Membrane Bioreactor Energy Optimization: Blower Power, α-Factor And Control

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MBR Energy Efficiency Background and Objectives

Membrane Bioreactor (MBR) technology has evolved significantly since its commercial introduction in the late 1960s, becoming a cornerstone of advanced wastewater treatment systems. The integration of membrane filtration with biological treatment processes has enabled superior effluent quality, reduced footprint requirements, and enhanced process stability compared to conventional activated sludge systems. However, this technological advancement comes with a substantial energy cost, positioning energy optimization as a critical focus area for sustainable MBR implementation.

Energy consumption represents approximately 30-50% of the total operational costs in MBR systems, with aeration being the predominant energy consumer. Historically, MBR technology development has prioritized performance reliability and effluent quality over energy efficiency, resulting in systems that, while effective, are often energy-intensive. Recent industry trends indicate a paradigm shift toward balancing treatment efficacy with energy conservation, driven by increasing energy costs and environmental sustainability imperatives.

The evolution of MBR technology has witnessed several generations of improvements, from early flat sheet and hollow fiber membranes to current advanced configurations with optimized module designs. Despite these advancements, the fundamental challenge of membrane fouling persists, necessitating intensive aeration for membrane scouring, which significantly contributes to the energy footprint of MBR systems.

Blower systems, responsible for providing air for both biological treatment and membrane scouring, typically account for 60-80% of the total energy consumption in MBR operations. The efficiency of oxygen transfer, quantified by the α-factor (the ratio of oxygen transfer in process water to that in clean water), is a critical parameter that influences aeration efficiency and, consequently, energy requirements. Understanding and optimizing this factor presents a substantial opportunity for energy reduction.

Control strategies for MBR systems have evolved from simple timer-based approaches to sophisticated demand-based algorithms. However, the integration of real-time monitoring with adaptive control systems remains an area with significant potential for further energy optimization. The development of intelligent control systems that can dynamically adjust aeration rates based on process demands represents a frontier in MBR energy efficiency research.

The primary objective of this technical research is to comprehensively evaluate current approaches to energy optimization in MBR systems, with specific focus on blower power management, α-factor enhancement, and advanced control strategies. By identifying key technological trends, assessing innovative solutions, and projecting future developments, this research aims to establish a roadmap for achieving substantial energy reductions in MBR operations while maintaining or improving treatment performance.

Energy consumption represents approximately 30-50% of the total operational costs in MBR systems, with aeration being the predominant energy consumer. Historically, MBR technology development has prioritized performance reliability and effluent quality over energy efficiency, resulting in systems that, while effective, are often energy-intensive. Recent industry trends indicate a paradigm shift toward balancing treatment efficacy with energy conservation, driven by increasing energy costs and environmental sustainability imperatives.

The evolution of MBR technology has witnessed several generations of improvements, from early flat sheet and hollow fiber membranes to current advanced configurations with optimized module designs. Despite these advancements, the fundamental challenge of membrane fouling persists, necessitating intensive aeration for membrane scouring, which significantly contributes to the energy footprint of MBR systems.

Blower systems, responsible for providing air for both biological treatment and membrane scouring, typically account for 60-80% of the total energy consumption in MBR operations. The efficiency of oxygen transfer, quantified by the α-factor (the ratio of oxygen transfer in process water to that in clean water), is a critical parameter that influences aeration efficiency and, consequently, energy requirements. Understanding and optimizing this factor presents a substantial opportunity for energy reduction.

Control strategies for MBR systems have evolved from simple timer-based approaches to sophisticated demand-based algorithms. However, the integration of real-time monitoring with adaptive control systems remains an area with significant potential for further energy optimization. The development of intelligent control systems that can dynamically adjust aeration rates based on process demands represents a frontier in MBR energy efficiency research.

The primary objective of this technical research is to comprehensively evaluate current approaches to energy optimization in MBR systems, with specific focus on blower power management, α-factor enhancement, and advanced control strategies. By identifying key technological trends, assessing innovative solutions, and projecting future developments, this research aims to establish a roadmap for achieving substantial energy reductions in MBR operations while maintaining or improving treatment performance.

Market Demand for Energy-Efficient Wastewater Treatment

The global wastewater treatment market is experiencing significant growth driven by increasing water scarcity, stringent environmental regulations, and rising awareness about water conservation. Within this sector, energy-efficient solutions are gaining substantial traction as treatment facilities face mounting pressure to reduce operational costs and carbon footprints.

Membrane Bioreactor (MBR) technology has emerged as a leading advanced wastewater treatment solution, combining conventional activated sludge processes with membrane filtration. However, energy consumption remains a critical challenge, with MBR systems typically requiring 0.8-1.2 kWh per cubic meter of treated water—significantly higher than conventional activated sludge systems.

Market research indicates that energy costs represent 25-40% of the total operational expenses in wastewater treatment plants, with aeration systems accounting for approximately 50-70% of the plant's energy consumption. This economic burden has created strong market demand for energy optimization solutions specifically targeting blower systems and aeration efficiency in MBR operations.

The municipal sector represents the largest market segment for energy-efficient MBR systems, driven by urbanization and infrastructure development. Municipalities worldwide are increasingly adopting energy performance contracting and seeking technologies that can demonstrate clear return on investment through reduced energy consumption.

Industrial applications are also showing robust growth, particularly in sectors such as food and beverage, pharmaceuticals, and textiles, where stringent discharge regulations necessitate advanced treatment solutions. These industries are increasingly willing to invest in energy-efficient MBR technologies that offer both compliance and cost savings.

Geographically, North America and Europe lead in adoption of energy-efficient wastewater technologies due to mature regulatory frameworks and higher energy costs. However, the Asia-Pacific region is witnessing the fastest growth rate, driven by rapid industrialization, water scarcity challenges, and increasing environmental regulations in countries like China and India.

Market forecasts project the global MBR market to grow at a CAGR of 7-8% through 2028, with energy-efficient solutions expected to capture an increasing market share. The demand for optimization technologies specifically addressing blower power consumption, α-factor improvement, and advanced control systems is anticipated to grow disproportionately faster than the overall MBR market.

Customer requirements increasingly emphasize solutions that offer real-time monitoring capabilities, adaptive control systems, and demonstrable energy savings with payback periods under three years. This market demand is driving innovation in sensor technologies, machine learning applications for process optimization, and more efficient membrane and diffuser designs.

Membrane Bioreactor (MBR) technology has emerged as a leading advanced wastewater treatment solution, combining conventional activated sludge processes with membrane filtration. However, energy consumption remains a critical challenge, with MBR systems typically requiring 0.8-1.2 kWh per cubic meter of treated water—significantly higher than conventional activated sludge systems.

Market research indicates that energy costs represent 25-40% of the total operational expenses in wastewater treatment plants, with aeration systems accounting for approximately 50-70% of the plant's energy consumption. This economic burden has created strong market demand for energy optimization solutions specifically targeting blower systems and aeration efficiency in MBR operations.

The municipal sector represents the largest market segment for energy-efficient MBR systems, driven by urbanization and infrastructure development. Municipalities worldwide are increasingly adopting energy performance contracting and seeking technologies that can demonstrate clear return on investment through reduced energy consumption.

Industrial applications are also showing robust growth, particularly in sectors such as food and beverage, pharmaceuticals, and textiles, where stringent discharge regulations necessitate advanced treatment solutions. These industries are increasingly willing to invest in energy-efficient MBR technologies that offer both compliance and cost savings.

Geographically, North America and Europe lead in adoption of energy-efficient wastewater technologies due to mature regulatory frameworks and higher energy costs. However, the Asia-Pacific region is witnessing the fastest growth rate, driven by rapid industrialization, water scarcity challenges, and increasing environmental regulations in countries like China and India.

Market forecasts project the global MBR market to grow at a CAGR of 7-8% through 2028, with energy-efficient solutions expected to capture an increasing market share. The demand for optimization technologies specifically addressing blower power consumption, α-factor improvement, and advanced control systems is anticipated to grow disproportionately faster than the overall MBR market.

Customer requirements increasingly emphasize solutions that offer real-time monitoring capabilities, adaptive control systems, and demonstrable energy savings with payback periods under three years. This market demand is driving innovation in sensor technologies, machine learning applications for process optimization, and more efficient membrane and diffuser designs.

Current Challenges in MBR Energy Consumption

Membrane Bioreactor (MBR) systems have emerged as a leading technology in wastewater treatment, offering superior effluent quality and reduced footprint compared to conventional activated sludge processes. However, energy consumption remains a significant challenge, with MBR systems typically requiring 30-50% more energy than conventional treatment methods. This energy demand represents not only a substantial operational cost but also a considerable environmental footprint that contradicts the sustainability goals of modern water treatment facilities.

The aeration system, particularly the membrane scouring process, accounts for approximately 40-60% of the total energy consumption in MBR operations. This high energy requirement stems from the need to maintain adequate air flow rates to prevent membrane fouling while ensuring efficient oxygen transfer for biological treatment. The delicate balance between these competing objectives presents a complex optimization challenge that has not been fully resolved in current implementations.

Membrane fouling control strategies often rely on conservative approaches that prioritize system reliability over energy efficiency, resulting in excessive aeration rates. Studies indicate that many facilities operate with aeration rates 15-30% higher than theoretically necessary, creating significant opportunities for optimization. This over-aeration is particularly problematic during low-load periods, where energy consumption remains high despite reduced treatment demands.

The α-factor, which represents the ratio of oxygen transfer efficiency in process water compared to clean water, presents another critical challenge. In MBR systems, this factor is typically reduced to 0.5-0.7 due to surfactants, mixed liquor suspended solids, and other contaminants that interfere with oxygen transfer. This reduction necessitates higher air flow rates to achieve the same treatment outcomes, further increasing energy consumption.

Current control systems often lack the sophistication needed for dynamic optimization of aeration parameters. Most facilities employ fixed aeration schedules or simple feedback control based on limited parameters, failing to account for the complex interactions between biological processes, membrane fouling dynamics, and varying influent characteristics. This results in suboptimal energy utilization across different operational conditions.

The high mixed liquor suspended solids (MLSS) concentration in MBR systems, while beneficial for treatment efficiency, creates additional energy demands. Higher MLSS levels increase viscosity and reduce oxygen transfer efficiency, requiring more energy for mixing and aeration. Finding the optimal MLSS concentration that balances treatment performance with energy consumption remains challenging.

Temperature fluctuations further complicate energy optimization efforts. Seasonal variations affect both biological activity and membrane permeability, necessitating adjustments to aeration strategies. Current systems often lack the predictive capabilities to proactively adapt to these changes, resulting in periods of energy inefficiency during transitional seasons.

The aeration system, particularly the membrane scouring process, accounts for approximately 40-60% of the total energy consumption in MBR operations. This high energy requirement stems from the need to maintain adequate air flow rates to prevent membrane fouling while ensuring efficient oxygen transfer for biological treatment. The delicate balance between these competing objectives presents a complex optimization challenge that has not been fully resolved in current implementations.

Membrane fouling control strategies often rely on conservative approaches that prioritize system reliability over energy efficiency, resulting in excessive aeration rates. Studies indicate that many facilities operate with aeration rates 15-30% higher than theoretically necessary, creating significant opportunities for optimization. This over-aeration is particularly problematic during low-load periods, where energy consumption remains high despite reduced treatment demands.

The α-factor, which represents the ratio of oxygen transfer efficiency in process water compared to clean water, presents another critical challenge. In MBR systems, this factor is typically reduced to 0.5-0.7 due to surfactants, mixed liquor suspended solids, and other contaminants that interfere with oxygen transfer. This reduction necessitates higher air flow rates to achieve the same treatment outcomes, further increasing energy consumption.

Current control systems often lack the sophistication needed for dynamic optimization of aeration parameters. Most facilities employ fixed aeration schedules or simple feedback control based on limited parameters, failing to account for the complex interactions between biological processes, membrane fouling dynamics, and varying influent characteristics. This results in suboptimal energy utilization across different operational conditions.

The high mixed liquor suspended solids (MLSS) concentration in MBR systems, while beneficial for treatment efficiency, creates additional energy demands. Higher MLSS levels increase viscosity and reduce oxygen transfer efficiency, requiring more energy for mixing and aeration. Finding the optimal MLSS concentration that balances treatment performance with energy consumption remains challenging.

Temperature fluctuations further complicate energy optimization efforts. Seasonal variations affect both biological activity and membrane permeability, necessitating adjustments to aeration strategies. Current systems often lack the predictive capabilities to proactively adapt to these changes, resulting in periods of energy inefficiency during transitional seasons.

Current Blower Power Optimization Strategies

01 Aeration system optimization for MBR energy efficiency

Optimizing aeration systems in membrane bioreactors can significantly reduce energy consumption. This includes implementing advanced control strategies for air flow, using energy-efficient diffusers, and adjusting aeration patterns based on real-time monitoring of membrane fouling and biological requirements. Intermittent aeration and demand-based air supply can maintain effective membrane scouring while reducing the overall energy footprint of the MBR system.- Process control optimization for energy efficiency: Advanced control systems and algorithms can optimize membrane bioreactor operations by adjusting operational parameters in real-time based on influent characteristics, membrane conditions, and energy consumption patterns. These systems can regulate aeration rates, membrane filtration cycles, and backwashing frequencies to minimize energy usage while maintaining treatment performance. Machine learning and predictive analytics enable proactive adjustments to operational parameters before system inefficiencies occur.

- Aeration system design and optimization: Innovative aeration system designs can significantly reduce energy consumption in membrane bioreactors. These include fine-bubble diffusers, intermittent aeration strategies, and demand-based aeration control. By optimizing air distribution patterns and implementing pulsed aeration techniques, membrane fouling can be controlled while reducing blower energy requirements. Advanced diffuser technologies improve oxygen transfer efficiency, allowing for lower airflow rates while maintaining adequate mixing and membrane scouring.

- Energy recovery and renewable integration: Membrane bioreactors can be designed to recover energy from wastewater treatment processes and integrate renewable energy sources. Techniques include harvesting biogas from anaerobic processes, implementing heat exchangers to recover thermal energy, and integrating solar or wind power systems to offset operational energy demands. Energy storage systems can be incorporated to optimize energy usage patterns and take advantage of off-peak electricity rates.

- Membrane fouling reduction strategies: Specialized membrane materials and surface modifications can reduce fouling propensity, thereby decreasing the energy required for membrane cleaning and maintenance. Advanced filtration protocols, including optimized backwashing sequences and chemical cleaning regimes, can maintain membrane permeability with minimal energy input. Physical modifications to membrane modules and tank designs can improve hydrodynamics and reduce dead zones where fouling typically occurs.

- System configuration and hydraulic optimization: Innovative MBR configurations can reduce energy consumption through optimized hydraulic designs and flow patterns. These include gravity-driven systems, hybrid configurations combining different treatment processes, and decentralized modular designs. Pump scheduling algorithms and variable frequency drives can adjust flow rates based on demand, reducing pumping energy requirements. Strategic placement of components and optimized tank geometries can minimize head losses and improve overall system hydraulics.

02 Intelligent control systems for MBR operation

Implementation of intelligent control systems using machine learning algorithms and real-time data analytics can optimize MBR energy consumption. These systems continuously monitor operational parameters and automatically adjust settings to maintain optimal performance while minimizing energy use. Predictive maintenance capabilities help prevent energy-intensive membrane fouling events and optimize cleaning cycles based on actual system conditions rather than fixed schedules.Expand Specific Solutions03 Innovative membrane module designs for energy reduction

Advanced membrane module designs can reduce energy requirements in MBR systems. These innovations include improved membrane materials with higher permeability, optimized module configurations that enhance fluid dynamics, and novel membrane surface modifications that reduce fouling propensity. Energy-efficient membrane designs allow for lower transmembrane pressure operation while maintaining filtration performance, directly reducing pumping energy requirements.Expand Specific Solutions04 Energy recovery and renewable integration in MBR systems

Integration of energy recovery technologies and renewable energy sources can improve the overall energy balance of MBR systems. This includes capturing biogas from anaerobic processes for electricity generation, heat recovery from effluent streams, and direct coupling with solar or wind power systems. Advanced energy storage solutions enable optimized energy use patterns that take advantage of variable renewable energy availability and off-peak electricity rates.Expand Specific Solutions05 Process configuration optimization for energy efficiency

Optimizing the overall process configuration of MBR systems can yield significant energy savings. This includes implementing anaerobic-anoxic-aerobic process sequences, optimizing hydraulic retention times, and employing innovative nutrient removal strategies that reduce aeration requirements. Strategic placement of mixing equipment, smart sequencing of treatment stages, and integration of primary treatment technologies can further reduce the energy intensity of the overall treatment process.Expand Specific Solutions

Leading Companies in MBR Technology and Equipment

Membrane Bioreactor Energy Optimization is currently in a growth phase, with the market expanding due to increasing water treatment demands and sustainability requirements. The global market size is estimated to reach $8-10 billion by 2025, growing at 7-9% annually. Technologically, the field is in mid-maturity, with established solutions evolving toward higher efficiency. Leading players include Evoqua Water Technologies and Veolia Water Solutions, who offer comprehensive MBR systems with energy optimization features. General Electric and Bühler AG are advancing blower technology and control systems, while research institutions like Vanderbilt University and Zhejiang University are developing next-generation α-factor optimization approaches. Companies like ITM Power and ABEC are focusing on specialized components for energy reduction, creating a competitive landscape balanced between established providers and innovative newcomers.

Evoqua Water Technologies LLC

Technical Solution: Evoqua has developed advanced membrane bioreactor (MBR) systems with integrated energy optimization solutions focusing on blower power management. Their MemPulse MBR technology utilizes a unique air scouring system that reduces energy consumption by up to 40% compared to conventional MBR systems. The system employs intelligent aeration control algorithms that adjust blower output based on real-time monitoring of transmembrane pressure (TMP), dissolved oxygen levels, and MLSS concentration. Evoqua's BioMind control platform continuously optimizes the α-factor (oxygen transfer efficiency) by dynamically adjusting air flow rates and distribution patterns across membrane modules. Their patented air cycling technology alternates between high and low aeration periods, maintaining effective membrane cleaning while significantly reducing overall energy consumption. Additionally, Evoqua has implemented variable frequency drives (VFDs) on all blowers, allowing precise control of air delivery based on actual demand rather than fixed operational parameters.

Strengths: Industry-leading energy efficiency with up to 40% reduction in aeration energy requirements; advanced real-time monitoring and control systems; proven technology with extensive installation base. Weaknesses: Higher initial capital investment compared to conventional treatment systems; requires more sophisticated maintenance and operational expertise; performance can be affected by influent variability requiring system adjustments.

Veolia Water Solutions & Technologies Support SAS

Technical Solution: Veolia has pioneered comprehensive MBR energy optimization solutions through their Hybas™ and Neosep® MBR technologies. Their approach integrates sophisticated blower control systems with advanced membrane configurations to maximize energy efficiency. Veolia's proprietary AQUAVISTA™ digital platform provides real-time monitoring and control of the entire MBR process, with specific algorithms dedicated to optimizing blower operation based on multiple parameters including membrane fouling rates, biological oxygen demand, and α-factor variations. The system employs a cascade aeration control strategy that maintains optimal dissolved oxygen levels while minimizing energy consumption. Veolia has also developed specialized membrane modules with enhanced surface patterns that improve air scouring efficiency, allowing for reduced air flow requirements while maintaining effective membrane cleaning. Their latest innovation includes implementing intermittent aeration cycles with precise timing controlled by machine learning algorithms that adapt to changing influent characteristics and membrane conditions over time, resulting in energy savings of up to 30-45% compared to conventional continuous aeration systems.

Strengths: Comprehensive digital control platform with predictive capabilities; global installation base providing extensive operational data for optimization; integrated approach combining hardware and software solutions. Weaknesses: Complex implementation requiring significant technical expertise; higher initial investment costs; system optimization requires extended calibration period to achieve maximum energy efficiency.

Key Innovations in α-Factor Enhancement

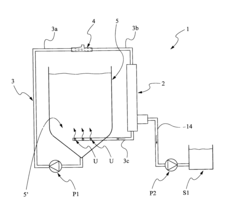

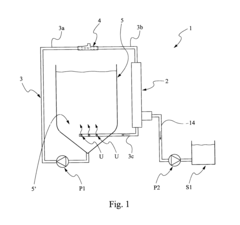

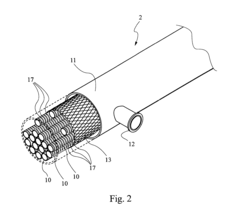

Aeration and filtration system and process for treating wastewater

PatentInactiveUS20110089108A1

Innovation

- An aeration and filtration system where a Venturi ejector mixes oxygen with the wastewater and biological sludge mixture, followed by filtration through a microporous tubular membrane, allowing efficient oxygen transfer in multiple stages and reducing energy consumption by utilizing residual energy for filtration.

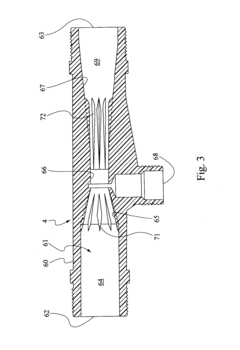

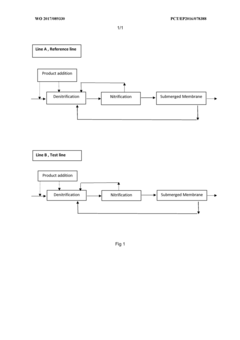

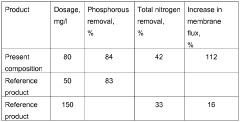

Improve phosphorus precipitation and membrane FLUX in membrane bioreactors

PatentWO2017089330A1

Innovation

- A blend of inorganic coagulants, such as iron and aluminum compounds, and organic water-soluble polymers, like anionic, cationic, and nonionic polymers, is added to the influent of membrane bioreactors to enhance phosphorus precipitation and permeate flux, improving membrane performance and water treatment efficiency.

Environmental Impact and Sustainability Metrics

Membrane Bioreactor (MBR) systems represent a significant advancement in wastewater treatment technology, yet their environmental footprint remains a critical consideration. The optimization of energy consumption in MBR operations directly correlates with reduced greenhouse gas emissions, particularly carbon dioxide from electricity generation. Current estimates indicate that optimized blower systems can reduce carbon emissions by 15-30% compared to conventional activated sludge processes when evaluated on a lifecycle basis.

The environmental benefits extend beyond carbon reduction. Optimized MBR systems demonstrate superior effluent quality, removing up to 99% of pathogens and emerging contaminants that conventional systems fail to address. This enhanced treatment capability prevents downstream ecosystem degradation and reduces the burden on natural water purification processes. Furthermore, the compact footprint of MBR installations preserves land resources, allowing for more sustainable land use planning in urban environments.

Water reuse capabilities represent another significant sustainability advantage. Energy-optimized MBRs produce effluent suitable for non-potable reuse applications, reducing freshwater withdrawal demands by up to 25% in water-stressed regions. This circular approach to water management creates a positive feedback loop where energy investments yield substantial environmental returns through conservation of freshwater resources.

Quantifiable sustainability metrics for MBR energy optimization include Energy Intensity (kWh/m³ treated), which can be reduced from typical values of 0.8-1.2 kWh/m³ to 0.4-0.6 kWh/m³ through advanced blower control strategies and α-factor optimization. The Water-Energy Nexus Efficiency Index (WENEI) improves by approximately 40% when implementing adaptive aeration control systems that respond to real-time loading conditions.

Chemical consumption represents another environmental consideration, with optimized MBR systems requiring 20-30% less cleaning chemicals through improved membrane fouling management. This reduction minimizes the environmental impact associated with chemical production, transportation, and disposal. Additionally, the extended membrane life resulting from optimized operations reduces waste generation and resource consumption associated with membrane replacement.

Resilience metrics also factor into sustainability assessments. Energy-optimized MBRs demonstrate enhanced operational stability during variable influent conditions, maintaining treatment efficacy while minimizing energy spikes that would otherwise increase environmental impact. This adaptability proves particularly valuable in regions experiencing increasing climate variability, where treatment systems must accommodate more extreme weather events while maintaining environmental performance standards.

The environmental benefits extend beyond carbon reduction. Optimized MBR systems demonstrate superior effluent quality, removing up to 99% of pathogens and emerging contaminants that conventional systems fail to address. This enhanced treatment capability prevents downstream ecosystem degradation and reduces the burden on natural water purification processes. Furthermore, the compact footprint of MBR installations preserves land resources, allowing for more sustainable land use planning in urban environments.

Water reuse capabilities represent another significant sustainability advantage. Energy-optimized MBRs produce effluent suitable for non-potable reuse applications, reducing freshwater withdrawal demands by up to 25% in water-stressed regions. This circular approach to water management creates a positive feedback loop where energy investments yield substantial environmental returns through conservation of freshwater resources.

Quantifiable sustainability metrics for MBR energy optimization include Energy Intensity (kWh/m³ treated), which can be reduced from typical values of 0.8-1.2 kWh/m³ to 0.4-0.6 kWh/m³ through advanced blower control strategies and α-factor optimization. The Water-Energy Nexus Efficiency Index (WENEI) improves by approximately 40% when implementing adaptive aeration control systems that respond to real-time loading conditions.

Chemical consumption represents another environmental consideration, with optimized MBR systems requiring 20-30% less cleaning chemicals through improved membrane fouling management. This reduction minimizes the environmental impact associated with chemical production, transportation, and disposal. Additionally, the extended membrane life resulting from optimized operations reduces waste generation and resource consumption associated with membrane replacement.

Resilience metrics also factor into sustainability assessments. Energy-optimized MBRs demonstrate enhanced operational stability during variable influent conditions, maintaining treatment efficacy while minimizing energy spikes that would otherwise increase environmental impact. This adaptability proves particularly valuable in regions experiencing increasing climate variability, where treatment systems must accommodate more extreme weather events while maintaining environmental performance standards.

Regulatory Framework for Wastewater Treatment Efficiency

The regulatory landscape governing wastewater treatment efficiency has evolved significantly in response to growing environmental concerns and resource conservation imperatives. Membrane Bioreactor (MBR) systems, particularly their energy optimization aspects, are increasingly subject to stringent regulatory frameworks worldwide. These regulations typically establish minimum standards for effluent quality while encouraging energy efficiency improvements.

In the United States, the Environmental Protection Agency (EPA) has implemented the Clean Water Act which mandates secondary treatment standards for municipal wastewater. More recently, the EPA's Energy Star program has expanded to include wastewater treatment facilities, creating benchmarks for energy performance. These regulations indirectly influence MBR blower operations by setting parameters that facilities must achieve while optimizing energy consumption.

The European Union's Water Framework Directive and Urban Waste Water Treatment Directive establish comprehensive requirements for wastewater treatment, with particular emphasis on energy efficiency. The EU's Energy Efficiency Directive further complements these regulations by requiring large facilities to conduct energy audits, which often highlight blower systems as significant energy consumers in MBR operations.

In Asia, countries like Japan and Singapore have pioneered regulatory frameworks specifically addressing MBR technology. Japan's Ministry of Land, Infrastructure, Transport and Tourism has established guidelines for MBR operation that include specific provisions for aeration efficiency and α-factor optimization. Singapore's Public Utilities Board has implemented performance-based regulations that incentivize energy-efficient MBR operations.

International standards organizations have also contributed to the regulatory framework. ISO 20468 provides guidelines for the evaluation of water reuse technologies from an energy perspective, while ISO 50001 for energy management systems is increasingly applied to wastewater treatment facilities, driving systematic approaches to blower power optimization.

Emerging regulatory trends include carbon neutrality targets for utilities, which directly impact MBR energy optimization strategies. Several jurisdictions are moving toward outcome-based regulations that specify performance targets rather than prescriptive technologies, allowing operators more flexibility in implementing energy-efficient control strategies for MBR systems.

Financial incentives and penalties are increasingly incorporated into regulatory frameworks, with some regions implementing carbon pricing mechanisms that make energy-intensive wastewater treatment more costly, thus driving innovation in blower efficiency and control systems for MBRs.

In the United States, the Environmental Protection Agency (EPA) has implemented the Clean Water Act which mandates secondary treatment standards for municipal wastewater. More recently, the EPA's Energy Star program has expanded to include wastewater treatment facilities, creating benchmarks for energy performance. These regulations indirectly influence MBR blower operations by setting parameters that facilities must achieve while optimizing energy consumption.

The European Union's Water Framework Directive and Urban Waste Water Treatment Directive establish comprehensive requirements for wastewater treatment, with particular emphasis on energy efficiency. The EU's Energy Efficiency Directive further complements these regulations by requiring large facilities to conduct energy audits, which often highlight blower systems as significant energy consumers in MBR operations.

In Asia, countries like Japan and Singapore have pioneered regulatory frameworks specifically addressing MBR technology. Japan's Ministry of Land, Infrastructure, Transport and Tourism has established guidelines for MBR operation that include specific provisions for aeration efficiency and α-factor optimization. Singapore's Public Utilities Board has implemented performance-based regulations that incentivize energy-efficient MBR operations.

International standards organizations have also contributed to the regulatory framework. ISO 20468 provides guidelines for the evaluation of water reuse technologies from an energy perspective, while ISO 50001 for energy management systems is increasingly applied to wastewater treatment facilities, driving systematic approaches to blower power optimization.

Emerging regulatory trends include carbon neutrality targets for utilities, which directly impact MBR energy optimization strategies. Several jurisdictions are moving toward outcome-based regulations that specify performance targets rather than prescriptive technologies, allowing operators more flexibility in implementing energy-efficient control strategies for MBR systems.

Financial incentives and penalties are increasingly incorporated into regulatory frameworks, with some regions implementing carbon pricing mechanisms that make energy-intensive wastewater treatment more costly, thus driving innovation in blower efficiency and control systems for MBRs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!