How Membrane Bioreactors Minimize Irreversible Fouling While Maintaining Flux?

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MBR Fouling Mechanisms and Research Objectives

Membrane bioreactors (MBRs) have revolutionized wastewater treatment by combining conventional activated sludge processes with membrane filtration. However, membrane fouling remains the primary operational challenge, particularly irreversible fouling which significantly impacts system performance and operational costs. The fouling mechanisms in MBRs are complex and multifaceted, involving interactions between biological components, operational parameters, and membrane characteristics.

Fouling in MBRs can be categorized into reversible fouling, which can be removed by physical cleaning, and irreversible fouling, which requires chemical cleaning or may permanently damage membranes. The primary fouling mechanisms include pore blocking, cake layer formation, and adsorption of soluble microbial products (SMPs) and extracellular polymeric substances (EPS). These mechanisms are influenced by biomass characteristics, membrane properties, and operational conditions.

The biological components in MBRs, particularly mixed liquor suspended solids (MLSS), contribute significantly to fouling. High MLSS concentrations, while beneficial for treatment efficiency, accelerate membrane fouling through increased deposition of particulate matter and enhanced production of foulants. Additionally, EPS and SMPs, produced during microbial metabolism, form a gel layer on membrane surfaces, leading to severe irreversible fouling.

Operational parameters such as hydraulic retention time (HRT), solids retention time (SRT), and flux rate directly impact fouling propensity. Higher flux rates increase the transport of foulants to the membrane surface, while inappropriate HRT and SRT settings can lead to excessive EPS production and poor floc formation, exacerbating fouling issues.

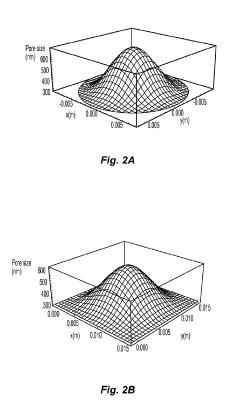

Membrane characteristics, including material composition, pore size, hydrophobicity, and surface roughness, also play crucial roles in fouling development. Hydrophobic membranes are more susceptible to organic fouling, while membranes with larger pores may experience more severe internal fouling.

The research objectives in this field focus on developing comprehensive understanding of fouling mechanisms to design effective anti-fouling strategies. This includes investigating the relationship between biological processes and fouling development, optimizing operational parameters to minimize foulant production, and developing novel membrane materials with enhanced anti-fouling properties.

Advanced monitoring techniques are being explored to detect early signs of fouling, allowing for timely intervention. Additionally, research aims to develop sustainable cleaning protocols that effectively remove foulants without compromising membrane integrity or generating harmful by-products.

The ultimate goal is to establish a balance between maintaining high flux rates and minimizing irreversible fouling, thereby enhancing the economic viability and environmental sustainability of MBR systems in wastewater treatment applications.

Fouling in MBRs can be categorized into reversible fouling, which can be removed by physical cleaning, and irreversible fouling, which requires chemical cleaning or may permanently damage membranes. The primary fouling mechanisms include pore blocking, cake layer formation, and adsorption of soluble microbial products (SMPs) and extracellular polymeric substances (EPS). These mechanisms are influenced by biomass characteristics, membrane properties, and operational conditions.

The biological components in MBRs, particularly mixed liquor suspended solids (MLSS), contribute significantly to fouling. High MLSS concentrations, while beneficial for treatment efficiency, accelerate membrane fouling through increased deposition of particulate matter and enhanced production of foulants. Additionally, EPS and SMPs, produced during microbial metabolism, form a gel layer on membrane surfaces, leading to severe irreversible fouling.

Operational parameters such as hydraulic retention time (HRT), solids retention time (SRT), and flux rate directly impact fouling propensity. Higher flux rates increase the transport of foulants to the membrane surface, while inappropriate HRT and SRT settings can lead to excessive EPS production and poor floc formation, exacerbating fouling issues.

Membrane characteristics, including material composition, pore size, hydrophobicity, and surface roughness, also play crucial roles in fouling development. Hydrophobic membranes are more susceptible to organic fouling, while membranes with larger pores may experience more severe internal fouling.

The research objectives in this field focus on developing comprehensive understanding of fouling mechanisms to design effective anti-fouling strategies. This includes investigating the relationship between biological processes and fouling development, optimizing operational parameters to minimize foulant production, and developing novel membrane materials with enhanced anti-fouling properties.

Advanced monitoring techniques are being explored to detect early signs of fouling, allowing for timely intervention. Additionally, research aims to develop sustainable cleaning protocols that effectively remove foulants without compromising membrane integrity or generating harmful by-products.

The ultimate goal is to establish a balance between maintaining high flux rates and minimizing irreversible fouling, thereby enhancing the economic viability and environmental sustainability of MBR systems in wastewater treatment applications.

Market Demand Analysis for High-Efficiency MBR Systems

The global market for Membrane Bioreactor (MBR) systems has experienced significant growth in recent years, driven by increasing water scarcity concerns and stringent environmental regulations. The demand for high-efficiency MBR systems that can minimize irreversible fouling while maintaining optimal flux is particularly strong, as these systems directly address the primary operational challenge in wastewater treatment facilities.

Water treatment industry analysts project the global MBR market to reach approximately $8.2 billion by 2026, with a compound annual growth rate of 7.4% from 2021. This growth is primarily fueled by the industrial and municipal sectors seeking more efficient and sustainable wastewater treatment solutions. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment due to rapid industrialization and urbanization coupled with increasing regulatory pressure on water quality standards.

Municipal wastewater treatment facilities constitute the largest end-user segment, accounting for nearly 65% of the total MBR market. These facilities are increasingly adopting advanced MBR systems to meet more stringent effluent quality requirements while optimizing operational costs. The industrial sector, particularly food and beverage, pharmaceuticals, and chemical processing, represents the second-largest market segment with growing demand for on-site water recycling solutions.

Market research indicates that end-users are willing to pay premium prices for MBR systems that demonstrate superior anti-fouling capabilities and extended membrane life. A survey of wastewater treatment plant operators revealed that 78% consider membrane fouling as the most significant operational challenge, directly impacting maintenance costs and system downtime. Consequently, technologies that effectively address irreversible fouling while maintaining consistent flux rates command significant market interest.

The demand for retrofit solutions is also expanding rapidly, with existing conventional activated sludge treatment plants upgrading to MBR systems to increase treatment capacity without expanding physical footprint. This trend is particularly evident in densely populated urban areas where space constraints limit facility expansion options.

Energy efficiency has emerged as a critical market driver, with end-users increasingly focused on the total cost of ownership rather than initial capital expenditure. MBR systems that can minimize fouling without increasing energy consumption for aeration or chemical cleaning processes are experiencing the highest demand growth. Market data suggests that a 15% reduction in energy consumption can translate to approximately 20% higher market adoption rates for new MBR technologies.

The service and maintenance segment of the MBR market is also expanding, with a projected value of $1.9 billion by 2025. This growth reflects the increasing recognition of proper maintenance protocols in extending membrane life and preventing irreversible fouling, creating opportunities for comprehensive service packages and performance-based contracting models.

Water treatment industry analysts project the global MBR market to reach approximately $8.2 billion by 2026, with a compound annual growth rate of 7.4% from 2021. This growth is primarily fueled by the industrial and municipal sectors seeking more efficient and sustainable wastewater treatment solutions. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment due to rapid industrialization and urbanization coupled with increasing regulatory pressure on water quality standards.

Municipal wastewater treatment facilities constitute the largest end-user segment, accounting for nearly 65% of the total MBR market. These facilities are increasingly adopting advanced MBR systems to meet more stringent effluent quality requirements while optimizing operational costs. The industrial sector, particularly food and beverage, pharmaceuticals, and chemical processing, represents the second-largest market segment with growing demand for on-site water recycling solutions.

Market research indicates that end-users are willing to pay premium prices for MBR systems that demonstrate superior anti-fouling capabilities and extended membrane life. A survey of wastewater treatment plant operators revealed that 78% consider membrane fouling as the most significant operational challenge, directly impacting maintenance costs and system downtime. Consequently, technologies that effectively address irreversible fouling while maintaining consistent flux rates command significant market interest.

The demand for retrofit solutions is also expanding rapidly, with existing conventional activated sludge treatment plants upgrading to MBR systems to increase treatment capacity without expanding physical footprint. This trend is particularly evident in densely populated urban areas where space constraints limit facility expansion options.

Energy efficiency has emerged as a critical market driver, with end-users increasingly focused on the total cost of ownership rather than initial capital expenditure. MBR systems that can minimize fouling without increasing energy consumption for aeration or chemical cleaning processes are experiencing the highest demand growth. Market data suggests that a 15% reduction in energy consumption can translate to approximately 20% higher market adoption rates for new MBR technologies.

The service and maintenance segment of the MBR market is also expanding, with a projected value of $1.9 billion by 2025. This growth reflects the increasing recognition of proper maintenance protocols in extending membrane life and preventing irreversible fouling, creating opportunities for comprehensive service packages and performance-based contracting models.

Current Challenges in Membrane Fouling Mitigation

Membrane bioreactors (MBRs) face significant challenges in maintaining operational efficiency due to membrane fouling, particularly irreversible fouling that cannot be removed by conventional cleaning methods. This persistent issue substantially reduces membrane lifespan and increases operational costs. The primary challenge lies in the complex interaction between biomass characteristics and membrane properties, creating a multifaceted fouling mechanism that is difficult to predict and control.

One major challenge is the formation of extracellular polymeric substances (EPS) and soluble microbial products (SMP), which are recognized as principal foulants in MBR systems. These biological compounds adhere to membrane surfaces, creating a gel-like layer that becomes increasingly resistant to removal over time. Current mitigation strategies often fail to address the root causes of EPS and SMP production, focusing instead on symptomatic treatment through chemical cleaning.

The trade-off between fouling control and biological treatment efficiency presents another significant challenge. Aggressive anti-fouling measures, such as high shear forces or chemical cleaning, can disrupt microbial communities essential for wastewater treatment. This disruption potentially compromises the core function of the bioreactor while attempting to maintain membrane flux, creating a delicate balancing act for operators.

Scaling up laboratory findings to full-scale applications remains problematic. Many promising fouling mitigation techniques demonstrate effectiveness in controlled environments but fail to deliver similar results in industrial settings due to the heterogeneity of real wastewater compositions and operational variabilities. This gap between research and application significantly hinders the implementation of innovative solutions.

Energy consumption associated with fouling mitigation represents a substantial operational challenge. Traditional approaches like air scouring and frequent backwashing require considerable energy input, contradicting the sustainability goals often associated with MBR technology. The industry struggles to develop energy-efficient fouling control methods that do not compromise treatment performance.

The lack of standardized fouling assessment protocols further complicates mitigation efforts. Different measurement methods and parameters across studies make it difficult to compare results and establish universal best practices. This inconsistency impedes the development of reliable predictive models for fouling behavior and effective prevention strategies.

Emerging contaminants, including microplastics and pharmaceutical residues, introduce new fouling mechanisms that existing mitigation strategies were not designed to address. These contaminants interact with membrane surfaces and biological components in ways that are not fully understood, creating novel fouling patterns that resist conventional treatment approaches.

One major challenge is the formation of extracellular polymeric substances (EPS) and soluble microbial products (SMP), which are recognized as principal foulants in MBR systems. These biological compounds adhere to membrane surfaces, creating a gel-like layer that becomes increasingly resistant to removal over time. Current mitigation strategies often fail to address the root causes of EPS and SMP production, focusing instead on symptomatic treatment through chemical cleaning.

The trade-off between fouling control and biological treatment efficiency presents another significant challenge. Aggressive anti-fouling measures, such as high shear forces or chemical cleaning, can disrupt microbial communities essential for wastewater treatment. This disruption potentially compromises the core function of the bioreactor while attempting to maintain membrane flux, creating a delicate balancing act for operators.

Scaling up laboratory findings to full-scale applications remains problematic. Many promising fouling mitigation techniques demonstrate effectiveness in controlled environments but fail to deliver similar results in industrial settings due to the heterogeneity of real wastewater compositions and operational variabilities. This gap between research and application significantly hinders the implementation of innovative solutions.

Energy consumption associated with fouling mitigation represents a substantial operational challenge. Traditional approaches like air scouring and frequent backwashing require considerable energy input, contradicting the sustainability goals often associated with MBR technology. The industry struggles to develop energy-efficient fouling control methods that do not compromise treatment performance.

The lack of standardized fouling assessment protocols further complicates mitigation efforts. Different measurement methods and parameters across studies make it difficult to compare results and establish universal best practices. This inconsistency impedes the development of reliable predictive models for fouling behavior and effective prevention strategies.

Emerging contaminants, including microplastics and pharmaceutical residues, introduce new fouling mechanisms that existing mitigation strategies were not designed to address. These contaminants interact with membrane surfaces and biological components in ways that are not fully understood, creating novel fouling patterns that resist conventional treatment approaches.

State-of-the-Art Fouling Control Strategies

01 Fouling prevention and control strategies in MBRs

Various strategies can be implemented to prevent and control fouling in membrane bioreactors, which helps maintain optimal flux rates. These include physical cleaning methods, chemical cleaning protocols, and operational adjustments such as intermittent aeration or relaxation periods. Implementing these strategies can significantly reduce irreversible fouling and extend membrane life while maintaining desired flux rates.- Fouling prevention and control strategies in MBRs: Various strategies can be implemented to prevent and control fouling in membrane bioreactors, which helps maintain optimal flux rates. These include physical cleaning methods, chemical cleaning protocols, and operational adjustments such as intermittent aeration or relaxation periods. By implementing these strategies, the formation of irreversible fouling can be significantly reduced, extending membrane life and maintaining higher flux rates over longer operational periods.

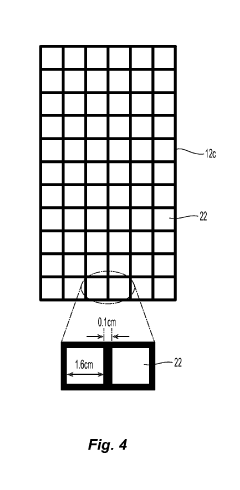

- Membrane modification techniques to reduce irreversible fouling: Surface modification of membranes can significantly reduce irreversible fouling in MBRs. Techniques include hydrophilic coating applications, incorporation of nanoparticles, and grafting of anti-fouling polymers onto membrane surfaces. These modifications alter the membrane surface properties to reduce foulant adhesion and improve flux recovery after cleaning cycles, thereby maintaining higher sustainable flux rates during long-term operation.

- Advanced monitoring and flux prediction systems: Real-time monitoring systems and predictive models can be employed to detect early signs of irreversible fouling and optimize flux rates in membrane bioreactors. These systems utilize sensors, machine learning algorithms, and mathematical models to analyze operational parameters and predict fouling behavior. By implementing these advanced monitoring techniques, operators can make proactive adjustments to prevent severe fouling events and maintain optimal flux conditions.

- Novel membrane materials for enhanced fouling resistance: Development of novel membrane materials with inherent fouling resistance properties can significantly reduce irreversible fouling in MBRs. These materials include composite membranes, ceramic membranes, and membranes with specialized pore structures. The advanced materials demonstrate superior resistance to organic and inorganic fouling, allowing for higher sustainable flux rates and reduced cleaning frequency compared to conventional membrane materials.

- Biological and feed pretreatment approaches: Pretreatment of feed water and optimization of biological processes can significantly reduce irreversible fouling in membrane bioreactors. Techniques include coagulation/flocculation, addition of adsorbents, optimization of sludge characteristics, and control of extracellular polymeric substances (EPS). These approaches modify the characteristics of the mixed liquor to reduce its fouling potential, thereby maintaining higher sustainable flux rates and extending intervals between intensive cleaning procedures.

02 Membrane modification techniques to reduce fouling

Surface modification of membranes can significantly reduce irreversible fouling in MBRs. Techniques include incorporating hydrophilic materials, antimicrobial agents, or nanoparticles into membrane structures. These modifications create surfaces that resist foulant adhesion, thereby maintaining higher flux rates over extended operational periods and reducing the frequency of intensive cleaning procedures.Expand Specific Solutions03 Advanced monitoring and detection systems for fouling

Implementing advanced monitoring systems allows for real-time detection of fouling development in membrane bioreactors. These systems utilize sensors, pressure differential measurements, and flux decline analysis to identify the onset of irreversible fouling before it significantly impacts performance. Early detection enables timely intervention, optimizing cleaning schedules and maintaining stable flux rates throughout operation.Expand Specific Solutions04 Biological and enzymatic approaches to fouling control

Biological and enzymatic treatments offer innovative approaches to controlling irreversible fouling in MBRs. These methods involve introducing specific microorganisms or enzymes that can degrade foulants on membrane surfaces. By targeting the biological components of fouling layers, these approaches can restore flux rates without harsh chemical cleaning, potentially extending membrane lifespan and reducing operational downtime.Expand Specific Solutions05 Hydrodynamic optimization for flux enhancement

Optimizing hydrodynamic conditions in membrane bioreactors can significantly improve flux performance and reduce irreversible fouling. Techniques include strategic bubble diffuser placement, membrane module configuration adjustments, and flow pattern optimization. These approaches create shear forces that continuously scour membrane surfaces, preventing foulant accumulation and maintaining higher sustainable flux rates during long-term operation.Expand Specific Solutions

Leading Manufacturers and Research Institutions in MBR Technology

Membrane Bioreactor (MBR) technology for minimizing irreversible fouling while maintaining flux is currently in a growth phase, with the global market expected to reach $8.2 billion by 2025. The technology has reached moderate maturity but continues to evolve with innovations in anti-fouling strategies. Academic institutions like Tianjin University, Harbin Institute of Technology, and Zhejiang University are leading fundamental research, while companies such as Sartorius Stedim Biotech, Aquatech International, and Doosan Enerbility are commercializing advanced MBR solutions. Chinese universities and companies are particularly active in this field, with significant contributions from Guangzhou Xinhuan Technology and Chongqing Yuanxian Environmental Technology in developing practical applications for industrial wastewater treatment that balance fouling control with operational efficiency.

Sartorius Stedim Biotech GmbH

Technical Solution: Sartorius has developed advanced Membrane Bioreactor (MBR) systems featuring their patented Crossflow Filtration Technology that significantly reduces irreversible fouling. Their approach combines optimized membrane materials with controlled hydrodynamic conditions to minimize fouling mechanisms. The company's Biostat MBR systems incorporate specially designed flat-sheet membranes with modified hydrophilic surfaces that resist protein adhesion and biofilm formation. These systems employ precise air scouring mechanisms that create turbulent flow patterns across membrane surfaces, effectively removing deposited foulants while maintaining optimal flux rates. Sartorius has also implemented intelligent process control algorithms that automatically adjust operational parameters based on transmembrane pressure (TMP) trends, preventing the transition from reversible to irreversible fouling states. Their systems typically maintain stable flux rates of 15-25 LMH while extending cleaning intervals by up to 40% compared to conventional MBR designs.

Strengths: Industry-leading membrane materials with specialized surface modifications that inherently resist fouling; sophisticated process control systems that proactively prevent fouling conditions before they become irreversible. Weaknesses: Higher initial capital investment compared to conventional systems; requires more complex maintenance protocols and operator training for optimal performance.

Aquatech International LLC

Technical Solution: Aquatech International has pioneered an integrated MBR solution called BioMod that specifically addresses irreversible fouling challenges. Their technology employs a multi-barrier approach combining specialized pre-treatment, optimized membrane configuration, and advanced fouling control strategies. The BioMod system features proprietary hollow-fiber membranes with nano-structured surfaces that minimize protein and polysaccharide adhesion, key contributors to irreversible fouling. Aquatech's solution incorporates a two-stage biological process that reduces extracellular polymeric substances (EPS) production, which are primary foulants in MBR systems. Their patented Cyclic Aeration System creates precisely timed high-shear conditions at the membrane surface, effectively removing deposited materials before they can form persistent fouling layers. The system maintains consistent flux rates between 18-22 LMH even during high-load conditions, with recovery rates exceeding 95% after standard cleaning procedures. Aquatech has implemented this technology in over 200 installations worldwide, demonstrating consistent performance in maintaining membrane permeability over extended operational periods.

Strengths: Comprehensive approach addressing biological, chemical and physical aspects of fouling; proven track record in maintaining stable flux in challenging wastewater applications with high organic loading. Weaknesses: System complexity requires specialized technical support; higher energy consumption compared to conventional activated sludge processes due to intensive aeration requirements.

Critical Patents and Innovations in Anti-Fouling Membranes

Elastic membrane-based membrane bioreactor with high-efficiency for fouling control

PatentWO2016011128A1

Innovation

- The development of elastic microfiltration membranes with polyether-based thermoplastic polymers and electrospinning technology, which includes a non-woven substrate and perforated support members, allows for improved fouling removal through reversible deformation during backwashing, increasing membrane efficiency and longevity.

Elastic membrane-based membrane bioreactor with high-efficiency for fouling control

PatentActiveUS10532322B2

Innovation

- Development of elastic microfiltration membranes using materials like polyether-based thermoplastic polymers and electrospinning techniques, combined with a non-woven substrate and perforated support members, to enhance fouling removal efficiency and membrane longevity.

Energy Efficiency Considerations in MBR Operation

Energy efficiency represents a critical factor in the operational economics and environmental sustainability of Membrane Bioreactor (MBR) systems. The relationship between energy consumption and fouling management is particularly significant, as strategies to minimize irreversible fouling often require additional energy inputs that must be carefully balanced against performance benefits.

The primary energy demand in MBR operation comes from aeration, which serves the dual purpose of providing oxygen for biological processes and creating shear forces that help control membrane fouling. Research indicates that aeration accounts for 60-80% of the total energy consumption in typical MBR installations, making it the most significant target for efficiency improvements.

Advanced aeration strategies have emerged as key approaches to optimize energy usage while maintaining effective fouling control. Intermittent aeration protocols, which alternate between high and low aeration periods, have demonstrated energy savings of 20-30% compared to continuous aeration while maintaining comparable fouling prevention capabilities. Similarly, intelligent aeration control systems that adjust bubble size, flow rate, and distribution based on real-time fouling indicators have shown promising results in laboratory and pilot-scale studies.

Membrane module configuration significantly impacts energy requirements for fouling management. Vertical modules typically require less energy for air scouring compared to horizontal configurations, while submerged systems generally consume less energy than side-stream arrangements when total operational energy is considered. Recent innovations in module design have focused on optimizing the interaction between air bubbles and membrane surfaces to maximize cleaning efficiency while minimizing air consumption.

Operating parameters such as flux rate, transmembrane pressure (TMP), and mixed liquor suspended solids (MLSS) concentration must be carefully balanced to achieve energy-efficient fouling control. Operating at sustainable flux rates below critical flux values reduces fouling propensity and associated energy demands for cleaning. Similarly, maintaining optimal MLSS concentrations prevents excessive viscosity that would otherwise increase aeration energy requirements.

Energy recovery systems represent an emerging approach to improving overall efficiency. Technologies such as heat exchangers that capture thermal energy from MBR effluent and biogas recovery systems that utilize methane produced during anaerobic digestion can offset energy requirements for fouling control measures, improving the net energy balance of MBR operations while maintaining effective fouling management.

The primary energy demand in MBR operation comes from aeration, which serves the dual purpose of providing oxygen for biological processes and creating shear forces that help control membrane fouling. Research indicates that aeration accounts for 60-80% of the total energy consumption in typical MBR installations, making it the most significant target for efficiency improvements.

Advanced aeration strategies have emerged as key approaches to optimize energy usage while maintaining effective fouling control. Intermittent aeration protocols, which alternate between high and low aeration periods, have demonstrated energy savings of 20-30% compared to continuous aeration while maintaining comparable fouling prevention capabilities. Similarly, intelligent aeration control systems that adjust bubble size, flow rate, and distribution based on real-time fouling indicators have shown promising results in laboratory and pilot-scale studies.

Membrane module configuration significantly impacts energy requirements for fouling management. Vertical modules typically require less energy for air scouring compared to horizontal configurations, while submerged systems generally consume less energy than side-stream arrangements when total operational energy is considered. Recent innovations in module design have focused on optimizing the interaction between air bubbles and membrane surfaces to maximize cleaning efficiency while minimizing air consumption.

Operating parameters such as flux rate, transmembrane pressure (TMP), and mixed liquor suspended solids (MLSS) concentration must be carefully balanced to achieve energy-efficient fouling control. Operating at sustainable flux rates below critical flux values reduces fouling propensity and associated energy demands for cleaning. Similarly, maintaining optimal MLSS concentrations prevents excessive viscosity that would otherwise increase aeration energy requirements.

Energy recovery systems represent an emerging approach to improving overall efficiency. Technologies such as heat exchangers that capture thermal energy from MBR effluent and biogas recovery systems that utilize methane produced during anaerobic digestion can offset energy requirements for fouling control measures, improving the net energy balance of MBR operations while maintaining effective fouling management.

Environmental Impact and Regulatory Framework for MBR Systems

Membrane Bioreactor (MBR) systems have gained significant recognition for their environmental benefits compared to conventional wastewater treatment processes. These systems produce higher quality effluent with reduced footprints, making them increasingly attractive as regulatory standards become more stringent worldwide. The environmental impact of MBR technology extends across multiple dimensions, including energy consumption, greenhouse gas emissions, and resource recovery potential.

Energy consumption represents a critical environmental consideration for MBR operations. While these systems typically require 20-50% more energy than conventional activated sludge processes due to membrane aeration requirements, advanced fouling control strategies can significantly reduce this energy demand. Innovations in membrane materials and module designs that minimize irreversible fouling have demonstrated energy savings of up to 30% in full-scale applications, directly reducing the carbon footprint associated with treatment operations.

Water quality regulations have become increasingly stringent in recent years, particularly regarding nutrient removal and micropollutant elimination. MBR systems excel in meeting these enhanced standards due to their superior solid-liquid separation capabilities. The regulatory framework in North America, Europe, and Asia has evolved to recognize MBR technology as Best Available Technology (BAT) for certain applications, particularly where space constraints exist or water reuse is prioritized.

The sludge management aspect of MBR operations presents both challenges and opportunities from an environmental perspective. While MBRs typically produce less excess sludge than conventional processes, the management of concentrated waste streams requires careful consideration. Regulatory frameworks increasingly emphasize beneficial reuse options, with some jurisdictions implementing incentives for resource recovery from MBR sludge, including energy generation and nutrient reclamation.

Climate change considerations have also entered the regulatory landscape for wastewater treatment technologies. MBR systems with optimized fouling control strategies demonstrate resilience to variable influent conditions, an increasingly valuable attribute as extreme weather events become more common. Several countries have incorporated climate adaptation metrics into their wastewater treatment facility permitting processes, potentially favoring MBR technologies that maintain stable performance despite challenging conditions.

The life cycle assessment (LCA) of MBR systems reveals that membrane fouling control strategies significantly influence overall environmental impact. Regulatory frameworks in the EU and parts of Asia now incorporate LCA considerations in technology approval processes. Systems demonstrating effective irreversible fouling minimization while maintaining flux typically show 15-25% lower lifetime environmental impacts compared to those requiring frequent chemical cleaning or membrane replacement.

Energy consumption represents a critical environmental consideration for MBR operations. While these systems typically require 20-50% more energy than conventional activated sludge processes due to membrane aeration requirements, advanced fouling control strategies can significantly reduce this energy demand. Innovations in membrane materials and module designs that minimize irreversible fouling have demonstrated energy savings of up to 30% in full-scale applications, directly reducing the carbon footprint associated with treatment operations.

Water quality regulations have become increasingly stringent in recent years, particularly regarding nutrient removal and micropollutant elimination. MBR systems excel in meeting these enhanced standards due to their superior solid-liquid separation capabilities. The regulatory framework in North America, Europe, and Asia has evolved to recognize MBR technology as Best Available Technology (BAT) for certain applications, particularly where space constraints exist or water reuse is prioritized.

The sludge management aspect of MBR operations presents both challenges and opportunities from an environmental perspective. While MBRs typically produce less excess sludge than conventional processes, the management of concentrated waste streams requires careful consideration. Regulatory frameworks increasingly emphasize beneficial reuse options, with some jurisdictions implementing incentives for resource recovery from MBR sludge, including energy generation and nutrient reclamation.

Climate change considerations have also entered the regulatory landscape for wastewater treatment technologies. MBR systems with optimized fouling control strategies demonstrate resilience to variable influent conditions, an increasingly valuable attribute as extreme weather events become more common. Several countries have incorporated climate adaptation metrics into their wastewater treatment facility permitting processes, potentially favoring MBR technologies that maintain stable performance despite challenging conditions.

The life cycle assessment (LCA) of MBR systems reveals that membrane fouling control strategies significantly influence overall environmental impact. Regulatory frameworks in the EU and parts of Asia now incorporate LCA considerations in technology approval processes. Systems demonstrating effective irreversible fouling minimization while maintaining flux typically show 15-25% lower lifetime environmental impacts compared to those requiring frequent chemical cleaning or membrane replacement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!