Membrane Bioreactor Vs Conventional Activated Sludge: Footprint, Effluent Quality And Energy

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MBR vs CAS Technology Evolution and Objectives

Wastewater treatment technologies have evolved significantly over the past century, with Conventional Activated Sludge (CAS) systems serving as the backbone of municipal and industrial wastewater treatment since the early 1900s. The CAS process, characterized by its biological degradation of organic matter through suspended microorganisms, has undergone numerous refinements but remained fundamentally unchanged in its core principles for decades.

The emergence of Membrane Bioreactor (MBR) technology in the 1960s marked a pivotal shift in wastewater treatment approaches. Initially developed as a laboratory-scale concept, MBR systems integrated membrane filtration with biological treatment, offering a revolutionary alternative to conventional separation methods. However, early MBR systems faced significant challenges including membrane fouling, high energy consumption, and prohibitive costs, limiting their practical application.

The 1990s witnessed a technological breakthrough with the development of submerged membrane configurations, substantially reducing energy requirements and operational complexity. This innovation catalyzed the commercial viability of MBR systems, leading to their gradual adoption in municipal and industrial applications where space constraints or stringent effluent quality requirements prevailed.

The technological evolution trajectory of both systems has been driven by increasing regulatory pressures on effluent quality, urbanization-induced space limitations, and growing emphasis on energy efficiency and operational sustainability. CAS systems have evolved through improvements in aeration systems, clarifier designs, and process control strategies, while MBR technology has advanced through membrane material innovations, module configurations, and fouling control mechanisms.

Current technological objectives in the MBR versus CAS comparison center around three critical parameters: footprint optimization, effluent quality enhancement, and energy efficiency. The industry aims to develop MBR systems with reduced membrane fouling propensity, lower specific energy consumption, and extended membrane lifespans to improve their competitive position against optimized CAS alternatives.

Simultaneously, research efforts focus on enhancing CAS performance through advanced process control, innovative settler designs, and integration with tertiary treatment technologies to narrow the effluent quality gap with MBR systems while maintaining their energy advantage. The convergence of these technological trajectories suggests a future where hybrid systems may capitalize on the strengths of both approaches.

The ultimate objective remains developing wastewater treatment solutions that balance the competing demands of space efficiency, treatment performance, and energy consumption while adapting to emerging challenges such as micropollutant removal, resource recovery, and climate change resilience.

The emergence of Membrane Bioreactor (MBR) technology in the 1960s marked a pivotal shift in wastewater treatment approaches. Initially developed as a laboratory-scale concept, MBR systems integrated membrane filtration with biological treatment, offering a revolutionary alternative to conventional separation methods. However, early MBR systems faced significant challenges including membrane fouling, high energy consumption, and prohibitive costs, limiting their practical application.

The 1990s witnessed a technological breakthrough with the development of submerged membrane configurations, substantially reducing energy requirements and operational complexity. This innovation catalyzed the commercial viability of MBR systems, leading to their gradual adoption in municipal and industrial applications where space constraints or stringent effluent quality requirements prevailed.

The technological evolution trajectory of both systems has been driven by increasing regulatory pressures on effluent quality, urbanization-induced space limitations, and growing emphasis on energy efficiency and operational sustainability. CAS systems have evolved through improvements in aeration systems, clarifier designs, and process control strategies, while MBR technology has advanced through membrane material innovations, module configurations, and fouling control mechanisms.

Current technological objectives in the MBR versus CAS comparison center around three critical parameters: footprint optimization, effluent quality enhancement, and energy efficiency. The industry aims to develop MBR systems with reduced membrane fouling propensity, lower specific energy consumption, and extended membrane lifespans to improve their competitive position against optimized CAS alternatives.

Simultaneously, research efforts focus on enhancing CAS performance through advanced process control, innovative settler designs, and integration with tertiary treatment technologies to narrow the effluent quality gap with MBR systems while maintaining their energy advantage. The convergence of these technological trajectories suggests a future where hybrid systems may capitalize on the strengths of both approaches.

The ultimate objective remains developing wastewater treatment solutions that balance the competing demands of space efficiency, treatment performance, and energy consumption while adapting to emerging challenges such as micropollutant removal, resource recovery, and climate change resilience.

Wastewater Treatment Market Demand Analysis

The global wastewater treatment market is experiencing significant growth driven by increasing water scarcity, stringent environmental regulations, and growing awareness about water quality. The market was valued at approximately $250 billion in 2022 and is projected to reach $375 billion by 2028, growing at a CAGR of 7.2% during the forecast period.

Membrane Bioreactor (MBR) technology is gaining substantial traction within this market due to its superior effluent quality and smaller footprint compared to Conventional Activated Sludge (CAS) systems. The MBR segment is growing at a faster rate of 9.5% annually, outpacing the overall market growth, indicating a shift in preference toward more advanced treatment technologies.

Municipal wastewater treatment represents the largest application segment, accounting for 65% of the total market share. However, industrial applications are growing rapidly at 8.3% annually as manufacturing facilities face increasingly strict discharge regulations and water reuse requirements. Industries such as pharmaceuticals, food and beverage, and textiles are particularly driving demand for advanced treatment solutions like MBR.

Regionally, Asia-Pacific dominates the wastewater treatment market with a 38% share, followed by North America (25%) and Europe (22%). China and India are experiencing the fastest growth rates due to rapid industrialization, urbanization, and government initiatives to address water pollution. The Middle East region shows particular interest in MBR technology due to severe water scarcity and the need for water reuse.

The demand for smaller footprint solutions is particularly strong in urban areas where space constraints are significant. This trend favors MBR systems, which typically require 30-50% less space than conventional systems. Market research indicates that 72% of new municipal installations in densely populated urban centers are considering space-efficient technologies as a primary selection criterion.

Energy efficiency has emerged as a critical factor influencing technology selection, with 68% of utility managers citing operational costs as a key decision driver. While MBR systems traditionally consume more energy than CAS systems, recent technological innovations have reduced this gap, with new-generation MBRs demonstrating only 15-20% higher energy consumption compared to the 30-40% difference observed in earlier generations.

Water reuse applications represent the fastest-growing segment within the wastewater treatment market, expanding at 11.2% annually. This growth is directly benefiting MBR technology due to its superior effluent quality that requires minimal additional treatment for reuse applications. Market surveys indicate that 78% of water reuse projects implemented in the last five years have utilized MBR technology.

Membrane Bioreactor (MBR) technology is gaining substantial traction within this market due to its superior effluent quality and smaller footprint compared to Conventional Activated Sludge (CAS) systems. The MBR segment is growing at a faster rate of 9.5% annually, outpacing the overall market growth, indicating a shift in preference toward more advanced treatment technologies.

Municipal wastewater treatment represents the largest application segment, accounting for 65% of the total market share. However, industrial applications are growing rapidly at 8.3% annually as manufacturing facilities face increasingly strict discharge regulations and water reuse requirements. Industries such as pharmaceuticals, food and beverage, and textiles are particularly driving demand for advanced treatment solutions like MBR.

Regionally, Asia-Pacific dominates the wastewater treatment market with a 38% share, followed by North America (25%) and Europe (22%). China and India are experiencing the fastest growth rates due to rapid industrialization, urbanization, and government initiatives to address water pollution. The Middle East region shows particular interest in MBR technology due to severe water scarcity and the need for water reuse.

The demand for smaller footprint solutions is particularly strong in urban areas where space constraints are significant. This trend favors MBR systems, which typically require 30-50% less space than conventional systems. Market research indicates that 72% of new municipal installations in densely populated urban centers are considering space-efficient technologies as a primary selection criterion.

Energy efficiency has emerged as a critical factor influencing technology selection, with 68% of utility managers citing operational costs as a key decision driver. While MBR systems traditionally consume more energy than CAS systems, recent technological innovations have reduced this gap, with new-generation MBRs demonstrating only 15-20% higher energy consumption compared to the 30-40% difference observed in earlier generations.

Water reuse applications represent the fastest-growing segment within the wastewater treatment market, expanding at 11.2% annually. This growth is directly benefiting MBR technology due to its superior effluent quality that requires minimal additional treatment for reuse applications. Market surveys indicate that 78% of water reuse projects implemented in the last five years have utilized MBR technology.

Current Technical Challenges in MBR and CAS Systems

Membrane Bioreactor (MBR) and Conventional Activated Sludge (CAS) systems both face significant technical challenges that impact their performance, efficiency, and adoption rates. Despite MBR's growing popularity, it continues to struggle with membrane fouling issues, which remain the primary operational challenge. Fouling occurs when solids, colloids, and biological materials accumulate on membrane surfaces, restricting flow and increasing transmembrane pressure. This necessitates frequent chemical cleaning and potentially membrane replacement, adding to operational costs and system downtime.

Energy consumption represents another critical challenge for MBR systems. They typically require 20-50% more energy than CAS systems due to the need for membrane aeration to control fouling and maintain permeate flux. This higher energy demand directly impacts operational expenses and carbon footprint, making MBR less attractive for facilities with limited energy resources or sustainability targets.

For CAS systems, the primary technical challenge remains their large physical footprint requirement. The need for separate secondary clarifiers and often tertiary treatment units demands substantial land area, limiting their applicability in urban or space-constrained environments. This spatial inefficiency becomes increasingly problematic as land values rise and available space for wastewater treatment diminishes in developing urban areas.

Effluent quality consistency presents an ongoing challenge for CAS systems. They are more susceptible to operational upsets from hydraulic or organic loading variations, resulting in inconsistent treatment performance. Sludge bulking and poor settling in secondary clarifiers can lead to elevated suspended solids in the effluent, compromising discharge quality and compliance with increasingly stringent regulatory standards.

Both technologies face challenges related to nutrient removal capabilities. While MBRs generally perform better in this regard, achieving consistent and simultaneous nitrogen and phosphorus removal remains technically demanding for both systems, often requiring additional process modifications or chemical additions.

Operational complexity and expertise requirements present barriers to widespread adoption, particularly for MBR systems. The sophisticated control systems, membrane maintenance protocols, and troubleshooting procedures demand higher operator skill levels than conventional systems, creating implementation challenges in regions with limited technical expertise or training resources.

Cost considerations remain significant for both technologies. MBR systems face higher capital expenditure due to membrane costs and more complex instrumentation, while CAS systems often require greater land acquisition expenses and potentially additional treatment stages to match MBR effluent quality. Finding the optimal balance between capital investment, operational expenses, and performance outcomes continues to challenge engineers and decision-makers in the wastewater treatment sector.

Energy consumption represents another critical challenge for MBR systems. They typically require 20-50% more energy than CAS systems due to the need for membrane aeration to control fouling and maintain permeate flux. This higher energy demand directly impacts operational expenses and carbon footprint, making MBR less attractive for facilities with limited energy resources or sustainability targets.

For CAS systems, the primary technical challenge remains their large physical footprint requirement. The need for separate secondary clarifiers and often tertiary treatment units demands substantial land area, limiting their applicability in urban or space-constrained environments. This spatial inefficiency becomes increasingly problematic as land values rise and available space for wastewater treatment diminishes in developing urban areas.

Effluent quality consistency presents an ongoing challenge for CAS systems. They are more susceptible to operational upsets from hydraulic or organic loading variations, resulting in inconsistent treatment performance. Sludge bulking and poor settling in secondary clarifiers can lead to elevated suspended solids in the effluent, compromising discharge quality and compliance with increasingly stringent regulatory standards.

Both technologies face challenges related to nutrient removal capabilities. While MBRs generally perform better in this regard, achieving consistent and simultaneous nitrogen and phosphorus removal remains technically demanding for both systems, often requiring additional process modifications or chemical additions.

Operational complexity and expertise requirements present barriers to widespread adoption, particularly for MBR systems. The sophisticated control systems, membrane maintenance protocols, and troubleshooting procedures demand higher operator skill levels than conventional systems, creating implementation challenges in regions with limited technical expertise or training resources.

Cost considerations remain significant for both technologies. MBR systems face higher capital expenditure due to membrane costs and more complex instrumentation, while CAS systems often require greater land acquisition expenses and potentially additional treatment stages to match MBR effluent quality. Finding the optimal balance between capital investment, operational expenses, and performance outcomes continues to challenge engineers and decision-makers in the wastewater treatment sector.

Comparative Analysis of MBR and CAS Implementation Strategies

01 Footprint comparison between MBR and CAS systems

Membrane Bioreactor (MBR) systems generally require significantly less space compared to Conventional Activated Sludge (CAS) systems. This reduced footprint is primarily due to the elimination of secondary clarifiers and the ability to operate at higher mixed liquor suspended solids (MLSS) concentrations. MBR systems can achieve the same treatment capacity in approximately 30-50% of the space required by CAS systems, making them particularly advantageous for installations with space constraints or for facility upgrades without expanding the physical plant.- Footprint comparison between MBR and CAS systems: Membrane Bioreactor (MBR) systems generally require significantly less space compared to Conventional Activated Sludge (CAS) systems. This reduced footprint is primarily due to the elimination of secondary clarifiers and the ability to operate at higher mixed liquor suspended solids (MLSS) concentrations. MBR systems can achieve the same treatment capacity in approximately 30-50% of the space required for CAS systems, making them particularly advantageous for installations with space constraints or for facility upgrades without expanding the physical plant.

- Effluent quality differences between MBR and CAS: MBR systems consistently produce higher quality effluent compared to CAS systems. The membrane filtration component in MBRs provides an absolute barrier to suspended solids and microorganisms, resulting in effluent with very low turbidity, virtually complete removal of bacteria and pathogens, and significantly reduced levels of biochemical oxygen demand (BOD) and chemical oxygen demand (COD). This superior effluent quality makes MBR systems particularly suitable for applications requiring water reuse or discharge into environmentally sensitive areas, whereas CAS systems typically require additional tertiary treatment to achieve comparable quality.

- Energy consumption comparison in wastewater treatment systems: MBR systems generally consume more energy than CAS systems, primarily due to the additional energy required for membrane aeration and permeate pumping. The energy consumption of MBR systems typically ranges from 0.8-1.2 kWh/m³ of treated wastewater, compared to 0.3-0.6 kWh/m³ for CAS systems. However, recent technological advancements have focused on reducing the energy footprint of MBR systems through improved membrane designs, more efficient aeration systems, and optimized operational strategies, narrowing the energy efficiency gap between the two technologies.

- Hybrid and integrated MBR-CAS systems: Hybrid and integrated systems combining elements of both MBR and CAS technologies have been developed to leverage the advantages of each while mitigating their respective limitations. These systems may incorporate partial membrane filtration alongside conventional clarification, allowing for operational flexibility, reduced energy consumption compared to full MBR systems, and improved effluent quality compared to standard CAS systems. Such hybrid approaches can be particularly beneficial for retrofitting existing CAS plants to achieve higher treatment standards without complete system replacement, offering a balance between performance enhancement and capital investment.

- Operational considerations and maintenance requirements: MBR and CAS systems differ significantly in their operational and maintenance requirements. MBR systems require more specialized maintenance due to membrane fouling issues, necessitating regular chemical cleaning and occasional membrane replacement. They also demand more sophisticated monitoring and control systems. CAS systems are generally simpler to operate but may require more operator attention for managing sludge settling properties and clarifier performance. The operational complexity of MBR systems typically results in higher skilled labor requirements and maintenance costs, though they offer greater process stability and resilience to influent variations compared to CAS systems.

02 Effluent quality differences between MBR and CAS

MBR systems consistently produce higher quality effluent compared to CAS systems. The membrane filtration component in MBRs provides an absolute barrier to suspended solids and microorganisms, resulting in effluent with very low turbidity, virtually complete removal of bacteria and pathogens, and significantly reduced levels of biochemical oxygen demand (BOD) and chemical oxygen demand (COD). This superior effluent quality makes MBR systems particularly suitable for applications requiring water reuse or discharge into environmentally sensitive areas, whereas CAS systems typically require additional tertiary treatment to achieve comparable quality.Expand Specific Solutions03 Energy consumption comparison in wastewater treatment systems

MBR systems generally consume more energy than CAS systems, primarily due to the additional energy required for membrane aeration and permeate pumping. The energy consumption of MBR systems typically ranges from 0.8-1.2 kWh/m³ of treated wastewater, compared to 0.3-0.6 kWh/m³ for CAS systems. However, recent technological advancements have focused on reducing the energy footprint of MBR systems through improved membrane designs, more efficient aeration systems, and optimized operational strategies such as intermittent aeration and intelligent control systems.Expand Specific Solutions04 Hybrid and integrated MBR-CAS systems

Hybrid systems combining elements of both MBR and CAS technologies have been developed to leverage the advantages of each while mitigating their respective limitations. These systems typically incorporate membrane filtration into specific treatment zones while maintaining conventional clarification in others, or employ flexible operational modes that can switch between MBR and CAS configurations based on treatment demands. Such hybrid approaches can optimize the balance between treatment efficiency, effluent quality, and energy consumption, providing more sustainable solutions for wastewater treatment facilities facing varying influent characteristics or seasonal fluctuations.Expand Specific Solutions05 Operational considerations and maintenance requirements

MBR systems typically require more sophisticated operational management and maintenance compared to CAS systems, primarily due to membrane fouling issues. Membrane cleaning and replacement represent significant operational costs for MBR systems, with chemical cleaning required periodically and membrane replacement typically necessary every 5-10 years. Conversely, CAS systems have simpler operational requirements but may face challenges with sludge settling and bulking issues. The higher MLSS concentrations in MBR systems also result in different sludge handling characteristics, potentially affecting dewatering efficiency and disposal costs compared to CAS systems.Expand Specific Solutions

Leading Companies in Membrane and Activated Sludge Technologies

The membrane bioreactor (MBR) versus conventional activated sludge (CAS) technology landscape is currently in a mature growth phase, with the global MBR market expected to reach $8.27 billion by 2025. MBR technology offers significant advantages in footprint reduction (60-70% smaller than CAS systems) and superior effluent quality, though typically requires 10-20% more energy. The competitive landscape features established water treatment specialists like Degremont SA, Kubota Corp, and General Electric Company providing comprehensive MBR solutions, while innovative companies such as Aquatech International and Microvi Biotech are developing energy-efficient MBR variants. Academic institutions including Nanyang Technological University and Tongji University are actively researching optimization techniques to address energy consumption challenges, the primary barrier to wider MBR adoption.

Degremont SA

Technical Solution: Degremont (now part of SUEZ) has developed the Ultrafor™ MBR system that combines biological treatment with ultrafiltration membranes. Their technology employs hollow fiber PVDF membranes with pore sizes of 0.03-0.1μm, achieving superior pathogen removal (>4-log removal of bacteria and >2-log removal of viruses). The Ultrafor™ system operates with a 60-80% smaller footprint than equivalent CAS plants while producing effluent with consistently <2 mg/L BOD, <0.5 mg/L TSS, and significantly reduced nitrogen and phosphorus levels. Degremont's energy efficiency approach includes their proprietary AirLift™ aeration system that reduces energy consumption by up to 25% compared to conventional MBR designs. Their system incorporates intelligent control algorithms that optimize membrane cleaning cycles based on real-time fouling measurements, extending membrane life while minimizing chemical usage. The technology allows for operation at higher MLSS concentrations (12,000-18,000 mg/L) and incorporates anoxic zones for enhanced nutrient removal.

Strengths: Exceptional effluent quality suitable for stringent discharge requirements or water reuse; advanced control systems that optimize energy usage; proven track record in large municipal installations worldwide. Weaknesses: Higher capital and operational costs compared to CAS; membrane fouling can still be problematic in certain wastewater compositions; requires specialized maintenance expertise.

Zenon Technology Partnership

Technical Solution: Zenon (acquired by GE, now SUEZ) pioneered the ZeeWeed® ultrafiltration membrane technology that revolutionized MBR systems. Their hollow-fiber PVDF membranes with 0.04μm pore size operate in an outside-in filtration mode, allowing for effective backwashing and cleaning. Zenon's MBR systems achieve 60-70% smaller footprint compared to conventional activated sludge while producing consistently superior effluent quality with turbidity <0.1 NTU, TSS <1 mg/L, and BOD <5 mg/L. Their energy optimization approach includes the innovative air cycling technology that reduces air scouring requirements by up to 50% compared to continuous aeration systems. The technology operates at elevated MLSS concentrations (10,000-15,000 mg/L) and incorporates advanced process control algorithms that adjust membrane flux rates and cleaning cycles based on influent characteristics and membrane performance metrics. Zenon's systems feature modular cassette designs that facilitate easy maintenance and membrane replacement without system shutdown, significantly reducing operational disruptions.

Strengths: Proven technology with thousands of installations worldwide; excellent effluent quality suitable for water reuse applications; modular design allowing for phased implementation and expansion. Weaknesses: Energy consumption remains higher than optimized CAS systems despite efficiency improvements; membrane replacement costs contribute significantly to lifecycle expenses; requires regular chemical cleaning to maintain optimal performance.

Key Patents and Innovations in Membrane Filtration

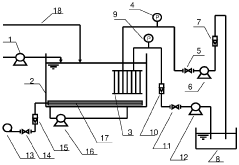

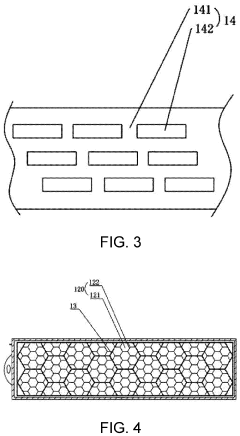

Membrane bioreactor with micro stainless steel wire mesh filtration module for wastewater treatment

PatentInactiveSG173242A1

Innovation

- The integration of micro stainless steel wire mesh filtration modules with pore sizes ranging from 1 to 10 μm, combined with an automatically-controlled suction and back-washing system, to enhance filtration efficiency and reduce maintenance needs.

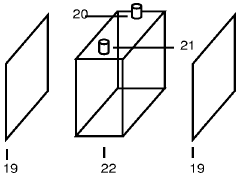

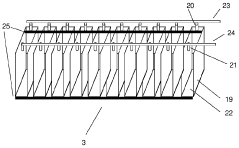

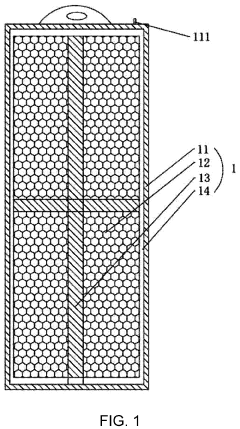

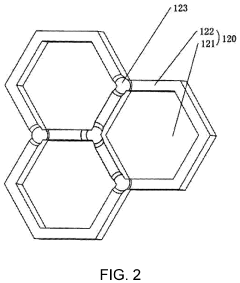

Flat membrane support plate

PatentActiveUS20210171374A1

Innovation

- A flat membrane support plate with a honeycomb structural portion and support units, featuring through-holes and flow channels that reduce material usage and enhance stability, while maintaining rigidity and reducing transmembrane pressure differences.

Environmental Impact Assessment of Treatment Technologies

The environmental impact assessment of wastewater treatment technologies requires comprehensive analysis of both Membrane Bioreactor (MBR) and Conventional Activated Sludge (CAS) systems across multiple ecological dimensions. These technologies differ significantly in their environmental footprints, with implications for sustainable water management practices globally.

MBR systems demonstrate superior environmental performance in terms of effluent quality, producing water with significantly lower suspended solids, biochemical oxygen demand, and pathogen concentrations. This higher quality effluent reduces the ecological impact on receiving water bodies, decreasing eutrophication potential and minimizing harm to aquatic ecosystems. Studies indicate that MBR effluent contains up to 99% fewer suspended solids compared to CAS systems, substantially reducing the discharge of pollutants to natural environments.

However, the environmental advantages of MBR systems come with energy-related trade-offs. MBR facilities typically consume 20-50% more energy than CAS plants of equivalent capacity, primarily due to the aeration requirements for membrane fouling control. This increased energy consumption translates to higher greenhouse gas emissions when power is derived from fossil fuel sources, potentially offsetting some environmental benefits in regions without access to renewable energy.

Land use efficiency represents a significant environmental advantage for MBR technology. MBR plants require approximately 30-50% less land area than comparable CAS facilities, reducing habitat disruption and preserving natural landscapes. This smaller footprint makes MBR particularly valuable in densely populated areas where land availability is limited and ecosystem preservation is critical.

Chemical usage patterns differ between the technologies, with MBR systems often requiring additional cleaning chemicals for membrane maintenance. These chemicals, including sodium hypochlorite and citric acid, introduce additional environmental considerations regarding manufacturing impacts, transportation emissions, and potential aquatic toxicity from residual discharge.

Life cycle assessment (LCA) studies reveal that MBR systems generally demonstrate lower eutrophication potential but higher global warming potential compared to CAS when considering the entire operational lifespan. The environmental impact ratio shifts depending on local energy mix, with MBR becoming increasingly favorable as renewable energy adoption increases.

Sludge production characteristics also differ between technologies, with MBR typically generating more concentrated but lower volume waste sludge. This concentration effect can reduce the environmental impacts associated with sludge transportation and disposal, though the higher organic content may require different management approaches to minimize greenhouse gas emissions during processing.

MBR systems demonstrate superior environmental performance in terms of effluent quality, producing water with significantly lower suspended solids, biochemical oxygen demand, and pathogen concentrations. This higher quality effluent reduces the ecological impact on receiving water bodies, decreasing eutrophication potential and minimizing harm to aquatic ecosystems. Studies indicate that MBR effluent contains up to 99% fewer suspended solids compared to CAS systems, substantially reducing the discharge of pollutants to natural environments.

However, the environmental advantages of MBR systems come with energy-related trade-offs. MBR facilities typically consume 20-50% more energy than CAS plants of equivalent capacity, primarily due to the aeration requirements for membrane fouling control. This increased energy consumption translates to higher greenhouse gas emissions when power is derived from fossil fuel sources, potentially offsetting some environmental benefits in regions without access to renewable energy.

Land use efficiency represents a significant environmental advantage for MBR technology. MBR plants require approximately 30-50% less land area than comparable CAS facilities, reducing habitat disruption and preserving natural landscapes. This smaller footprint makes MBR particularly valuable in densely populated areas where land availability is limited and ecosystem preservation is critical.

Chemical usage patterns differ between the technologies, with MBR systems often requiring additional cleaning chemicals for membrane maintenance. These chemicals, including sodium hypochlorite and citric acid, introduce additional environmental considerations regarding manufacturing impacts, transportation emissions, and potential aquatic toxicity from residual discharge.

Life cycle assessment (LCA) studies reveal that MBR systems generally demonstrate lower eutrophication potential but higher global warming potential compared to CAS when considering the entire operational lifespan. The environmental impact ratio shifts depending on local energy mix, with MBR becoming increasingly favorable as renewable energy adoption increases.

Sludge production characteristics also differ between technologies, with MBR typically generating more concentrated but lower volume waste sludge. This concentration effect can reduce the environmental impacts associated with sludge transportation and disposal, though the higher organic content may require different management approaches to minimize greenhouse gas emissions during processing.

Operational Cost Analysis and ROI Considerations

The operational costs of wastewater treatment systems represent a significant portion of the total expenditure for municipalities and industries. When comparing Membrane Bioreactor (MBR) and Conventional Activated Sludge (CAS) systems, several key financial factors must be considered to determine the most cost-effective solution for specific applications.

Initial capital investment for MBR systems typically exceeds that of CAS systems by 15-40%, primarily due to the membrane components and more sophisticated control systems. However, this higher upfront cost must be evaluated against long-term operational expenses and potential returns.

Energy consumption constitutes a major operational cost for both technologies. MBR systems generally require 0.4-0.8 kWh/m³ of treated wastewater, approximately 20-50% higher than CAS systems (0.3-0.6 kWh/m³). This difference is primarily attributed to the additional aeration needed for membrane scouring and higher pumping requirements in MBR systems.

Chemical costs present another significant operational consideration. MBR systems require periodic membrane cleaning with specialized chemicals to prevent fouling and maintain performance. These cleaning regimes typically add $0.02-0.05 per cubic meter of treated water to operational costs, an expense not present in CAS systems.

Labor requirements differ between the two technologies. While MBR systems feature higher automation levels potentially reducing staffing needs, they also demand more specialized technical expertise for maintenance and troubleshooting. This specialized labor typically commands higher compensation, partially offsetting the reduced staffing advantage.

The return on investment (ROI) calculation must incorporate several factors beyond direct operational costs. The superior effluent quality from MBR systems may enable water reuse applications, creating potential revenue streams or cost savings that improve the overall financial equation. In water-scarce regions, this benefit can be particularly valuable, with reclaimed water potentially valued at $0.30-1.50 per cubic meter.

Space efficiency represents another crucial ROI consideration. MBR systems typically require 30-50% less land area than comparable CAS installations. In urban or industrial settings with high land values, this spatial efficiency can translate to substantial cost savings, sometimes offsetting the higher capital and operational expenses of MBR systems.

Lifecycle analysis reveals that while MBR systems have higher initial and energy costs, their extended membrane life (7-10 years with proper maintenance) and potential for water reuse can yield favorable long-term economics in specific applications. The payback period for the additional investment in MBR technology typically ranges from 3-8 years, depending on local energy costs, water scarcity conditions, and land values.

Initial capital investment for MBR systems typically exceeds that of CAS systems by 15-40%, primarily due to the membrane components and more sophisticated control systems. However, this higher upfront cost must be evaluated against long-term operational expenses and potential returns.

Energy consumption constitutes a major operational cost for both technologies. MBR systems generally require 0.4-0.8 kWh/m³ of treated wastewater, approximately 20-50% higher than CAS systems (0.3-0.6 kWh/m³). This difference is primarily attributed to the additional aeration needed for membrane scouring and higher pumping requirements in MBR systems.

Chemical costs present another significant operational consideration. MBR systems require periodic membrane cleaning with specialized chemicals to prevent fouling and maintain performance. These cleaning regimes typically add $0.02-0.05 per cubic meter of treated water to operational costs, an expense not present in CAS systems.

Labor requirements differ between the two technologies. While MBR systems feature higher automation levels potentially reducing staffing needs, they also demand more specialized technical expertise for maintenance and troubleshooting. This specialized labor typically commands higher compensation, partially offsetting the reduced staffing advantage.

The return on investment (ROI) calculation must incorporate several factors beyond direct operational costs. The superior effluent quality from MBR systems may enable water reuse applications, creating potential revenue streams or cost savings that improve the overall financial equation. In water-scarce regions, this benefit can be particularly valuable, with reclaimed water potentially valued at $0.30-1.50 per cubic meter.

Space efficiency represents another crucial ROI consideration. MBR systems typically require 30-50% less land area than comparable CAS installations. In urban or industrial settings with high land values, this spatial efficiency can translate to substantial cost savings, sometimes offsetting the higher capital and operational expenses of MBR systems.

Lifecycle analysis reveals that while MBR systems have higher initial and energy costs, their extended membrane life (7-10 years with proper maintenance) and potential for water reuse can yield favorable long-term economics in specific applications. The payback period for the additional investment in MBR technology typically ranges from 3-8 years, depending on local energy costs, water scarcity conditions, and land values.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!