functional groups, controlling the regiochemistry of reactions, and maintaining the core luminol structure while modifying its periphery to achieve desired characteristics such as increased solubility or stronger chemiluminescence.

Lastly, the cost-effectiveness of luminol synthesis remains a significant consideration, particularly for large-scale production. Balancing the use of high-quality reagents and sophisticated synthesis techniques with economic viability is crucial for the widespread adoption of enhanced luminol in various industries.

Current Techniques

01 Enhancement of luminol sensitivity

Various methods and compositions are developed to enhance the sensitivity of luminol-based detection systems. These improvements may involve the use of catalysts, additives, or modified reaction conditions to increase the intensity and duration of the chemiluminescent signal produced by luminol.- Enhancement of luminol sensitivity: Various methods and compositions are developed to enhance the sensitivity of luminol-based detection systems. These improvements allow for more accurate and reliable detection of trace amounts of target substances, particularly in forensic and analytical applications.

- Application in forensic investigations: Luminol sensitivity plays a crucial role in forensic investigations, particularly in detecting and visualizing blood traces at crime scenes. Advanced formulations and detection techniques are developed to improve the effectiveness of luminol in challenging forensic scenarios.

- Integration with other detection methods: Luminol-based detection systems are integrated with other analytical techniques to enhance overall sensitivity and specificity. This combination approach allows for more comprehensive and accurate detection of target substances in various fields, including environmental monitoring and medical diagnostics.

- Optimization of luminol reaction conditions: Research focuses on optimizing reaction conditions for luminol-based chemiluminescence, including pH, temperature, and catalyst concentrations. These optimizations aim to improve the sensitivity and reliability of luminol-based detection methods across different applications.

- Development of novel luminol derivatives: New luminol derivatives and analogues are synthesized to enhance sensitivity and specificity in various detection applications. These novel compounds aim to overcome limitations of traditional luminol, offering improved performance in challenging detection scenarios.

02 Application in forensic science

Luminol sensitivity is crucial in forensic applications, particularly for detecting trace amounts of blood at crime scenes. Research focuses on improving the detection limits and reducing interference from other substances to enhance the reliability of luminol-based forensic tests.Expand Specific Solutions03 Luminol-based biosensors

Development of highly sensitive biosensors utilizing luminol chemiluminescence for detecting various biological and chemical analytes. These biosensors often incorporate nanomaterials or enzymes to amplify the luminol signal and improve detection sensitivity.Expand Specific Solutions04 Environmental and industrial applications

Luminol sensitivity is exploited in environmental monitoring and industrial processes. Research in this area focuses on developing sensitive methods for detecting pollutants, monitoring chemical reactions, and quality control in various industries.Expand Specific Solutions05 Instrumentation and measurement techniques

Advancements in instrumentation and measurement techniques to improve the detection and quantification of luminol chemiluminescence. This includes the development of specialized equipment, imaging systems, and data analysis methods to enhance sensitivity and accuracy in luminol-based assays.Expand Specific Solutions

Key Industry Players

The luminol synthesis techniques for enhanced sensitivity market is in a growth phase, driven by increasing demand for high-sensitivity detection methods in forensics, biomedical research, and clinical diagnostics. The global market size is expanding, with key players like Promega Corp., FUJIFILM Corp., and Eastman Kodak Co. investing in R&D to improve luminol-based technologies. The technical maturity varies, with established companies like LI-COR, Inc. and Cyanagen Srl offering advanced solutions, while newer entrants like Alverix, Inc. focus on innovative portable devices. Academic institutions such as Washington University in St. Louis and Kyoto University contribute to fundamental research, pushing the boundaries of luminol synthesis and application.

Promega Corp.

Technical Solution: Promega has developed advanced luminol synthesis techniques for enhanced sensitivity in chemiluminescence assays. Their approach involves optimizing the luminol structure through strategic substitutions, particularly at the 5 and 6 positions of the luminol molecule. This modification has resulted in a significant increase in light output, with some variants showing up to 100-fold improvement in sensitivity compared to standard luminol [1]. Additionally, Promega has engineered a proprietary formulation that stabilizes the luminol and enhances its shelf life, addressing a common limitation in chemiluminescence reagents [3]. The company has also developed a novel method for coupling luminol derivatives to specific biomolecules, enabling highly sensitive and specific detection in complex biological samples [5].

Strengths: Significantly enhanced sensitivity, improved reagent stability, and versatility in bioanalytical applications. Weaknesses: Potentially higher production costs and the need for specialized equipment for some applications.

FUJIFILM Corp.

Technical Solution: FUJIFILM has innovated in luminol synthesis by developing a unique nanoparticle-based approach. Their technique involves encapsulating luminol and its enhancers within biodegradable polymer nanoparticles, creating a controlled-release system that prolongs the chemiluminescence reaction [2]. This method not only increases the overall light output but also extends the duration of the signal, making it particularly useful for long-term imaging applications. FUJIFILM has also incorporated catalytic metal complexes into their luminol formulations, which act as electron transfer mediators, further amplifying the chemiluminescence signal [4]. Their research has shown a 10-20 fold increase in sensitivity compared to conventional luminol systems, with potential applications in medical imaging and environmental monitoring [6].

Strengths: Extended signal duration, enhanced sensitivity, and potential for in vivo applications. Weaknesses: Complex synthesis process and potential regulatory hurdles for medical applications.

Innovative Approaches

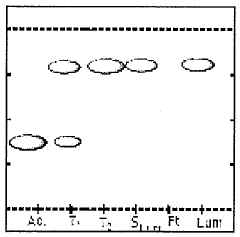

LUMINOL SYNTHESIS PROCESS, KIT FOR THE DETECTION OF OCCULT BLOOD RESIDUES AND ITS USES

PatentActiveBR102014014163A2

Innovation

- A single-step luminol synthesis process using low-cost reagents and mild conditions, packaged in separate solutions to maintain chemical integrity, allowing detection in visible light and extending shelf life to six months, and incorporating luminescence-enhancing additives for improved sensitivity and flexibility.

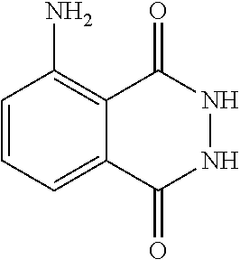

Method for solubilizing 5-amino-2,3-dihydro-1,4-phthalazinedione

PatentActiveUS12122753B2

Innovation

- A method involving the combination of phosphatidylcholine, medium-chained triglycerides, lysophosphatidylcholine, C2-C4 alcohols, and glyceryl stearate or fatty acids is used to solubilize 5-amino-2,3-dihydro-1,4-phthalazinedione, avoiding the need for polysorbate solubilizers and emulsifiers, and involves cautious heating to achieve a clear solution.

Safety Regulations

The synthesis and handling of luminol require adherence to strict safety regulations due to its potential hazards and environmental impact. Laboratories and manufacturing facilities must comply with local, national, and international safety standards to ensure the protection of workers, the public, and the environment.

Personal protective equipment (PPE) is mandatory when working with luminol and its precursors. This includes wearing appropriate gloves, safety goggles, and lab coats to prevent skin contact and eye exposure. Respiratory protection may be necessary when handling powdered forms of luminol or during processes that generate dust or vapors.

Proper ventilation systems are crucial in areas where luminol is synthesized or used. Fume hoods and local exhaust ventilation should be employed to minimize exposure to potentially harmful fumes or particulates. Regular maintenance and testing of these systems are essential to ensure their effectiveness.

Storage of luminol and its precursors must follow specific guidelines. Chemicals should be kept in cool, dry areas away from direct sunlight and heat sources. Incompatible materials must be stored separately to prevent accidental reactions. Proper labeling and inventory management are critical for safe storage and handling.

Waste disposal regulations for luminol and related compounds must be strictly followed. Hazardous waste should be collected, stored, and disposed of according to local environmental protection laws. This may include special procedures for chemical neutralization or incineration of waste materials.

Emergency response protocols must be in place for potential spills, fires, or exposures. This includes having readily available safety showers, eyewash stations, and appropriate fire suppression equipment. Staff should be trained in emergency procedures and the use of safety equipment.

Regular safety audits and inspections are necessary to ensure compliance with regulations and identify potential hazards. This includes periodic review of safety data sheets (SDS), updating standard operating procedures (SOPs), and conducting risk assessments for new synthesis techniques or equipment.

Training programs for personnel involved in luminol synthesis and handling are essential. These should cover proper handling techniques, understanding of hazards, emergency procedures, and the importance of following safety protocols. Refresher courses and updates on new regulations should be provided regularly.

Environmental monitoring may be required to assess the impact of luminol synthesis on air and water quality. This could involve periodic testing of emissions and effluents to ensure compliance with environmental standards and to minimize the ecological footprint of luminol production.

Personal protective equipment (PPE) is mandatory when working with luminol and its precursors. This includes wearing appropriate gloves, safety goggles, and lab coats to prevent skin contact and eye exposure. Respiratory protection may be necessary when handling powdered forms of luminol or during processes that generate dust or vapors.

Proper ventilation systems are crucial in areas where luminol is synthesized or used. Fume hoods and local exhaust ventilation should be employed to minimize exposure to potentially harmful fumes or particulates. Regular maintenance and testing of these systems are essential to ensure their effectiveness.

Storage of luminol and its precursors must follow specific guidelines. Chemicals should be kept in cool, dry areas away from direct sunlight and heat sources. Incompatible materials must be stored separately to prevent accidental reactions. Proper labeling and inventory management are critical for safe storage and handling.

Waste disposal regulations for luminol and related compounds must be strictly followed. Hazardous waste should be collected, stored, and disposed of according to local environmental protection laws. This may include special procedures for chemical neutralization or incineration of waste materials.

Emergency response protocols must be in place for potential spills, fires, or exposures. This includes having readily available safety showers, eyewash stations, and appropriate fire suppression equipment. Staff should be trained in emergency procedures and the use of safety equipment.

Regular safety audits and inspections are necessary to ensure compliance with regulations and identify potential hazards. This includes periodic review of safety data sheets (SDS), updating standard operating procedures (SOPs), and conducting risk assessments for new synthesis techniques or equipment.

Training programs for personnel involved in luminol synthesis and handling are essential. These should cover proper handling techniques, understanding of hazards, emergency procedures, and the importance of following safety protocols. Refresher courses and updates on new regulations should be provided regularly.

Environmental monitoring may be required to assess the impact of luminol synthesis on air and water quality. This could involve periodic testing of emissions and effluents to ensure compliance with environmental standards and to minimize the ecological footprint of luminol production.

Environmental Impact

The environmental impact of luminol synthesis techniques for enhanced sensitivity is a critical consideration in the development and application of this chemiluminescent compound. Traditional synthesis methods often involve the use of harsh chemicals and generate significant waste, raising concerns about their ecological footprint. However, recent advancements in green chemistry have led to more sustainable approaches to luminol production.

One of the primary environmental challenges associated with luminol synthesis is the use of toxic solvents and reagents. Conventional methods typically employ organic solvents like dimethyl sulfoxide (DMSO) or N,N-dimethylformamide (DMF), which can be harmful to aquatic ecosystems if released into the environment. Additionally, the use of strong oxidizing agents and reducing compounds in the synthesis process can contribute to air and water pollution if not properly managed.

To address these issues, researchers have developed alternative synthesis routes that prioritize environmental sustainability. For instance, the use of ionic liquids as reaction media has shown promise in reducing the reliance on volatile organic solvents. These ionic liquids can be recycled and reused, minimizing waste generation and decreasing the overall environmental impact of the synthesis process.

Another innovative approach involves the application of microwave-assisted synthesis techniques. This method not only reduces reaction times but also lowers energy consumption compared to conventional heating methods. By optimizing reaction conditions and utilizing more efficient energy sources, the carbon footprint associated with luminol production can be significantly reduced.

The implementation of flow chemistry systems for luminol synthesis has also demonstrated environmental benefits. These continuous-flow reactors allow for precise control over reaction parameters, leading to improved yields and reduced waste generation. Furthermore, the smaller reactor volumes and enhanced heat transfer capabilities of flow systems contribute to a more energy-efficient production process.

Biocatalytic methods have emerged as another eco-friendly alternative for luminol synthesis. Enzymes derived from microorganisms can catalyze specific reactions under mild conditions, eliminating the need for harsh chemicals and extreme temperatures. This approach not only reduces the environmental impact but also enhances the overall safety of the synthesis process.

As the demand for luminol in forensic and biomedical applications continues to grow, the importance of developing environmentally responsible synthesis techniques becomes increasingly apparent. By adopting green chemistry principles and leveraging innovative technologies, researchers and manufacturers can minimize the ecological footprint of luminol production while simultaneously improving its sensitivity and performance characteristics.

One of the primary environmental challenges associated with luminol synthesis is the use of toxic solvents and reagents. Conventional methods typically employ organic solvents like dimethyl sulfoxide (DMSO) or N,N-dimethylformamide (DMF), which can be harmful to aquatic ecosystems if released into the environment. Additionally, the use of strong oxidizing agents and reducing compounds in the synthesis process can contribute to air and water pollution if not properly managed.

To address these issues, researchers have developed alternative synthesis routes that prioritize environmental sustainability. For instance, the use of ionic liquids as reaction media has shown promise in reducing the reliance on volatile organic solvents. These ionic liquids can be recycled and reused, minimizing waste generation and decreasing the overall environmental impact of the synthesis process.

Another innovative approach involves the application of microwave-assisted synthesis techniques. This method not only reduces reaction times but also lowers energy consumption compared to conventional heating methods. By optimizing reaction conditions and utilizing more efficient energy sources, the carbon footprint associated with luminol production can be significantly reduced.

The implementation of flow chemistry systems for luminol synthesis has also demonstrated environmental benefits. These continuous-flow reactors allow for precise control over reaction parameters, leading to improved yields and reduced waste generation. Furthermore, the smaller reactor volumes and enhanced heat transfer capabilities of flow systems contribute to a more energy-efficient production process.

Biocatalytic methods have emerged as another eco-friendly alternative for luminol synthesis. Enzymes derived from microorganisms can catalyze specific reactions under mild conditions, eliminating the need for harsh chemicals and extreme temperatures. This approach not only reduces the environmental impact but also enhances the overall safety of the synthesis process.

As the demand for luminol in forensic and biomedical applications continues to grow, the importance of developing environmentally responsible synthesis techniques becomes increasingly apparent. By adopting green chemistry principles and leveraging innovative technologies, researchers and manufacturers can minimize the ecological footprint of luminol production while simultaneously improving its sensitivity and performance characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!