How Membrane Bioreactors Maintain Stable Effluent Under Variable Loads?

SEP 17, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MBR Technology Background and Objectives

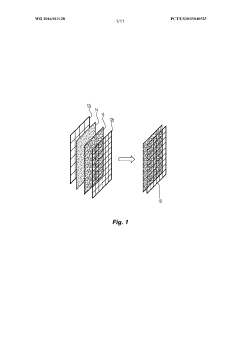

Membrane Bioreactor (MBR) technology represents a significant advancement in wastewater treatment, combining conventional activated sludge processes with membrane filtration. Since its inception in the late 1960s, MBR technology has evolved from experimental laboratory applications to full-scale municipal and industrial wastewater treatment systems. The fundamental innovation of MBRs lies in replacing traditional secondary clarifiers with membrane filtration units, enabling more efficient solid-liquid separation and higher quality effluent.

The evolution of MBR technology has been marked by several key developments, including the transition from external to submerged membrane configurations in the 1990s, which significantly reduced energy consumption and operational costs. Subsequent innovations have focused on membrane material improvements, module design optimization, and enhanced fouling control strategies, collectively contributing to the increased adoption of MBR systems worldwide.

Current technological trends in the MBR field include the development of novel membrane materials with superior anti-fouling properties, energy-efficient aeration systems, advanced process control algorithms, and hybrid configurations that combine MBRs with other treatment technologies. These innovations aim to address persistent challenges such as membrane fouling, energy consumption, and operational complexity.

The primary objective of modern MBR technology is to maintain stable effluent quality despite variable influent loads, which represents a critical challenge in wastewater treatment operations. Fluctuations in hydraulic loading, organic content, and nutrient concentrations can significantly impact treatment efficiency and membrane performance. Achieving consistent effluent quality under these dynamic conditions requires sophisticated control strategies, robust membrane designs, and optimized biological processes.

Research objectives in this field focus on enhancing system resilience to load variations through improved membrane materials, advanced fouling control mechanisms, and intelligent process control systems. Additionally, there is growing interest in developing MBR configurations that can efficiently handle peak flows while maintaining treatment performance and minimizing energy consumption.

The long-term technological goal for MBR systems is to achieve autonomous operation with self-adapting capabilities that can respond to influent variations without operator intervention. This vision encompasses predictive maintenance protocols, real-time performance optimization, and seamless integration with digital monitoring systems, ultimately leading to more reliable and cost-effective wastewater treatment solutions.

Understanding the historical context and evolutionary trajectory of MBR technology provides valuable insights for addressing current challenges and identifying promising research directions. By building upon decades of technological progress and operational experience, future MBR systems can be designed to better withstand variable loads while delivering consistently high-quality effluent.

The evolution of MBR technology has been marked by several key developments, including the transition from external to submerged membrane configurations in the 1990s, which significantly reduced energy consumption and operational costs. Subsequent innovations have focused on membrane material improvements, module design optimization, and enhanced fouling control strategies, collectively contributing to the increased adoption of MBR systems worldwide.

Current technological trends in the MBR field include the development of novel membrane materials with superior anti-fouling properties, energy-efficient aeration systems, advanced process control algorithms, and hybrid configurations that combine MBRs with other treatment technologies. These innovations aim to address persistent challenges such as membrane fouling, energy consumption, and operational complexity.

The primary objective of modern MBR technology is to maintain stable effluent quality despite variable influent loads, which represents a critical challenge in wastewater treatment operations. Fluctuations in hydraulic loading, organic content, and nutrient concentrations can significantly impact treatment efficiency and membrane performance. Achieving consistent effluent quality under these dynamic conditions requires sophisticated control strategies, robust membrane designs, and optimized biological processes.

Research objectives in this field focus on enhancing system resilience to load variations through improved membrane materials, advanced fouling control mechanisms, and intelligent process control systems. Additionally, there is growing interest in developing MBR configurations that can efficiently handle peak flows while maintaining treatment performance and minimizing energy consumption.

The long-term technological goal for MBR systems is to achieve autonomous operation with self-adapting capabilities that can respond to influent variations without operator intervention. This vision encompasses predictive maintenance protocols, real-time performance optimization, and seamless integration with digital monitoring systems, ultimately leading to more reliable and cost-effective wastewater treatment solutions.

Understanding the historical context and evolutionary trajectory of MBR technology provides valuable insights for addressing current challenges and identifying promising research directions. By building upon decades of technological progress and operational experience, future MBR systems can be designed to better withstand variable loads while delivering consistently high-quality effluent.

Market Demand Analysis for Stable Wastewater Treatment

The global wastewater treatment market is experiencing significant growth, driven by increasing water scarcity, stringent environmental regulations, and growing industrialization. The demand for stable and reliable wastewater treatment solutions, particularly those capable of handling variable loads, has become a critical market requirement across multiple sectors.

Municipal wastewater treatment represents the largest market segment, with urban populations expected to reach 6.7 billion by 2050. This demographic shift is creating unprecedented pressure on existing wastewater infrastructure, necessitating solutions that can maintain consistent effluent quality despite daily and seasonal flow variations. Membrane Bioreactor (MBR) technology has emerged as a preferred solution due to its ability to deliver high-quality effluent regardless of influent fluctuations.

Industrial applications present another substantial market opportunity. Manufacturing, food processing, pharmaceutical, and chemical industries face increasingly strict discharge regulations while dealing with highly variable wastewater compositions and volumes. The market value for industrial wastewater treatment using MBR technology is projected to grow at a CAGR of 7.2% through 2028, reflecting the urgent need for stable treatment solutions.

Developing economies represent the fastest-growing market segment, with rapid industrialization and urbanization creating severe water quality challenges. Countries across Asia-Pacific, particularly China and India, are implementing ambitious wastewater infrastructure programs, with MBR installations increasing by over 200% in the past five years.

Market research indicates that end-users are willing to pay premium prices for treatment systems that guarantee compliance with regulatory standards regardless of load variations. This price premium ranges from 15-30% compared to conventional activated sludge systems, justified by reduced compliance risks and operational flexibility.

The tourism and hospitality sector represents an emerging niche market with highly seasonal wastewater flows. Resorts, hotels, and recreational facilities in environmentally sensitive areas require treatment systems that can scale operations efficiently between peak and off-peak periods while maintaining environmental compliance.

Climate change is further amplifying market demand for resilient wastewater treatment. Increasing frequency of extreme weather events creates unprecedented flow variations in collection systems. Treatment facilities capable of maintaining stable operation during both drought conditions and intense rainfall events command significant market value.

Return on investment calculations show that despite higher initial capital costs, MBR systems that maintain stable effluent quality under variable loads typically achieve payback periods of 3-5 years through reduced operational interventions, compliance penalties, and expanded operational windows.

Municipal wastewater treatment represents the largest market segment, with urban populations expected to reach 6.7 billion by 2050. This demographic shift is creating unprecedented pressure on existing wastewater infrastructure, necessitating solutions that can maintain consistent effluent quality despite daily and seasonal flow variations. Membrane Bioreactor (MBR) technology has emerged as a preferred solution due to its ability to deliver high-quality effluent regardless of influent fluctuations.

Industrial applications present another substantial market opportunity. Manufacturing, food processing, pharmaceutical, and chemical industries face increasingly strict discharge regulations while dealing with highly variable wastewater compositions and volumes. The market value for industrial wastewater treatment using MBR technology is projected to grow at a CAGR of 7.2% through 2028, reflecting the urgent need for stable treatment solutions.

Developing economies represent the fastest-growing market segment, with rapid industrialization and urbanization creating severe water quality challenges. Countries across Asia-Pacific, particularly China and India, are implementing ambitious wastewater infrastructure programs, with MBR installations increasing by over 200% in the past five years.

Market research indicates that end-users are willing to pay premium prices for treatment systems that guarantee compliance with regulatory standards regardless of load variations. This price premium ranges from 15-30% compared to conventional activated sludge systems, justified by reduced compliance risks and operational flexibility.

The tourism and hospitality sector represents an emerging niche market with highly seasonal wastewater flows. Resorts, hotels, and recreational facilities in environmentally sensitive areas require treatment systems that can scale operations efficiently between peak and off-peak periods while maintaining environmental compliance.

Climate change is further amplifying market demand for resilient wastewater treatment. Increasing frequency of extreme weather events creates unprecedented flow variations in collection systems. Treatment facilities capable of maintaining stable operation during both drought conditions and intense rainfall events command significant market value.

Return on investment calculations show that despite higher initial capital costs, MBR systems that maintain stable effluent quality under variable loads typically achieve payback periods of 3-5 years through reduced operational interventions, compliance penalties, and expanded operational windows.

Current MBR Challenges Under Variable Load Conditions

Membrane Bioreactors (MBRs) face significant operational challenges when subjected to variable load conditions, which have become increasingly common in modern wastewater treatment facilities. Fluctuating influent characteristics, including variations in flow rate, organic loading, and nutrient concentrations, can severely disrupt the biological treatment processes and membrane filtration performance. These variations may occur due to seasonal changes, industrial discharge patterns, storm events, or diurnal fluctuations in municipal wastewater generation.

One of the primary challenges is biomass destabilization under shock loads. When organic loading suddenly increases, the microbial community may not adapt quickly enough, leading to incomplete degradation of pollutants. Conversely, during periods of low loading, microorganisms may enter endogenous respiration phases, affecting their viability and treatment efficiency when loads return to normal levels. This biological instability directly impacts effluent quality and system reliability.

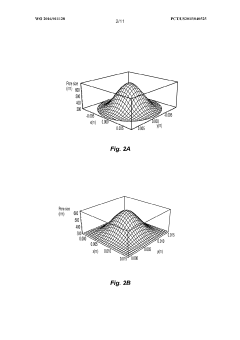

Membrane fouling acceleration represents another critical challenge during variable loading. Sudden increases in organic matter or suspended solids can rapidly accelerate membrane fouling rates, necessitating more frequent chemical cleaning or even premature membrane replacement. The fouling mechanisms become more complex under variable conditions, with combinations of organic, inorganic, and biological fouling occurring simultaneously and synergistically.

Oxygen transfer limitations also emerge during peak loading periods. The increased oxygen demand from higher organic loads may exceed the aeration system's capacity, leading to insufficient dissolved oxygen levels. This oxygen deficiency can trigger filamentous bacteria growth, sludge bulking issues, and deterioration of both biological treatment performance and membrane filterability.

Nutrient removal processes are particularly vulnerable to load variations. Nitrification and denitrification processes require stable conditions and sufficient retention times. Variable loading can disrupt the delicate balance of autotrophic and heterotrophic bacteria responsible for nitrogen removal, potentially leading to ammonia or nitrate breakthrough in the effluent.

Control system limitations further exacerbate these challenges. Many existing MBR control systems operate based on fixed parameters and struggle to respond effectively to rapid load changes. The lag between detecting changed conditions and implementing appropriate operational adjustments often results in suboptimal performance during transitional periods.

Energy consumption inefficiencies also become pronounced under variable loading. MBR systems typically operate with fixed aeration and pumping schedules that may be excessive during low-load periods and insufficient during peak loads, resulting in energy wastage or performance compromises. This challenge is particularly relevant given the increasing focus on energy efficiency and carbon footprint reduction in wastewater treatment operations.

One of the primary challenges is biomass destabilization under shock loads. When organic loading suddenly increases, the microbial community may not adapt quickly enough, leading to incomplete degradation of pollutants. Conversely, during periods of low loading, microorganisms may enter endogenous respiration phases, affecting their viability and treatment efficiency when loads return to normal levels. This biological instability directly impacts effluent quality and system reliability.

Membrane fouling acceleration represents another critical challenge during variable loading. Sudden increases in organic matter or suspended solids can rapidly accelerate membrane fouling rates, necessitating more frequent chemical cleaning or even premature membrane replacement. The fouling mechanisms become more complex under variable conditions, with combinations of organic, inorganic, and biological fouling occurring simultaneously and synergistically.

Oxygen transfer limitations also emerge during peak loading periods. The increased oxygen demand from higher organic loads may exceed the aeration system's capacity, leading to insufficient dissolved oxygen levels. This oxygen deficiency can trigger filamentous bacteria growth, sludge bulking issues, and deterioration of both biological treatment performance and membrane filterability.

Nutrient removal processes are particularly vulnerable to load variations. Nitrification and denitrification processes require stable conditions and sufficient retention times. Variable loading can disrupt the delicate balance of autotrophic and heterotrophic bacteria responsible for nitrogen removal, potentially leading to ammonia or nitrate breakthrough in the effluent.

Control system limitations further exacerbate these challenges. Many existing MBR control systems operate based on fixed parameters and struggle to respond effectively to rapid load changes. The lag between detecting changed conditions and implementing appropriate operational adjustments often results in suboptimal performance during transitional periods.

Energy consumption inefficiencies also become pronounced under variable loading. MBR systems typically operate with fixed aeration and pumping schedules that may be excessive during low-load periods and insufficient during peak loads, resulting in energy wastage or performance compromises. This challenge is particularly relevant given the increasing focus on energy efficiency and carbon footprint reduction in wastewater treatment operations.

Current Solutions for Load Fluctuation Management

01 Membrane configuration and design for stable effluent

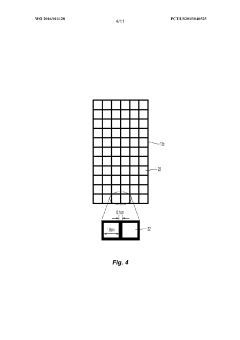

Specific membrane configurations and designs can significantly improve the stability of effluent in membrane bioreactors. These designs include submerged membrane modules, hollow fiber membranes, and flat sheet membranes arranged in optimal configurations to prevent fouling and maintain consistent filtration performance. Advanced module designs incorporate features that enhance fluid dynamics around the membrane surface, promoting better mixing and reducing the formation of cake layers that can destabilize effluent quality.- Membrane configuration and design for stable effluent: Specific membrane configurations and designs can significantly improve the stability of effluent in membrane bioreactors. These designs include submerged membrane modules, hollow fiber membranes, and flat sheet membranes arranged in optimal configurations to minimize fouling and maintain consistent filtration performance. Advanced module designs incorporate features that enhance fluid dynamics around the membrane surface, promoting better solids separation and more stable effluent quality over extended operational periods.

- Fouling control mechanisms for effluent stability: Various fouling control mechanisms are implemented in membrane bioreactors to maintain stable effluent quality. These include air scouring systems, backwashing protocols, and relaxation cycles that prevent membrane fouling and maintain consistent permeability. Some systems incorporate mechanical cleaning devices or pulsed aeration to remove accumulated solids from membrane surfaces. These mechanisms work together to ensure continuous and reliable operation, resulting in consistent effluent quality regardless of influent variations.

- Process control strategies for effluent stability: Advanced process control strategies are essential for maintaining stable effluent quality in membrane bioreactors. These include real-time monitoring of critical parameters such as transmembrane pressure, mixed liquor suspended solids concentration, and dissolved oxygen levels. Automated control systems adjust operational parameters based on these measurements to optimize biological treatment and membrane filtration processes. Implementing feed-forward control algorithms that anticipate influent variations helps maintain consistent effluent quality despite changing input conditions.

- Biological treatment optimization for stable effluent: Optimizing the biological treatment component of membrane bioreactors is crucial for producing stable effluent. This involves maintaining appropriate microbial communities through controlled sludge retention time, nutrient balancing, and optimal dissolved oxygen levels. Some systems incorporate specialized biomass carriers or granular sludge to enhance biological treatment efficiency and resilience. Advanced bioreactor configurations, such as multi-stage systems or those with anoxic and aerobic zones, provide more robust treatment capabilities that result in consistently high-quality effluent.

- Integrated system designs for effluent stability: Integrated system designs combine multiple treatment technologies with membrane bioreactors to achieve stable effluent quality. These systems may incorporate pre-treatment processes such as screening and grit removal, as well as post-treatment steps like disinfection or advanced oxidation. Some designs include buffer tanks or equalization basins to dampen influent variations. Hybrid systems that combine different membrane types or biological treatment processes provide redundancy and operational flexibility, ensuring consistent effluent quality even during maintenance activities or process upsets.

02 Fouling control mechanisms for effluent stability

Various fouling control mechanisms are employed in membrane bioreactors to maintain stable effluent quality over extended operation periods. These include air scouring systems, backwashing protocols, relaxation cycles, and chemical cleaning regimes. By preventing membrane fouling, these mechanisms ensure consistent permeate flux and maintain the rejection capabilities of the membrane, resulting in stable effluent characteristics regardless of influent variations or operational conditions.Expand Specific Solutions03 Biological process optimization for effluent stability

Optimizing the biological processes within membrane bioreactors is crucial for achieving stable effluent quality. This includes maintaining appropriate mixed liquor suspended solids (MLSS) concentrations, controlling sludge retention time (SRT), optimizing dissolved oxygen levels, and managing nutrient ratios. Advanced biological process control strategies help develop robust microbial communities that can effectively handle variations in influent characteristics while consistently producing high-quality effluent with stable parameters.Expand Specific Solutions04 Integrated treatment systems for enhanced effluent stability

Integrating membrane bioreactors with complementary treatment processes creates synergistic systems that produce exceptionally stable effluent. These integrated approaches may combine MBRs with processes such as advanced oxidation, ion exchange, activated carbon adsorption, or nutrient removal technologies. The multi-barrier approach ensures that fluctuations in any single treatment step are compensated for by subsequent processes, resulting in consistently high-quality effluent regardless of influent variability or operational disturbances.Expand Specific Solutions05 Advanced monitoring and control systems for effluent stability

Advanced monitoring and control systems play a critical role in maintaining stable effluent quality in membrane bioreactors. These systems utilize real-time sensors, predictive algorithms, and automated response mechanisms to detect and address potential issues before they affect effluent quality. Parameters such as transmembrane pressure, permeate turbidity, conductivity, and organic content are continuously monitored, allowing for immediate adjustments to operational parameters that maintain stable effluent characteristics even under changing conditions.Expand Specific Solutions

Leading MBR Technology Providers and Competitors

Membrane Bioreactor (MBR) technology is currently in a growth phase, with the global market expected to reach $8.27 billion by 2025, expanding at a CAGR of 7.2%. The technology has reached moderate maturity, with key players demonstrating varying levels of innovation. Companies like Evoqua Water Technologies and Aquatech International lead with commercial-scale implementations of advanced MBR systems capable of handling variable loads through adaptive control systems. Academic institutions such as Harbin Institute of Technology and Zhejiang University are driving fundamental research in membrane fouling prevention. Research organizations like CNRS and Industrial Technology Research Institute are bridging the gap between laboratory findings and industrial applications, while companies like Grundfos and Siemens Water Technologies focus on optimizing energy efficiency and operational stability under fluctuating conditions.

Evoqua Water Technologies LLC

Technical Solution: Evoqua's membrane bioreactor (MBR) technology employs advanced flat-sheet and hollow-fiber membrane configurations with optimized pore sizes (0.03-0.1 μm) to maintain stable effluent quality under variable loads. Their systems incorporate real-time monitoring with proprietary MemPulse™ aeration technology that automatically adjusts air scouring intensity based on transmembrane pressure (TMP) fluctuations. This adaptive aeration system reduces energy consumption by up to 30% while effectively controlling membrane fouling during peak load events. Evoqua's MBRs feature integrated equalization tanks and flow balancing mechanisms that can accommodate flow variations of 2-3 times average daily flow without compromising treatment efficiency. Their OSCAR™ process control system continuously optimizes mixed liquor suspended solids (MLSS) concentration (typically maintained between 8,000-12,000 mg/L) and adjusts hydraulic retention time to maintain consistent nutrient removal even during significant load variations.

Strengths: Superior adaptability to variable influent conditions through automated process controls; energy-efficient membrane cleaning mechanisms; comprehensive data analytics for performance optimization. Weaknesses: Higher initial capital investment compared to conventional treatment systems; requires skilled operators for complex control systems; membrane replacement costs can be significant over system lifetime.

Aquatech International LLC

Technical Solution: Aquatech International's MBR solution employs a hybrid membrane configuration combining both ultrafiltration and microfiltration technologies to maintain stable effluent quality under variable loads. Their system features a proprietary BioMod™ process that incorporates a pre-denitrification selector zone to buffer incoming organic load variations. This selector zone acclimates microorganisms to changing substrate concentrations, enhancing the system's resilience to shock loads. Aquatech's MBRs utilize dynamic flux control algorithms that continuously adjust membrane filtration rates based on real-time monitoring of sludge filterability indices and transmembrane pressure trends. The system incorporates a multi-stage biological treatment process with cascading reactors that distribute organic loading, preventing inhibition of sensitive nitrifying bacteria during peak load events. Their membrane modules feature an innovative backpulse cleaning mechanism that uses treated effluent for periodic reverse flow cleaning, maintaining consistent permeability without chemical cleaning for extended periods (typically 3-6 months) even under variable influent conditions.

Strengths: Exceptional nutrient removal performance (>95% nitrogen removal) even during load variations; lower chemical consumption for membrane maintenance; robust operation in high-salinity applications. Weaknesses: Higher energy requirements compared to conventional systems; more complex control systems requiring specialized technical support; larger physical footprint compared to some competing MBR technologies.

Key Innovations in Membrane Fouling Control

Elastic membrane-based membrane bioreactor with high-efficiency for fouling control

PatentWO2016011128A1

Innovation

- The development of elastic microfiltration membranes with polyether-based thermoplastic polymers and electrospinning technology, which includes a non-woven substrate and perforated support members, allows for improved fouling removal through reversible deformation during backwashing, increasing membrane efficiency and longevity.

Regulatory Framework for Wastewater Treatment Effluent

The regulatory landscape governing wastewater treatment effluent has become increasingly stringent worldwide, directly impacting the design and operation of Membrane Bioreactor (MBR) systems. These regulations establish specific parameters for effluent quality that MBR facilities must consistently meet, regardless of influent load variations. Understanding this framework is essential for implementing effective MBR solutions that maintain stable effluent quality.

At the international level, organizations such as the World Health Organization (WHO) and the United Nations Environment Programme (UNEP) have established guidelines that influence national regulatory standards. These guidelines typically address key parameters including Biochemical Oxygen Demand (BOD), Chemical Oxygen Demand (COD), Total Suspended Solids (TSS), nitrogen compounds, phosphorus, and pathogen levels.

In the United States, the Clean Water Act (CWA) administered by the Environmental Protection Agency (EPA) establishes the National Pollutant Discharge Elimination System (NPDES) permit program, which regulates point source discharges. MBR facilities must obtain these permits and comply with their specific effluent limitations. The EPA has also developed the Effluent Guidelines, which are technology-based regulations for different industrial categories.

The European Union implements the Water Framework Directive (WFD) and the Urban Waste Water Treatment Directive, which set comprehensive standards for water quality and treatment requirements. These directives mandate secondary treatment for all wastewater from agglomerations and more stringent treatment for discharges into sensitive areas, creating a driving force for MBR adoption.

Asian countries, particularly China and Japan, have implemented progressively stricter discharge standards in recent years. China's Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant (GB 18918-2002) categorizes effluent quality into four classes with increasingly stringent requirements. Japan's regulatory framework emphasizes advanced treatment technologies like MBRs for water reuse applications.

Emerging regulatory trends include increased focus on micropollutants, pharmaceutical residues, and microplastics removal. Several jurisdictions are beginning to incorporate these parameters into their regulatory frameworks, potentially driving further technological advancements in MBR design and operation.

Compliance with these regulations under variable load conditions presents significant challenges for treatment facilities. MBR systems must be designed with sufficient operational flexibility and robust control strategies to accommodate fluctuations while consistently meeting regulatory requirements. This has led to innovations in process control, membrane design, and operational strategies specifically aimed at maintaining stable effluent quality regardless of influent variability.

At the international level, organizations such as the World Health Organization (WHO) and the United Nations Environment Programme (UNEP) have established guidelines that influence national regulatory standards. These guidelines typically address key parameters including Biochemical Oxygen Demand (BOD), Chemical Oxygen Demand (COD), Total Suspended Solids (TSS), nitrogen compounds, phosphorus, and pathogen levels.

In the United States, the Clean Water Act (CWA) administered by the Environmental Protection Agency (EPA) establishes the National Pollutant Discharge Elimination System (NPDES) permit program, which regulates point source discharges. MBR facilities must obtain these permits and comply with their specific effluent limitations. The EPA has also developed the Effluent Guidelines, which are technology-based regulations for different industrial categories.

The European Union implements the Water Framework Directive (WFD) and the Urban Waste Water Treatment Directive, which set comprehensive standards for water quality and treatment requirements. These directives mandate secondary treatment for all wastewater from agglomerations and more stringent treatment for discharges into sensitive areas, creating a driving force for MBR adoption.

Asian countries, particularly China and Japan, have implemented progressively stricter discharge standards in recent years. China's Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant (GB 18918-2002) categorizes effluent quality into four classes with increasingly stringent requirements. Japan's regulatory framework emphasizes advanced treatment technologies like MBRs for water reuse applications.

Emerging regulatory trends include increased focus on micropollutants, pharmaceutical residues, and microplastics removal. Several jurisdictions are beginning to incorporate these parameters into their regulatory frameworks, potentially driving further technological advancements in MBR design and operation.

Compliance with these regulations under variable load conditions presents significant challenges for treatment facilities. MBR systems must be designed with sufficient operational flexibility and robust control strategies to accommodate fluctuations while consistently meeting regulatory requirements. This has led to innovations in process control, membrane design, and operational strategies specifically aimed at maintaining stable effluent quality regardless of influent variability.

Energy Efficiency Optimization in MBR Operations

Energy efficiency represents a critical factor in the operational sustainability of Membrane Bioreactor (MBR) systems, particularly when managing variable load conditions. MBR systems typically consume 0.4-1.6 kWh/m³ of treated wastewater, with aeration accounting for 60-80% of this energy consumption. This significant energy requirement necessitates optimization strategies to maintain economic viability while ensuring stable effluent quality.

The energy consumption profile of MBRs varies considerably under fluctuating load conditions. During peak loading periods, conventional control systems often respond with increased aeration and pumping rates, leading to disproportionate energy consumption without necessarily improving treatment efficiency. Research indicates that implementing dynamic control algorithms can reduce energy consumption by 15-25% while maintaining effluent quality standards.

Advanced aeration control strategies represent a primary avenue for energy optimization. Intermittent aeration protocols, which alternate between aerobic and anoxic conditions based on real-time monitoring of dissolved oxygen levels and ammonium concentrations, have demonstrated energy savings of up to 30% compared to continuous aeration systems. These protocols are particularly effective during low-load periods when full aeration capacity is unnecessary.

Membrane fouling control constitutes another significant energy demand in MBR operations. Traditional time-based backwashing and air scouring regimes often operate regardless of actual fouling conditions, consuming excess energy. Implementing transmembrane pressure (TMP)-based cleaning protocols that trigger only when necessary can reduce air scouring energy requirements by 20-40%, with minimal impact on permeate quality.

Energy recovery systems present emerging opportunities for MBR efficiency enhancement. Biogas production from anaerobic digestion of waste activated sludge can offset 30-50% of the energy requirements in larger installations. Additionally, heat recovery systems can capture thermal energy from effluent streams, further improving the overall energy balance of MBR facilities.

Digital twin technology and machine learning algorithms are revolutionizing energy management in MBR systems. These advanced modeling approaches enable predictive control strategies that anticipate load variations and optimize operational parameters in real-time. Studies demonstrate that AI-driven control systems can achieve energy reductions of 15-30% compared to conventional control strategies while maintaining consistent effluent quality under variable influent conditions.

The economic implications of energy optimization are substantial. Life-cycle cost analyses indicate that energy-efficient MBR designs can reduce operational costs by 20-40% over a 20-year period, despite potentially higher initial capital investments. This economic advantage becomes increasingly significant as energy prices rise and regulatory requirements for treatment quality become more stringent.

The energy consumption profile of MBRs varies considerably under fluctuating load conditions. During peak loading periods, conventional control systems often respond with increased aeration and pumping rates, leading to disproportionate energy consumption without necessarily improving treatment efficiency. Research indicates that implementing dynamic control algorithms can reduce energy consumption by 15-25% while maintaining effluent quality standards.

Advanced aeration control strategies represent a primary avenue for energy optimization. Intermittent aeration protocols, which alternate between aerobic and anoxic conditions based on real-time monitoring of dissolved oxygen levels and ammonium concentrations, have demonstrated energy savings of up to 30% compared to continuous aeration systems. These protocols are particularly effective during low-load periods when full aeration capacity is unnecessary.

Membrane fouling control constitutes another significant energy demand in MBR operations. Traditional time-based backwashing and air scouring regimes often operate regardless of actual fouling conditions, consuming excess energy. Implementing transmembrane pressure (TMP)-based cleaning protocols that trigger only when necessary can reduce air scouring energy requirements by 20-40%, with minimal impact on permeate quality.

Energy recovery systems present emerging opportunities for MBR efficiency enhancement. Biogas production from anaerobic digestion of waste activated sludge can offset 30-50% of the energy requirements in larger installations. Additionally, heat recovery systems can capture thermal energy from effluent streams, further improving the overall energy balance of MBR facilities.

Digital twin technology and machine learning algorithms are revolutionizing energy management in MBR systems. These advanced modeling approaches enable predictive control strategies that anticipate load variations and optimize operational parameters in real-time. Studies demonstrate that AI-driven control systems can achieve energy reductions of 15-30% compared to conventional control strategies while maintaining consistent effluent quality under variable influent conditions.

The economic implications of energy optimization are substantial. Life-cycle cost analyses indicate that energy-efficient MBR designs can reduce operational costs by 20-40% over a 20-year period, despite potentially higher initial capital investments. This economic advantage becomes increasingly significant as energy prices rise and regulatory requirements for treatment quality become more stringent.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!