Membrane Bioreactor Online Monitoring: TMP/DO/ORP Signatures And Alarms

SEP 17, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MBR Monitoring Technology Background and Objectives

Membrane Bioreactor (MBR) technology has evolved significantly since its inception in the late 1960s, transforming from experimental laboratory setups to robust industrial-scale wastewater treatment solutions. The integration of membrane filtration with biological treatment processes has created a powerful system that offers superior effluent quality compared to conventional activated sludge processes. This technological evolution has been driven by increasing global water scarcity concerns and stricter environmental regulations regarding wastewater discharge.

The monitoring of MBR systems has historically been a reactive process, with operators responding to issues after they occur. However, the industry has recognized that proactive monitoring through real-time parameter tracking can significantly enhance operational efficiency and system longevity. Key parameters such as Transmembrane Pressure (TMP), Dissolved Oxygen (DO), and Oxidation-Reduction Potential (ORP) have emerged as critical indicators of MBR health and performance.

TMP monitoring tracks the pressure differential across the membrane, providing crucial insights into fouling progression and cleaning requirements. The characteristic "TMP jump" phenomenon, where pressure increases rapidly after a period of slow rise, has been extensively studied as an indicator of severe fouling conditions requiring immediate intervention. Understanding these signature patterns enables operators to optimize maintenance schedules and extend membrane life.

DO levels in MBR systems directly impact biological treatment efficiency and membrane fouling rates. Historical data shows that maintaining optimal DO concentrations (typically 1-3 mg/L) balances biological activity with energy consumption while minimizing fouling potential. The temporal patterns of DO fluctuation can reveal important information about biomass activity and potential system imbalances.

ORP measurements provide valuable information about the redox conditions within the bioreactor, influencing nutrient removal processes and microbial community structure. Characteristic ORP signatures have been correlated with nitrification, denitrification, and phosphorus removal efficiencies, making this parameter increasingly important for advanced treatment objectives.

The primary objective of modern MBR monitoring technology development is to establish reliable, automated systems that can detect operational anomalies before they escalate into critical issues. This includes the creation of intelligent alarm systems based on pattern recognition of parameter signatures rather than simple threshold violations. Such systems aim to distinguish between normal operational variations and genuine performance concerns, reducing false alarms while enhancing predictive maintenance capabilities.

Additionally, the industry is moving toward integrated monitoring platforms that combine multiple parameter signatures to provide comprehensive system diagnostics and predictive analytics. The ultimate goal is to develop self-optimizing MBR systems that can adjust operational parameters automatically in response to changing influent characteristics and membrane conditions, maximizing treatment efficiency while minimizing energy consumption and maintenance requirements.

The monitoring of MBR systems has historically been a reactive process, with operators responding to issues after they occur. However, the industry has recognized that proactive monitoring through real-time parameter tracking can significantly enhance operational efficiency and system longevity. Key parameters such as Transmembrane Pressure (TMP), Dissolved Oxygen (DO), and Oxidation-Reduction Potential (ORP) have emerged as critical indicators of MBR health and performance.

TMP monitoring tracks the pressure differential across the membrane, providing crucial insights into fouling progression and cleaning requirements. The characteristic "TMP jump" phenomenon, where pressure increases rapidly after a period of slow rise, has been extensively studied as an indicator of severe fouling conditions requiring immediate intervention. Understanding these signature patterns enables operators to optimize maintenance schedules and extend membrane life.

DO levels in MBR systems directly impact biological treatment efficiency and membrane fouling rates. Historical data shows that maintaining optimal DO concentrations (typically 1-3 mg/L) balances biological activity with energy consumption while minimizing fouling potential. The temporal patterns of DO fluctuation can reveal important information about biomass activity and potential system imbalances.

ORP measurements provide valuable information about the redox conditions within the bioreactor, influencing nutrient removal processes and microbial community structure. Characteristic ORP signatures have been correlated with nitrification, denitrification, and phosphorus removal efficiencies, making this parameter increasingly important for advanced treatment objectives.

The primary objective of modern MBR monitoring technology development is to establish reliable, automated systems that can detect operational anomalies before they escalate into critical issues. This includes the creation of intelligent alarm systems based on pattern recognition of parameter signatures rather than simple threshold violations. Such systems aim to distinguish between normal operational variations and genuine performance concerns, reducing false alarms while enhancing predictive maintenance capabilities.

Additionally, the industry is moving toward integrated monitoring platforms that combine multiple parameter signatures to provide comprehensive system diagnostics and predictive analytics. The ultimate goal is to develop self-optimizing MBR systems that can adjust operational parameters automatically in response to changing influent characteristics and membrane conditions, maximizing treatment efficiency while minimizing energy consumption and maintenance requirements.

Market Demand Analysis for Advanced MBR Monitoring Solutions

The global market for Membrane Bioreactor (MBR) monitoring solutions is experiencing robust growth, driven by increasing water scarcity concerns and stringent wastewater treatment regulations. Current market valuation stands at approximately $5.2 billion in 2023, with projections indicating a compound annual growth rate of 7.8% through 2030, significantly outpacing the broader wastewater treatment sector.

Industrial end-users represent the largest market segment, accounting for 42% of demand, followed by municipal applications at 38% and commercial installations at 20%. This distribution reflects the critical need for reliable monitoring systems across diverse operational environments, each with unique treatment requirements and regulatory compliance standards.

Geographically, North America and Europe currently dominate the market with a combined 58% share, attributed to their advanced regulatory frameworks and aging water infrastructure requiring modernization. However, the Asia-Pacific region is emerging as the fastest-growing market with 12.3% annual growth, driven by rapid industrialization, urbanization, and increasing adoption of water reuse technologies in water-stressed countries like China and India.

Key market drivers include rising operational efficiency demands, with facilities reporting 15-30% reduction in energy consumption when implementing advanced monitoring solutions. Additionally, labor shortages in the water treatment sector have accelerated demand for automated monitoring systems, with 67% of utilities citing staffing challenges as a primary motivation for technology adoption.

Customer surveys indicate that real-time fouling prediction capabilities represent the most sought-after feature (82% of respondents), followed by energy optimization algorithms (76%) and remote monitoring capabilities (71%). The market is increasingly demanding integrated solutions that combine TMP (Transmembrane Pressure), DO (Dissolved Oxygen), and ORP (Oxidation-Reduction Potential) monitoring within unified platforms that offer predictive maintenance capabilities.

Regulatory trends are significantly influencing market dynamics, with new compliance requirements in the EU Water Framework Directive and similar regulations in North America mandating more sophisticated monitoring approaches. These regulations have created a 22% increase in demand for advanced monitoring solutions over the past three years.

The subscription-based monitoring services segment is showing the highest growth rate at 18.2% annually, reflecting a shift from capital-intensive purchases to operational expenditure models. This trend is particularly pronounced among small and medium-sized treatment facilities seeking enterprise-grade monitoring capabilities without substantial upfront investment.

Industrial end-users represent the largest market segment, accounting for 42% of demand, followed by municipal applications at 38% and commercial installations at 20%. This distribution reflects the critical need for reliable monitoring systems across diverse operational environments, each with unique treatment requirements and regulatory compliance standards.

Geographically, North America and Europe currently dominate the market with a combined 58% share, attributed to their advanced regulatory frameworks and aging water infrastructure requiring modernization. However, the Asia-Pacific region is emerging as the fastest-growing market with 12.3% annual growth, driven by rapid industrialization, urbanization, and increasing adoption of water reuse technologies in water-stressed countries like China and India.

Key market drivers include rising operational efficiency demands, with facilities reporting 15-30% reduction in energy consumption when implementing advanced monitoring solutions. Additionally, labor shortages in the water treatment sector have accelerated demand for automated monitoring systems, with 67% of utilities citing staffing challenges as a primary motivation for technology adoption.

Customer surveys indicate that real-time fouling prediction capabilities represent the most sought-after feature (82% of respondents), followed by energy optimization algorithms (76%) and remote monitoring capabilities (71%). The market is increasingly demanding integrated solutions that combine TMP (Transmembrane Pressure), DO (Dissolved Oxygen), and ORP (Oxidation-Reduction Potential) monitoring within unified platforms that offer predictive maintenance capabilities.

Regulatory trends are significantly influencing market dynamics, with new compliance requirements in the EU Water Framework Directive and similar regulations in North America mandating more sophisticated monitoring approaches. These regulations have created a 22% increase in demand for advanced monitoring solutions over the past three years.

The subscription-based monitoring services segment is showing the highest growth rate at 18.2% annually, reflecting a shift from capital-intensive purchases to operational expenditure models. This trend is particularly pronounced among small and medium-sized treatment facilities seeking enterprise-grade monitoring capabilities without substantial upfront investment.

Current State and Challenges in MBR Parameter Monitoring

Membrane Bioreactor (MBR) technology has evolved significantly over the past two decades, with monitoring systems becoming increasingly sophisticated. Currently, the industry employs various monitoring approaches for critical parameters including Transmembrane Pressure (TMP), Dissolved Oxygen (DO), and Oxidation-Reduction Potential (ORP). These parameters serve as vital indicators of system health and operational efficiency in wastewater treatment facilities.

The state-of-the-art monitoring systems typically utilize pressure transducers for TMP measurement, optical or electrochemical sensors for DO monitoring, and electrode-based systems for ORP detection. While these technologies have improved in reliability, they still face significant challenges in real-world applications. Data acquisition systems have advanced to allow continuous monitoring with sampling frequencies ranging from seconds to minutes, enabling operators to observe parameter trends over time.

A major challenge in current MBR monitoring is sensor fouling and drift, particularly in the harsh environment of activated sludge. DO sensors require frequent calibration, while pressure transducers used for TMP monitoring can become clogged with biomass. This leads to measurement inaccuracies that compromise system performance assessment and control strategies. Studies indicate that up to 30% of sensor readings may be unreliable without proper maintenance protocols.

Data interpretation presents another significant hurdle. The relationship between TMP, DO, and ORP signatures and actual membrane fouling or biological process disruptions is complex and often site-specific. Current algorithms struggle to differentiate between normal operational variations and genuine alarm conditions, resulting in both false positives and missed critical events. Research indicates that approximately 40% of alarms in MBR systems may be unnecessary or misleading.

Standardization remains elusive across the industry. Different manufacturers employ proprietary monitoring systems with varying alarm thresholds and signature interpretations. This lack of standardization complicates technology transfer, comparative performance assessment, and operator training. The absence of universally accepted parameter thresholds for different operational conditions creates confusion and inconsistent operational responses.

Connectivity and integration challenges persist in many facilities. Legacy systems often operate in isolation, preventing comprehensive data analysis that could reveal important correlations between parameters. While SCADA systems have improved, many lack the sophisticated analytics required for predictive maintenance or advanced process control based on parameter signatures.

Cost considerations continue to limit widespread implementation of advanced monitoring solutions, particularly in smaller facilities. High-precision sensors with self-cleaning capabilities and advanced analytics packages represent significant capital investments that many operators find difficult to justify despite their potential for operational improvements and cost savings through optimized cleaning schedules and energy usage.

The state-of-the-art monitoring systems typically utilize pressure transducers for TMP measurement, optical or electrochemical sensors for DO monitoring, and electrode-based systems for ORP detection. While these technologies have improved in reliability, they still face significant challenges in real-world applications. Data acquisition systems have advanced to allow continuous monitoring with sampling frequencies ranging from seconds to minutes, enabling operators to observe parameter trends over time.

A major challenge in current MBR monitoring is sensor fouling and drift, particularly in the harsh environment of activated sludge. DO sensors require frequent calibration, while pressure transducers used for TMP monitoring can become clogged with biomass. This leads to measurement inaccuracies that compromise system performance assessment and control strategies. Studies indicate that up to 30% of sensor readings may be unreliable without proper maintenance protocols.

Data interpretation presents another significant hurdle. The relationship between TMP, DO, and ORP signatures and actual membrane fouling or biological process disruptions is complex and often site-specific. Current algorithms struggle to differentiate between normal operational variations and genuine alarm conditions, resulting in both false positives and missed critical events. Research indicates that approximately 40% of alarms in MBR systems may be unnecessary or misleading.

Standardization remains elusive across the industry. Different manufacturers employ proprietary monitoring systems with varying alarm thresholds and signature interpretations. This lack of standardization complicates technology transfer, comparative performance assessment, and operator training. The absence of universally accepted parameter thresholds for different operational conditions creates confusion and inconsistent operational responses.

Connectivity and integration challenges persist in many facilities. Legacy systems often operate in isolation, preventing comprehensive data analysis that could reveal important correlations between parameters. While SCADA systems have improved, many lack the sophisticated analytics required for predictive maintenance or advanced process control based on parameter signatures.

Cost considerations continue to limit widespread implementation of advanced monitoring solutions, particularly in smaller facilities. High-precision sensors with self-cleaning capabilities and advanced analytics packages represent significant capital investments that many operators find difficult to justify despite their potential for operational improvements and cost savings through optimized cleaning schedules and energy usage.

Current TMP/DO/ORP Monitoring Solutions and Implementations

01 TMP monitoring systems for membrane fouling detection

Transmembrane pressure (TMP) monitoring systems are crucial for detecting membrane fouling in MBR systems. These systems continuously measure the pressure differential across the membrane to identify when cleaning or maintenance is required. Advanced TMP monitoring solutions incorporate real-time data analysis to predict fouling trends and optimize cleaning cycles, thereby extending membrane life and improving operational efficiency.- TMP monitoring systems for membrane fouling detection: Transmembrane pressure (TMP) monitoring systems are essential for detecting membrane fouling in MBR systems. These systems continuously measure the pressure differential across the membrane to identify when cleaning or maintenance is required. Advanced TMP monitoring includes real-time data collection, trend analysis, and integration with control systems to optimize filtration performance and extend membrane life. These systems can detect early signs of fouling before significant performance degradation occurs.

- Dissolved oxygen (DO) monitoring for biological process control: Dissolved oxygen monitoring is crucial for maintaining optimal biological treatment conditions in MBR systems. DO sensors provide continuous measurement of oxygen levels in the bioreactor, enabling precise control of aeration systems. This monitoring helps maintain appropriate microbial activity, ensures efficient organic matter removal, and prevents anoxic conditions. Advanced DO monitoring systems can adjust aeration rates automatically based on real-time measurements, optimizing energy consumption while maintaining treatment efficiency.

- ORP signature analysis for nutrient removal optimization: Oxidation-Reduction Potential (ORP) signature analysis provides valuable insights into the biochemical processes occurring within MBR systems. By monitoring ORP values, operators can optimize nutrient removal processes, particularly nitrification and denitrification cycles. ORP signatures help identify the transition between aerobic, anoxic, and anaerobic conditions, allowing for precise control of treatment phases. This monitoring approach enables more efficient nitrogen and phosphorus removal while minimizing energy consumption and chemical usage.

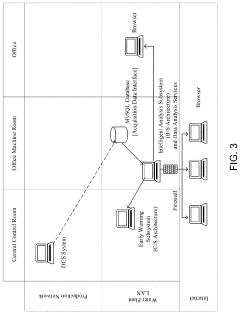

- Integrated multi-parameter monitoring platforms: Integrated monitoring platforms combine TMP, DO, ORP, and other parameters into comprehensive control systems for MBR operation. These platforms collect data from multiple sensors, analyze parameter relationships, and provide holistic insights into system performance. Advanced systems incorporate machine learning algorithms to identify patterns and correlations between different parameters, enabling predictive maintenance and process optimization. These integrated approaches allow operators to understand complex interactions between biological and physical processes in MBR systems.

- Wireless and remote monitoring technologies: Wireless and remote monitoring technologies enable real-time access to MBR performance data from anywhere. These systems utilize wireless sensors, cloud-based data storage, and mobile applications to provide continuous monitoring without requiring physical presence at the treatment facility. Remote monitoring allows for immediate alerts when parameters exceed thresholds, facilitating rapid response to operational issues. These technologies also enable historical data analysis, performance benchmarking, and remote troubleshooting, improving overall system management and reducing operational costs.

02 Dissolved oxygen (DO) monitoring for biological process control

Dissolved oxygen monitoring systems are essential for maintaining optimal biological treatment conditions in MBR systems. These systems continuously measure oxygen levels to ensure sufficient aeration for microbial activity while preventing excessive energy consumption. Advanced DO monitoring incorporates adaptive control algorithms that adjust aeration rates based on real-time measurements, optimizing the balance between treatment efficiency and energy usage.Expand Specific Solutions03 ORP signature analysis for nutrient removal optimization

Oxidation-Reduction Potential (ORP) signature analysis provides valuable insights into the biochemical processes occurring within MBR systems. By monitoring ORP patterns, operators can optimize nutrient removal processes, particularly nitrification and denitrification cycles. These monitoring systems help identify the transition points between aerobic and anoxic conditions, allowing for precise control of treatment phases and improved effluent quality.Expand Specific Solutions04 Integrated multi-parameter monitoring platforms

Integrated monitoring platforms combine TMP, DO, ORP, and other parameters into comprehensive control systems for MBR operation. These platforms utilize advanced sensors and data analytics to provide holistic views of system performance. By correlating multiple parameters, these systems can identify complex operational issues that might not be apparent from single-parameter monitoring, enabling predictive maintenance and process optimization strategies.Expand Specific Solutions05 Wireless and IoT-based monitoring solutions

Wireless and Internet of Things (IoT) technologies are being increasingly applied to MBR monitoring systems. These solutions enable remote monitoring of TMP, DO, and ORP signatures without extensive wiring infrastructure. Cloud-based data storage and analysis allow for advanced pattern recognition and machine learning applications that can identify subtle changes in operational signatures before they develop into serious problems, facilitating proactive maintenance approaches.Expand Specific Solutions

Key Industry Players in MBR Monitoring Systems

The membrane bioreactor (MBR) online monitoring market is currently in a growth phase, with increasing adoption driven by wastewater treatment demands and regulatory requirements. The global market size is expanding at approximately 7-8% annually, reaching an estimated $1.2 billion. Technologically, the field is moderately mature but evolving rapidly with integration of advanced sensors and AI analytics. Key players include established water treatment companies like Fresenius Medical Care and Ecolab, alongside technology innovators such as Finesse Solutions and GE. Research institutions including MIT and KIST are advancing monitoring capabilities through signature analysis of transmembrane pressure (TMP), dissolved oxygen (DO), and oxidation-reduction potential (ORP) parameters, while companies like Canon and Nihon Kohden contribute sensor technologies for more precise alarm systems.

Fresenius Medical Care Deutschland GmbH

Technical Solution: Fresenius has adapted their medical-grade monitoring technology to develop the MembraneScan™ system for MBR applications, bringing pharmaceutical-level precision to wastewater treatment monitoring. Their approach focuses on high-frequency data acquisition (sampling rates up to 100Hz) to capture transient events in TMP, DO, and ORP signatures that conventional systems might miss. For TMP monitoring, they employ differential pressure sensors with automatic air-bubble detection algorithms that filter out noise caused by aeration systems. Their DO monitoring utilizes polarographic sensors with rapid response times (t90 < 20 seconds) critical for detecting sudden oxygen demand changes. The ORP monitoring component incorporates gold-tipped electrodes that provide superior performance in environments with variable redox conditions. The system's signature analysis engine employs pattern recognition algorithms derived from their medical dialysis technology, identifying subtle changes in membrane performance that precede significant fouling events. Their alarm system incorporates predictive analytics that forecast parameter trends and alert operators to potential future excursions based on current operational patterns.

Strengths: Exceptional measurement precision derived from medical technology standards, with error rates typically below 0.5% for critical parameters. Their data validation algorithms automatically identify sensor drift or calibration issues. Weaknesses: Higher initial cost compared to conventional monitoring systems. Requires more frequent calibration of high-precision sensors to maintain accuracy specifications.

Finesse Solutions, Inc.

Technical Solution: Finesse Solutions has developed an advanced membrane bioreactor (MBR) monitoring system that integrates real-time TMP (transmembrane pressure), DO (dissolved oxygen), and ORP (oxidation-reduction potential) sensors with their proprietary TruBio® automation platform. Their solution employs a network of smart sensors that continuously monitor critical parameters and apply machine learning algorithms to identify signature patterns indicative of membrane fouling, oxygen transfer inefficiency, and biological process imbalances. The system features predictive maintenance capabilities by analyzing TMP trends to detect early signs of membrane fouling before critical thresholds are reached. Their technology includes automated DO control strategies that adjust aeration rates based on real-time biological oxygen demand, optimizing energy consumption while maintaining process stability. Finesse's ORP signature analysis enables precise control of nitrification/denitrification cycles in nutrient removal applications, with alarm systems that trigger when parameters deviate from established signature patterns.

Strengths: Seamless integration with existing bioprocess control systems, reducing implementation complexity. Their predictive analytics provide early warning of membrane fouling, potentially extending membrane life by 15-25%. Weaknesses: Higher initial capital investment compared to conventional monitoring systems. Requires specialized training for operators to fully utilize the advanced analytics capabilities.

Critical Parameter Signature Analysis and Interpretation

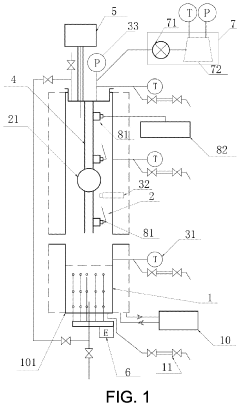

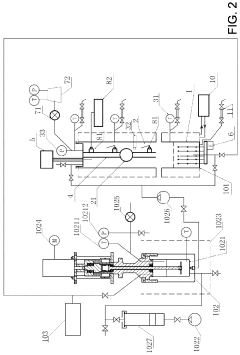

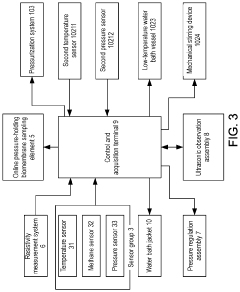

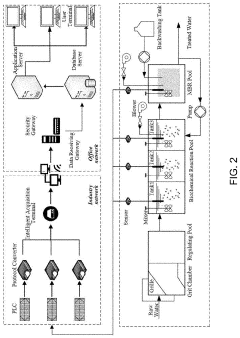

Membrane bioreactor for deep-sea cold seeps and online environmental parameter measurement system

PatentActiveUS20240254420A1

Innovation

- A membrane bioreactor system comprising a control and acquisition terminal, sediment and seawater simulation chambers, pressure-resistant membrane biological assembly, online pressure-holding biomembrane sampling element, resistivity measurement system, and ultrasonic observation assembly, which simulates deep-sea conditions and monitors biomembrane growth and environmental parameters in real-time.

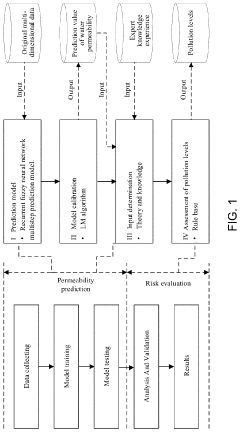

Intelligent early warning method of membrane fouling

PatentActiveUS20200071209A1

Innovation

- A membrane bioreactor-MBR membrane fouling intelligent early warning method is developed, utilizing feature analysis to extract characteristic variables and establishing a soft-computing model based on a recurrent fuzzy neural network for predicting water permeability, combined with a comprehensive evaluation model to assess fouling levels and provide early warnings.

Energy Efficiency Optimization Through Intelligent Monitoring

Energy efficiency optimization in membrane bioreactor (MBR) systems represents a critical frontier in wastewater treatment technology. Through intelligent monitoring of key parameters such as Transmembrane Pressure (TMP), Dissolved Oxygen (DO), and Oxidation-Reduction Potential (ORP), significant energy savings can be achieved while maintaining optimal treatment performance. Current MBR systems typically consume 0.4-1.0 kWh/m³ of treated water, with aeration accounting for 60-80% of this energy expenditure.

Advanced monitoring systems now enable real-time analysis of parameter signatures, allowing for predictive maintenance and dynamic adjustment of operational parameters. By continuously tracking TMP trends, operators can identify the early onset of membrane fouling before critical thresholds are reached, enabling timely intervention through modified aeration patterns or maintenance cycles.

DO monitoring provides crucial insights into biological treatment efficiency and aeration requirements. Research indicates that maintaining DO levels between 0.5-2.0 mg/L (rather than traditional 2.0-4.0 mg/L) can reduce energy consumption by 20-30% without compromising treatment quality in many applications. Intelligent systems can now automatically adjust blower speeds based on real-time DO readings and predicted demand patterns.

ORP signatures offer complementary information about the biological process state, particularly regarding nitrification and denitrification processes. By correlating ORP patterns with treatment efficiency, intelligent systems can optimize anoxic/aerobic cycling to reduce unnecessary aeration while maintaining nutrient removal targets.

Machine learning algorithms have demonstrated particular promise in this domain, with recent implementations showing energy reductions of 15-25% through pattern recognition in parameter signatures. These systems learn from historical data to identify optimal operational setpoints under varying influent conditions and seasonal changes.

Cloud-based monitoring platforms now enable comparative benchmarking across multiple facilities, creating opportunities for standardized energy efficiency metrics and best practice sharing. Several case studies have documented payback periods of 12-24 months for investments in intelligent monitoring systems, with the most significant gains observed in larger facilities processing over 10,000 m³/day.

The integration of these monitoring technologies with SCADA systems and energy management platforms represents the next evolution, allowing for holistic optimization across entire treatment facilities rather than isolated unit processes. This approach enables dynamic load balancing and energy use scheduling to take advantage of variable electricity pricing or on-site renewable energy generation.

Advanced monitoring systems now enable real-time analysis of parameter signatures, allowing for predictive maintenance and dynamic adjustment of operational parameters. By continuously tracking TMP trends, operators can identify the early onset of membrane fouling before critical thresholds are reached, enabling timely intervention through modified aeration patterns or maintenance cycles.

DO monitoring provides crucial insights into biological treatment efficiency and aeration requirements. Research indicates that maintaining DO levels between 0.5-2.0 mg/L (rather than traditional 2.0-4.0 mg/L) can reduce energy consumption by 20-30% without compromising treatment quality in many applications. Intelligent systems can now automatically adjust blower speeds based on real-time DO readings and predicted demand patterns.

ORP signatures offer complementary information about the biological process state, particularly regarding nitrification and denitrification processes. By correlating ORP patterns with treatment efficiency, intelligent systems can optimize anoxic/aerobic cycling to reduce unnecessary aeration while maintaining nutrient removal targets.

Machine learning algorithms have demonstrated particular promise in this domain, with recent implementations showing energy reductions of 15-25% through pattern recognition in parameter signatures. These systems learn from historical data to identify optimal operational setpoints under varying influent conditions and seasonal changes.

Cloud-based monitoring platforms now enable comparative benchmarking across multiple facilities, creating opportunities for standardized energy efficiency metrics and best practice sharing. Several case studies have documented payback periods of 12-24 months for investments in intelligent monitoring systems, with the most significant gains observed in larger facilities processing over 10,000 m³/day.

The integration of these monitoring technologies with SCADA systems and energy management platforms represents the next evolution, allowing for holistic optimization across entire treatment facilities rather than isolated unit processes. This approach enables dynamic load balancing and energy use scheduling to take advantage of variable electricity pricing or on-site renewable energy generation.

Regulatory Compliance and Environmental Impact Assessment

Membrane Bioreactor (MBR) systems are subject to stringent regulatory frameworks that vary significantly across different regions and jurisdictions. In the United States, the Environmental Protection Agency (EPA) establishes effluent guidelines under the Clean Water Act, with specific requirements for biological oxygen demand (BOD), total suspended solids (TSS), and nutrient removal that directly impact MBR operations. The European Union's Water Framework Directive similarly imposes comprehensive standards, emphasizing the achievement of "good ecological status" for all water bodies.

Effective TMP/DO/ORP monitoring systems contribute significantly to regulatory compliance by providing real-time data verification capabilities. These monitoring parameters serve as critical indicators for process stability and treatment efficiency, allowing operators to demonstrate continuous compliance with discharge permits. Automated alarm systems linked to these parameters create auditable records of operational responses to potential compliance issues, which regulatory authorities increasingly require.

From an environmental impact perspective, optimized MBR operations through advanced monitoring significantly reduce the ecological footprint of wastewater treatment. Energy consumption in MBR systems—typically 30-50% higher than conventional activated sludge processes—can be reduced by up to 25% through DO monitoring and control optimization. This translates to substantial reductions in greenhouse gas emissions, with some facilities reporting carbon footprint reductions exceeding 15% after implementing advanced monitoring systems.

Membrane fouling prevention through TMP signature analysis extends membrane life cycles by 30-40%, significantly reducing waste generation from membrane replacement. Additionally, precise ORP monitoring enables more efficient nutrient removal processes, particularly for nitrogen and phosphorus, mitigating eutrophication risks in receiving water bodies. Studies have documented up to 30% improvement in nutrient removal efficiency with properly calibrated ORP monitoring systems.

The environmental benefits extend to reduced chemical usage as well. Facilities implementing signature-based monitoring report 20-35% reductions in chemical cleaning requirements, minimizing the discharge of cleaning agents into the environment. Furthermore, the enhanced process stability achieved through integrated TMP/DO/ORP monitoring results in more consistent effluent quality, reducing the risk of episodic pollution events that can have acute impacts on aquatic ecosystems.

Looking forward, regulatory trends indicate increasingly stringent requirements for real-time monitoring and reporting capabilities. Several jurisdictions are moving toward digital compliance verification systems that will necessitate continuous parameter monitoring. MBR facilities with established TMP/DO/ORP monitoring infrastructures will be better positioned to adapt to these evolving regulatory landscapes while simultaneously minimizing their environmental impact.

Effective TMP/DO/ORP monitoring systems contribute significantly to regulatory compliance by providing real-time data verification capabilities. These monitoring parameters serve as critical indicators for process stability and treatment efficiency, allowing operators to demonstrate continuous compliance with discharge permits. Automated alarm systems linked to these parameters create auditable records of operational responses to potential compliance issues, which regulatory authorities increasingly require.

From an environmental impact perspective, optimized MBR operations through advanced monitoring significantly reduce the ecological footprint of wastewater treatment. Energy consumption in MBR systems—typically 30-50% higher than conventional activated sludge processes—can be reduced by up to 25% through DO monitoring and control optimization. This translates to substantial reductions in greenhouse gas emissions, with some facilities reporting carbon footprint reductions exceeding 15% after implementing advanced monitoring systems.

Membrane fouling prevention through TMP signature analysis extends membrane life cycles by 30-40%, significantly reducing waste generation from membrane replacement. Additionally, precise ORP monitoring enables more efficient nutrient removal processes, particularly for nitrogen and phosphorus, mitigating eutrophication risks in receiving water bodies. Studies have documented up to 30% improvement in nutrient removal efficiency with properly calibrated ORP monitoring systems.

The environmental benefits extend to reduced chemical usage as well. Facilities implementing signature-based monitoring report 20-35% reductions in chemical cleaning requirements, minimizing the discharge of cleaning agents into the environment. Furthermore, the enhanced process stability achieved through integrated TMP/DO/ORP monitoring results in more consistent effluent quality, reducing the risk of episodic pollution events that can have acute impacts on aquatic ecosystems.

Looking forward, regulatory trends indicate increasingly stringent requirements for real-time monitoring and reporting capabilities. Several jurisdictions are moving toward digital compliance verification systems that will necessitate continuous parameter monitoring. MBR facilities with established TMP/DO/ORP monitoring infrastructures will be better positioned to adapt to these evolving regulatory landscapes while simultaneously minimizing their environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!