Membrane Bioreactor Modules: Hollow Fiber Vs Flat Sheet, Integrity And Cleaning

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MBR Technology Evolution and Objectives

Membrane Bioreactor (MBR) technology has evolved significantly since its inception in the late 1960s, transforming from experimental laboratory setups to robust industrial-scale wastewater treatment systems. The initial MBR designs were primarily side-stream configurations where the membrane module was separate from the bioreactor. By the 1990s, the industry witnessed a paradigm shift with the introduction of submerged or immersed membrane configurations, which substantially reduced energy consumption and operational costs.

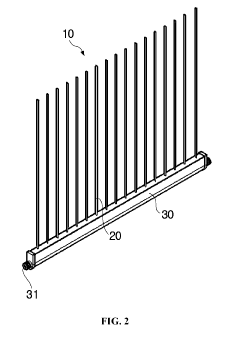

The evolution of MBR modules has been characterized by two dominant membrane configurations: hollow fiber and flat sheet. Hollow fiber modules, introduced in the early stages of MBR development, consist of bundles of tubular membranes with diameters typically ranging from 0.5 to 2.0 mm. These modules offer high packing density and surface area-to-volume ratio, making them space-efficient. Flat sheet modules, which emerged later, feature membrane sheets arranged in parallel, providing better fouling resistance but at the cost of lower packing density.

Material science advancements have played a crucial role in MBR technology development. Early membranes were primarily made of cellulose acetate, which had limited chemical and thermal stability. Modern MBR modules utilize synthetic polymers such as polyvinylidene fluoride (PVDF), polyethersulfone (PES), and polyethylene (PE), offering enhanced durability, fouling resistance, and chemical compatibility.

The primary objectives driving MBR technology evolution include improving membrane integrity, enhancing cleaning efficiency, reducing energy consumption, and extending membrane lifespan. Membrane integrity is paramount as it directly impacts effluent quality and system reliability. Manufacturers have focused on developing robust membrane materials and module designs that can withstand mechanical stress, chemical exposure, and biological fouling while maintaining consistent filtration performance.

Cleaning protocols have evolved from simple backwashing to sophisticated chemical cleaning regimes incorporating various agents for organic, inorganic, and biological fouling removal. The industry has been moving toward more sustainable cleaning approaches that minimize chemical usage while maximizing cleaning effectiveness.

Energy efficiency remains a critical objective in MBR development, with innovations focusing on reducing aeration requirements for membrane scouring, optimizing filtration cycles, and improving hydraulic designs. Recent advancements include the development of anaerobic MBRs (AnMBRs) that can generate energy while treating wastewater, representing a significant step toward energy-neutral or energy-positive wastewater treatment.

The future trajectory of MBR technology aims at developing "smart" systems with real-time monitoring and adaptive control capabilities, novel anti-fouling materials, and hybrid processes that combine MBR with other treatment technologies to address emerging contaminants and resource recovery challenges.

The evolution of MBR modules has been characterized by two dominant membrane configurations: hollow fiber and flat sheet. Hollow fiber modules, introduced in the early stages of MBR development, consist of bundles of tubular membranes with diameters typically ranging from 0.5 to 2.0 mm. These modules offer high packing density and surface area-to-volume ratio, making them space-efficient. Flat sheet modules, which emerged later, feature membrane sheets arranged in parallel, providing better fouling resistance but at the cost of lower packing density.

Material science advancements have played a crucial role in MBR technology development. Early membranes were primarily made of cellulose acetate, which had limited chemical and thermal stability. Modern MBR modules utilize synthetic polymers such as polyvinylidene fluoride (PVDF), polyethersulfone (PES), and polyethylene (PE), offering enhanced durability, fouling resistance, and chemical compatibility.

The primary objectives driving MBR technology evolution include improving membrane integrity, enhancing cleaning efficiency, reducing energy consumption, and extending membrane lifespan. Membrane integrity is paramount as it directly impacts effluent quality and system reliability. Manufacturers have focused on developing robust membrane materials and module designs that can withstand mechanical stress, chemical exposure, and biological fouling while maintaining consistent filtration performance.

Cleaning protocols have evolved from simple backwashing to sophisticated chemical cleaning regimes incorporating various agents for organic, inorganic, and biological fouling removal. The industry has been moving toward more sustainable cleaning approaches that minimize chemical usage while maximizing cleaning effectiveness.

Energy efficiency remains a critical objective in MBR development, with innovations focusing on reducing aeration requirements for membrane scouring, optimizing filtration cycles, and improving hydraulic designs. Recent advancements include the development of anaerobic MBRs (AnMBRs) that can generate energy while treating wastewater, representing a significant step toward energy-neutral or energy-positive wastewater treatment.

The future trajectory of MBR technology aims at developing "smart" systems with real-time monitoring and adaptive control capabilities, novel anti-fouling materials, and hybrid processes that combine MBR with other treatment technologies to address emerging contaminants and resource recovery challenges.

Market Demand Analysis for MBR Systems

The global Membrane Bioreactor (MBR) systems market has demonstrated robust growth over the past decade, driven primarily by increasing water scarcity concerns and stringent wastewater treatment regulations. The market was valued at approximately $3.8 billion in 2022 and is projected to reach $7.2 billion by 2028, representing a compound annual growth rate (CAGR) of 11.2%.

Municipal wastewater treatment remains the dominant application segment, accounting for over 60% of the total MBR systems market. However, industrial applications are witnessing faster growth rates, particularly in sectors such as food and beverage, pharmaceuticals, and textiles, where high-quality treated water is essential for operational processes.

Regionally, Asia-Pacific represents the largest and fastest-growing market for MBR systems, with China, Japan, and South Korea leading the adoption. This growth is attributed to rapid industrialization, urbanization, and government initiatives promoting advanced wastewater treatment technologies. North America and Europe follow as mature markets with steady growth, primarily driven by replacement and upgrade activities.

The demand for hollow fiber MBR modules currently dominates the market with approximately 65% market share, valued for their higher packing density and lower footprint requirements. However, flat sheet modules are gaining traction, growing at a faster rate of 13.5% annually, due to their superior fouling resistance and easier cleaning characteristics.

End-users are increasingly prioritizing total cost of ownership over initial capital expenditure, creating market demand for modules with longer operational lifespans, improved cleaning efficiency, and reduced energy consumption. This shift has intensified competition among manufacturers to develop modules with enhanced integrity and optimized cleaning protocols.

Water reuse applications represent the fastest-growing segment within the MBR market, expanding at 14.8% annually. This trend is particularly evident in water-stressed regions where treated wastewater is increasingly valued as a resource rather than waste.

The COVID-19 pandemic temporarily disrupted supply chains but simultaneously heightened awareness about water security, potentially accelerating long-term market growth. Post-pandemic recovery has been strong, with increased infrastructure spending in several countries including MBR technology as part of water treatment facility upgrades.

Market analysts predict that technological innovations focusing on energy efficiency, membrane fouling reduction, and simplified maintenance will be key differentiators for manufacturers in the coming years, as end-users seek solutions that minimize operational costs while maximizing treatment efficiency.

Municipal wastewater treatment remains the dominant application segment, accounting for over 60% of the total MBR systems market. However, industrial applications are witnessing faster growth rates, particularly in sectors such as food and beverage, pharmaceuticals, and textiles, where high-quality treated water is essential for operational processes.

Regionally, Asia-Pacific represents the largest and fastest-growing market for MBR systems, with China, Japan, and South Korea leading the adoption. This growth is attributed to rapid industrialization, urbanization, and government initiatives promoting advanced wastewater treatment technologies. North America and Europe follow as mature markets with steady growth, primarily driven by replacement and upgrade activities.

The demand for hollow fiber MBR modules currently dominates the market with approximately 65% market share, valued for their higher packing density and lower footprint requirements. However, flat sheet modules are gaining traction, growing at a faster rate of 13.5% annually, due to their superior fouling resistance and easier cleaning characteristics.

End-users are increasingly prioritizing total cost of ownership over initial capital expenditure, creating market demand for modules with longer operational lifespans, improved cleaning efficiency, and reduced energy consumption. This shift has intensified competition among manufacturers to develop modules with enhanced integrity and optimized cleaning protocols.

Water reuse applications represent the fastest-growing segment within the MBR market, expanding at 14.8% annually. This trend is particularly evident in water-stressed regions where treated wastewater is increasingly valued as a resource rather than waste.

The COVID-19 pandemic temporarily disrupted supply chains but simultaneously heightened awareness about water security, potentially accelerating long-term market growth. Post-pandemic recovery has been strong, with increased infrastructure spending in several countries including MBR technology as part of water treatment facility upgrades.

Market analysts predict that technological innovations focusing on energy efficiency, membrane fouling reduction, and simplified maintenance will be key differentiators for manufacturers in the coming years, as end-users seek solutions that minimize operational costs while maximizing treatment efficiency.

Current Challenges in Membrane Bioreactor Technology

Membrane bioreactor (MBR) technology faces several significant challenges that hinder its wider adoption and operational efficiency. One of the most persistent issues is membrane fouling, which occurs when contaminants accumulate on membrane surfaces, reducing permeability and flux rates. This phenomenon necessitates frequent cleaning cycles, increasing operational costs and system downtime. The fouling mechanisms differ substantially between hollow fiber and flat sheet configurations, with hollow fibers being more susceptible to internal clogging while flat sheets tend to experience surface fouling.

Energy consumption represents another major challenge, particularly for submerged MBR systems that require continuous aeration for both biological treatment and membrane scouring. This energy requirement can account for up to 70-80% of the total operational costs in some installations. The aeration needs differ between module types, with hollow fiber modules typically requiring more intense aeration to prevent fouling due to their higher packing density.

Membrane integrity monitoring remains problematic across the industry. Current methods for detecting breaches or failures in membranes are often inadequate, especially for early-stage detection. Hollow fiber modules present particular challenges as individual fiber breakage can be difficult to identify until significant performance deterioration occurs. Flat sheet modules, while generally more robust, still lack reliable real-time integrity monitoring solutions.

Chemical cleaning protocols present another significant challenge. The balance between effective cleaning and membrane longevity is difficult to achieve, as aggressive cleaning regimes can reduce membrane lifespan. Different membrane materials and configurations require tailored cleaning approaches, complicating standardization efforts. Additionally, the environmental impact of cleaning chemicals and their disposal represents growing regulatory concerns.

Operational flexibility challenges emerge when MBR systems face variable influent conditions or flow rates. Hollow fiber modules typically offer better turndown capabilities but may struggle with high solid loadings, while flat sheet modules generally handle solids better but have more limited flexibility in operational parameters.

Cost remains a persistent barrier to wider MBR adoption. Capital expenditure for membrane modules represents a significant portion of initial system costs, with flat sheet modules typically commanding higher prices than hollow fiber alternatives. The total cost of ownership calculation is complicated by differences in operational expenses, replacement frequencies, and maintenance requirements between module types.

Standardization across the industry is lacking, with manufacturers using proprietary designs and operating protocols that complicate system integration and comparison. This fragmentation impedes knowledge sharing and technological advancement in addressing common challenges facing MBR technology.

Energy consumption represents another major challenge, particularly for submerged MBR systems that require continuous aeration for both biological treatment and membrane scouring. This energy requirement can account for up to 70-80% of the total operational costs in some installations. The aeration needs differ between module types, with hollow fiber modules typically requiring more intense aeration to prevent fouling due to their higher packing density.

Membrane integrity monitoring remains problematic across the industry. Current methods for detecting breaches or failures in membranes are often inadequate, especially for early-stage detection. Hollow fiber modules present particular challenges as individual fiber breakage can be difficult to identify until significant performance deterioration occurs. Flat sheet modules, while generally more robust, still lack reliable real-time integrity monitoring solutions.

Chemical cleaning protocols present another significant challenge. The balance between effective cleaning and membrane longevity is difficult to achieve, as aggressive cleaning regimes can reduce membrane lifespan. Different membrane materials and configurations require tailored cleaning approaches, complicating standardization efforts. Additionally, the environmental impact of cleaning chemicals and their disposal represents growing regulatory concerns.

Operational flexibility challenges emerge when MBR systems face variable influent conditions or flow rates. Hollow fiber modules typically offer better turndown capabilities but may struggle with high solid loadings, while flat sheet modules generally handle solids better but have more limited flexibility in operational parameters.

Cost remains a persistent barrier to wider MBR adoption. Capital expenditure for membrane modules represents a significant portion of initial system costs, with flat sheet modules typically commanding higher prices than hollow fiber alternatives. The total cost of ownership calculation is complicated by differences in operational expenses, replacement frequencies, and maintenance requirements between module types.

Standardization across the industry is lacking, with manufacturers using proprietary designs and operating protocols that complicate system integration and comparison. This fragmentation impedes knowledge sharing and technological advancement in addressing common challenges facing MBR technology.

Comparative Analysis: Hollow Fiber vs Flat Sheet Designs

01 Integrity testing methods for membrane bioreactor modules

Various methods are employed to test the integrity of membrane bioreactor modules to ensure proper filtration performance. These methods include pressure decay tests, bubble point tests, and acoustic sensing technologies that can detect membrane breaches or failures. Integrity testing is crucial for maintaining water quality standards and preventing contaminant breakthrough in the treated effluent. Regular integrity monitoring helps in early detection of membrane damage and ensures operational reliability of the bioreactor system.- Integrity testing methods for membrane bioreactor modules: Various methods are employed to test the integrity of membrane bioreactor modules to ensure proper filtration performance. These methods include pressure decay tests, bubble point tests, and acoustic sensing technologies that can detect membrane breaches or failures. Integrity testing is crucial for maintaining water quality standards and preventing contaminant breakthrough in the treated effluent. Regular integrity monitoring helps in early detection of membrane damage and ensures operational reliability of the bioreactor system.

- Chemical cleaning protocols for membrane fouling: Chemical cleaning is essential for removing organic and inorganic fouling from membrane bioreactor modules. Cleaning protocols typically involve the use of acids to remove inorganic scaling, bases to remove organic fouling, and oxidizing agents like chlorine to control biofouling. The effectiveness of chemical cleaning depends on factors such as chemical concentration, contact time, temperature, and flow conditions. Optimized cleaning schedules can significantly extend membrane life and maintain filtration efficiency without compromising membrane integrity.

- Physical cleaning mechanisms and backwashing systems: Physical cleaning mechanisms are implemented to remove foulants from membrane surfaces without chemical intervention. These include air scouring, where air bubbles create shear forces to dislodge deposits, backwashing where permeate flow is reversed to push foulants off the membrane surface, and relaxation periods where filtration is temporarily halted. Advanced systems may incorporate pulsed backwashing or sequential cleaning cycles to optimize cleaning efficiency while minimizing energy consumption and maintaining membrane integrity.

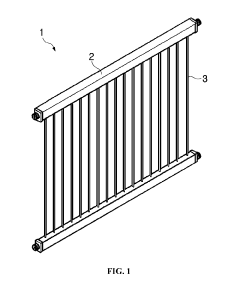

- Module design innovations for improved cleaning efficiency: Innovative membrane module designs focus on enhancing cleaning efficiency and maintaining membrane integrity. These designs include optimized fiber packing density, improved flow distribution channels, and specialized module configurations that minimize dead zones where fouling can accumulate. Some designs incorporate movable components that create additional turbulence during cleaning cycles or feature self-cleaning mechanisms. Module design innovations aim to balance filtration performance with cleanability while ensuring structural integrity during operation and maintenance procedures.

- Monitoring and control systems for membrane integrity and cleaning: Advanced monitoring and control systems are implemented to maintain membrane integrity and optimize cleaning processes. These systems utilize sensors to continuously monitor parameters such as transmembrane pressure, permeability, and flow rates to detect fouling trends and membrane damage. Automated control systems can adjust cleaning frequency and intensity based on real-time performance data. Some systems incorporate predictive algorithms that anticipate cleaning needs before critical fouling occurs, thereby extending membrane life and ensuring consistent treatment quality while reducing operational costs.

02 Chemical cleaning protocols for membrane fouling prevention

Chemical cleaning protocols are essential for maintaining membrane performance in bioreactor systems. These protocols typically involve the use of oxidizing agents, acids, bases, or specialized cleaning chemicals to remove organic and inorganic foulants from membrane surfaces. The cleaning frequency and chemical composition are optimized based on the fouling characteristics and membrane material compatibility. Effective chemical cleaning extends membrane lifespan, maintains permeability, and ensures consistent treatment efficiency in membrane bioreactor operations.Expand Specific Solutions03 Physical cleaning mechanisms for membrane modules

Physical cleaning mechanisms are employed to remove fouling materials from membrane surfaces without chemical agents. These include air scouring, backwashing, relaxation periods, and mechanical agitation systems that create shear forces at the membrane surface. Some advanced systems incorporate ultrasonic cleaning or vibration technologies to dislodge foulants. Physical cleaning is often performed continuously or intermittently during operation to maintain filtration efficiency and reduce the frequency of intensive chemical cleaning procedures.Expand Specific Solutions04 Innovative membrane module designs for improved cleanability

Innovative membrane module designs focus on enhancing cleanability and maintaining integrity during operation. These designs include optimized fiber packing density, improved flow distribution channels, and novel module configurations that minimize dead zones where fouling can accumulate. Some designs incorporate special features for targeted cleaning agent delivery or integrated monitoring systems. The module geometry and membrane arrangement are engineered to maximize surface area while ensuring effective cleaning access to all membrane surfaces.Expand Specific Solutions05 Automated monitoring and control systems for membrane integrity

Automated monitoring and control systems are implemented to continuously assess membrane integrity and optimize cleaning cycles. These systems utilize sensors, data analytics, and control algorithms to detect performance deterioration and trigger appropriate cleaning responses. Real-time monitoring parameters include transmembrane pressure, permeate quality, and flow rates. Advanced systems may incorporate machine learning to predict fouling patterns and optimize cleaning schedules, thereby extending membrane life and reducing operational costs while maintaining treatment efficiency.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The membrane bioreactor (MBR) modules market is currently in a growth phase, with increasing adoption across municipal and industrial wastewater treatment sectors. The global MBR market is projected to reach approximately $8-10 billion by 2025, driven by stringent water quality regulations and water scarcity concerns. The technology landscape is dominated by two primary configurations: hollow fiber and flat sheet membranes, with companies like Toray Industries, Asahi Kasei, and Mitsubishi Rayon leading in hollow fiber technology, while Kubota, Fibracast, and Ovivo have established strong positions in flat sheet technology. Technological maturity varies, with hollow fiber membranes representing more mature technology with higher market penetration, while flat sheet membranes offer advantages in fouling resistance and cleaning efficiency. Recent innovations from companies like Nitto Denko, 3M, and Evoqua are focused on improving membrane integrity, reducing energy consumption, and developing advanced cleaning protocols to extend membrane life.

Toray Industries, Inc.

Technical Solution: Toray has developed advanced hollow fiber membrane bioreactor (MBR) modules utilizing polyvinylidene fluoride (PVDF) materials with optimized pore structure. Their MEMBRAY® series features outside-in filtration that reduces fouling by up to 30% compared to conventional designs[1]. The modules incorporate proprietary braided fiber technology that enhances mechanical strength while maintaining high permeability (>1,000 LMH/bar). Toray's hollow fiber modules employ automated air scouring systems that create efficient two-phase flow patterns around the fiber bundles, significantly reducing membrane fouling and extending cleaning intervals to 3-6 months[2]. Their latest generation modules feature improved chemical resistance allowing for maintenance cleaning with 500-1000 mg/L sodium hypochlorite and recovery cleaning with up to 3000 mg/L, while maintaining membrane integrity over a 5+ year operational lifespan.

Strengths: Superior fouling resistance through optimized fiber arrangement and air scouring; excellent mechanical strength from braided fiber technology; high chemical tolerance enabling effective cleaning protocols. Weaknesses: Higher initial capital cost compared to flat sheet alternatives; potentially higher energy consumption for air scouring; more complex module replacement procedures compared to flat sheet designs.

Mitsubishi Rayon Co Ltd

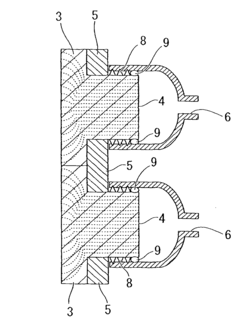

Technical Solution: Mitsubishi Rayon has pioneered the STERAPORE® hollow fiber MBR technology featuring chlorinated polyethylene (PE) membranes with enhanced oxidation resistance. Their modules employ a unique fiber loosening technique that allows individual fibers to move independently during operation, creating a self-cleaning effect that reduces fouling by up to 40%[3]. The company's hollow fiber design utilizes a proprietary potting technology that ensures superior fiber-header connection integrity, virtually eliminating fiber breakage at connection points - a common failure mode in hollow fiber systems. Their modules incorporate intelligent air diffusion systems that optimize bubble size (1-3mm) and distribution, reducing specific energy consumption to 0.25-0.35 kWh/m³ treated water[4]. Mitsubishi's cleaning protocol combines continuous low-intensity air scouring with intermittent high-intensity pulses and scheduled maintenance cleaning using 200-500 mg/L sodium hypochlorite, maintaining stable flux rates of 20-25 LMH in municipal applications.

Strengths: Exceptional fiber-header integrity reducing failure points; energy-efficient air scouring system; self-cleaning fiber movement mechanism reducing fouling propensity. Weaknesses: More complex module design increases manufacturing costs; requires precise control of operating parameters; potential for internal clogging in high-solids applications compared to flat sheet alternatives.

Key Innovations in Membrane Integrity Monitoring

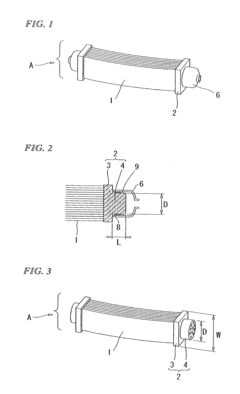

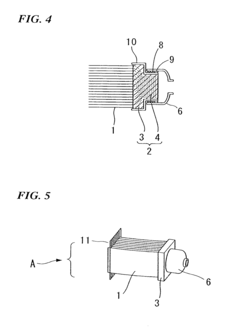

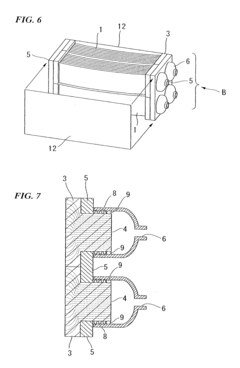

Cartridge-type hollow fiber membrane module comprising submerged hollow fiber membrane unit module with free end and submerged apparatus for water treatment comprising air diffuser apparatus capable of intermittent/continuous aeration and its aeration method

PatentActiveUS10543461B2

Innovation

- A cartridge-type hollow fiber membrane module with a free end and an air diffuser apparatus using an air accumulation pipe for intermittent and continuous aeration, which reduces cleaning air usage, prevents entanglement, and enhances mobility, integrity, and energy efficiency by generating coarse bubbles and adjusting aeration cycles based on raw water and solid concentrations.

Hollow fiber membrane module, hollow fiber membrane module unit, and water treatment method

PatentInactiveUS8636904B2

Innovation

- A hollow fiber membrane module with a non-porous layer and anchoring member configuration, where the anchoring member has a rectangular end face for exposure and a circular end face for opening, allowing for efficient cleaning and high-density membrane anchoring, along with a plate member to secure modules, ensuring uniform gas supply and high pressure resistance.

Energy Efficiency Optimization in MBR Operations

Energy efficiency represents a critical factor in the operational economics of membrane bioreactor (MBR) systems, with aeration typically accounting for 60-80% of the total energy consumption. The optimization of energy usage in MBR operations requires a comprehensive understanding of the differences between hollow fiber and flat sheet membrane configurations, as these directly impact energy requirements.

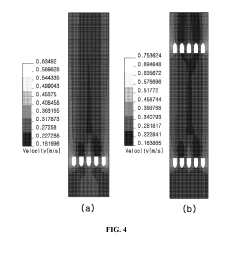

Hollow fiber modules generally demonstrate lower specific energy consumption for membrane aeration compared to flat sheet configurations, with typical values ranging from 0.2-0.4 kWh/m³ versus 0.3-0.5 kWh/m³ respectively. This advantage stems from the higher packing density of hollow fibers, allowing more membrane surface area within the same footprint, thereby distributing energy costs across greater treatment capacity.

However, flat sheet modules often exhibit superior fouling resistance characteristics, which can translate to more stable long-term energy profiles. The planar configuration facilitates more uniform air scouring across the membrane surface, reducing the frequency of intensive cleaning operations that temporarily spike energy consumption during operational cycles.

Membrane integrity maintenance strategies significantly influence energy efficiency. Advanced monitoring systems that detect integrity breaches early can prevent unnecessary increases in transmembrane pressure (TMP), which would otherwise demand higher energy inputs. Real-time monitoring technologies have demonstrated energy savings of 15-25% in large-scale installations by enabling precise adjustment of aeration rates based on actual fouling conditions rather than conservative fixed protocols.

Cleaning regimes represent another crucial aspect of energy optimization. Chemical cleaning in place (CIP) procedures, while temporarily halting production, can restore membrane permeability and reduce the energy required for permeate extraction. Innovative cleaning approaches, such as sequential air scouring combined with low-concentration chemical maintenance cleaning, have shown promise in reducing overall energy consumption by up to 30% compared to conventional protocols.

Recent technological innovations focus on dynamic aeration control systems that adjust air scouring intensity based on real-time fouling indicators. These systems have demonstrated energy reductions of 20-40% compared to fixed-rate aeration strategies. Additionally, the integration of energy recovery devices in MBR systems, particularly in larger installations, offers potential for capturing and reusing energy from pressure differentials within the treatment process.

The selection between hollow fiber and flat sheet technologies should therefore consider not only initial energy requirements but also long-term efficiency profiles based on specific wastewater characteristics, cleaning requirements, and operational patterns. Hybrid systems that combine elements of both technologies are emerging as promising solutions for optimizing energy efficiency across diverse operational conditions.

Hollow fiber modules generally demonstrate lower specific energy consumption for membrane aeration compared to flat sheet configurations, with typical values ranging from 0.2-0.4 kWh/m³ versus 0.3-0.5 kWh/m³ respectively. This advantage stems from the higher packing density of hollow fibers, allowing more membrane surface area within the same footprint, thereby distributing energy costs across greater treatment capacity.

However, flat sheet modules often exhibit superior fouling resistance characteristics, which can translate to more stable long-term energy profiles. The planar configuration facilitates more uniform air scouring across the membrane surface, reducing the frequency of intensive cleaning operations that temporarily spike energy consumption during operational cycles.

Membrane integrity maintenance strategies significantly influence energy efficiency. Advanced monitoring systems that detect integrity breaches early can prevent unnecessary increases in transmembrane pressure (TMP), which would otherwise demand higher energy inputs. Real-time monitoring technologies have demonstrated energy savings of 15-25% in large-scale installations by enabling precise adjustment of aeration rates based on actual fouling conditions rather than conservative fixed protocols.

Cleaning regimes represent another crucial aspect of energy optimization. Chemical cleaning in place (CIP) procedures, while temporarily halting production, can restore membrane permeability and reduce the energy required for permeate extraction. Innovative cleaning approaches, such as sequential air scouring combined with low-concentration chemical maintenance cleaning, have shown promise in reducing overall energy consumption by up to 30% compared to conventional protocols.

Recent technological innovations focus on dynamic aeration control systems that adjust air scouring intensity based on real-time fouling indicators. These systems have demonstrated energy reductions of 20-40% compared to fixed-rate aeration strategies. Additionally, the integration of energy recovery devices in MBR systems, particularly in larger installations, offers potential for capturing and reusing energy from pressure differentials within the treatment process.

The selection between hollow fiber and flat sheet technologies should therefore consider not only initial energy requirements but also long-term efficiency profiles based on specific wastewater characteristics, cleaning requirements, and operational patterns. Hybrid systems that combine elements of both technologies are emerging as promising solutions for optimizing energy efficiency across diverse operational conditions.

Environmental Impact and Sustainability Considerations

The environmental impact and sustainability considerations of membrane bioreactor (MBR) modules are increasingly critical factors in their selection and operation. Both hollow fiber and flat sheet configurations present distinct environmental footprints throughout their lifecycle, from manufacturing to disposal.

Manufacturing hollow fiber modules typically requires more energy-intensive processes due to the complexity of fiber extrusion and bundling. Conversely, flat sheet modules, with their simpler construction, generally demand fewer resources during production. This difference in manufacturing energy requirements translates to varying carbon footprints between the two technologies.

Operational sustainability metrics favor hollow fiber modules in terms of energy efficiency when operating at optimal conditions. Their higher packing density allows for more treatment capacity in smaller footprints, reducing the physical space requirements and associated environmental impacts. However, this advantage diminishes when fouling occurs, as the energy consumption for aeration and cleaning increases substantially.

Flat sheet modules demonstrate superior sustainability in cleaning operations, requiring less frequent chemical cleaning and lower volumes of cleaning agents. This reduction in chemical usage not only decreases operational costs but also minimizes the environmental burden of chemical production, transportation, and disposal of cleaning waste streams.

Water conservation aspects must also be considered. The backwashing requirements of hollow fiber systems consume significant volumes of treated water, whereas flat sheet modules typically operate with forward-flush cleaning mechanisms that are less water-intensive. This difference becomes particularly important in water-scarce regions where conservation is paramount.

End-of-life considerations reveal that flat sheet modules often offer better recyclability due to their simpler material composition. Hollow fiber modules, containing multiple materials bonded together, present greater challenges for material recovery and recycling, potentially leading to more waste entering landfills.

The longevity of the modules also impacts their sustainability profile. While hollow fiber modules may have shorter lifespans due to fiber breakage and integrity issues, flat sheet modules typically demonstrate greater durability. This extended operational life reduces the frequency of replacement and the associated environmental impacts of manufacturing new components.

Overall, a comprehensive life cycle assessment approach is essential when evaluating the environmental impact of MBR module selection, considering not only immediate operational factors but also long-term sustainability implications across the entire product lifecycle.

Manufacturing hollow fiber modules typically requires more energy-intensive processes due to the complexity of fiber extrusion and bundling. Conversely, flat sheet modules, with their simpler construction, generally demand fewer resources during production. This difference in manufacturing energy requirements translates to varying carbon footprints between the two technologies.

Operational sustainability metrics favor hollow fiber modules in terms of energy efficiency when operating at optimal conditions. Their higher packing density allows for more treatment capacity in smaller footprints, reducing the physical space requirements and associated environmental impacts. However, this advantage diminishes when fouling occurs, as the energy consumption for aeration and cleaning increases substantially.

Flat sheet modules demonstrate superior sustainability in cleaning operations, requiring less frequent chemical cleaning and lower volumes of cleaning agents. This reduction in chemical usage not only decreases operational costs but also minimizes the environmental burden of chemical production, transportation, and disposal of cleaning waste streams.

Water conservation aspects must also be considered. The backwashing requirements of hollow fiber systems consume significant volumes of treated water, whereas flat sheet modules typically operate with forward-flush cleaning mechanisms that are less water-intensive. This difference becomes particularly important in water-scarce regions where conservation is paramount.

End-of-life considerations reveal that flat sheet modules often offer better recyclability due to their simpler material composition. Hollow fiber modules, containing multiple materials bonded together, present greater challenges for material recovery and recycling, potentially leading to more waste entering landfills.

The longevity of the modules also impacts their sustainability profile. While hollow fiber modules may have shorter lifespans due to fiber breakage and integrity issues, flat sheet modules typically demonstrate greater durability. This extended operational life reduces the frequency of replacement and the associated environmental impacts of manufacturing new components.

Overall, a comprehensive life cycle assessment approach is essential when evaluating the environmental impact of MBR module selection, considering not only immediate operational factors but also long-term sustainability implications across the entire product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!