Membrane Bioreactor Fouling Control: TMP Management, Air Scour And EPS Mitigation

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MBR Fouling Control Background and Objectives

Membrane Bioreactor (MBR) technology has evolved significantly since its inception in the late 1960s, representing a revolutionary advancement in wastewater treatment processes. The integration of membrane filtration with biological treatment has enabled higher effluent quality, reduced footprint requirements, and enhanced operational flexibility compared to conventional activated sludge systems. However, membrane fouling remains the primary challenge limiting the widespread adoption and operational efficiency of MBR systems, necessitating comprehensive control strategies.

The evolution of MBR technology has been characterized by three distinct generations, with each addressing specific operational challenges. First-generation systems focused on basic functionality, while second-generation developments emphasized energy efficiency and fouling reduction. Current third-generation systems incorporate advanced monitoring, automated control mechanisms, and novel membrane materials designed specifically to mitigate fouling phenomena.

Membrane fouling in MBR systems manifests through the gradual accumulation of foulants on membrane surfaces, leading to increased transmembrane pressure (TMP), reduced permeate flux, and ultimately, compromised system performance. This fouling phenomenon is influenced by a complex interplay of factors including biomass characteristics, extracellular polymeric substances (EPS) production, operational parameters, and membrane properties.

The technical objectives of MBR fouling control research center on developing sustainable strategies to maintain stable long-term operation while minimizing energy consumption and maintenance requirements. Specifically, these objectives include: optimizing TMP management protocols to prevent irreversible fouling; enhancing air scouring efficiency to maximize cleaning effectiveness while reducing energy inputs; and developing innovative approaches to mitigate EPS accumulation, which represents a primary contributor to membrane fouling.

Recent technological trends indicate a shift toward intelligent fouling control systems that incorporate real-time monitoring, predictive analytics, and automated response mechanisms. These systems aim to detect early fouling indicators and implement preventive measures before critical fouling thresholds are reached. Additionally, research is increasingly focused on understanding the fundamental mechanisms of biofouling at the molecular and microbiological levels to develop targeted intervention strategies.

The global water scarcity crisis and increasingly stringent effluent quality regulations are driving unprecedented interest in advanced MBR technologies. As water reuse becomes essential in many regions, the demand for reliable, low-maintenance MBR systems continues to grow. Consequently, effective fouling control strategies represent not only a technical imperative but also a critical factor in addressing global water management challenges.

The evolution of MBR technology has been characterized by three distinct generations, with each addressing specific operational challenges. First-generation systems focused on basic functionality, while second-generation developments emphasized energy efficiency and fouling reduction. Current third-generation systems incorporate advanced monitoring, automated control mechanisms, and novel membrane materials designed specifically to mitigate fouling phenomena.

Membrane fouling in MBR systems manifests through the gradual accumulation of foulants on membrane surfaces, leading to increased transmembrane pressure (TMP), reduced permeate flux, and ultimately, compromised system performance. This fouling phenomenon is influenced by a complex interplay of factors including biomass characteristics, extracellular polymeric substances (EPS) production, operational parameters, and membrane properties.

The technical objectives of MBR fouling control research center on developing sustainable strategies to maintain stable long-term operation while minimizing energy consumption and maintenance requirements. Specifically, these objectives include: optimizing TMP management protocols to prevent irreversible fouling; enhancing air scouring efficiency to maximize cleaning effectiveness while reducing energy inputs; and developing innovative approaches to mitigate EPS accumulation, which represents a primary contributor to membrane fouling.

Recent technological trends indicate a shift toward intelligent fouling control systems that incorporate real-time monitoring, predictive analytics, and automated response mechanisms. These systems aim to detect early fouling indicators and implement preventive measures before critical fouling thresholds are reached. Additionally, research is increasingly focused on understanding the fundamental mechanisms of biofouling at the molecular and microbiological levels to develop targeted intervention strategies.

The global water scarcity crisis and increasingly stringent effluent quality regulations are driving unprecedented interest in advanced MBR technologies. As water reuse becomes essential in many regions, the demand for reliable, low-maintenance MBR systems continues to grow. Consequently, effective fouling control strategies represent not only a technical imperative but also a critical factor in addressing global water management challenges.

Market Analysis for Advanced Wastewater Treatment Solutions

The global advanced wastewater treatment market is experiencing robust growth, with membrane bioreactor (MBR) technology emerging as a leading solution. Currently valued at approximately $8.3 billion in 2023, the MBR market is projected to reach $12.6 billion by 2028, representing a compound annual growth rate of 8.7%. This growth is primarily driven by increasingly stringent environmental regulations, water scarcity concerns, and the rising demand for water reuse applications across various industries.

Municipal wastewater treatment represents the largest market segment, accounting for roughly 65% of the total MBR installations worldwide. Industrial applications, particularly in food and beverage, pharmaceuticals, and chemical manufacturing, constitute the remaining 35% with the fastest growth trajectory due to tightening discharge regulations and process water recycling initiatives.

Geographically, Asia-Pacific dominates the market with approximately 40% share, led by China's massive infrastructure investments and Japan's advanced technological implementations. North America and Europe follow with 25% and 22% market shares respectively, where replacement of aging wastewater infrastructure and upgrading to more efficient systems drive demand.

The fouling control segment within the MBR market is particularly dynamic, with specialized anti-fouling solutions estimated at $1.2 billion annually. Technologies specifically addressing transmembrane pressure (TMP) management, air scouring optimization, and extracellular polymeric substances (EPS) mitigation collectively represent a high-growth subsector expanding at 10.3% annually, outpacing the broader MBR market.

Customer demand increasingly focuses on solutions that extend membrane life and reduce operational costs. End-users report that fouling-related issues account for approximately 70% of MBR operational challenges and up to 50% of maintenance costs. This creates substantial market opportunity for innovative fouling control technologies that can demonstrate clear return on investment through reduced energy consumption, decreased chemical usage, and extended membrane replacement intervals.

Competition in this space is intensifying with both established water treatment companies and specialized technology startups. The market exhibits a clear willingness to pay premium prices for solutions that effectively address fouling issues, with customers reporting readiness to invest 15-20% more in systems with proven fouling control capabilities compared to conventional MBR systems.

Future market growth will be particularly strong in regions facing severe water stress, including the Middle East, parts of Asia, and the southwestern United States, where water recycling and reuse are becoming essential rather than optional considerations in water management strategies.

Municipal wastewater treatment represents the largest market segment, accounting for roughly 65% of the total MBR installations worldwide. Industrial applications, particularly in food and beverage, pharmaceuticals, and chemical manufacturing, constitute the remaining 35% with the fastest growth trajectory due to tightening discharge regulations and process water recycling initiatives.

Geographically, Asia-Pacific dominates the market with approximately 40% share, led by China's massive infrastructure investments and Japan's advanced technological implementations. North America and Europe follow with 25% and 22% market shares respectively, where replacement of aging wastewater infrastructure and upgrading to more efficient systems drive demand.

The fouling control segment within the MBR market is particularly dynamic, with specialized anti-fouling solutions estimated at $1.2 billion annually. Technologies specifically addressing transmembrane pressure (TMP) management, air scouring optimization, and extracellular polymeric substances (EPS) mitigation collectively represent a high-growth subsector expanding at 10.3% annually, outpacing the broader MBR market.

Customer demand increasingly focuses on solutions that extend membrane life and reduce operational costs. End-users report that fouling-related issues account for approximately 70% of MBR operational challenges and up to 50% of maintenance costs. This creates substantial market opportunity for innovative fouling control technologies that can demonstrate clear return on investment through reduced energy consumption, decreased chemical usage, and extended membrane replacement intervals.

Competition in this space is intensifying with both established water treatment companies and specialized technology startups. The market exhibits a clear willingness to pay premium prices for solutions that effectively address fouling issues, with customers reporting readiness to invest 15-20% more in systems with proven fouling control capabilities compared to conventional MBR systems.

Future market growth will be particularly strong in regions facing severe water stress, including the Middle East, parts of Asia, and the southwestern United States, where water recycling and reuse are becoming essential rather than optional considerations in water management strategies.

Current Challenges in Membrane Bioreactor Technology

Membrane Bioreactor (MBR) technology faces several critical challenges that impede its widespread adoption and operational efficiency. The most significant issue is membrane fouling, which occurs when solids, colloids, and microbial products accumulate on membrane surfaces, reducing permeability and increasing transmembrane pressure (TMP). This phenomenon necessitates frequent cleaning cycles, higher energy consumption, and ultimately shortens membrane lifespan, substantially increasing operational costs.

Biofouling, a specific type of fouling caused by microbial growth and extracellular polymeric substances (EPS) production, presents particular difficulties due to its complex biological nature. The EPS matrix forms a gel-like layer that is highly resistant to conventional cleaning methods and significantly impairs filtration performance. Current research indicates that EPS composition varies widely depending on wastewater characteristics, microbial communities, and operational conditions, making standardized mitigation strategies challenging to implement.

Energy consumption represents another major hurdle for MBR systems. Aeration requirements for membrane scouring typically account for 40-60% of total energy usage in MBR plants. While air scouring effectively controls fouling, optimizing this process without compromising membrane performance remains difficult. The energy-intensive nature of MBRs contributes to higher operational costs compared to conventional activated sludge processes, limiting their application in resource-constrained environments.

Operational complexity also poses significant challenges. MBR systems require sophisticated control systems to manage multiple parameters simultaneously, including mixed liquor suspended solids (MLSS) concentration, hydraulic retention time, sludge retention time, and aeration intensity. Maintaining optimal TMP levels demands continuous monitoring and adjustment, requiring skilled operators and advanced instrumentation. Many facilities struggle with this complexity, leading to suboptimal performance and increased maintenance requirements.

Membrane material limitations further constrain MBR advancement. Current membrane materials often face trade-offs between permeability, selectivity, and fouling resistance. Polymeric membranes, while cost-effective, are susceptible to chemical degradation and mechanical damage. Ceramic membranes offer superior durability but at significantly higher costs. The development of novel membrane materials that balance these properties remains an active research area but has yet to yield commercially viable solutions for all applications.

Scale-up challenges persist when transitioning from laboratory or pilot-scale to full-scale implementation. Hydrodynamic conditions, fouling behaviors, and cleaning efficiencies often differ substantially between scales, making performance prediction difficult. This scaling issue frequently results in unexpected operational problems and higher-than-anticipated costs when implementing MBR technology at municipal or industrial scales.

Biofouling, a specific type of fouling caused by microbial growth and extracellular polymeric substances (EPS) production, presents particular difficulties due to its complex biological nature. The EPS matrix forms a gel-like layer that is highly resistant to conventional cleaning methods and significantly impairs filtration performance. Current research indicates that EPS composition varies widely depending on wastewater characteristics, microbial communities, and operational conditions, making standardized mitigation strategies challenging to implement.

Energy consumption represents another major hurdle for MBR systems. Aeration requirements for membrane scouring typically account for 40-60% of total energy usage in MBR plants. While air scouring effectively controls fouling, optimizing this process without compromising membrane performance remains difficult. The energy-intensive nature of MBRs contributes to higher operational costs compared to conventional activated sludge processes, limiting their application in resource-constrained environments.

Operational complexity also poses significant challenges. MBR systems require sophisticated control systems to manage multiple parameters simultaneously, including mixed liquor suspended solids (MLSS) concentration, hydraulic retention time, sludge retention time, and aeration intensity. Maintaining optimal TMP levels demands continuous monitoring and adjustment, requiring skilled operators and advanced instrumentation. Many facilities struggle with this complexity, leading to suboptimal performance and increased maintenance requirements.

Membrane material limitations further constrain MBR advancement. Current membrane materials often face trade-offs between permeability, selectivity, and fouling resistance. Polymeric membranes, while cost-effective, are susceptible to chemical degradation and mechanical damage. Ceramic membranes offer superior durability but at significantly higher costs. The development of novel membrane materials that balance these properties remains an active research area but has yet to yield commercially viable solutions for all applications.

Scale-up challenges persist when transitioning from laboratory or pilot-scale to full-scale implementation. Hydrodynamic conditions, fouling behaviors, and cleaning efficiencies often differ substantially between scales, making performance prediction difficult. This scaling issue frequently results in unexpected operational problems and higher-than-anticipated costs when implementing MBR technology at municipal or industrial scales.

Existing TMP Management and Air Scouring Techniques

01 Physical cleaning methods for membrane fouling control

Physical cleaning methods are employed to control membrane fouling in bioreactors. These methods include backwashing, air scouring, and mechanical cleaning techniques that help remove foulants from the membrane surface. By applying physical forces to dislodge accumulated particles and biofilm, these approaches can effectively restore membrane permeability and extend operational periods between chemical cleanings.- Physical cleaning methods for membrane fouling control: Physical cleaning methods are employed to control membrane fouling in bioreactors. These methods include backwashing, air scouring, and mechanical cleaning techniques that help remove foulants from the membrane surface. Physical cleaning can be performed periodically or continuously to maintain membrane permeability and extend the operational life of membrane bioreactors without requiring chemical additives.

- Chemical cleaning and anti-fouling agents: Chemical cleaning methods and anti-fouling agents are used to control membrane fouling in bioreactors. These include the application of cleaning chemicals such as acids, bases, oxidants, and surfactants that can dissolve or detach foulants from membrane surfaces. Additionally, anti-fouling agents can be incorporated into membrane materials or added to the feed to prevent fouling formation, thereby maintaining system performance and reducing cleaning frequency.

- Hydrodynamic optimization techniques: Hydrodynamic optimization techniques involve controlling fluid dynamics within membrane bioreactors to minimize fouling. These techniques include optimizing cross-flow velocity, implementing intermittent suction, creating turbulence near membrane surfaces, and designing specific flow patterns. By managing the hydrodynamic conditions, shear forces can be increased at the membrane surface, reducing the accumulation of foulants and extending filtration cycles.

- Biological fouling control strategies: Biological fouling control strategies focus on managing the microbial community and biological processes within membrane bioreactors. These approaches include controlling sludge retention time, optimizing nutrient ratios, managing dissolved oxygen levels, and introducing specific microorganisms that can reduce biofouling. By manipulating biological parameters, the production of extracellular polymeric substances that contribute to membrane fouling can be minimized.

- Advanced monitoring and control systems: Advanced monitoring and control systems employ sensors, real-time data analysis, and automated control mechanisms to detect and respond to fouling conditions in membrane bioreactors. These systems can monitor parameters such as transmembrane pressure, permeate flux, and water quality to identify early signs of fouling. Based on this information, automated cleaning sequences or operational adjustments can be triggered to maintain optimal performance and prevent severe fouling events.

02 Chemical cleaning and anti-fouling agents

Chemical cleaning strategies involve the use of various agents to dissolve or detach foulants from membrane surfaces. These include oxidizing agents, acids, bases, and specialized cleaning chemicals that target specific types of fouling. Additionally, anti-fouling agents can be incorporated into membrane materials or added to the feed to prevent initial attachment of foulants, thereby extending the operational lifetime of membrane bioreactors.Expand Specific Solutions03 Hydrodynamic optimization techniques

Hydrodynamic optimization involves controlling fluid dynamics within the membrane bioreactor to minimize fouling. Techniques include optimizing cross-flow velocity, implementing intermittent suction, creating turbulence near membrane surfaces, and designing specific flow patterns. These approaches help reduce the formation of concentration polarization layers and prevent the accumulation of foulants on membrane surfaces.Expand Specific Solutions04 Biological fouling control strategies

Biological fouling control focuses on managing the microbial community and its byproducts within the bioreactor. Strategies include optimizing sludge retention time, controlling food-to-microorganism ratios, managing dissolved oxygen levels, and implementing specific operational protocols to reduce extracellular polymeric substances production. These approaches target the biological mechanisms that contribute to membrane fouling.Expand Specific Solutions05 Advanced monitoring and control systems

Advanced monitoring and control systems employ sensors, real-time data analysis, and automated response mechanisms to detect and address fouling before it becomes severe. These systems can monitor transmembrane pressure, permeate flux, and other parameters to identify early signs of fouling. Integrated control algorithms can then automatically adjust operational parameters or initiate cleaning sequences to maintain optimal membrane performance.Expand Specific Solutions

Leading Companies and Research Institutions in MBR Technology

Membrane Bioreactor (MBR) fouling control is currently in a growth phase, with the global market expanding due to increasing water scarcity and stringent discharge regulations. The market is projected to reach significant scale as municipalities and industries adopt advanced wastewater treatment technologies. Technologically, the field shows moderate maturity with ongoing innovation. Leading academic institutions (Tsinghua University, Harbin Institute of Technology, King Abdullah University) are advancing fundamental research on EPS mitigation and air scouring optimization, while commercial players like Ecolab, Doosan Enerbility, and Beijing Drainage Group focus on practical TMP management solutions and system integration. The collaboration between research institutions and industry partners is accelerating technology transfer and implementation of novel fouling control strategies.

Ecolab USA, Inc.

Technical Solution: Ecolab has developed an integrated MBR fouling control system that combines chemical cleaning protocols with real-time TMP monitoring. Their solution utilizes proprietary anti-fouling chemicals that specifically target protein and polysaccharide components of EPS. The system employs a dual-frequency air scouring mechanism that alternates between high-intensity and low-intensity air flow patterns to optimize energy consumption while maintaining effective membrane cleaning. Ecolab's approach includes automated chemical dosing based on real-time fouling indicators, with their Membrane Performance Enhancer (MPE) technology reducing cleaning frequency by up to 50% compared to conventional methods. Their system incorporates machine learning algorithms to predict TMP spikes and automatically adjusts operational parameters to extend membrane life and reduce downtime[1][3].

Strengths: Comprehensive integration of chemical and physical cleaning strategies with predictive analytics provides superior fouling prevention. The automated system reduces operator intervention and optimizes chemical usage. Weaknesses: Higher initial implementation costs compared to conventional systems, and requires specialized training for maintenance personnel.

Tsinghua University

Technical Solution: Tsinghua University has developed an innovative Quorum Quenching (QQ) approach to MBR fouling control that targets the biological mechanisms of EPS production. Their technology employs engineered bacterial strains that produce enzymes capable of degrading quorum sensing signal molecules, thereby disrupting the cell-to-cell communication that triggers excessive EPS secretion. The system incorporates a novel ceramic membrane module with modified surface properties that reduce initial foulant adhesion. Tsinghua's approach includes a multi-parameter TMP control strategy that integrates filtration resistance, permeate quality, and biological activity indicators to optimize cleaning cycles. Their research has demonstrated that combining QQ with optimized air scouring patterns can reduce membrane fouling rates by up to 65% compared to conventional MBR operations[6][8]. The university has also pioneered the use of magnetic nanoparticles as carriers for QQ enzymes, allowing for efficient recovery and reuse of these biological fouling control agents while maintaining stable long-term performance in full-scale applications.

Strengths: Addresses fouling at its biological source rather than just treating symptoms, resulting in more sustainable long-term operation. The integrated approach significantly reduces chemical cleaning requirements. Weaknesses: The biological fouling control agents require careful handling and storage conditions to maintain activity. Implementation requires more sophisticated biological monitoring than conventional systems.

Critical Patents and Research on EPS Mitigation Methods

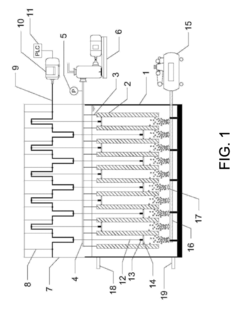

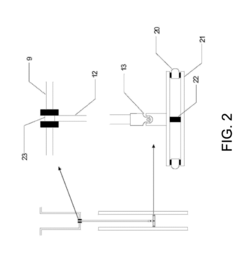

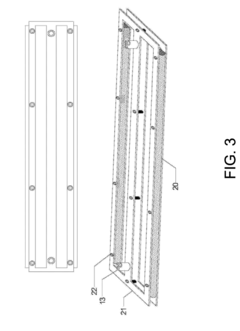

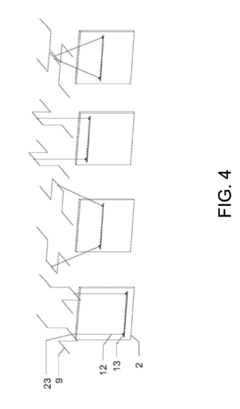

Membrane bioreactor for strengthening membrane fouling control and method thereof

PatentActiveUS20180370828A1

Innovation

- An automated mechanical transmission system with a cleaning unit, featuring a stainless steel frame, crane, and programmable logic controller, uses a flexible cleaning head to perform in situ cleaning of the membrane surface, reducing fouling and increasing membrane flux without removing the membrane elements.

Energy Efficiency Considerations in MBR Operation

Energy consumption represents a significant operational cost in membrane bioreactor (MBR) systems, accounting for approximately 30-50% of total operational expenses. The primary energy demands in MBR operation stem from aeration requirements for both biological processes and membrane scouring, as well as permeate extraction through pumping systems. Optimizing these energy-intensive processes is crucial for sustainable MBR implementation.

Aeration energy efficiency presents the most substantial opportunity for improvement, as air scouring alone can consume up to 70% of the total energy in an MBR system. Advanced aeration strategies such as intermittent aeration, where air scouring is applied in controlled cycles rather than continuously, have demonstrated energy savings of 20-40% without compromising fouling control effectiveness. Similarly, demand-based aeration control systems that adjust air flow rates based on real-time TMP measurements optimize energy usage while maintaining membrane performance.

Hydraulic optimization offers another avenue for energy conservation. Implementing flux-stepping protocols, where permeate extraction rates are gradually increased and decreased rather than operating at constant high flux, reduces energy consumption while extending cleaning intervals. Additionally, gravity-driven systems that minimize or eliminate permeate pumping requirements have shown promising results in pilot-scale applications, reducing energy demands by up to 25% compared to conventional pumped systems.

Biological process modifications can indirectly improve energy efficiency by mitigating EPS production. Lower food-to-microorganism (F/M) ratios and optimized sludge retention times (SRT) reduce the metabolic stress on microbial communities, decreasing EPS release and subsequent fouling. This biological approach extends membrane cleaning intervals and reduces the energy required for both air scouring and chemical cleaning processes.

Emerging technologies such as vibrating membranes and ultrasonic fouling control systems offer alternatives to traditional air scouring. These mechanical methods can achieve comparable fouling control with 30-45% less energy consumption. Similarly, electrochemical membrane cleaning techniques that apply low-voltage electric fields to repel foulants have demonstrated energy savings of up to 50% in laboratory studies, though their full-scale implementation remains limited.

The integration of renewable energy sources, particularly solar power, has gained traction for MBR operations in remote locations. Solar-powered MBR systems with energy storage capabilities can significantly reduce operational costs while maintaining reliable performance, especially when coupled with smart control systems that optimize energy usage based on availability and demand patterns.

Aeration energy efficiency presents the most substantial opportunity for improvement, as air scouring alone can consume up to 70% of the total energy in an MBR system. Advanced aeration strategies such as intermittent aeration, where air scouring is applied in controlled cycles rather than continuously, have demonstrated energy savings of 20-40% without compromising fouling control effectiveness. Similarly, demand-based aeration control systems that adjust air flow rates based on real-time TMP measurements optimize energy usage while maintaining membrane performance.

Hydraulic optimization offers another avenue for energy conservation. Implementing flux-stepping protocols, where permeate extraction rates are gradually increased and decreased rather than operating at constant high flux, reduces energy consumption while extending cleaning intervals. Additionally, gravity-driven systems that minimize or eliminate permeate pumping requirements have shown promising results in pilot-scale applications, reducing energy demands by up to 25% compared to conventional pumped systems.

Biological process modifications can indirectly improve energy efficiency by mitigating EPS production. Lower food-to-microorganism (F/M) ratios and optimized sludge retention times (SRT) reduce the metabolic stress on microbial communities, decreasing EPS release and subsequent fouling. This biological approach extends membrane cleaning intervals and reduces the energy required for both air scouring and chemical cleaning processes.

Emerging technologies such as vibrating membranes and ultrasonic fouling control systems offer alternatives to traditional air scouring. These mechanical methods can achieve comparable fouling control with 30-45% less energy consumption. Similarly, electrochemical membrane cleaning techniques that apply low-voltage electric fields to repel foulants have demonstrated energy savings of up to 50% in laboratory studies, though their full-scale implementation remains limited.

The integration of renewable energy sources, particularly solar power, has gained traction for MBR operations in remote locations. Solar-powered MBR systems with energy storage capabilities can significantly reduce operational costs while maintaining reliable performance, especially when coupled with smart control systems that optimize energy usage based on availability and demand patterns.

Sustainability Impact and Circular Economy Integration

Membrane bioreactor (MBR) technology represents a significant advancement in wastewater treatment with substantial implications for sustainability and circular economy principles. The implementation of effective fouling control strategies—including TMP management, air scouring techniques, and EPS mitigation—directly contributes to reduced energy consumption and operational costs, enhancing the overall sustainability profile of wastewater treatment facilities.

The energy efficiency improvements achieved through optimized fouling control can reduce the carbon footprint of MBR operations by up to 30%, according to recent industry analyses. This reduction aligns with global carbon emission targets and supports organizations in meeting increasingly stringent environmental regulations and sustainability goals.

From a circular economy perspective, effective MBR fouling control enables higher quality effluent production, facilitating water reuse applications in agriculture, industry, and urban settings. This water reclamation capability transforms wastewater from a disposal challenge into a valuable resource, exemplifying circular economy principles in practice.

The recovered biomass and EPS components from MBR systems represent another dimension of circular economy integration. These biological materials can be repurposed for bioenergy production through anaerobic digestion or as feedstock for bioplastic manufacturing, creating additional value streams from what was previously considered waste material.

Advanced fouling control strategies also extend membrane lifespan significantly, reducing replacement frequency and associated material consumption. This longevity contributes to resource conservation and waste reduction, key tenets of sustainable industrial practices. Studies indicate that effective fouling management can extend membrane life by 40-60%, substantially reducing the environmental impact associated with membrane production and disposal.

The water-energy nexus is particularly relevant in MBR technology, where fouling control directly influences both water quality and energy efficiency. By optimizing this relationship through innovative TMP management and air scouring techniques, MBR systems can achieve a more favorable sustainability profile compared to conventional treatment technologies.

Looking forward, the integration of digital monitoring systems and predictive analytics for fouling control represents an emerging opportunity to further enhance sustainability outcomes. These technologies enable real-time optimization of operational parameters, minimizing resource consumption while maximizing treatment efficiency and supporting the transition toward more circular and sustainable water management paradigms.

The energy efficiency improvements achieved through optimized fouling control can reduce the carbon footprint of MBR operations by up to 30%, according to recent industry analyses. This reduction aligns with global carbon emission targets and supports organizations in meeting increasingly stringent environmental regulations and sustainability goals.

From a circular economy perspective, effective MBR fouling control enables higher quality effluent production, facilitating water reuse applications in agriculture, industry, and urban settings. This water reclamation capability transforms wastewater from a disposal challenge into a valuable resource, exemplifying circular economy principles in practice.

The recovered biomass and EPS components from MBR systems represent another dimension of circular economy integration. These biological materials can be repurposed for bioenergy production through anaerobic digestion or as feedstock for bioplastic manufacturing, creating additional value streams from what was previously considered waste material.

Advanced fouling control strategies also extend membrane lifespan significantly, reducing replacement frequency and associated material consumption. This longevity contributes to resource conservation and waste reduction, key tenets of sustainable industrial practices. Studies indicate that effective fouling management can extend membrane life by 40-60%, substantially reducing the environmental impact associated with membrane production and disposal.

The water-energy nexus is particularly relevant in MBR technology, where fouling control directly influences both water quality and energy efficiency. By optimizing this relationship through innovative TMP management and air scouring techniques, MBR systems can achieve a more favorable sustainability profile compared to conventional treatment technologies.

Looking forward, the integration of digital monitoring systems and predictive analytics for fouling control represents an emerging opportunity to further enhance sustainability outcomes. These technologies enable real-time optimization of operational parameters, minimizing resource consumption while maximizing treatment efficiency and supporting the transition toward more circular and sustainable water management paradigms.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!