Membrane Bioreactor Nutrient Removal: Nitrification/Denitrification And Process Coupling

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MBR Nutrient Removal Background and Objectives

Membrane Bioreactor (MBR) technology has evolved significantly since its inception in the late 1960s, transforming from an experimental concept to a mainstream wastewater treatment solution. The integration of membrane filtration with biological treatment processes represents a pivotal advancement in wastewater management, offering superior effluent quality compared to conventional activated sludge systems. This technological evolution has been driven by increasing global water scarcity concerns and stricter environmental regulations regarding nutrient discharge.

The trajectory of MBR development has been characterized by continuous improvements in membrane materials, module configurations, and operational strategies. Early systems faced challenges related to membrane fouling, high energy consumption, and limited nutrient removal capabilities. However, recent decades have witnessed substantial progress in addressing these limitations, particularly in enhancing nitrogen and phosphorus removal efficiencies through optimized biological processes.

Nutrient removal, specifically nitrification and denitrification processes, has become a central focus in MBR technology advancement. Excessive discharge of nutrients into water bodies leads to eutrophication, harmful algal blooms, and ecosystem degradation. Consequently, regulatory frameworks worldwide have established increasingly stringent limits on nitrogen and phosphorus concentrations in treated effluents, necessitating more effective removal strategies.

The primary technical objective in MBR nutrient removal is to achieve stable and efficient nitrification/denitrification processes while maintaining membrane performance. This involves optimizing operational parameters such as hydraulic retention time (HRT), solids retention time (SRT), dissolved oxygen levels, and carbon-to-nitrogen ratios. Additionally, process coupling—the strategic integration of anaerobic, anoxic, and aerobic zones—has emerged as a critical approach to enhance nutrient removal efficiency while minimizing energy consumption and operational costs.

Current research trends are focused on developing novel process configurations that can simultaneously achieve high removal rates for nitrogen, phosphorus, and emerging contaminants. These include modified UCT (University of Cape Town) processes, integrated fixed-film activated sludge MBRs, and granular sludge MBRs. Furthermore, the application of advanced control systems and real-time monitoring technologies is being explored to optimize process performance and adapt to fluctuating influent characteristics.

The ultimate goal of MBR nutrient removal technology development is to establish sustainable, energy-efficient, and cost-effective solutions that can consistently meet or exceed regulatory requirements while minimizing environmental footprint. This aligns with broader industry objectives of resource recovery, energy neutrality, and circular economy principles in wastewater treatment operations.

The trajectory of MBR development has been characterized by continuous improvements in membrane materials, module configurations, and operational strategies. Early systems faced challenges related to membrane fouling, high energy consumption, and limited nutrient removal capabilities. However, recent decades have witnessed substantial progress in addressing these limitations, particularly in enhancing nitrogen and phosphorus removal efficiencies through optimized biological processes.

Nutrient removal, specifically nitrification and denitrification processes, has become a central focus in MBR technology advancement. Excessive discharge of nutrients into water bodies leads to eutrophication, harmful algal blooms, and ecosystem degradation. Consequently, regulatory frameworks worldwide have established increasingly stringent limits on nitrogen and phosphorus concentrations in treated effluents, necessitating more effective removal strategies.

The primary technical objective in MBR nutrient removal is to achieve stable and efficient nitrification/denitrification processes while maintaining membrane performance. This involves optimizing operational parameters such as hydraulic retention time (HRT), solids retention time (SRT), dissolved oxygen levels, and carbon-to-nitrogen ratios. Additionally, process coupling—the strategic integration of anaerobic, anoxic, and aerobic zones—has emerged as a critical approach to enhance nutrient removal efficiency while minimizing energy consumption and operational costs.

Current research trends are focused on developing novel process configurations that can simultaneously achieve high removal rates for nitrogen, phosphorus, and emerging contaminants. These include modified UCT (University of Cape Town) processes, integrated fixed-film activated sludge MBRs, and granular sludge MBRs. Furthermore, the application of advanced control systems and real-time monitoring technologies is being explored to optimize process performance and adapt to fluctuating influent characteristics.

The ultimate goal of MBR nutrient removal technology development is to establish sustainable, energy-efficient, and cost-effective solutions that can consistently meet or exceed regulatory requirements while minimizing environmental footprint. This aligns with broader industry objectives of resource recovery, energy neutrality, and circular economy principles in wastewater treatment operations.

Market Demand Analysis for Advanced Wastewater Treatment

The global wastewater treatment market is experiencing significant growth driven by increasing water scarcity, stringent environmental regulations, and growing awareness of water quality issues. The advanced wastewater treatment segment, particularly technologies focused on nutrient removal like Membrane Bioreactor (MBR) systems with nitrification/denitrification capabilities, is projected to grow at a CAGR of 7.5% through 2030.

Municipal wastewater treatment represents the largest market segment for MBR nutrient removal technologies, accounting for approximately 65% of the total market share. This dominance stems from increasing urbanization and the need for compact treatment solutions in densely populated areas where MBR systems offer significant advantages due to their smaller footprint compared to conventional treatment methods.

Industrial applications constitute the fastest-growing segment, with food and beverage, pharmaceutical, and chemical industries leading adoption. These sectors face increasingly strict discharge regulations for nitrogen and phosphorus compounds, driving investment in advanced nutrient removal technologies. The pharmaceutical industry, in particular, has shown increased interest in MBR systems due to their ability to effectively remove both conventional pollutants and emerging contaminants.

Geographically, North America and Europe currently dominate the market for advanced nutrient removal technologies due to stringent regulatory frameworks. The EU Water Framework Directive and the U.S. Clean Water Act amendments have established increasingly stringent nitrogen and phosphorus discharge limits, creating substantial demand for technologies that can achieve enhanced nutrient removal.

The Asia-Pacific region represents the fastest-growing market, with China and India making significant investments in wastewater infrastructure. China's 14th Five-Year Plan specifically emphasizes water pollution control and advanced wastewater treatment, allocating substantial funding for upgrading existing facilities with nutrient removal capabilities.

Market research indicates that end-users are increasingly seeking integrated solutions that combine nutrient removal with energy efficiency and resource recovery. This trend has led to growing demand for process coupling technologies that integrate MBR systems with anaerobic processes, allowing for simultaneous nutrient removal and energy production through biogas generation.

The COVID-19 pandemic temporarily disrupted the market growth in 2020-2021 due to project delays and budget constraints. However, the market has shown strong recovery since 2022, with increased emphasis on water security and sustainable water management driving renewed investments in advanced treatment technologies.

Municipal wastewater treatment represents the largest market segment for MBR nutrient removal technologies, accounting for approximately 65% of the total market share. This dominance stems from increasing urbanization and the need for compact treatment solutions in densely populated areas where MBR systems offer significant advantages due to their smaller footprint compared to conventional treatment methods.

Industrial applications constitute the fastest-growing segment, with food and beverage, pharmaceutical, and chemical industries leading adoption. These sectors face increasingly strict discharge regulations for nitrogen and phosphorus compounds, driving investment in advanced nutrient removal technologies. The pharmaceutical industry, in particular, has shown increased interest in MBR systems due to their ability to effectively remove both conventional pollutants and emerging contaminants.

Geographically, North America and Europe currently dominate the market for advanced nutrient removal technologies due to stringent regulatory frameworks. The EU Water Framework Directive and the U.S. Clean Water Act amendments have established increasingly stringent nitrogen and phosphorus discharge limits, creating substantial demand for technologies that can achieve enhanced nutrient removal.

The Asia-Pacific region represents the fastest-growing market, with China and India making significant investments in wastewater infrastructure. China's 14th Five-Year Plan specifically emphasizes water pollution control and advanced wastewater treatment, allocating substantial funding for upgrading existing facilities with nutrient removal capabilities.

Market research indicates that end-users are increasingly seeking integrated solutions that combine nutrient removal with energy efficiency and resource recovery. This trend has led to growing demand for process coupling technologies that integrate MBR systems with anaerobic processes, allowing for simultaneous nutrient removal and energy production through biogas generation.

The COVID-19 pandemic temporarily disrupted the market growth in 2020-2021 due to project delays and budget constraints. However, the market has shown strong recovery since 2022, with increased emphasis on water security and sustainable water management driving renewed investments in advanced treatment technologies.

Current MBR Technology Status and Challenges

Membrane Bioreactor (MBR) technology has evolved significantly over the past two decades, establishing itself as a robust solution for wastewater treatment with enhanced nutrient removal capabilities. Currently, MBR systems are deployed in over 5,000 installations worldwide, with a market value exceeding $3 billion annually and growing at approximately 15% per year. The technology combines conventional biological treatment processes with membrane filtration, offering superior effluent quality compared to conventional activated sludge systems.

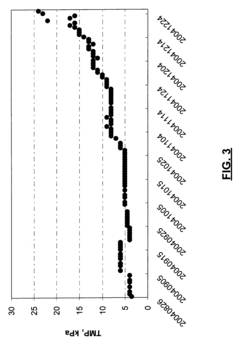

Despite its widespread adoption, MBR technology faces several critical challenges in the context of nutrient removal. The primary technical limitation remains membrane fouling, which significantly impacts operational efficiency and increases energy consumption. Biofouling, in particular, occurs when microorganisms and their extracellular polymeric substances (EPS) accumulate on membrane surfaces, reducing permeability by up to 80% in severe cases and necessitating frequent chemical cleaning cycles.

Energy consumption represents another substantial challenge, with current MBR systems requiring 0.8-1.2 kWh/m³ of treated water, approximately 30-50% higher than conventional treatment processes. This energy intensity is primarily attributed to aeration requirements for both biological processes and membrane scouring, creating a significant operational cost burden and limiting the technology's sustainability credentials.

The integration of nitrification and denitrification processes within MBR systems presents specific operational complexities. Achieving optimal conditions for both processes simultaneously remains difficult, as nitrification requires aerobic conditions while denitrification demands anoxic environments. Current configurations often struggle to maintain the precise dissolved oxygen gradients necessary for efficient nitrogen removal, resulting in removal efficiencies that typically plateau at 70-85% in full-scale applications.

Phosphorus removal capabilities in existing MBR systems are similarly constrained, with biological phosphorus removal often destabilized by the extended solids retention times characteristic of MBR operation. Chemical precipitation remains the predominant approach for phosphorus removal, introducing additional operational costs and generating increased chemical sludge volumes.

Geographically, MBR technology development shows distinct regional patterns. East Asia, particularly China and Japan, leads in terms of installation capacity and research output, while Europe focuses on energy optimization and North America emphasizes regulatory compliance solutions. Developing regions face significant barriers to MBR adoption, including high capital costs and limited technical expertise for system maintenance.

The scalability of nutrient removal MBR systems presents ongoing challenges, with diminishing efficiency observed in larger installations due to uneven flow distribution and membrane module configuration limitations. This has restricted the technology's application in very large municipal facilities exceeding 100,000 m³/day capacity.

Despite its widespread adoption, MBR technology faces several critical challenges in the context of nutrient removal. The primary technical limitation remains membrane fouling, which significantly impacts operational efficiency and increases energy consumption. Biofouling, in particular, occurs when microorganisms and their extracellular polymeric substances (EPS) accumulate on membrane surfaces, reducing permeability by up to 80% in severe cases and necessitating frequent chemical cleaning cycles.

Energy consumption represents another substantial challenge, with current MBR systems requiring 0.8-1.2 kWh/m³ of treated water, approximately 30-50% higher than conventional treatment processes. This energy intensity is primarily attributed to aeration requirements for both biological processes and membrane scouring, creating a significant operational cost burden and limiting the technology's sustainability credentials.

The integration of nitrification and denitrification processes within MBR systems presents specific operational complexities. Achieving optimal conditions for both processes simultaneously remains difficult, as nitrification requires aerobic conditions while denitrification demands anoxic environments. Current configurations often struggle to maintain the precise dissolved oxygen gradients necessary for efficient nitrogen removal, resulting in removal efficiencies that typically plateau at 70-85% in full-scale applications.

Phosphorus removal capabilities in existing MBR systems are similarly constrained, with biological phosphorus removal often destabilized by the extended solids retention times characteristic of MBR operation. Chemical precipitation remains the predominant approach for phosphorus removal, introducing additional operational costs and generating increased chemical sludge volumes.

Geographically, MBR technology development shows distinct regional patterns. East Asia, particularly China and Japan, leads in terms of installation capacity and research output, while Europe focuses on energy optimization and North America emphasizes regulatory compliance solutions. Developing regions face significant barriers to MBR adoption, including high capital costs and limited technical expertise for system maintenance.

The scalability of nutrient removal MBR systems presents ongoing challenges, with diminishing efficiency observed in larger installations due to uneven flow distribution and membrane module configuration limitations. This has restricted the technology's application in very large municipal facilities exceeding 100,000 m³/day capacity.

Current MBR Process Coupling Solutions

01 MBR system design for enhanced nitrification/denitrification

Specialized membrane bioreactor designs that optimize nutrient removal through strategic arrangement of aerobic and anoxic zones. These systems incorporate specific flow patterns and reactor configurations to enhance the biological processes of nitrification and denitrification, resulting in improved nitrogen removal efficiency from wastewater. The designs often include multiple treatment chambers with controlled oxygen conditions to support different microbial communities responsible for converting ammonia to nitrate and subsequently to nitrogen gas.- MBR systems with integrated nitrification-denitrification processes: Membrane bioreactor systems can be designed with specific zones or compartments to facilitate both nitrification and denitrification processes. These systems typically include aerobic zones where ammonia is oxidized to nitrate (nitrification) and anoxic zones where nitrate is reduced to nitrogen gas (denitrification). The integration of these processes within a single MBR system allows for efficient nutrient removal from wastewater while maintaining high effluent quality through membrane filtration.

- Advanced MBR configurations for enhanced nutrient removal: Various advanced configurations of membrane bioreactors have been developed to improve nutrient removal efficiency. These include sequencing batch MBRs, multi-stage MBRs, and hybrid systems combining MBR technology with other treatment processes. These configurations can be optimized to create ideal conditions for nitrifying and denitrifying bacteria, thereby enhancing the removal of nitrogen compounds from wastewater while minimizing energy consumption and operational costs.

- Biofilm-based MBR systems for nutrient removal: Biofilm-based membrane bioreactor systems utilize attached growth processes where microorganisms form biofilms on carriers or directly on membrane surfaces. These systems can create stratified microbial communities with aerobic nitrifying bacteria on the outer layers and anoxic denitrifying bacteria in deeper layers of the biofilm. This spatial arrangement allows for simultaneous nitrification and denitrification even within a single reactor, improving nitrogen removal efficiency while potentially reducing the footprint and energy requirements of the treatment system.

- Control strategies for optimizing nutrient removal in MBRs: Effective control strategies are essential for optimizing nutrient removal in membrane bioreactors. These strategies may include dissolved oxygen control, carbon dosing for denitrification, mixed liquor recirculation, and real-time monitoring of key parameters such as ammonia, nitrate, and phosphate concentrations. Advanced control systems can adjust operational parameters based on influent characteristics and treatment objectives, ensuring stable and efficient nitrification and denitrification processes while minimizing energy consumption and membrane fouling.

- Novel membrane materials and configurations for improved nutrient removal: Innovative membrane materials and configurations can significantly enhance nutrient removal in MBR systems. These innovations include membranes with modified surface properties to reduce fouling, composite membranes with selective permeability, and novel module designs that improve hydraulic conditions and mass transfer. Some membranes may incorporate specific functional groups or catalysts that facilitate biological processes or directly participate in nutrient transformation, thereby improving the overall efficiency of nitrification and denitrification processes in MBR systems.

02 Integration of advanced aeration control in MBR systems

Implementation of sophisticated aeration control strategies in membrane bioreactors to create optimal conditions for nitrification while supporting denitrification processes. These systems utilize sensors and automated controls to maintain precise dissolved oxygen levels in different zones of the bioreactor, reducing energy consumption while maximizing nutrient removal efficiency. Intermittent aeration techniques and oxygen gradient management are employed to create microenvironments that support both aerobic and anoxic microbial activities simultaneously.Expand Specific Solutions03 Novel membrane configurations for nutrient removal

Innovative membrane designs and configurations specifically developed to enhance nutrient removal capabilities in MBR systems. These include specialized membrane materials, module arrangements, and surface modifications that improve filtration efficiency while supporting the growth of nitrifying and denitrifying bacteria. Some designs incorporate biofilm carriers directly on membrane surfaces to increase the concentration of specialized microorganisms, while others feature compartmentalized membrane modules that create distinct treatment zones within a single system.Expand Specific Solutions04 Biological additives and microbial enhancement for MBR nutrient removal

Application of specialized microbial cultures, enzymes, and biological additives to enhance nitrification and denitrification processes in membrane bioreactors. These biological enhancements include the introduction of specific bacterial strains with high ammonia oxidation capabilities, bioaugmentation techniques to establish robust nitrifying and denitrifying communities, and the use of natural carriers to increase microbial retention within the system. Such approaches improve the stability and efficiency of nutrient removal, particularly under variable influent conditions or during system startup.Expand Specific Solutions05 Hybrid MBR systems combining multiple nutrient removal technologies

Integration of membrane bioreactors with complementary treatment technologies to achieve comprehensive nutrient removal. These hybrid systems combine MBR technology with processes such as moving bed biofilm reactors, anaerobic ammonium oxidation (Anammox), constructed wetlands, or chemical precipitation methods. By leveraging the strengths of multiple treatment approaches, these systems achieve higher removal efficiencies for nitrogen and phosphorus while potentially reducing operational costs and energy requirements compared to conventional MBR systems alone.Expand Specific Solutions

Leading Companies and Research Institutions in MBR Technology

The Membrane Bioreactor (MBR) Nutrient Removal market is currently in a growth phase, with increasing adoption driven by stringent wastewater regulations globally. The market size is expanding steadily, estimated to reach several billion dollars by 2025, with Asia-Pacific showing the fastest growth. Technologically, MBR systems for nitrification/denitrification are approaching maturity, with companies like Kemira Oyj, Sulzer AG, and BioGill Operations leading innovation in process coupling techniques. Academic institutions including Columbia University, Zhejiang University, and Boston University are advancing fundamental research, while industrial players such as China Petroleum & Chemical Corp. and BCR Environmental are implementing commercial-scale applications. The integration of MBR with other treatment processes represents the current technological frontier, with significant R&D investments focused on energy efficiency and nutrient recovery optimization.

Research Center For Eco-Environmental Sciences

Technical Solution: The Research Center for Eco-Environmental Sciences has developed advanced membrane bioreactor (MBR) systems specifically designed for enhanced nutrient removal through optimized nitrification/denitrification processes. Their technology employs a multi-stage biological treatment approach with specialized membrane configurations that create distinct aerobic and anoxic zones within a single reactor system. This design facilitates simultaneous nitrification (ammonia conversion to nitrate) in aerobic zones and denitrification (nitrate conversion to nitrogen gas) in anoxic zones. The center has pioneered the integration of biofilm carriers within MBRs to increase the microbial population density and diversity, significantly improving nitrogen removal efficiency while maintaining a smaller footprint compared to conventional systems. Their process coupling innovation includes strategic internal recirculation patterns that optimize carbon utilization and reduce the need for external carbon sources during denitrification, making the system more economically viable for municipal and industrial applications.

Strengths: Superior nitrogen removal efficiency (>90%) even at low temperatures; reduced footprint compared to conventional systems; lower operational costs through optimized carbon utilization. Weaknesses: Higher initial capital investment; requires more sophisticated control systems; potential for membrane fouling in high-load applications requiring frequent maintenance.

Zhejiang University

Technical Solution: Zhejiang University has developed an innovative Simultaneous Nitrification-Denitrification Membrane Bioreactor (SND-MBR) system that achieves efficient nutrient removal through process intensification. Their technology creates micro-environments within a single reactor where both aerobic and anoxic conditions coexist, allowing nitrification and denitrification to occur simultaneously. The system employs specially designed hollow fiber membranes with controlled oxygen transfer rates that create oxygen gradients within bacterial flocs. The outer layers of these flocs maintain aerobic conditions for nitrification while the inner cores remain anoxic for denitrification. This approach eliminates the need for separate reactors or recirculation systems. Zhejiang University researchers have also incorporated novel biomedia carriers with high specific surface area to enhance microbial attachment and activity, resulting in improved nitrogen removal rates. Their process coupling strategy includes integrating phosphorus removal mechanisms through the selection of phosphorus accumulating organisms (PAOs) that can function effectively within the SND-MBR environment, achieving comprehensive nutrient removal in a single system.

Strengths: Significantly reduced system footprint and infrastructure requirements; lower energy consumption compared to conventional MBR systems; simplified operation without the need for internal recirculation. Weaknesses: Requires precise control of dissolved oxygen levels; may have limitations in handling extreme load variations; potential challenges in maintaining optimal microbial community structure over long-term operation.

Key Patents and Innovations in Nutrient Removal

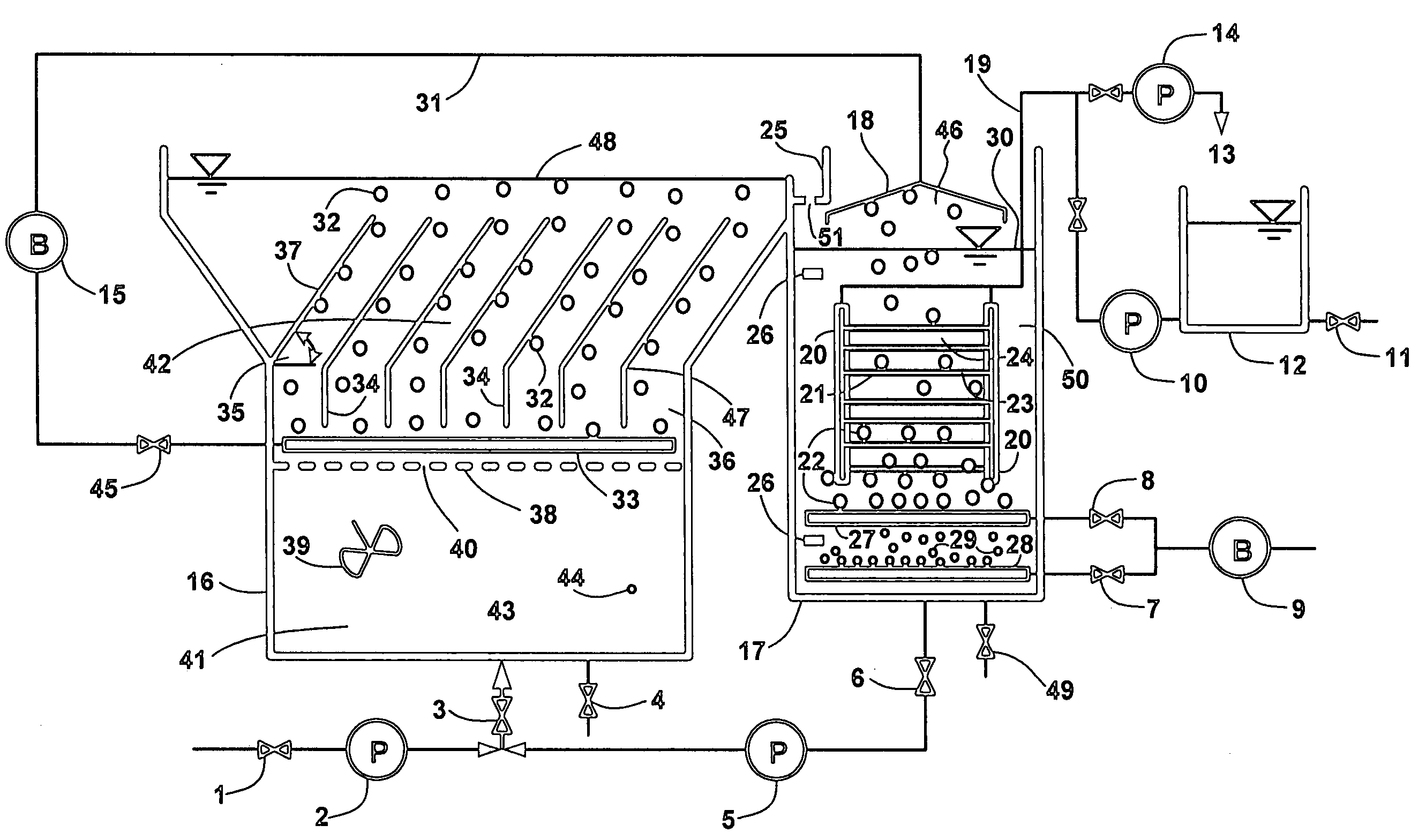

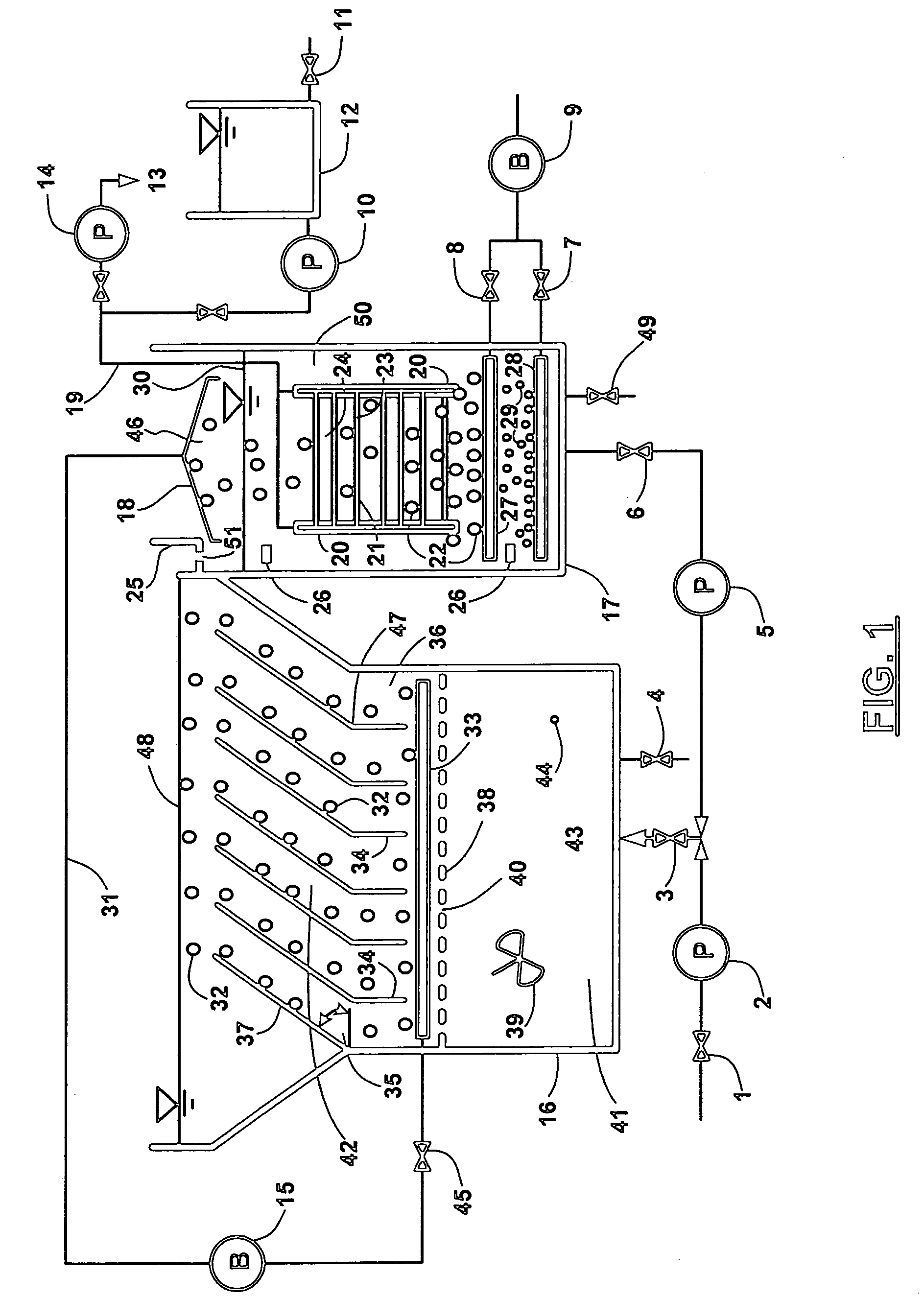

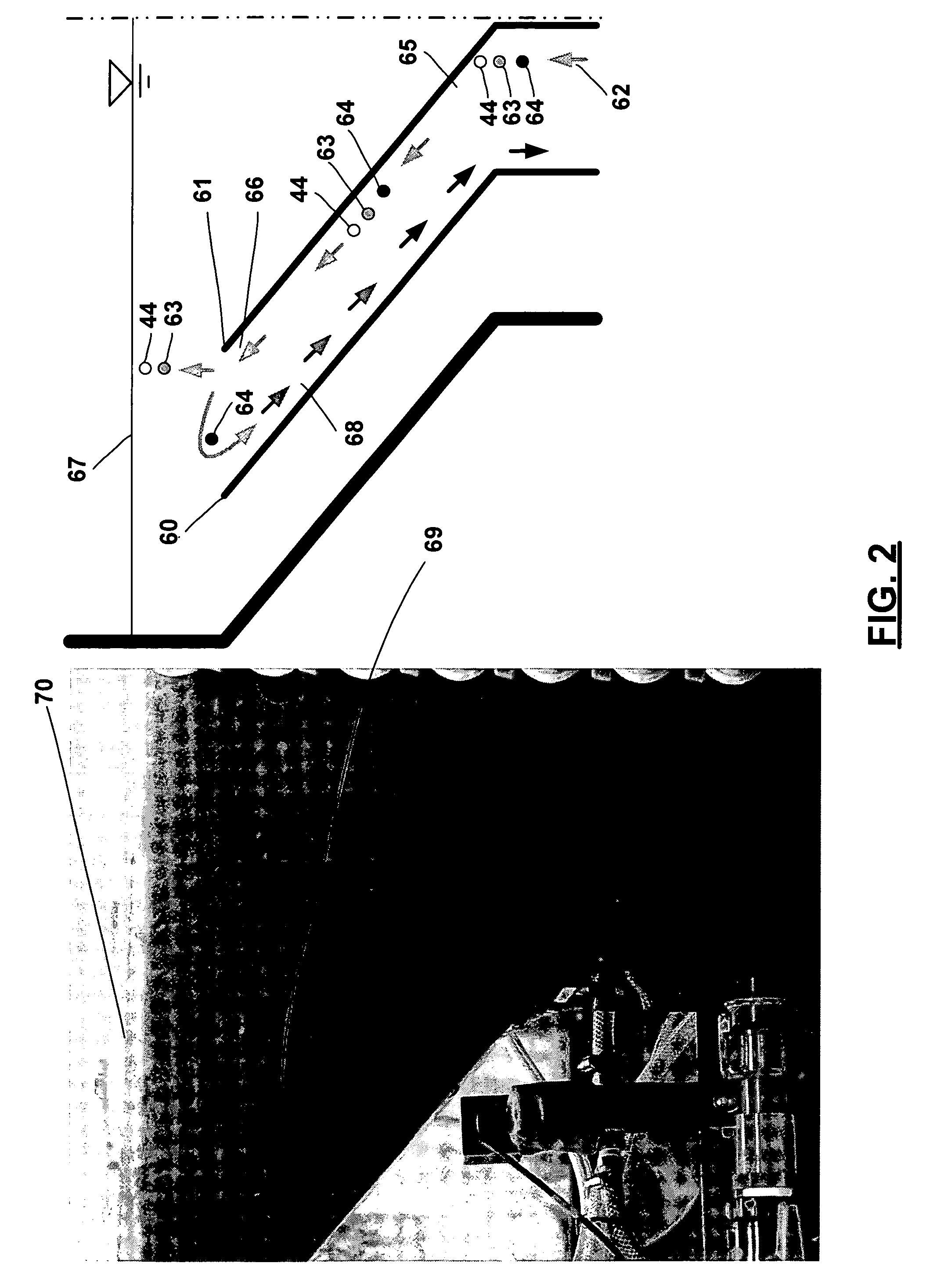

Zero excess sludge membrane bioreactor

PatentInactiveUS7311833B2

Innovation

- A membrane bioreactor system incorporating a compact aerobic bioreactor with submerged membranes and an anoxic bioreactor using movable inclined plates for continuous nitrification and denitrification, where the anoxic sludge concentration is maintained above 10 g/L, and aerobic sludge concentration is kept below 10 g/L, with adjustable inclined plates and air scouring to manage sludge settling and fouling.

Environmental Regulations and Compliance Standards

The regulatory landscape governing membrane bioreactor (MBR) nutrient removal processes has become increasingly stringent worldwide, reflecting growing concerns about water quality and ecosystem health. In the United States, the Clean Water Act establishes the National Pollutant Discharge Elimination System (NPDES) permit program, which sets specific effluent limitations for wastewater treatment facilities. These regulations typically mandate maximum allowable concentrations for total nitrogen (often between 3-10 mg/L) and total phosphorus (frequently below 1 mg/L), depending on the receiving water body's classification and sensitivity.

The European Union's Water Framework Directive and Urban Waste Water Treatment Directive impose similarly strict requirements, with many member states implementing even more stringent standards in environmentally sensitive areas. For instance, facilities discharging into designated "sensitive areas" must achieve nitrogen removal efficiencies of at least 70-80% and phosphorus removal of 80% or higher.

In Asia, rapidly industrializing nations like China have enacted the Discharge Standard of Pollutants for Municipal Wastewater Treatment Plants (GB 18918-2002), which establishes a tiered classification system with Class IA representing the most stringent standards for sensitive water bodies. Japan's effluent standards are particularly rigorous, often requiring total nitrogen concentrations below 10 mg/L and total phosphorus below 1 mg/L.

Compliance monitoring requirements present additional challenges for MBR operators. Most regulatory frameworks mandate regular sampling and analysis of influent and effluent streams, with frequencies ranging from daily to monthly depending on facility size and discharge sensitivity. Online monitoring systems for parameters such as ammonia, nitrate, and orthophosphate are increasingly becoming standard requirements for larger facilities.

Emerging regulatory trends indicate a shift toward watershed-based permitting approaches that consider cumulative impacts of multiple dischargers within a watershed. This holistic approach often results in more stringent nutrient limits for individual facilities based on total maximum daily load (TMDL) calculations for the receiving water body. Additionally, several jurisdictions are implementing seasonal variation in permitted discharge limits, recognizing that ecosystem sensitivity to nutrient loading varies throughout the year.

The economic implications of these regulations are substantial. Capital investments for advanced MBR systems with enhanced nutrient removal capabilities typically range from $15-25 million for medium-sized facilities (5-10 MGD), with operating costs approximately 20-30% higher than conventional activated sludge systems. Non-compliance penalties can be severe, often exceeding $10,000 per violation day in the United States and similar proportional amounts in other developed nations.

The European Union's Water Framework Directive and Urban Waste Water Treatment Directive impose similarly strict requirements, with many member states implementing even more stringent standards in environmentally sensitive areas. For instance, facilities discharging into designated "sensitive areas" must achieve nitrogen removal efficiencies of at least 70-80% and phosphorus removal of 80% or higher.

In Asia, rapidly industrializing nations like China have enacted the Discharge Standard of Pollutants for Municipal Wastewater Treatment Plants (GB 18918-2002), which establishes a tiered classification system with Class IA representing the most stringent standards for sensitive water bodies. Japan's effluent standards are particularly rigorous, often requiring total nitrogen concentrations below 10 mg/L and total phosphorus below 1 mg/L.

Compliance monitoring requirements present additional challenges for MBR operators. Most regulatory frameworks mandate regular sampling and analysis of influent and effluent streams, with frequencies ranging from daily to monthly depending on facility size and discharge sensitivity. Online monitoring systems for parameters such as ammonia, nitrate, and orthophosphate are increasingly becoming standard requirements for larger facilities.

Emerging regulatory trends indicate a shift toward watershed-based permitting approaches that consider cumulative impacts of multiple dischargers within a watershed. This holistic approach often results in more stringent nutrient limits for individual facilities based on total maximum daily load (TMDL) calculations for the receiving water body. Additionally, several jurisdictions are implementing seasonal variation in permitted discharge limits, recognizing that ecosystem sensitivity to nutrient loading varies throughout the year.

The economic implications of these regulations are substantial. Capital investments for advanced MBR systems with enhanced nutrient removal capabilities typically range from $15-25 million for medium-sized facilities (5-10 MGD), with operating costs approximately 20-30% higher than conventional activated sludge systems. Non-compliance penalties can be severe, often exceeding $10,000 per violation day in the United States and similar proportional amounts in other developed nations.

Energy Efficiency and Operational Cost Analysis

Energy efficiency represents a critical factor in the operational viability of Membrane Bioreactor (MBR) systems for nutrient removal. Current analysis indicates that energy consumption in MBR systems typically ranges from 0.8 to 2.0 kWh/m³ of treated wastewater, significantly higher than conventional activated sludge processes which average 0.3-0.6 kWh/m³. This differential primarily stems from the energy requirements for membrane aeration, which accounts for approximately 40-60% of total operational energy consumption.

The integration of nitrification/denitrification processes within MBR systems introduces additional energy considerations. Nitrification, being an aerobic process, demands substantial oxygen supply, while denitrification requires anoxic conditions with supplementary carbon sources. Recent technological innovations have demonstrated potential energy savings of 20-30% through implementation of intermittent aeration strategies and advanced process control systems that optimize oxygen transfer efficiency.

Operational cost analysis reveals that energy expenses typically constitute 30-40% of total operational costs in MBR nutrient removal systems. A comprehensive five-year cost assessment across multiple facilities indicates that membrane replacement (15-25%) and chemical cleaning (10-15%) represent the next most significant operational expenditures. Labor costs generally account for 8-12% of operational expenses, with maintenance and repairs comprising the remainder.

Process coupling strategies have demonstrated promising cost-efficiency improvements. Specifically, the integration of anaerobic ammonium oxidation (anammox) processes with conventional nitrification has shown potential to reduce aeration energy requirements by up to 60% and eliminate the need for external carbon addition. Similarly, simultaneous nitrification-denitrification configurations can decrease energy consumption by 25-35% compared to traditional sequential processes.

Recent advancements in membrane technology have yielded energy-efficient materials with lower fouling propensities, reducing the frequency and intensity of required cleaning operations. These innovations have demonstrated potential operational cost reductions of 15-20% over conventional membranes. Additionally, the implementation of energy recovery systems, particularly in larger installations, has shown capability to recapture 10-15% of energy inputs through biogas utilization and heat recovery mechanisms.

Comparative analysis between different MBR configurations reveals that submerged membrane systems generally offer superior energy efficiency compared to side-stream alternatives, with energy savings of approximately 30-40%. However, this advantage must be balanced against higher membrane replacement costs and more complex maintenance requirements in submerged systems.

The integration of nitrification/denitrification processes within MBR systems introduces additional energy considerations. Nitrification, being an aerobic process, demands substantial oxygen supply, while denitrification requires anoxic conditions with supplementary carbon sources. Recent technological innovations have demonstrated potential energy savings of 20-30% through implementation of intermittent aeration strategies and advanced process control systems that optimize oxygen transfer efficiency.

Operational cost analysis reveals that energy expenses typically constitute 30-40% of total operational costs in MBR nutrient removal systems. A comprehensive five-year cost assessment across multiple facilities indicates that membrane replacement (15-25%) and chemical cleaning (10-15%) represent the next most significant operational expenditures. Labor costs generally account for 8-12% of operational expenses, with maintenance and repairs comprising the remainder.

Process coupling strategies have demonstrated promising cost-efficiency improvements. Specifically, the integration of anaerobic ammonium oxidation (anammox) processes with conventional nitrification has shown potential to reduce aeration energy requirements by up to 60% and eliminate the need for external carbon addition. Similarly, simultaneous nitrification-denitrification configurations can decrease energy consumption by 25-35% compared to traditional sequential processes.

Recent advancements in membrane technology have yielded energy-efficient materials with lower fouling propensities, reducing the frequency and intensity of required cleaning operations. These innovations have demonstrated potential operational cost reductions of 15-20% over conventional membranes. Additionally, the implementation of energy recovery systems, particularly in larger installations, has shown capability to recapture 10-15% of energy inputs through biogas utilization and heat recovery mechanisms.

Comparative analysis between different MBR configurations reveals that submerged membrane systems generally offer superior energy efficiency compared to side-stream alternatives, with energy savings of approximately 30-40%. However, this advantage must be balanced against higher membrane replacement costs and more complex maintenance requirements in submerged systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!