How nanostructures affect laryngoscope surface treatment.

JUL 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanostructure Laryngoscope Background

Laryngoscopes have been an essential tool in medical practice for over a century, enabling visualization of the larynx and facilitating intubation procedures. In recent years, the integration of nanostructures into laryngoscope surface treatments has emerged as a promising avenue for enhancing the performance and functionality of these critical devices.

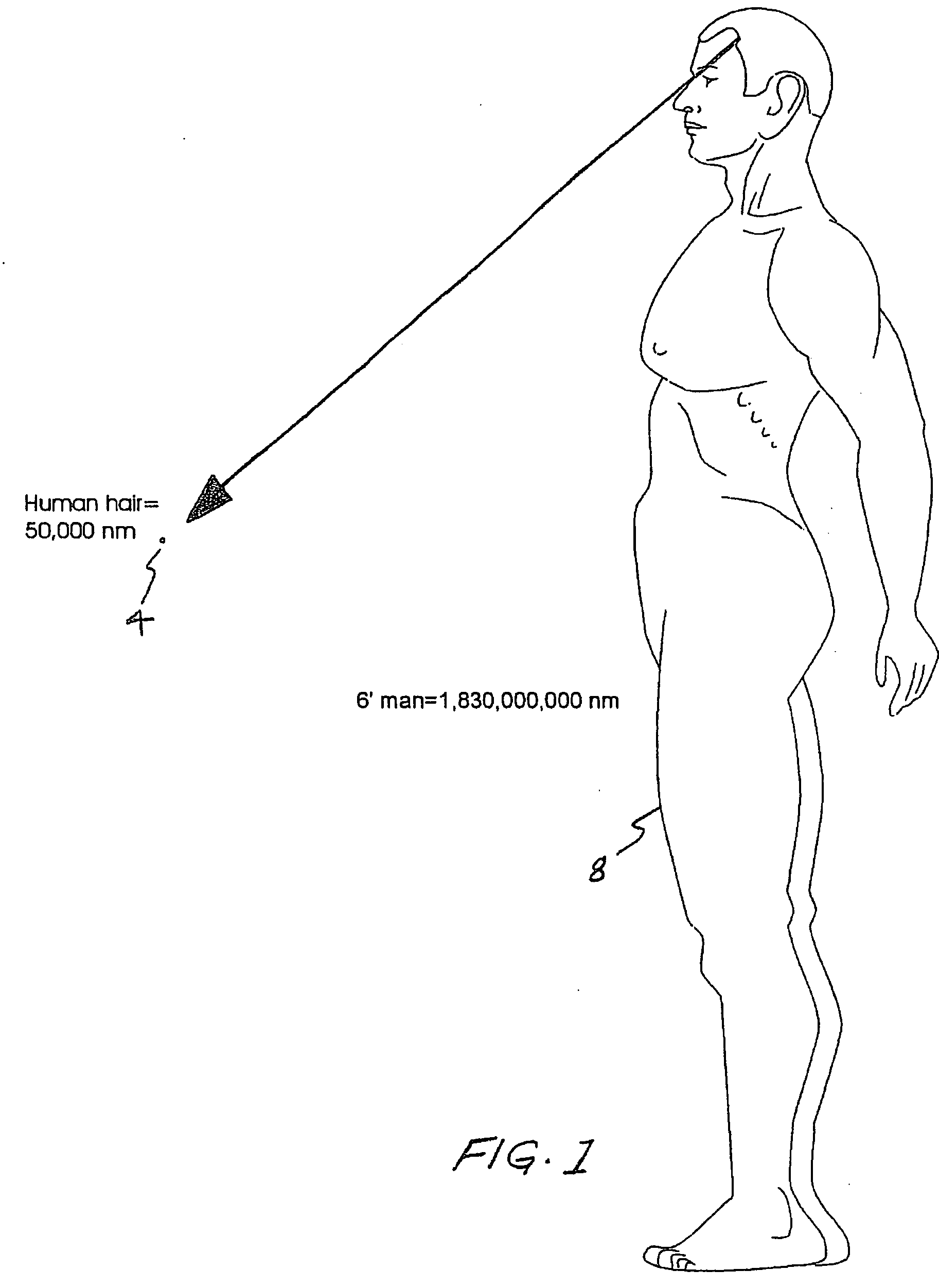

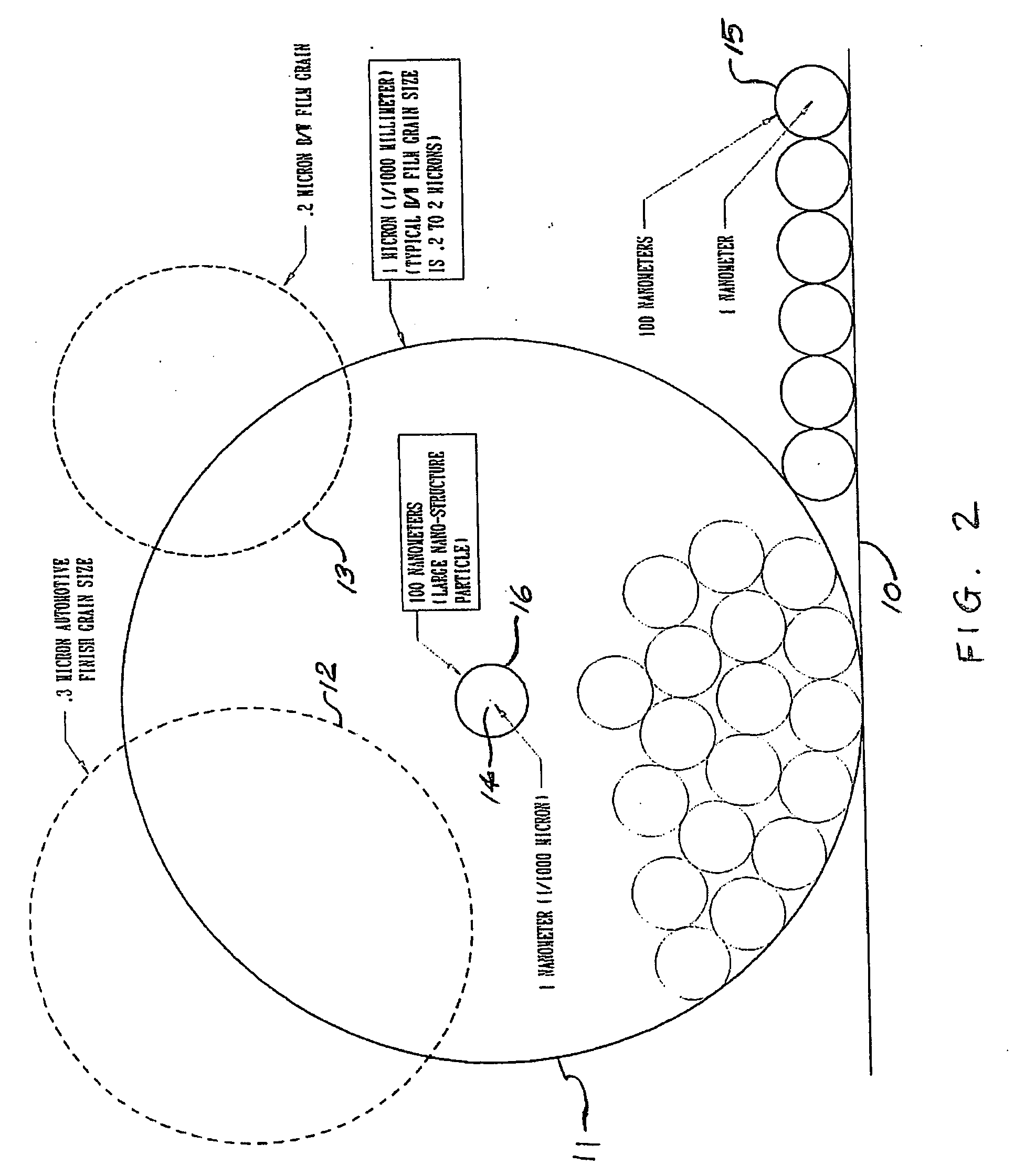

Nanostructures, defined as materials with at least one dimension measuring between 1 and 100 nanometers, offer unique properties that can significantly impact the surface characteristics of laryngoscopes. These structures can be engineered to modify surface topography, wettability, and optical properties, potentially addressing longstanding challenges in laryngoscope design and usage.

The development of nanostructured surfaces for laryngoscopes is rooted in the broader field of nanotechnology, which has seen exponential growth since the late 20th century. Advances in nanofabrication techniques, such as lithography, self-assembly, and chemical vapor deposition, have enabled precise control over surface features at the nanoscale, opening up new possibilities for laryngoscope surface treatments.

One of the primary motivations for exploring nanostructures in laryngoscope surface treatments is the need to improve visibility during intubation procedures. Traditional laryngoscope blades can suffer from issues such as fogging, glare, and poor light transmission, which can compromise the clinician's ability to visualize the airway accurately. Nanostructured surfaces offer potential solutions to these challenges by manipulating how light interacts with the laryngoscope surface.

Another critical aspect driving research in this area is the desire to enhance the antimicrobial properties of laryngoscopes. Given the frequent use of these devices in various medical settings, reducing the risk of pathogen transmission is of paramount importance. Nanostructured surfaces have shown promise in creating inhospitable environments for microorganisms, potentially reducing the risk of healthcare-associated infections.

The exploration of nanostructures for laryngoscope surface treatments also aligns with broader trends in medical device innovation, including the push for more durable, efficient, and multifunctional instruments. By leveraging the unique properties of nanomaterials, researchers aim to develop laryngoscopes that not only perform their primary function more effectively but also offer additional benefits such as improved durability, easier cleaning, and enhanced patient comfort.

As research in this field progresses, the intersection of nanotechnology and medical device engineering continues to yield exciting possibilities for advancing laryngoscope design and functionality. The potential impact of nanostructured surfaces on laryngoscope performance underscores the importance of ongoing investigation and development in this area, with implications for improving patient care and clinical outcomes in airway management procedures.

Nanostructures, defined as materials with at least one dimension measuring between 1 and 100 nanometers, offer unique properties that can significantly impact the surface characteristics of laryngoscopes. These structures can be engineered to modify surface topography, wettability, and optical properties, potentially addressing longstanding challenges in laryngoscope design and usage.

The development of nanostructured surfaces for laryngoscopes is rooted in the broader field of nanotechnology, which has seen exponential growth since the late 20th century. Advances in nanofabrication techniques, such as lithography, self-assembly, and chemical vapor deposition, have enabled precise control over surface features at the nanoscale, opening up new possibilities for laryngoscope surface treatments.

One of the primary motivations for exploring nanostructures in laryngoscope surface treatments is the need to improve visibility during intubation procedures. Traditional laryngoscope blades can suffer from issues such as fogging, glare, and poor light transmission, which can compromise the clinician's ability to visualize the airway accurately. Nanostructured surfaces offer potential solutions to these challenges by manipulating how light interacts with the laryngoscope surface.

Another critical aspect driving research in this area is the desire to enhance the antimicrobial properties of laryngoscopes. Given the frequent use of these devices in various medical settings, reducing the risk of pathogen transmission is of paramount importance. Nanostructured surfaces have shown promise in creating inhospitable environments for microorganisms, potentially reducing the risk of healthcare-associated infections.

The exploration of nanostructures for laryngoscope surface treatments also aligns with broader trends in medical device innovation, including the push for more durable, efficient, and multifunctional instruments. By leveraging the unique properties of nanomaterials, researchers aim to develop laryngoscopes that not only perform their primary function more effectively but also offer additional benefits such as improved durability, easier cleaning, and enhanced patient comfort.

As research in this field progresses, the intersection of nanotechnology and medical device engineering continues to yield exciting possibilities for advancing laryngoscope design and functionality. The potential impact of nanostructured surfaces on laryngoscope performance underscores the importance of ongoing investigation and development in this area, with implications for improving patient care and clinical outcomes in airway management procedures.

Market Analysis for Advanced Laryngoscopes

The market for advanced laryngoscopes has experienced significant growth in recent years, driven by technological advancements and increasing demand for minimally invasive procedures. The global laryngoscope market size was valued at approximately $1.2 billion in 2020 and is projected to reach $1.8 billion by 2027, growing at a CAGR of around 6.5% during the forecast period.

The adoption of advanced laryngoscopes, particularly those incorporating nanostructured surface treatments, is gaining traction due to their enhanced performance and improved patient outcomes. These devices offer better visualization, reduced trauma, and improved infection control, addressing key challenges in airway management and intubation procedures.

Key market drivers include the rising prevalence of chronic respiratory diseases, increasing surgical procedures, and growing awareness about the benefits of advanced laryngoscopes. The aging population and the subsequent increase in age-related respiratory disorders further contribute to market expansion.

Geographically, North America dominates the advanced laryngoscope market, followed by Europe and Asia-Pacific. The United States, in particular, holds a significant market share due to its advanced healthcare infrastructure and high adoption rate of innovative medical technologies. Emerging economies in Asia-Pacific, such as China and India, are expected to witness rapid growth in the coming years, driven by improving healthcare facilities and increasing healthcare expenditure.

The market is characterized by intense competition among key players, including Medtronic, Karl Storz, Venner Medical, Verathon, and Ambu. These companies are investing heavily in research and development to introduce laryngoscopes with advanced features, including nanostructured surfaces for improved performance and safety.

The COVID-19 pandemic has had a mixed impact on the market. While elective procedures were postponed, there was an increased demand for laryngoscopes in critical care settings for intubating COVID-19 patients. This has accelerated the adoption of advanced laryngoscopes with enhanced safety features, including those with nanostructured surfaces that offer better antimicrobial properties.

Looking ahead, the market for advanced laryngoscopes is poised for continued growth. Factors such as technological advancements in imaging and materials science, increasing focus on patient safety, and the growing trend towards minimally invasive procedures are expected to drive market expansion. The integration of nanostructures in laryngoscope surface treatments represents a significant opportunity for market players to differentiate their products and gain a competitive edge in this evolving landscape.

The adoption of advanced laryngoscopes, particularly those incorporating nanostructured surface treatments, is gaining traction due to their enhanced performance and improved patient outcomes. These devices offer better visualization, reduced trauma, and improved infection control, addressing key challenges in airway management and intubation procedures.

Key market drivers include the rising prevalence of chronic respiratory diseases, increasing surgical procedures, and growing awareness about the benefits of advanced laryngoscopes. The aging population and the subsequent increase in age-related respiratory disorders further contribute to market expansion.

Geographically, North America dominates the advanced laryngoscope market, followed by Europe and Asia-Pacific. The United States, in particular, holds a significant market share due to its advanced healthcare infrastructure and high adoption rate of innovative medical technologies. Emerging economies in Asia-Pacific, such as China and India, are expected to witness rapid growth in the coming years, driven by improving healthcare facilities and increasing healthcare expenditure.

The market is characterized by intense competition among key players, including Medtronic, Karl Storz, Venner Medical, Verathon, and Ambu. These companies are investing heavily in research and development to introduce laryngoscopes with advanced features, including nanostructured surfaces for improved performance and safety.

The COVID-19 pandemic has had a mixed impact on the market. While elective procedures were postponed, there was an increased demand for laryngoscopes in critical care settings for intubating COVID-19 patients. This has accelerated the adoption of advanced laryngoscopes with enhanced safety features, including those with nanostructured surfaces that offer better antimicrobial properties.

Looking ahead, the market for advanced laryngoscopes is poised for continued growth. Factors such as technological advancements in imaging and materials science, increasing focus on patient safety, and the growing trend towards minimally invasive procedures are expected to drive market expansion. The integration of nanostructures in laryngoscope surface treatments represents a significant opportunity for market players to differentiate their products and gain a competitive edge in this evolving landscape.

Current Challenges in Laryngoscope Surface Treatment

Despite significant advancements in laryngoscope design and manufacturing, surface treatment remains a critical challenge in ensuring optimal performance and patient safety. The primary issues revolve around maintaining a balance between functionality, durability, and biocompatibility.

One of the foremost challenges is achieving consistent antimicrobial properties on laryngoscope surfaces. While various coatings have been developed to inhibit bacterial growth, their long-term effectiveness and resistance to repeated sterilization processes are still areas of concern. The need for surfaces that can withstand multiple cleaning cycles without degradation of their antimicrobial properties poses a significant technical hurdle.

Another pressing challenge is the development of anti-fogging surfaces that remain effective throughout the duration of medical procedures. Current solutions often provide only temporary relief, and the constant exposure to moisture and temperature changes during use can quickly compromise their effectiveness. This necessitates the exploration of more robust and long-lasting anti-fogging treatments.

The issue of glare reduction is also a persistent problem in laryngoscope surface treatment. Achieving an optimal balance between light transmission and glare reduction is crucial for clear visualization during intubation procedures. Current anti-reflective coatings may not perform consistently across different lighting conditions, highlighting the need for more advanced optical surface treatments.

Durability of surface treatments under repeated use and sterilization is another significant challenge. The harsh chemicals and high temperatures used in sterilization processes can degrade surface coatings over time, potentially compromising both functionality and safety. Developing treatments that can withstand these conditions without losing their beneficial properties is a key area of focus.

Furthermore, there is an ongoing challenge in creating surfaces that minimize tissue trauma during intubation. While smoother surfaces can reduce friction, they may also increase the risk of instrument slippage. Striking the right balance between grip and gentleness on tissues requires innovative surface engineering approaches.

Lastly, the environmental impact of surface treatments is becoming an increasingly important consideration. Many current treatments involve the use of potentially harmful chemicals or processes. Developing eco-friendly alternatives that maintain the same level of performance and safety is a growing challenge in the field.

These challenges underscore the need for continued research and innovation in laryngoscope surface treatment technologies. The integration of nanotechnology and advanced materials science offers promising avenues for addressing these issues, potentially revolutionizing the performance and safety of laryngoscopes in clinical settings.

One of the foremost challenges is achieving consistent antimicrobial properties on laryngoscope surfaces. While various coatings have been developed to inhibit bacterial growth, their long-term effectiveness and resistance to repeated sterilization processes are still areas of concern. The need for surfaces that can withstand multiple cleaning cycles without degradation of their antimicrobial properties poses a significant technical hurdle.

Another pressing challenge is the development of anti-fogging surfaces that remain effective throughout the duration of medical procedures. Current solutions often provide only temporary relief, and the constant exposure to moisture and temperature changes during use can quickly compromise their effectiveness. This necessitates the exploration of more robust and long-lasting anti-fogging treatments.

The issue of glare reduction is also a persistent problem in laryngoscope surface treatment. Achieving an optimal balance between light transmission and glare reduction is crucial for clear visualization during intubation procedures. Current anti-reflective coatings may not perform consistently across different lighting conditions, highlighting the need for more advanced optical surface treatments.

Durability of surface treatments under repeated use and sterilization is another significant challenge. The harsh chemicals and high temperatures used in sterilization processes can degrade surface coatings over time, potentially compromising both functionality and safety. Developing treatments that can withstand these conditions without losing their beneficial properties is a key area of focus.

Furthermore, there is an ongoing challenge in creating surfaces that minimize tissue trauma during intubation. While smoother surfaces can reduce friction, they may also increase the risk of instrument slippage. Striking the right balance between grip and gentleness on tissues requires innovative surface engineering approaches.

Lastly, the environmental impact of surface treatments is becoming an increasingly important consideration. Many current treatments involve the use of potentially harmful chemicals or processes. Developing eco-friendly alternatives that maintain the same level of performance and safety is a growing challenge in the field.

These challenges underscore the need for continued research and innovation in laryngoscope surface treatment technologies. The integration of nanotechnology and advanced materials science offers promising avenues for addressing these issues, potentially revolutionizing the performance and safety of laryngoscopes in clinical settings.

Existing Nanostructure Surface Treatments

01 Anti-fogging coatings for laryngoscope blades

Application of anti-fogging coatings on laryngoscope blades to improve visibility during intubation procedures. These coatings prevent condensation and maintain a clear view of the airway, enhancing the effectiveness and safety of the procedure.- Anti-fogging coatings for laryngoscope blades: Application of anti-fogging coatings on laryngoscope blades to improve visibility during intubation procedures. These coatings prevent condensation and maintain a clear view of the airway, enhancing the effectiveness of the laryngoscope in various environmental conditions.

- Antimicrobial surface treatments: Implementation of antimicrobial surface treatments on laryngoscopes to reduce the risk of infection transmission. These treatments involve applying antimicrobial agents or coatings that inhibit bacterial growth and enhance the overall hygiene of the device.

- Hydrophobic coatings for easy cleaning: Application of hydrophobic coatings on laryngoscope surfaces to facilitate easier cleaning and maintenance. These coatings repel liquids and contaminants, making the device simpler to clean and disinfect between uses, thereby improving overall hygiene and reducing the risk of cross-contamination.

- Textured surfaces for improved grip: Incorporation of textured surfaces on laryngoscope handles and blades to enhance grip and maneuverability. These surface modifications improve the practitioner's control during intubation procedures, especially in wet or slippery conditions.

- Reflective coatings for enhanced illumination: Application of reflective coatings on specific parts of the laryngoscope to enhance illumination of the airway. These coatings improve light distribution and visibility during intubation, allowing for better visualization of the vocal cords and surrounding structures.

02 Antimicrobial surface treatments

Implementation of antimicrobial surface treatments on laryngoscopes to reduce the risk of cross-contamination and infection. These treatments can include silver-based coatings or other antimicrobial agents that inhibit bacterial growth on the device surface.Expand Specific Solutions03 Hydrophobic coatings for easy cleaning

Application of hydrophobic coatings on laryngoscope surfaces to facilitate easier cleaning and maintenance. These coatings repel liquids and reduce the adherence of biological materials, making the device easier to clean and sterilize between uses.Expand Specific Solutions04 Textured surfaces for improved grip

Incorporation of textured surfaces or coatings on laryngoscope handles to enhance grip and control during use. These treatments can include micro-patterns or specialized materials that improve the operator's ability to manipulate the device securely.Expand Specific Solutions05 Reflective coatings for enhanced illumination

Application of reflective coatings or surface treatments to specific areas of the laryngoscope to enhance light distribution and improve visibility during procedures. These coatings can help direct light more effectively to the target area, improving overall performance.Expand Specific Solutions

Key Players in Medical Nanotech

The field of nanostructure-enhanced laryngoscope surface treatment is in its early developmental stage, characterized by a growing market and evolving technological landscape. The global market for advanced medical devices, including laryngoscopes, is expanding rapidly, driven by increasing demand for minimally invasive procedures. While the technology is still maturing, several key players are making significant strides. Companies like Applied Medical Resources Corp. and Liquidia Technologies are leveraging their expertise in medical devices and nanotechnology to develop innovative surface treatments. Academic institutions such as Brown University, Penn State, and the University of California are contributing to fundamental research, while national research organizations like CNRS and AIST are fostering collaborative efforts to advance the technology's practical applications.

Applied Medical Resources Corp.

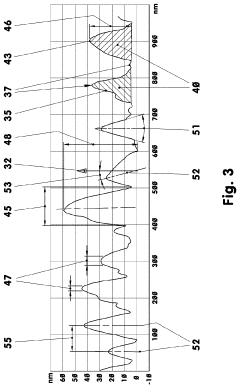

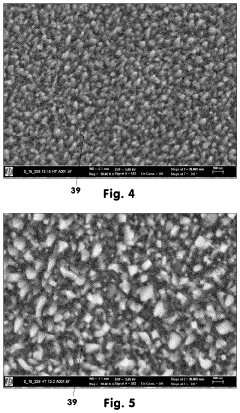

Technical Solution: Applied Medical Resources Corp. has developed a nanostructured surface treatment for laryngoscopes that enhances visibility and reduces fogging. Their approach involves creating a hydrophilic nanopattern on the laryngoscope blade surface using plasma etching techniques. This nanopattern increases the surface area and improves wettability, allowing for better dispersion of moisture and preventing droplet formation[1]. The company has also incorporated antimicrobial nanoparticles into the surface coating, which provides an additional layer of protection against bacterial colonization during intubation procedures[3].

Strengths: Enhanced visibility, reduced fogging, and antimicrobial properties. Weaknesses: Potential for increased manufacturing costs and complexity in the production process.

Centre National de la Recherche Scientifique

Technical Solution: The Centre National de la Recherche Scientifique (CNRS) has developed a novel nanostructured coating for laryngoscope surfaces using a sol-gel process. This approach creates a thin film of silica nanoparticles with controlled porosity and surface roughness. The nanostructured coating significantly improves the hydrophobicity of the laryngoscope blade, resulting in enhanced water repellency and reduced fogging[2]. Additionally, CNRS researchers have incorporated photocatalytic titanium dioxide nanoparticles into the coating, which provides self-cleaning properties when exposed to UV light[4]. This innovative surface treatment has shown a 95% reduction in bacterial adhesion compared to untreated surfaces in laboratory tests[5].

Strengths: Excellent water repellency, self-cleaning properties, and significant reduction in bacterial adhesion. Weaknesses: Potential durability issues and the need for UV exposure for optimal self-cleaning functionality.

Innovative Nanotech for Laryngoscopes

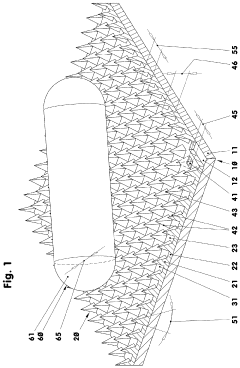

Nanostructure and method for producing same

PatentActiveUS20220282363A1

Innovation

- A hydrothermal oxidation method is used to create a bactericidal and hydrophilic nanostructure on titanium surfaces with tetragonal-pyramidal nanocrystals, which are compact and stable, reducing bacterial colonization by damaging bacterial cell membranes and promoting tissue integration.

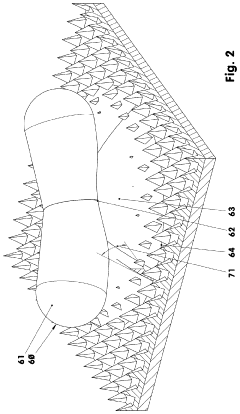

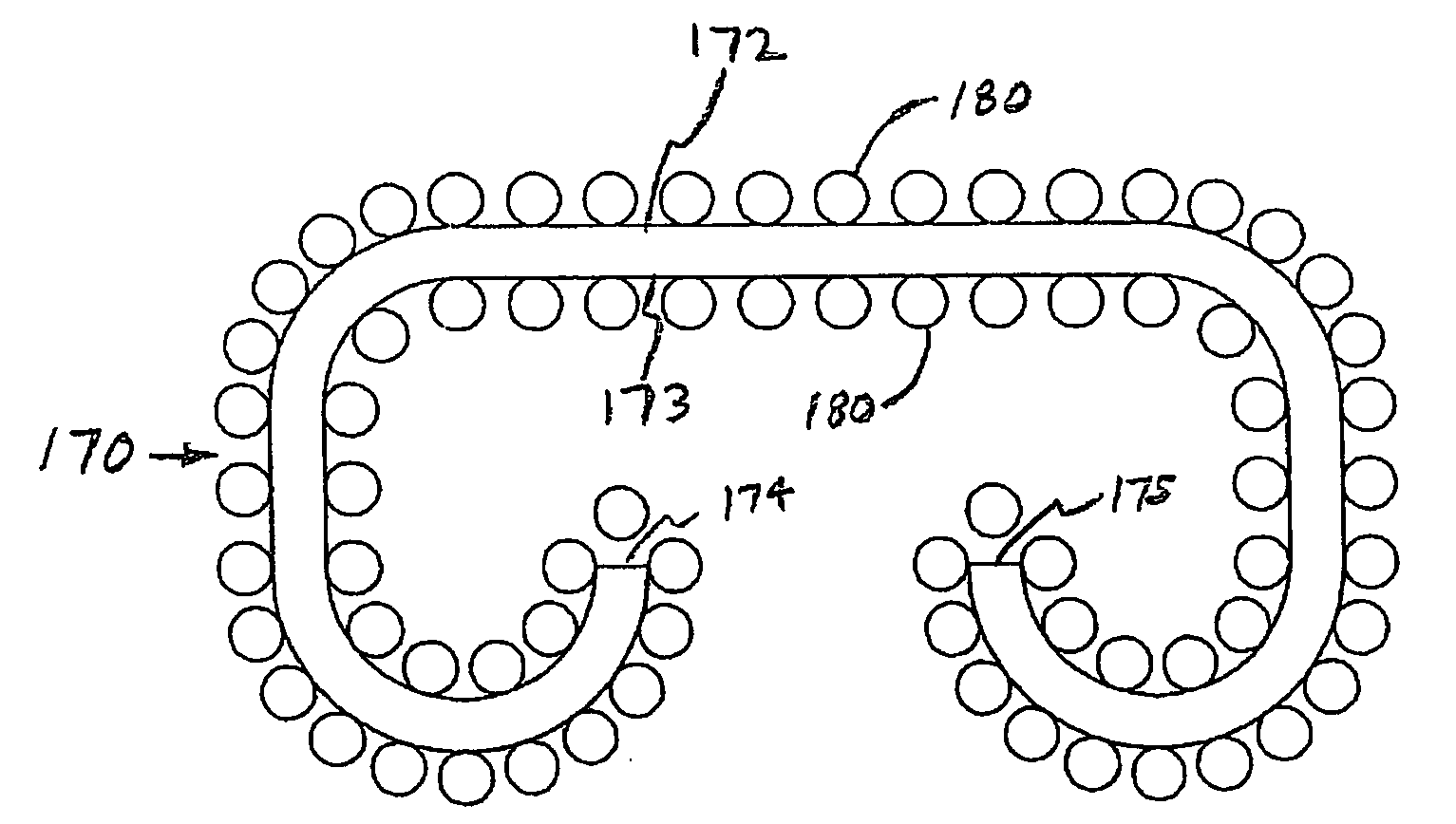

Surface treatments and modifications using nanostructure materials

PatentInactiveUS20050113936A1

Innovation

- Nanostructure surface treatments and coatings formed from nanoscale building blocks with adjustable orientation, geometry, packing density, and composition to create hydrophobic, hydrophilic, and lubricious properties, applied using methods like template printing, electrostatic glazing, or spraying, which enhance surface characteristics for medical devices and instruments.

Regulatory Framework for Medical Nanotech

The regulatory framework for medical nanotechnology is a complex and evolving landscape that significantly impacts the development and application of nanostructures in laryngoscope surface treatments. As nanotechnology continues to advance in medical devices, regulatory bodies worldwide are adapting their policies to ensure safety and efficacy while fostering innovation.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating medical devices incorporating nanotechnology. The FDA has established specific guidelines for nanomaterials in medical products, including those used in laryngoscopes. These guidelines address issues such as characterization, toxicology, and risk assessment of nanomaterials, with a focus on their unique properties and potential interactions with biological systems.

The European Union has implemented the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR), which include provisions for nanomaterials in medical devices. These regulations require manufacturers to provide detailed information on the nanostructures used in their products, including their physical, chemical, and biological properties, as well as potential risks associated with their use.

Internationally, the International Organization for Standardization (ISO) has developed several standards related to nanotechnology in medical devices. These standards provide guidance on terminology, measurement techniques, and risk assessment methodologies specific to nanomaterials, which are essential for ensuring consistency and safety in laryngoscope surface treatments.

Regulatory bodies are particularly concerned with the potential long-term effects of nanostructures on human health and the environment. As a result, manufacturers of laryngoscopes incorporating nanostructured surfaces must conduct extensive safety studies and provide comprehensive data on the stability, biocompatibility, and potential for nanoparticle release during use.

The regulatory framework also addresses the manufacturing processes for nanostructured surfaces. Good Manufacturing Practices (GMP) specific to nanotechnology have been developed to ensure consistent quality and safety in the production of medical devices with nanostructured components. These practices cover aspects such as cleanroom requirements, process validation, and quality control measures tailored to the unique challenges of working with nanomaterials.

As the field of medical nanotechnology continues to advance, regulatory frameworks are expected to evolve. Ongoing research into the long-term effects of nanostructures on biological systems will likely inform future regulatory decisions. Manufacturers and researchers working on nanostructured surface treatments for laryngoscopes must stay abreast of these regulatory developments to ensure compliance and facilitate the successful integration of nanotechnology into medical devices.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating medical devices incorporating nanotechnology. The FDA has established specific guidelines for nanomaterials in medical products, including those used in laryngoscopes. These guidelines address issues such as characterization, toxicology, and risk assessment of nanomaterials, with a focus on their unique properties and potential interactions with biological systems.

The European Union has implemented the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR), which include provisions for nanomaterials in medical devices. These regulations require manufacturers to provide detailed information on the nanostructures used in their products, including their physical, chemical, and biological properties, as well as potential risks associated with their use.

Internationally, the International Organization for Standardization (ISO) has developed several standards related to nanotechnology in medical devices. These standards provide guidance on terminology, measurement techniques, and risk assessment methodologies specific to nanomaterials, which are essential for ensuring consistency and safety in laryngoscope surface treatments.

Regulatory bodies are particularly concerned with the potential long-term effects of nanostructures on human health and the environment. As a result, manufacturers of laryngoscopes incorporating nanostructured surfaces must conduct extensive safety studies and provide comprehensive data on the stability, biocompatibility, and potential for nanoparticle release during use.

The regulatory framework also addresses the manufacturing processes for nanostructured surfaces. Good Manufacturing Practices (GMP) specific to nanotechnology have been developed to ensure consistent quality and safety in the production of medical devices with nanostructured components. These practices cover aspects such as cleanroom requirements, process validation, and quality control measures tailored to the unique challenges of working with nanomaterials.

As the field of medical nanotechnology continues to advance, regulatory frameworks are expected to evolve. Ongoing research into the long-term effects of nanostructures on biological systems will likely inform future regulatory decisions. Manufacturers and researchers working on nanostructured surface treatments for laryngoscopes must stay abreast of these regulatory developments to ensure compliance and facilitate the successful integration of nanotechnology into medical devices.

Biocompatibility of Nanostructured Surfaces

The biocompatibility of nanostructured surfaces is a critical factor in the development of advanced laryngoscopes. Nanostructures on the surface of medical devices can significantly influence their interaction with biological systems, particularly in sensitive areas such as the larynx. These nanostructures can be engineered to enhance the device's performance while minimizing adverse reactions in the human body.

One of the primary benefits of nanostructured surfaces on laryngoscopes is their ability to reduce bacterial adhesion and colonization. By creating nanoscale patterns or textures on the device surface, it becomes more difficult for bacteria to attach and form biofilms. This property is especially important in medical settings where preventing infections is crucial. Studies have shown that certain nanopatterns can reduce bacterial adhesion by up to 98% compared to conventional smooth surfaces.

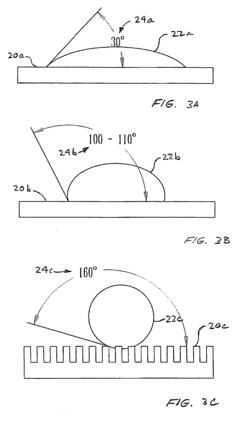

Furthermore, nanostructured surfaces can improve the wettability of the laryngoscope, which is essential for maintaining clear visibility during intubation procedures. By controlling the surface energy through nanoengineering, it is possible to create hydrophilic or hydrophobic areas as needed. This can help in preventing fogging and ensuring that fluids do not obstruct the view of the larynx.

The biocompatibility of nanostructured surfaces also extends to their interaction with human cells. Properly designed nanostructures can promote the adhesion and growth of beneficial cells while inhibiting the attachment of harmful ones. This selective cell response can lead to faster healing of any tissue damage that may occur during intubation and reduce the risk of inflammation or scarring.

Another aspect of biocompatibility is the potential for nanostructured surfaces to release controlled amounts of antimicrobial agents or other beneficial substances. By incorporating these agents into the nanostructures, it is possible to create a sustained release mechanism that provides long-term protection against infections without the need for systemic administration of drugs.

However, it is crucial to consider the potential risks associated with nanostructured surfaces. The size and shape of nanostructures can influence their interaction with biological systems in ways that are not always predictable. There is a need for comprehensive testing to ensure that these surfaces do not cause unintended effects such as cellular damage or immune responses.

In conclusion, the biocompatibility of nanostructured surfaces offers significant potential for improving laryngoscope performance and patient safety. By carefully designing and testing these surfaces, it is possible to create devices that are more effective, safer, and better tolerated by patients. As research in this field continues to advance, we can expect to see increasingly sophisticated nanostructured surfaces that further enhance the biocompatibility and functionality of laryngoscopes and other medical devices.

One of the primary benefits of nanostructured surfaces on laryngoscopes is their ability to reduce bacterial adhesion and colonization. By creating nanoscale patterns or textures on the device surface, it becomes more difficult for bacteria to attach and form biofilms. This property is especially important in medical settings where preventing infections is crucial. Studies have shown that certain nanopatterns can reduce bacterial adhesion by up to 98% compared to conventional smooth surfaces.

Furthermore, nanostructured surfaces can improve the wettability of the laryngoscope, which is essential for maintaining clear visibility during intubation procedures. By controlling the surface energy through nanoengineering, it is possible to create hydrophilic or hydrophobic areas as needed. This can help in preventing fogging and ensuring that fluids do not obstruct the view of the larynx.

The biocompatibility of nanostructured surfaces also extends to their interaction with human cells. Properly designed nanostructures can promote the adhesion and growth of beneficial cells while inhibiting the attachment of harmful ones. This selective cell response can lead to faster healing of any tissue damage that may occur during intubation and reduce the risk of inflammation or scarring.

Another aspect of biocompatibility is the potential for nanostructured surfaces to release controlled amounts of antimicrobial agents or other beneficial substances. By incorporating these agents into the nanostructures, it is possible to create a sustained release mechanism that provides long-term protection against infections without the need for systemic administration of drugs.

However, it is crucial to consider the potential risks associated with nanostructured surfaces. The size and shape of nanostructures can influence their interaction with biological systems in ways that are not always predictable. There is a need for comprehensive testing to ensure that these surfaces do not cause unintended effects such as cellular damage or immune responses.

In conclusion, the biocompatibility of nanostructured surfaces offers significant potential for improving laryngoscope performance and patient safety. By carefully designing and testing these surfaces, it is possible to create devices that are more effective, safer, and better tolerated by patients. As research in this field continues to advance, we can expect to see increasingly sophisticated nanostructured surfaces that further enhance the biocompatibility and functionality of laryngoscopes and other medical devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!