Membrane Bioreactor Industrial Wastewater: Toxic Shocks, Resilience And Compliance

SEP 17, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MBR Technology Background and Objectives

Membrane Bioreactor (MBR) technology represents a significant advancement in wastewater treatment systems, combining conventional activated sludge processes with membrane filtration. Since its commercial introduction in the late 1960s, MBR technology has evolved from small-scale applications to becoming a mainstream solution for industrial wastewater treatment. The technology's development trajectory has been characterized by continuous improvements in membrane materials, module designs, and operational strategies.

The evolution of MBR systems has been driven by increasing global water scarcity concerns and stricter environmental regulations regarding effluent quality. Early MBR systems faced challenges related to membrane fouling, high energy consumption, and limited operational flexibility. However, technological innovations over the past two decades have significantly enhanced system performance, reliability, and cost-effectiveness, making MBRs increasingly attractive for industrial applications.

Industrial wastewater treatment presents unique challenges compared to municipal applications, particularly regarding the presence of toxic compounds and variable influent characteristics. Industries such as pharmaceuticals, chemicals, textiles, and food processing generate wastewaters with complex compositions that can cause operational disruptions in biological treatment systems. The ability of MBR systems to withstand and recover from toxic shock loads has become a critical consideration for industrial adopters.

The primary technical objectives for MBR technology in industrial wastewater treatment focus on enhancing system resilience against toxic shocks while maintaining consistent compliance with increasingly stringent discharge regulations. This includes developing robust biological communities capable of adapting to variable influent conditions, implementing advanced monitoring and control systems for early detection of potential upsets, and designing flexible operational strategies to mitigate the impacts of toxic events.

Current research and development efforts are directed toward understanding the fundamental mechanisms of membrane fouling under toxic conditions, optimizing biomass characteristics for improved resilience, and integrating complementary technologies such as advanced oxidation processes or activated carbon treatment to enhance system performance during challenging operational periods.

The long-term technological trajectory points toward the development of "smart" MBR systems with self-diagnostic capabilities, predictive maintenance features, and automated response protocols for toxic shock events. These advancements aim to reduce operational complexity while improving treatment reliability and compliance consistency, ultimately positioning MBR technology as the preferred solution for industries dealing with challenging wastewater streams.

The evolution of MBR systems has been driven by increasing global water scarcity concerns and stricter environmental regulations regarding effluent quality. Early MBR systems faced challenges related to membrane fouling, high energy consumption, and limited operational flexibility. However, technological innovations over the past two decades have significantly enhanced system performance, reliability, and cost-effectiveness, making MBRs increasingly attractive for industrial applications.

Industrial wastewater treatment presents unique challenges compared to municipal applications, particularly regarding the presence of toxic compounds and variable influent characteristics. Industries such as pharmaceuticals, chemicals, textiles, and food processing generate wastewaters with complex compositions that can cause operational disruptions in biological treatment systems. The ability of MBR systems to withstand and recover from toxic shock loads has become a critical consideration for industrial adopters.

The primary technical objectives for MBR technology in industrial wastewater treatment focus on enhancing system resilience against toxic shocks while maintaining consistent compliance with increasingly stringent discharge regulations. This includes developing robust biological communities capable of adapting to variable influent conditions, implementing advanced monitoring and control systems for early detection of potential upsets, and designing flexible operational strategies to mitigate the impacts of toxic events.

Current research and development efforts are directed toward understanding the fundamental mechanisms of membrane fouling under toxic conditions, optimizing biomass characteristics for improved resilience, and integrating complementary technologies such as advanced oxidation processes or activated carbon treatment to enhance system performance during challenging operational periods.

The long-term technological trajectory points toward the development of "smart" MBR systems with self-diagnostic capabilities, predictive maintenance features, and automated response protocols for toxic shock events. These advancements aim to reduce operational complexity while improving treatment reliability and compliance consistency, ultimately positioning MBR technology as the preferred solution for industries dealing with challenging wastewater streams.

Industrial Wastewater Treatment Market Analysis

The industrial wastewater treatment market has experienced significant growth in recent years, driven by increasingly stringent environmental regulations and growing awareness of water scarcity issues. The global market was valued at approximately $25 billion in 2022 and is projected to reach $38 billion by 2028, representing a compound annual growth rate (CAGR) of 7.2% during the forecast period.

Membrane Bioreactor (MBR) technology has emerged as a particularly promising segment within this market, accounting for roughly 15% of the total industrial wastewater treatment market share. This technology combines conventional activated sludge treatment with membrane filtration, offering superior effluent quality and reduced footprint compared to traditional methods. The MBR segment is growing at an accelerated rate of 9.5% annually, outpacing the broader market.

Geographically, Asia-Pacific dominates the industrial wastewater treatment market, holding approximately 40% of the global share. This dominance is primarily attributed to rapid industrialization in countries like China and India, coupled with increasingly strict discharge regulations. North America and Europe follow with market shares of 25% and 22% respectively, where the focus is primarily on upgrading aging infrastructure and meeting advanced compliance standards.

By industry vertical, chemical manufacturing represents the largest end-user segment (28%), followed by food and beverage (22%), pharmaceuticals (18%), and textiles (12%). These industries generate wastewater with complex compositions that often contain toxic compounds, making them ideal candidates for advanced treatment solutions like MBR systems that can handle toxic shock loads.

A notable market trend is the increasing demand for resilient treatment systems capable of withstanding toxic shock events without compromising compliance. This has led to a 35% increase in R&D investments focused specifically on enhancing MBR resilience to toxic compounds over the past three years. Companies are developing specialized membrane materials and process control systems designed to detect and mitigate the impacts of sudden toxic influxes.

The competitive landscape features both established players and innovative startups. Major companies like Veolia, Suez, Evoqua Water Technologies, and Kubota hold significant market shares, while specialized firms like Pentair, Koch Membrane Systems, and Mitsubishi Chemical are gaining ground through technological innovation specifically addressing toxic shock resilience in MBR systems.

Customer purchasing decisions are increasingly influenced by total cost of ownership rather than initial capital expenditure, with particular emphasis on energy efficiency, maintenance requirements, and system resilience. This shift has created opportunities for service-based business models, with the water-as-a-service segment growing at 12% annually.

Membrane Bioreactor (MBR) technology has emerged as a particularly promising segment within this market, accounting for roughly 15% of the total industrial wastewater treatment market share. This technology combines conventional activated sludge treatment with membrane filtration, offering superior effluent quality and reduced footprint compared to traditional methods. The MBR segment is growing at an accelerated rate of 9.5% annually, outpacing the broader market.

Geographically, Asia-Pacific dominates the industrial wastewater treatment market, holding approximately 40% of the global share. This dominance is primarily attributed to rapid industrialization in countries like China and India, coupled with increasingly strict discharge regulations. North America and Europe follow with market shares of 25% and 22% respectively, where the focus is primarily on upgrading aging infrastructure and meeting advanced compliance standards.

By industry vertical, chemical manufacturing represents the largest end-user segment (28%), followed by food and beverage (22%), pharmaceuticals (18%), and textiles (12%). These industries generate wastewater with complex compositions that often contain toxic compounds, making them ideal candidates for advanced treatment solutions like MBR systems that can handle toxic shock loads.

A notable market trend is the increasing demand for resilient treatment systems capable of withstanding toxic shock events without compromising compliance. This has led to a 35% increase in R&D investments focused specifically on enhancing MBR resilience to toxic compounds over the past three years. Companies are developing specialized membrane materials and process control systems designed to detect and mitigate the impacts of sudden toxic influxes.

The competitive landscape features both established players and innovative startups. Major companies like Veolia, Suez, Evoqua Water Technologies, and Kubota hold significant market shares, while specialized firms like Pentair, Koch Membrane Systems, and Mitsubishi Chemical are gaining ground through technological innovation specifically addressing toxic shock resilience in MBR systems.

Customer purchasing decisions are increasingly influenced by total cost of ownership rather than initial capital expenditure, with particular emphasis on energy efficiency, maintenance requirements, and system resilience. This shift has created opportunities for service-based business models, with the water-as-a-service segment growing at 12% annually.

MBR Technical Challenges in Toxic Environments

Membrane Bioreactor (MBR) systems face significant technical challenges when exposed to toxic environments in industrial wastewater treatment. The primary challenge stems from the vulnerability of microbial communities to toxic shock loads, which can severely impair biological treatment processes. When industrial facilities discharge wastewater containing unexpected concentrations of toxic compounds such as heavy metals, phenols, or chlorinated organics, these substances can rapidly inhibit or kill the active biomass responsible for contaminant degradation.

Membrane fouling represents another critical challenge exacerbated in toxic environments. The presence of toxic compounds often leads to abnormal extracellular polymeric substance (EPS) production by stressed microorganisms, accelerating membrane fouling rates and necessitating more frequent chemical cleaning cycles. This not only increases operational costs but also shortens membrane lifespan, creating a significant economic burden for facility operators.

Process stability maintenance presents substantial difficulties when treating toxic industrial wastewater. MBR systems typically require stable operating conditions to maintain optimal performance, but toxic shock loads create unpredictable fluctuations in treatment efficiency. The recovery period following toxic events can extend from days to weeks, during which effluent quality may fail to meet regulatory requirements, potentially resulting in compliance violations and environmental impacts.

Oxygen transfer efficiency often deteriorates in the presence of certain toxic compounds, particularly surfactants and hydrophobic substances that can accumulate at air-liquid interfaces. This phenomenon reduces aeration effectiveness, increases energy consumption, and may lead to anoxic or anaerobic conditions within the bioreactor, further compromising treatment performance and potentially generating odor issues.

Biomass characteristics undergo significant alterations when exposed to toxicants. Floc structure deterioration, reduced settleability, and changes in microbial community composition directly impact sludge filterability and membrane performance. These changes can trigger a cascade of operational problems including increased transmembrane pressure, reduced flux rates, and more frequent backwashing requirements.

Analytical and monitoring challenges also emerge in toxic environments. Conventional online monitoring parameters (pH, dissolved oxygen, turbidity) often fail to provide early warning of toxic events, allowing damage to occur before operators can implement mitigation measures. The complex and variable nature of industrial wastewater makes it difficult to develop reliable, real-time toxicity monitoring systems that could enable proactive protection of the biological treatment process.

Temperature sensitivity represents an additional challenge, as many industrial wastewaters exhibit temperature extremes that can compound toxic effects. The combination of thermal stress and chemical toxicity often produces synergistic negative impacts on microbial communities, further reducing system resilience and recovery capacity following exposure events.

Membrane fouling represents another critical challenge exacerbated in toxic environments. The presence of toxic compounds often leads to abnormal extracellular polymeric substance (EPS) production by stressed microorganisms, accelerating membrane fouling rates and necessitating more frequent chemical cleaning cycles. This not only increases operational costs but also shortens membrane lifespan, creating a significant economic burden for facility operators.

Process stability maintenance presents substantial difficulties when treating toxic industrial wastewater. MBR systems typically require stable operating conditions to maintain optimal performance, but toxic shock loads create unpredictable fluctuations in treatment efficiency. The recovery period following toxic events can extend from days to weeks, during which effluent quality may fail to meet regulatory requirements, potentially resulting in compliance violations and environmental impacts.

Oxygen transfer efficiency often deteriorates in the presence of certain toxic compounds, particularly surfactants and hydrophobic substances that can accumulate at air-liquid interfaces. This phenomenon reduces aeration effectiveness, increases energy consumption, and may lead to anoxic or anaerobic conditions within the bioreactor, further compromising treatment performance and potentially generating odor issues.

Biomass characteristics undergo significant alterations when exposed to toxicants. Floc structure deterioration, reduced settleability, and changes in microbial community composition directly impact sludge filterability and membrane performance. These changes can trigger a cascade of operational problems including increased transmembrane pressure, reduced flux rates, and more frequent backwashing requirements.

Analytical and monitoring challenges also emerge in toxic environments. Conventional online monitoring parameters (pH, dissolved oxygen, turbidity) often fail to provide early warning of toxic events, allowing damage to occur before operators can implement mitigation measures. The complex and variable nature of industrial wastewater makes it difficult to develop reliable, real-time toxicity monitoring systems that could enable proactive protection of the biological treatment process.

Temperature sensitivity represents an additional challenge, as many industrial wastewaters exhibit temperature extremes that can compound toxic effects. The combination of thermal stress and chemical toxicity often produces synergistic negative impacts on microbial communities, further reducing system resilience and recovery capacity following exposure events.

Current Solutions for Toxic Shock Management

01 Membrane fouling prevention and control

Various methods and systems are employed to prevent and control membrane fouling in bioreactors, which is crucial for maintaining operational resilience. These include advanced filtration techniques, chemical cleaning protocols, and physical mechanisms that reduce the accumulation of foulants on membrane surfaces. By effectively managing membrane fouling, the system can maintain consistent performance and extend operational lifespan under varying conditions.- Membrane fouling prevention and control: Various techniques are employed to prevent and control membrane fouling in bioreactors, which is crucial for maintaining system resilience. These include advanced filtration mechanisms, chemical cleaning protocols, and physical disruption of foulants. By effectively managing membrane fouling, the operational lifespan of membrane bioreactors can be extended, ensuring consistent performance even under challenging conditions.

- Shock load handling and system stability: Membrane bioreactors can be designed to handle shock loads and maintain stability during fluctuating operating conditions. This resilience is achieved through buffer systems, adaptive control mechanisms, and robust membrane materials that can withstand varying hydraulic and organic loads. These features allow the system to recover quickly from disturbances and maintain treatment efficiency.

- Energy efficiency and sustainable operation: Energy-efficient designs and sustainable operational strategies enhance the long-term resilience of membrane bioreactors. These include optimized aeration systems, energy recovery mechanisms, and reduced chemical consumption approaches. By minimizing energy requirements while maintaining performance, these systems can operate reliably over extended periods with reduced environmental impact and operational costs.

- Advanced monitoring and control systems: Sophisticated monitoring and control systems enhance membrane bioreactor resilience through real-time performance tracking and automated response mechanisms. These systems utilize sensors, data analytics, and predictive algorithms to detect potential issues before they affect performance. By enabling proactive maintenance and operational adjustments, these technologies ensure consistent treatment quality and extended system lifespan.

- Modular and scalable design approaches: Modular and scalable membrane bioreactor designs provide inherent resilience through redundancy and flexible capacity adjustment. These systems can be expanded or reconfigured as needed, allowing for adaptation to changing treatment requirements or operational conditions. The modular approach also facilitates easier maintenance and component replacement, minimizing downtime and extending overall system reliability.

02 Shock load management systems

Membrane bioreactors incorporate specialized systems to handle sudden changes in influent characteristics or flow rates. These shock load management systems include buffer tanks, flow equalization mechanisms, and adaptive control algorithms that allow the bioreactor to maintain stable operation despite fluctuating input conditions. This resilience feature is essential for wastewater treatment facilities that experience variable influent quality or quantity.Expand Specific Solutions03 Self-healing membrane technologies

Advanced membrane materials with self-healing properties enhance the resilience of bioreactor systems. These membranes can automatically repair minor damage and resist degradation from chemical exposure or mechanical stress. The self-healing capability is achieved through innovative polymer compositions and surface modifications that respond to damage by initiating localized repair processes, thereby extending membrane lifespan and maintaining separation efficiency.Expand Specific Solutions04 Energy-efficient operation under variable conditions

Energy optimization systems enable membrane bioreactors to maintain resilience while minimizing energy consumption across varying operational conditions. These systems incorporate smart controls, variable frequency drives, and energy recovery devices that adjust operation based on real-time demand and influent characteristics. By optimizing aeration, pumping, and mixing processes, these technologies ensure consistent treatment performance while reducing energy costs and environmental impact.Expand Specific Solutions05 Remote monitoring and predictive maintenance

Integrated sensor networks and data analytics platforms enable remote monitoring and predictive maintenance of membrane bioreactors, enhancing system resilience. These technologies continuously assess operational parameters and membrane condition to predict potential failures before they occur. By identifying maintenance needs in advance and enabling remote troubleshooting, these systems minimize downtime and extend equipment life, ensuring consistent treatment performance even in challenging environments.Expand Specific Solutions

Leading MBR Technology Providers and Competitors

The membrane bioreactor (MBR) industrial wastewater treatment market is currently in a growth phase, with increasing regulatory pressures driving adoption. The global market is expanding at approximately 8-10% annually, valued at over $3 billion, as industries seek solutions for toxic shock resilience and compliance requirements. Technologically, the field shows moderate maturity with ongoing innovation focused on shock resistance. Leading players include established water treatment specialists like Evoqua Water Technologies, Aquatech International, and Kemira Oyj, alongside research-driven entities such as Xiamen University of Technology and Nanjing University. Chinese companies like Beijing OriginWater and Sinopec are making significant advances, while global corporations including Siemens Water Technologies and newterra Ltd. continue to develop proprietary MBR solutions addressing industrial wastewater challenges.

Aquatech International LLC

Technical Solution: Aquatech International has developed the BioResilience™ MBR system specifically engineered to handle industrial wastewater with unpredictable toxic shock loads. Their technology incorporates a multi-stage biological treatment process with specialized bacterial consortia selected for their ability to withstand and recover from exposure to industrial toxicants. The membrane component features a proprietary coating technology that resists chemical degradation while maintaining high flux rates even during challenging influent conditions. Aquatech's system includes an intelligent control platform that continuously monitors key biological indicators and automatically adjusts operational parameters to protect membrane integrity and biological viability during toxic events. Their approach incorporates a unique biomass preservation strategy that maintains protected microbial reserves that can be rapidly mobilized for system recovery following toxic exposure. The BioResilience™ system has been successfully implemented in pharmaceutical manufacturing, chemical processing, and food production facilities, consistently demonstrating rapid recovery from toxic shock events while maintaining regulatory compliance. The technology includes specialized cleaning protocols that can be implemented during operation to remove accumulated toxicants from membrane surfaces without requiring system shutdown.

Strengths: Exceptional biological resilience through specialized microbial communities; advanced membrane protection systems that prevent irreversible fouling; rapid recovery capabilities that minimize compliance violations. Weaknesses: Higher operational complexity requiring skilled operators; more frequent cleaning cycles compared to municipal MBR systems; relatively high chemical consumption for membrane maintenance.

Siemens Water Technologies Corp.

Technical Solution: Siemens Water Technologies has developed the MemPulse® MBR system with specific enhancements for industrial applications facing toxic shock challenges. Their technology incorporates a unique two-stage biological process with specialized selector zones that can absorb and gradually process toxic compounds before they reach the main treatment stage. The membrane modules feature a proprietary PVDF formulation with enhanced chemical resistance properties and a unique fiber configuration that reduces fouling potential during upset conditions. Siemens' approach includes an advanced process control system that continuously monitors key water quality parameters and automatically adjusts operational settings to maintain treatment efficiency during variable influent conditions. Their technology incorporates a rapid-response aeration system that can quickly increase oxygen transfer during toxic events to support biological recovery. The MemPulse® system has been successfully implemented in various industrial sectors including petrochemical, pharmaceutical, and food processing facilities, consistently demonstrating the ability to maintain effluent compliance even during severe toxic shock events. The system's design includes specialized cleaning protocols that can be implemented without taking the entire system offline, allowing for continuous operation even during maintenance activities.

Strengths: Highly effective two-stage biological process that buffers toxic impacts; sophisticated membrane materials with exceptional chemical resistance; comprehensive automation systems that reduce operator intervention requirements. Weaknesses: Higher energy consumption compared to conventional treatment systems; complex control systems require specialized maintenance expertise; significant footprint requirements for the complete system implementation.

Key Innovations in MBR Resilience Technologies

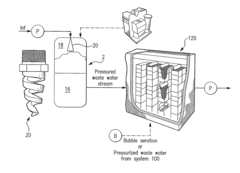

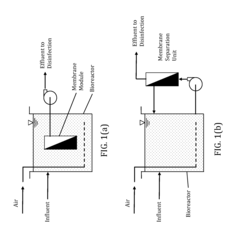

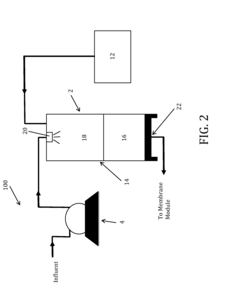

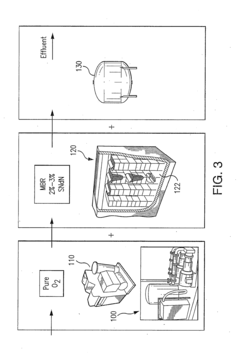

Systems and Methods for Wastewater Treatment

PatentActiveUS20120325741A1

Innovation

- A system that includes a dissolution tank with a pressure vessel and liquid spray nozzle to dissolve gases into wastewater, allowing for precise control of dissolved oxygen delivery directly into the bioreactor, reducing the need for bubble-based aeration and enabling efficient oxygenation even at high solids concentrations.

Regulatory Compliance Framework for Industrial Effluents

The regulatory landscape governing industrial wastewater treatment through Membrane Bioreactor (MBR) systems is increasingly complex and stringent worldwide. These regulations aim to protect water resources, public health, and ecosystems from the harmful effects of industrial effluents containing toxic compounds.

At the international level, frameworks such as the United Nations' Sustainable Development Goals (particularly SDG 6 on clean water and sanitation) and the Basel Convention provide overarching guidance on water quality management. These frameworks establish fundamental principles that influence national and regional regulatory approaches to industrial wastewater treatment.

In the European Union, the Water Framework Directive (2000/60/EC) and the Industrial Emissions Directive (2010/75/EU) form the cornerstone of regulatory compliance for industrial wastewater. These directives mandate specific discharge limits for various pollutants and require the implementation of Best Available Techniques (BAT) for wastewater treatment, which increasingly includes MBR technology for challenging industrial effluents.

The United States enforces compliance through the Clean Water Act and the National Pollutant Discharge Elimination System (NPDES), which establish permitting requirements and effluent guidelines for industrial facilities. The Environmental Protection Agency (EPA) has developed industry-specific standards that often necessitate advanced treatment technologies like MBRs to achieve compliance, particularly for industries generating high-strength or toxic wastewaters.

In Asia, countries like China have implemented the Water Pollution Prevention and Control Law with increasingly stringent discharge standards, while Japan's regulatory framework emphasizes advanced treatment technologies and water recycling. These regulations have driven significant adoption of MBR systems in industrial applications throughout the region.

Compliance monitoring for MBR systems typically involves continuous measurement of key parameters such as Chemical Oxygen Demand (COD), Biological Oxygen Demand (BOD), Total Suspended Solids (TSS), and specific toxic compounds relevant to the industry. Modern regulatory frameworks increasingly require real-time monitoring systems and reporting protocols to ensure consistent compliance, particularly during toxic shock events.

Penalties for non-compliance vary globally but generally include substantial financial sanctions, mandatory remediation requirements, and in severe cases, operational restrictions or facility closure. This has elevated the importance of MBR technology's resilience to toxic shocks as a critical factor in regulatory compliance strategies for industrial operators.

The regulatory trend is moving toward more comprehensive approaches that consider not only end-of-pipe treatment but also source reduction, water reuse, and resource recovery. This holistic perspective is reshaping how industries implement and operate MBR systems, with increasing emphasis on robust design parameters that can withstand toxic shock events while maintaining consistent compliance with discharge requirements.

At the international level, frameworks such as the United Nations' Sustainable Development Goals (particularly SDG 6 on clean water and sanitation) and the Basel Convention provide overarching guidance on water quality management. These frameworks establish fundamental principles that influence national and regional regulatory approaches to industrial wastewater treatment.

In the European Union, the Water Framework Directive (2000/60/EC) and the Industrial Emissions Directive (2010/75/EU) form the cornerstone of regulatory compliance for industrial wastewater. These directives mandate specific discharge limits for various pollutants and require the implementation of Best Available Techniques (BAT) for wastewater treatment, which increasingly includes MBR technology for challenging industrial effluents.

The United States enforces compliance through the Clean Water Act and the National Pollutant Discharge Elimination System (NPDES), which establish permitting requirements and effluent guidelines for industrial facilities. The Environmental Protection Agency (EPA) has developed industry-specific standards that often necessitate advanced treatment technologies like MBRs to achieve compliance, particularly for industries generating high-strength or toxic wastewaters.

In Asia, countries like China have implemented the Water Pollution Prevention and Control Law with increasingly stringent discharge standards, while Japan's regulatory framework emphasizes advanced treatment technologies and water recycling. These regulations have driven significant adoption of MBR systems in industrial applications throughout the region.

Compliance monitoring for MBR systems typically involves continuous measurement of key parameters such as Chemical Oxygen Demand (COD), Biological Oxygen Demand (BOD), Total Suspended Solids (TSS), and specific toxic compounds relevant to the industry. Modern regulatory frameworks increasingly require real-time monitoring systems and reporting protocols to ensure consistent compliance, particularly during toxic shock events.

Penalties for non-compliance vary globally but generally include substantial financial sanctions, mandatory remediation requirements, and in severe cases, operational restrictions or facility closure. This has elevated the importance of MBR technology's resilience to toxic shocks as a critical factor in regulatory compliance strategies for industrial operators.

The regulatory trend is moving toward more comprehensive approaches that consider not only end-of-pipe treatment but also source reduction, water reuse, and resource recovery. This holistic perspective is reshaping how industries implement and operate MBR systems, with increasing emphasis on robust design parameters that can withstand toxic shock events while maintaining consistent compliance with discharge requirements.

Environmental Impact Assessment of MBR Applications

The environmental impact assessment of MBR applications in industrial wastewater treatment reveals significant positive contributions to environmental sustainability compared to conventional treatment systems. MBR technology demonstrates superior performance in reducing the ecological footprint of industrial wastewater discharge through enhanced pollutant removal efficiency, particularly for recalcitrant compounds and micropollutants that conventional systems struggle to eliminate.

Water quality analyses from multiple industrial implementations show that MBR effluent consistently meets or exceeds regulatory standards, even during toxic shock events. The technology's ability to maintain high-quality effluent translates to reduced eutrophication potential in receiving water bodies and decreased stress on aquatic ecosystems. Studies across various industrial sectors indicate up to 99% removal of suspended solids and 95-98% reduction in biological oxygen demand, significantly minimizing oxygen depletion risks in natural water systems.

The compact footprint of MBR installations represents another environmental advantage, requiring 30-50% less land area than conventional treatment plants. This spatial efficiency preserves natural habitats and reduces the environmental disruption associated with facility construction. Additionally, the reduced sludge production—approximately 30-45% less than conventional activated sludge processes—decreases the environmental burden of waste disposal and associated transportation emissions.

Energy consumption remains a critical environmental consideration for MBR operations. While MBR systems typically require 20-30% more energy than conventional treatments due to membrane aeration requirements, recent technological innovations have narrowed this gap. Advanced membrane materials, optimized aeration systems, and energy recovery processes have improved energy efficiency by up to 25% in next-generation MBR installations, reducing the associated carbon footprint.

The resilience of MBR systems to toxic shocks further enhances their environmental profile by preventing catastrophic system failures that could result in untreated wastewater discharge during upset conditions. This protective capacity is particularly valuable in industrial settings where production variations can introduce sudden contaminant spikes. Life cycle assessments indicate that despite higher initial resource investment, the extended operational lifespan and superior treatment performance of MBRs result in net environmental benefits over conventional alternatives when evaluated across a 15-20 year horizon.

Water reuse capabilities of MBR systems contribute significantly to resource conservation, with treated effluent suitable for non-potable applications reducing freshwater withdrawal demands. In water-stressed regions, this aspect of MBR technology provides crucial environmental relief by preserving natural water resources and maintaining ecological flow requirements in surface water systems.

Water quality analyses from multiple industrial implementations show that MBR effluent consistently meets or exceeds regulatory standards, even during toxic shock events. The technology's ability to maintain high-quality effluent translates to reduced eutrophication potential in receiving water bodies and decreased stress on aquatic ecosystems. Studies across various industrial sectors indicate up to 99% removal of suspended solids and 95-98% reduction in biological oxygen demand, significantly minimizing oxygen depletion risks in natural water systems.

The compact footprint of MBR installations represents another environmental advantage, requiring 30-50% less land area than conventional treatment plants. This spatial efficiency preserves natural habitats and reduces the environmental disruption associated with facility construction. Additionally, the reduced sludge production—approximately 30-45% less than conventional activated sludge processes—decreases the environmental burden of waste disposal and associated transportation emissions.

Energy consumption remains a critical environmental consideration for MBR operations. While MBR systems typically require 20-30% more energy than conventional treatments due to membrane aeration requirements, recent technological innovations have narrowed this gap. Advanced membrane materials, optimized aeration systems, and energy recovery processes have improved energy efficiency by up to 25% in next-generation MBR installations, reducing the associated carbon footprint.

The resilience of MBR systems to toxic shocks further enhances their environmental profile by preventing catastrophic system failures that could result in untreated wastewater discharge during upset conditions. This protective capacity is particularly valuable in industrial settings where production variations can introduce sudden contaminant spikes. Life cycle assessments indicate that despite higher initial resource investment, the extended operational lifespan and superior treatment performance of MBRs result in net environmental benefits over conventional alternatives when evaluated across a 15-20 year horizon.

Water reuse capabilities of MBR systems contribute significantly to resource conservation, with treated effluent suitable for non-potable applications reducing freshwater withdrawal demands. In water-stressed regions, this aspect of MBR technology provides crucial environmental relief by preserving natural water resources and maintaining ecological flow requirements in surface water systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!