Investigating resistive materials in laryngoscope functionality.

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laryngoscope Evolution

The laryngoscope has undergone significant evolution since its inception in the early 19th century. Initially developed as a simple tool for examining the larynx, it has transformed into a sophisticated medical device crucial for airway management and intubation procedures.

The earliest laryngoscopes were rudimentary instruments consisting of a mirror and a light source. In 1844, Manuel García invented the first indirect laryngoscope, using a dental mirror to reflect sunlight onto the larynx. This breakthrough allowed for the first visualization of vocal cords in a living person.

A major advancement came in 1895 when Alfred Kirstein developed the first direct laryngoscope. This design allowed for a more straightforward view of the larynx and paved the way for modern laryngoscopy techniques. The early 20th century saw further refinements, including the introduction of electric illumination, which greatly improved visibility during procedures.

The mid-20th century marked a significant leap in laryngoscope design with the introduction of the Macintosh blade by Robert Macintosh in 1943. This curved blade revolutionized laryngoscopy by providing a better view of the glottis and facilitating easier intubation. The Macintosh blade remains one of the most widely used designs to this day.

In the latter half of the 20th century, technological advancements led to the development of flexible fiber-optic laryngoscopes. These devices allowed for more versatile and less traumatic examinations, particularly in patients with difficult airways. The integration of video technology in the 1990s further enhanced visualization capabilities, giving rise to video laryngoscopes.

Recent years have seen a focus on improving the materials used in laryngoscope construction. The investigation of resistive materials has become a key area of research, aiming to enhance durability, reduce the risk of cross-contamination, and improve overall functionality. This includes the exploration of antimicrobial coatings and materials that can withstand repeated sterilization processes without degradation.

The evolution of laryngoscopes continues with the integration of advanced technologies such as augmented reality and artificial intelligence. These innovations aim to assist practitioners in real-time decision-making during intubation procedures and provide enhanced training opportunities for medical professionals.

As we look to the future, the ongoing evolution of laryngoscopes is likely to focus on further improving visualization, reducing patient discomfort, and enhancing the device's adaptability to various clinical scenarios. The investigation of resistive materials will play a crucial role in this development, potentially leading to more robust, efficient, and safer laryngoscopes for medical use.

The earliest laryngoscopes were rudimentary instruments consisting of a mirror and a light source. In 1844, Manuel García invented the first indirect laryngoscope, using a dental mirror to reflect sunlight onto the larynx. This breakthrough allowed for the first visualization of vocal cords in a living person.

A major advancement came in 1895 when Alfred Kirstein developed the first direct laryngoscope. This design allowed for a more straightforward view of the larynx and paved the way for modern laryngoscopy techniques. The early 20th century saw further refinements, including the introduction of electric illumination, which greatly improved visibility during procedures.

The mid-20th century marked a significant leap in laryngoscope design with the introduction of the Macintosh blade by Robert Macintosh in 1943. This curved blade revolutionized laryngoscopy by providing a better view of the glottis and facilitating easier intubation. The Macintosh blade remains one of the most widely used designs to this day.

In the latter half of the 20th century, technological advancements led to the development of flexible fiber-optic laryngoscopes. These devices allowed for more versatile and less traumatic examinations, particularly in patients with difficult airways. The integration of video technology in the 1990s further enhanced visualization capabilities, giving rise to video laryngoscopes.

Recent years have seen a focus on improving the materials used in laryngoscope construction. The investigation of resistive materials has become a key area of research, aiming to enhance durability, reduce the risk of cross-contamination, and improve overall functionality. This includes the exploration of antimicrobial coatings and materials that can withstand repeated sterilization processes without degradation.

The evolution of laryngoscopes continues with the integration of advanced technologies such as augmented reality and artificial intelligence. These innovations aim to assist practitioners in real-time decision-making during intubation procedures and provide enhanced training opportunities for medical professionals.

As we look to the future, the ongoing evolution of laryngoscopes is likely to focus on further improving visualization, reducing patient discomfort, and enhancing the device's adaptability to various clinical scenarios. The investigation of resistive materials will play a crucial role in this development, potentially leading to more robust, efficient, and safer laryngoscopes for medical use.

Market Demand Analysis

The market demand for resistive materials in laryngoscope functionality has been steadily increasing due to the growing emphasis on patient safety and the need for more reliable medical devices. Laryngoscopes are essential tools in anesthesiology and emergency medicine, used for intubation procedures during surgeries and critical care situations. The global laryngoscope market is expected to reach significant growth in the coming years, driven by technological advancements and the rising prevalence of chronic respiratory diseases.

The healthcare industry's focus on infection control and prevention has led to a surge in demand for disposable laryngoscope blades, which often incorporate resistive materials. These materials help prevent cross-contamination between patients and reduce the risk of healthcare-associated infections. Additionally, the increasing number of surgical procedures worldwide, particularly in developing countries, is contributing to the expansion of the laryngoscope market.

Resistive materials in laryngoscopes serve multiple purposes, including enhancing durability, improving electrical insulation, and providing better grip for healthcare professionals during intubation procedures. The market demand for these materials is further fueled by the growing adoption of video laryngoscopes, which require specialized coatings and materials to ensure optimal performance and longevity of the devices.

The aging population in many countries is another significant factor driving the demand for laryngoscopes and, consequently, resistive materials. As the elderly population grows, there is an increased incidence of respiratory disorders and a higher frequency of surgical interventions, leading to greater utilization of laryngoscopes in healthcare settings.

Emerging economies in Asia-Pacific and Latin America present substantial growth opportunities for the laryngoscope market. The improving healthcare infrastructure, rising healthcare expenditure, and growing awareness about advanced medical technologies in these regions are expected to boost the demand for laryngoscopes and associated resistive materials.

The COVID-19 pandemic has also had a notable impact on the market demand for laryngoscopes and resistive materials. The increased number of patients requiring intubation due to severe respiratory complications has led to a surge in the use of these devices. This has highlighted the importance of reliable and durable laryngoscopes, further driving the demand for high-quality resistive materials.

In conclusion, the market demand for resistive materials in laryngoscope functionality is robust and expected to continue growing. Factors such as technological advancements, increasing surgical procedures, focus on infection control, and demographic trends all contribute to the expanding market. Manufacturers and researchers in this field should focus on developing innovative resistive materials that can enhance the performance, safety, and durability of laryngoscopes to meet the evolving needs of healthcare professionals and patients.

The healthcare industry's focus on infection control and prevention has led to a surge in demand for disposable laryngoscope blades, which often incorporate resistive materials. These materials help prevent cross-contamination between patients and reduce the risk of healthcare-associated infections. Additionally, the increasing number of surgical procedures worldwide, particularly in developing countries, is contributing to the expansion of the laryngoscope market.

Resistive materials in laryngoscopes serve multiple purposes, including enhancing durability, improving electrical insulation, and providing better grip for healthcare professionals during intubation procedures. The market demand for these materials is further fueled by the growing adoption of video laryngoscopes, which require specialized coatings and materials to ensure optimal performance and longevity of the devices.

The aging population in many countries is another significant factor driving the demand for laryngoscopes and, consequently, resistive materials. As the elderly population grows, there is an increased incidence of respiratory disorders and a higher frequency of surgical interventions, leading to greater utilization of laryngoscopes in healthcare settings.

Emerging economies in Asia-Pacific and Latin America present substantial growth opportunities for the laryngoscope market. The improving healthcare infrastructure, rising healthcare expenditure, and growing awareness about advanced medical technologies in these regions are expected to boost the demand for laryngoscopes and associated resistive materials.

The COVID-19 pandemic has also had a notable impact on the market demand for laryngoscopes and resistive materials. The increased number of patients requiring intubation due to severe respiratory complications has led to a surge in the use of these devices. This has highlighted the importance of reliable and durable laryngoscopes, further driving the demand for high-quality resistive materials.

In conclusion, the market demand for resistive materials in laryngoscope functionality is robust and expected to continue growing. Factors such as technological advancements, increasing surgical procedures, focus on infection control, and demographic trends all contribute to the expanding market. Manufacturers and researchers in this field should focus on developing innovative resistive materials that can enhance the performance, safety, and durability of laryngoscopes to meet the evolving needs of healthcare professionals and patients.

Resistive Materials

Resistive materials play a crucial role in the functionality and performance of laryngoscopes, medical devices used for examining the larynx and facilitating intubation procedures. These materials are primarily employed in the construction of laryngoscope blades and handles, contributing to their durability, electrical safety, and overall effectiveness in clinical settings.

The most commonly used resistive materials in laryngoscope manufacturing include high-grade stainless steel, reinforced plastics, and composite materials. Stainless steel, particularly grades such as 304 and 316, offers excellent corrosion resistance, strength, and durability. These properties are essential for withstanding repeated sterilization processes and maintaining structural integrity during use.

Reinforced plastics, such as glass-filled nylon or carbon fiber-reinforced polymers, are increasingly being utilized in laryngoscope components. These materials provide a balance between strength and weight reduction, enhancing the ergonomics and maneuverability of the device. Additionally, their inherent electrical resistance contributes to the safety profile of the laryngoscope, minimizing the risk of electrical conductivity during use.

Composite materials, combining multiple constituents with different physical or chemical properties, are emerging as innovative solutions in laryngoscope design. These materials can be engineered to possess specific characteristics, such as enhanced flexibility, impact resistance, or thermal stability, tailored to the unique requirements of laryngoscope functionality.

The selection of resistive materials for laryngoscopes is governed by several key factors. Biocompatibility is paramount, ensuring that the materials do not cause adverse reactions when in contact with human tissues. Sterilization compatibility is another critical consideration, as laryngoscopes must withstand repeated cycles of high-temperature and chemical sterilization without degradation.

Electrical resistance properties of these materials are essential for preventing unintended electrical conduction, particularly in scenarios where defibrillation may be necessary during intubation procedures. The materials must also exhibit low thermal conductivity to prevent discomfort or potential tissue damage during prolonged use.

Recent advancements in material science have led to the development of novel resistive materials with enhanced properties. For instance, nanocomposite materials incorporating carbon nanotubes or graphene have shown promise in improving the strength-to-weight ratio and electrical characteristics of laryngoscope components. These innovations aim to address the ongoing challenges in laryngoscope design, such as reducing device weight while maintaining robustness and improving visibility through integrated lighting systems.

The investigation of resistive materials in laryngoscope functionality continues to be an active area of research and development. As medical procedures evolve and new technologies emerge, the demand for advanced materials that can meet increasingly stringent performance and safety requirements grows. This ongoing exploration drives the continuous improvement of laryngoscope design and functionality, ultimately contributing to enhanced patient care and clinical outcomes in airway management procedures.

The most commonly used resistive materials in laryngoscope manufacturing include high-grade stainless steel, reinforced plastics, and composite materials. Stainless steel, particularly grades such as 304 and 316, offers excellent corrosion resistance, strength, and durability. These properties are essential for withstanding repeated sterilization processes and maintaining structural integrity during use.

Reinforced plastics, such as glass-filled nylon or carbon fiber-reinforced polymers, are increasingly being utilized in laryngoscope components. These materials provide a balance between strength and weight reduction, enhancing the ergonomics and maneuverability of the device. Additionally, their inherent electrical resistance contributes to the safety profile of the laryngoscope, minimizing the risk of electrical conductivity during use.

Composite materials, combining multiple constituents with different physical or chemical properties, are emerging as innovative solutions in laryngoscope design. These materials can be engineered to possess specific characteristics, such as enhanced flexibility, impact resistance, or thermal stability, tailored to the unique requirements of laryngoscope functionality.

The selection of resistive materials for laryngoscopes is governed by several key factors. Biocompatibility is paramount, ensuring that the materials do not cause adverse reactions when in contact with human tissues. Sterilization compatibility is another critical consideration, as laryngoscopes must withstand repeated cycles of high-temperature and chemical sterilization without degradation.

Electrical resistance properties of these materials are essential for preventing unintended electrical conduction, particularly in scenarios where defibrillation may be necessary during intubation procedures. The materials must also exhibit low thermal conductivity to prevent discomfort or potential tissue damage during prolonged use.

Recent advancements in material science have led to the development of novel resistive materials with enhanced properties. For instance, nanocomposite materials incorporating carbon nanotubes or graphene have shown promise in improving the strength-to-weight ratio and electrical characteristics of laryngoscope components. These innovations aim to address the ongoing challenges in laryngoscope design, such as reducing device weight while maintaining robustness and improving visibility through integrated lighting systems.

The investigation of resistive materials in laryngoscope functionality continues to be an active area of research and development. As medical procedures evolve and new technologies emerge, the demand for advanced materials that can meet increasingly stringent performance and safety requirements grows. This ongoing exploration drives the continuous improvement of laryngoscope design and functionality, ultimately contributing to enhanced patient care and clinical outcomes in airway management procedures.

Current Solutions

01 Resistive switching materials for memory devices

Resistive materials are used in memory devices to create resistive switching elements. These materials can change their resistance state when an electric field or current is applied, allowing for data storage and retrieval. The functionality of these materials is crucial for developing non-volatile memory technologies with high density and low power consumption.- Resistive switching materials for memory devices: Resistive materials are used in memory devices to create resistive switching elements. These materials can change their resistance state when subjected to electrical stimuli, allowing for data storage and retrieval. The functionality of these materials is crucial for developing non-volatile memory technologies with high density and low power consumption.

- Resistive materials in sensor applications: Resistive materials are employed in various sensor applications due to their ability to change resistance in response to external stimuli. These materials can be used to detect changes in temperature, pressure, strain, or chemical composition. The functionality of resistive materials in sensors allows for accurate and reliable measurements in diverse fields.

- Resistive heating elements: Resistive materials are utilized in heating elements where electrical energy is converted into heat through the material's resistance. These materials provide controlled and efficient heating in various applications, including industrial processes, household appliances, and automotive systems. The functionality of resistive heating elements depends on the material's electrical and thermal properties.

- Resistive materials in electronic components: Resistive materials play a crucial role in electronic components such as resistors, potentiometers, and voltage dividers. These materials provide precise control of current flow and voltage distribution in electronic circuits. The functionality of resistive materials in electronic components is essential for signal processing, power management, and circuit protection.

- Resistive materials for electromagnetic shielding: Resistive materials are used in electromagnetic shielding applications to protect sensitive electronic devices from electromagnetic interference. These materials can absorb or reflect electromagnetic waves, preventing them from interfering with the operation of electronic components. The functionality of resistive materials in shielding is crucial for maintaining the performance and reliability of electronic systems in various environments.

02 Thin film resistors and their applications

Resistive materials are utilized in the fabrication of thin film resistors, which are essential components in various electronic circuits. These resistors offer precise resistance values, low noise, and high stability. They find applications in analog circuits, sensors, and other electronic devices where accurate resistance is required.Expand Specific Solutions03 Phase change materials for resistive memory

Phase change materials exhibit resistive switching behavior and are used in phase change memory devices. These materials can reversibly switch between amorphous and crystalline states, each with different electrical resistance. This property enables the storage and retrieval of data in non-volatile memory applications.Expand Specific Solutions04 Resistive materials in sensor technologies

Resistive materials play a crucial role in various sensor technologies. They are used in the development of strain gauges, temperature sensors, and pressure sensors. The change in resistance of these materials in response to external stimuli allows for the measurement and detection of physical quantities.Expand Specific Solutions05 Resistive materials for electromagnetic shielding

Resistive materials are employed in electromagnetic shielding applications to protect electronic devices from electromagnetic interference. These materials can absorb or reflect electromagnetic waves, reducing their impact on sensitive components. The functionality of resistive materials in this context is essential for ensuring the proper operation of electronic devices in various environments.Expand Specific Solutions

Key Industry Players

The investigation of resistive materials in laryngoscope functionality is currently in an early development stage, with a growing market driven by increasing demand for advanced medical devices. The global laryngoscope market is expanding, with a projected CAGR of 6-8% over the next five years. Technologically, the field is evolving rapidly, with companies like Zhejiang Youyi Medical Equipment Co Ltd and FUJIFILM Corp leading innovations in visualized airway management tools. Academic institutions such as the University of Birmingham and Zhejiang University are contributing to research advancements. While the technology is promising, it is still maturing, with ongoing efforts to improve material properties and device performance.

Zhejiang Youyi Medical Equipment Co Ltd

Technical Solution: Zhejiang Youyi Medical Equipment Co Ltd has developed advanced laryngoscopes utilizing resistive materials to enhance functionality. Their innovative design incorporates a flexible tip with embedded resistive sensors, allowing for precise pressure feedback during intubation procedures[1]. The company has also implemented a novel coating technology that applies a thin layer of resistive material to the laryngoscope blade, improving electrical conductivity for better nerve stimulation detection[2]. This technology enables real-time monitoring of tissue contact and helps prevent potential injuries during use[3]. Additionally, Zhejiang Youyi has integrated temperature-sensitive resistive elements into their laryngoscope handles, providing thermal feedback to alert users of potential overheating issues during prolonged use[4].

Strengths: Enhanced pressure sensitivity, improved nerve stimulation detection, and thermal safety features. Weaknesses: Potentially higher manufacturing costs and the need for specialized training for users to fully utilize the advanced features.

Zhejiang University

Technical Solution: Zhejiang University's research team has made significant strides in investigating resistive materials for laryngoscope functionality. They have developed a novel composite material combining conductive polymers with nanoparticles, resulting in a highly responsive and durable coating for laryngoscope blades[1]. This material exhibits excellent strain-sensing properties, allowing for real-time feedback on the applied force during intubation[2]. The university's approach also includes the integration of piezoelectric elements within the laryngoscope handle, converting mechanical stress into electrical signals for improved tactile sensation[3]. Furthermore, they have explored the use of graphene-based resistive sensors in laryngoscope tips, enabling ultra-sensitive detection of tissue contact and potentially reducing the risk of trauma during procedures[4].

Strengths: Cutting-edge materials research, high sensitivity in force detection, and potential for reducing intubation-related injuries. Weaknesses: Technology may be in early stages of development and require extensive clinical trials before commercialization.

Core Innovations

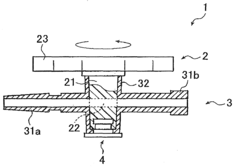

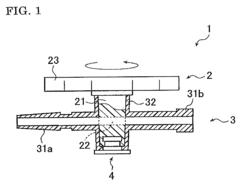

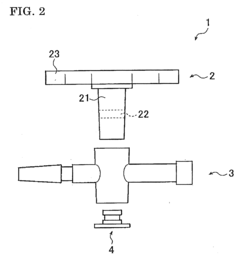

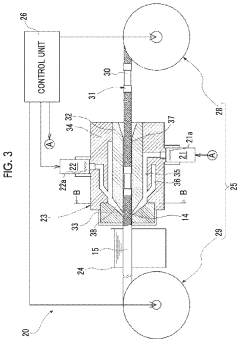

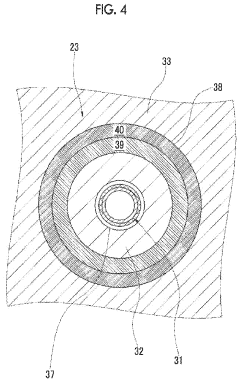

Medical stopcock

PatentInactiveUS20090173903A1

Innovation

- A medical stopcock with a housing made of polyarylene sulfide resin and a cock made of polyolefin-based resin, connected by press fit, providing enhanced pressure-proofness, chemical resistance, and tolerance to radiation sterilization, specifically electron beam sterilization, through the use of polyphenylene sulfide and polyethylene materials with added fillers for improved strength and stability.

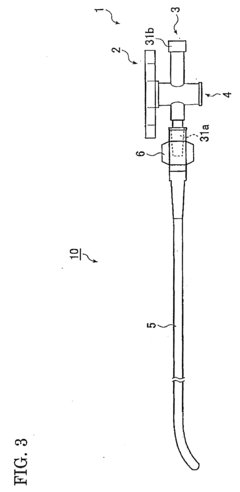

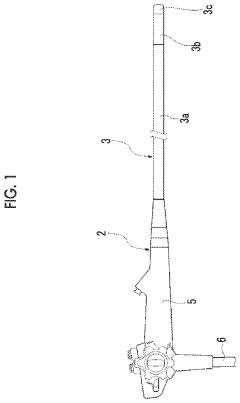

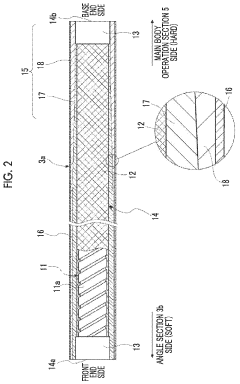

Flexible tube for endoscopes and method for producing same

PatentActiveUS11892104B2

Innovation

- A flexible tube design featuring a resin layer with a double-layer structure, comprising an inner layer of polyester, polyurethane, or polyamide elastomers and an outer layer of chain-extended forms of these elastomers, using specific chain extenders and catalysts, and incorporating hindered phenol and amine compounds for enhanced chemical resistance and adhesion.

Regulatory Landscape

The regulatory landscape surrounding resistive materials in laryngoscope functionality is complex and multifaceted, involving various governmental bodies and international standards. In the United States, the Food and Drug Administration (FDA) plays a crucial role in overseeing medical devices, including laryngoscopes. The FDA classifies laryngoscopes as Class I medical devices, which are subject to general controls but typically exempt from premarket notification requirements.

However, the use of novel resistive materials in laryngoscope design may necessitate additional scrutiny. Manufacturers must ensure compliance with FDA's Quality System Regulation (QSR) and Good Manufacturing Practices (GMP). The materials used must meet biocompatibility standards as outlined in ISO 10993, which evaluates the biological safety of medical devices.

In the European Union, laryngoscopes fall under the Medical Device Regulation (MDR), which came into effect in May 2021. The MDR imposes stricter requirements on medical device manufacturers, including enhanced clinical evaluation and post-market surveillance. Resistive materials used in laryngoscopes must comply with the Essential Requirements outlined in Annex I of the MDR.

International Electrotechnical Commission (IEC) standards, particularly IEC 60601-1 for medical electrical equipment, are crucial for ensuring the safety and performance of laryngoscopes. The resistive materials must not compromise the device's electrical safety or electromagnetic compatibility.

The regulatory landscape also encompasses environmental considerations. The Restriction of Hazardous Substances (RoHS) Directive in the EU and similar regulations worldwide restrict the use of certain hazardous materials in electronic equipment, including medical devices. Manufacturers must ensure that resistive materials comply with these environmental regulations.

As laryngoscopes are used in critical care settings, regulatory bodies emphasize the importance of reliability and durability. The resistive materials must demonstrate long-term stability and consistent performance under various environmental conditions. This may require extensive testing and documentation to satisfy regulatory requirements.

Emerging technologies and materials in medical devices often face additional regulatory scrutiny. Manufacturers investigating novel resistive materials may need to engage in early discussions with regulatory bodies to determine the appropriate pathway for approval. This proactive approach can help identify potential regulatory hurdles and streamline the approval process.

However, the use of novel resistive materials in laryngoscope design may necessitate additional scrutiny. Manufacturers must ensure compliance with FDA's Quality System Regulation (QSR) and Good Manufacturing Practices (GMP). The materials used must meet biocompatibility standards as outlined in ISO 10993, which evaluates the biological safety of medical devices.

In the European Union, laryngoscopes fall under the Medical Device Regulation (MDR), which came into effect in May 2021. The MDR imposes stricter requirements on medical device manufacturers, including enhanced clinical evaluation and post-market surveillance. Resistive materials used in laryngoscopes must comply with the Essential Requirements outlined in Annex I of the MDR.

International Electrotechnical Commission (IEC) standards, particularly IEC 60601-1 for medical electrical equipment, are crucial for ensuring the safety and performance of laryngoscopes. The resistive materials must not compromise the device's electrical safety or electromagnetic compatibility.

The regulatory landscape also encompasses environmental considerations. The Restriction of Hazardous Substances (RoHS) Directive in the EU and similar regulations worldwide restrict the use of certain hazardous materials in electronic equipment, including medical devices. Manufacturers must ensure that resistive materials comply with these environmental regulations.

As laryngoscopes are used in critical care settings, regulatory bodies emphasize the importance of reliability and durability. The resistive materials must demonstrate long-term stability and consistent performance under various environmental conditions. This may require extensive testing and documentation to satisfy regulatory requirements.

Emerging technologies and materials in medical devices often face additional regulatory scrutiny. Manufacturers investigating novel resistive materials may need to engage in early discussions with regulatory bodies to determine the appropriate pathway for approval. This proactive approach can help identify potential regulatory hurdles and streamline the approval process.

Biocompatibility

Biocompatibility is a critical consideration in the development of resistive materials for laryngoscope functionality. The materials used in laryngoscopes must be safe for human contact and not cause adverse reactions when in contact with tissues in the mouth and throat during intubation procedures.

The primary biocompatibility concerns for laryngoscope materials include cytotoxicity, sensitization, irritation, and systemic toxicity. Cytotoxicity refers to the potential of materials to cause cell death or inhibit cell growth. Sensitization involves the risk of allergic reactions upon repeated exposure. Irritation relates to localized inflammatory responses, while systemic toxicity addresses potential harmful effects on the body as a whole.

To ensure biocompatibility, resistive materials used in laryngoscopes undergo rigorous testing according to international standards, such as ISO 10993. These tests evaluate the materials' interactions with living tissues, cells, and biological systems. In vitro assays, including cell culture studies, are employed to assess cytotoxicity and potential genotoxicity. Animal studies may be conducted to evaluate sensitization and irritation potential.

The choice of resistive materials for laryngoscopes must balance biocompatibility with other essential properties, such as electrical resistance, durability, and ease of sterilization. Common biocompatible materials used in medical devices include certain grades of stainless steel, titanium alloys, and medical-grade polymers like polyethylene and silicone.

Surface modifications and coatings can enhance the biocompatibility of resistive materials. For instance, plasma treatment or the application of hydrophilic coatings can reduce protein adsorption and bacterial adhesion, minimizing the risk of infection and improving overall biocompatibility.

Researchers are exploring novel biocompatible materials with resistive properties for use in laryngoscopes. These include conductive polymers and nanocomposites that offer both electrical functionality and excellent biocompatibility. Such materials could potentially improve the performance and safety of laryngoscopes while meeting stringent biocompatibility requirements.

The long-term effects of resistive materials on tissues and the body must also be considered. This includes evaluating the potential for material degradation over time and assessing any risks associated with the release of particles or leachables. Comprehensive biocompatibility testing should account for both acute and chronic exposure scenarios to ensure patient safety throughout the device's lifecycle.

The primary biocompatibility concerns for laryngoscope materials include cytotoxicity, sensitization, irritation, and systemic toxicity. Cytotoxicity refers to the potential of materials to cause cell death or inhibit cell growth. Sensitization involves the risk of allergic reactions upon repeated exposure. Irritation relates to localized inflammatory responses, while systemic toxicity addresses potential harmful effects on the body as a whole.

To ensure biocompatibility, resistive materials used in laryngoscopes undergo rigorous testing according to international standards, such as ISO 10993. These tests evaluate the materials' interactions with living tissues, cells, and biological systems. In vitro assays, including cell culture studies, are employed to assess cytotoxicity and potential genotoxicity. Animal studies may be conducted to evaluate sensitization and irritation potential.

The choice of resistive materials for laryngoscopes must balance biocompatibility with other essential properties, such as electrical resistance, durability, and ease of sterilization. Common biocompatible materials used in medical devices include certain grades of stainless steel, titanium alloys, and medical-grade polymers like polyethylene and silicone.

Surface modifications and coatings can enhance the biocompatibility of resistive materials. For instance, plasma treatment or the application of hydrophilic coatings can reduce protein adsorption and bacterial adhesion, minimizing the risk of infection and improving overall biocompatibility.

Researchers are exploring novel biocompatible materials with resistive properties for use in laryngoscopes. These include conductive polymers and nanocomposites that offer both electrical functionality and excellent biocompatibility. Such materials could potentially improve the performance and safety of laryngoscopes while meeting stringent biocompatibility requirements.

The long-term effects of resistive materials on tissues and the body must also be considered. This includes evaluating the potential for material degradation over time and assessing any risks associated with the release of particles or leachables. Comprehensive biocompatibility testing should account for both acute and chronic exposure scenarios to ensure patient safety throughout the device's lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!