The integration of cooling technologies in laryngoscope handles.

JUL 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laryngoscope Cooling Tech Background and Objectives

Laryngoscopes have been an essential tool in medical practice for over a century, enabling healthcare professionals to visualize and access the larynx and vocal cords. As these devices have evolved, the integration of cooling technologies in laryngoscope handles has emerged as a significant area of development. This technological advancement aims to address several critical challenges in laryngoscopy procedures, particularly in prolonged or complex cases.

The primary objective of incorporating cooling technologies into laryngoscope handles is to enhance patient comfort and safety during intubation procedures. Traditional laryngoscopes can generate heat due to the illumination system, potentially causing discomfort or even tissue damage in sensitive areas of the throat. By implementing cooling mechanisms, manufacturers seek to mitigate these risks and improve overall procedural outcomes.

Another key goal is to extend the operational time of laryngoscopes, especially in scenarios where prolonged use is necessary. Heat buildup can affect the performance of electronic components and reduce battery life. Cooling technologies aim to maintain optimal operating temperatures, thereby increasing the device's reliability and longevity during critical medical procedures.

The evolution of cooling technologies in laryngoscope handles is closely tied to broader trends in medical device miniaturization and energy efficiency. As laryngoscopes become more sophisticated, incorporating features such as video capabilities and advanced sensors, the need for effective thermal management becomes increasingly crucial. This technological progression aligns with the healthcare industry's push towards more precise, less invasive, and patient-friendly diagnostic and treatment tools.

From a historical perspective, the integration of cooling technologies in laryngoscope handles represents a significant leap forward from early designs. Initial laryngoscopes relied on external light sources or basic battery-powered illumination without considering heat management. The recognition of thermal issues and the subsequent development of cooling solutions mark a new era in laryngoscope design, reflecting a deeper understanding of the interplay between medical functionality and patient experience.

Looking ahead, the objectives for further advancement in this field include the development of more efficient and compact cooling systems, exploration of novel materials with superior heat dissipation properties, and the integration of smart temperature control mechanisms. These goals are driven by the continuous pursuit of improving patient outcomes, enhancing practitioner usability, and meeting the evolving demands of modern medical procedures.

The primary objective of incorporating cooling technologies into laryngoscope handles is to enhance patient comfort and safety during intubation procedures. Traditional laryngoscopes can generate heat due to the illumination system, potentially causing discomfort or even tissue damage in sensitive areas of the throat. By implementing cooling mechanisms, manufacturers seek to mitigate these risks and improve overall procedural outcomes.

Another key goal is to extend the operational time of laryngoscopes, especially in scenarios where prolonged use is necessary. Heat buildup can affect the performance of electronic components and reduce battery life. Cooling technologies aim to maintain optimal operating temperatures, thereby increasing the device's reliability and longevity during critical medical procedures.

The evolution of cooling technologies in laryngoscope handles is closely tied to broader trends in medical device miniaturization and energy efficiency. As laryngoscopes become more sophisticated, incorporating features such as video capabilities and advanced sensors, the need for effective thermal management becomes increasingly crucial. This technological progression aligns with the healthcare industry's push towards more precise, less invasive, and patient-friendly diagnostic and treatment tools.

From a historical perspective, the integration of cooling technologies in laryngoscope handles represents a significant leap forward from early designs. Initial laryngoscopes relied on external light sources or basic battery-powered illumination without considering heat management. The recognition of thermal issues and the subsequent development of cooling solutions mark a new era in laryngoscope design, reflecting a deeper understanding of the interplay between medical functionality and patient experience.

Looking ahead, the objectives for further advancement in this field include the development of more efficient and compact cooling systems, exploration of novel materials with superior heat dissipation properties, and the integration of smart temperature control mechanisms. These goals are driven by the continuous pursuit of improving patient outcomes, enhancing practitioner usability, and meeting the evolving demands of modern medical procedures.

Market Demand for Temperature-Controlled Laryngoscopes

The market demand for temperature-controlled laryngoscopes has been steadily increasing in recent years, driven by the growing awareness of patient comfort and safety during intubation procedures. Healthcare professionals are increasingly recognizing the importance of maintaining optimal temperature in laryngoscope handles to enhance visibility and reduce fogging of the laryngoscope blade, ultimately improving the success rate of intubations.

In the global medical devices market, laryngoscopes represent a significant segment, with an estimated value of several billion dollars. The integration of cooling technologies in laryngoscope handles is expected to further boost this market, as it addresses a critical need in both emergency and surgical settings. Hospitals, ambulatory surgical centers, and emergency medical services are the primary end-users driving this demand.

The increasing prevalence of chronic respiratory diseases and the rising number of surgical procedures requiring intubation are key factors contributing to the growth of the temperature-controlled laryngoscope market. Additionally, the ongoing COVID-19 pandemic has highlighted the importance of efficient and safe intubation techniques, further accelerating the adoption of advanced laryngoscope technologies.

Market research indicates that healthcare providers are willing to invest in innovative medical devices that can improve patient outcomes and reduce procedure-related complications. Temperature-controlled laryngoscopes are perceived as a valuable tool in this regard, as they can potentially reduce the risk of trauma to the patient's airway and improve the overall success rate of intubations.

The demand for these advanced laryngoscopes is particularly high in developed countries with well-established healthcare infrastructure. However, emerging economies are also showing increased interest in adopting these technologies as they upgrade their healthcare facilities and focus on improving patient care standards.

Manufacturers in the medical device industry are responding to this market demand by investing in research and development to create more efficient and user-friendly temperature-controlled laryngoscope handles. There is a growing trend towards the development of disposable laryngoscopes with integrated cooling technologies, addressing concerns related to cross-contamination and infection control.

As healthcare systems worldwide continue to emphasize the importance of patient safety and procedure efficiency, the market for temperature-controlled laryngoscopes is expected to expand further. This growth is likely to be supported by ongoing technological advancements, such as the integration of smart sensors and digital displays in laryngoscope handles, providing real-time temperature monitoring and control capabilities.

In the global medical devices market, laryngoscopes represent a significant segment, with an estimated value of several billion dollars. The integration of cooling technologies in laryngoscope handles is expected to further boost this market, as it addresses a critical need in both emergency and surgical settings. Hospitals, ambulatory surgical centers, and emergency medical services are the primary end-users driving this demand.

The increasing prevalence of chronic respiratory diseases and the rising number of surgical procedures requiring intubation are key factors contributing to the growth of the temperature-controlled laryngoscope market. Additionally, the ongoing COVID-19 pandemic has highlighted the importance of efficient and safe intubation techniques, further accelerating the adoption of advanced laryngoscope technologies.

Market research indicates that healthcare providers are willing to invest in innovative medical devices that can improve patient outcomes and reduce procedure-related complications. Temperature-controlled laryngoscopes are perceived as a valuable tool in this regard, as they can potentially reduce the risk of trauma to the patient's airway and improve the overall success rate of intubations.

The demand for these advanced laryngoscopes is particularly high in developed countries with well-established healthcare infrastructure. However, emerging economies are also showing increased interest in adopting these technologies as they upgrade their healthcare facilities and focus on improving patient care standards.

Manufacturers in the medical device industry are responding to this market demand by investing in research and development to create more efficient and user-friendly temperature-controlled laryngoscope handles. There is a growing trend towards the development of disposable laryngoscopes with integrated cooling technologies, addressing concerns related to cross-contamination and infection control.

As healthcare systems worldwide continue to emphasize the importance of patient safety and procedure efficiency, the market for temperature-controlled laryngoscopes is expected to expand further. This growth is likely to be supported by ongoing technological advancements, such as the integration of smart sensors and digital displays in laryngoscope handles, providing real-time temperature monitoring and control capabilities.

Current Cooling Technologies in Medical Devices

Cooling technologies have become increasingly important in medical devices, particularly in instruments that generate heat during operation or require temperature control for optimal performance. In the context of medical devices, cooling technologies serve multiple purposes, including enhancing patient comfort, improving device efficiency, and ensuring safety during prolonged use.

One of the most common cooling technologies employed in medical devices is passive cooling. This approach relies on materials with high thermal conductivity to dissipate heat without the need for active components. Heat sinks, often made of aluminum or copper, are frequently used in devices such as diagnostic imaging equipment and surgical lights. These heat sinks efficiently transfer heat away from critical components, maintaining safe operating temperatures.

Active cooling systems, on the other hand, utilize powered components to remove heat more effectively. Thermoelectric cooling, based on the Peltier effect, is widely used in smaller medical devices. This technology employs semiconductor elements to create a temperature differential, allowing for precise temperature control. Thermoelectric coolers are found in applications such as blood analyzers and PCR machines, where maintaining specific temperatures is crucial for accurate results.

For larger medical devices or those requiring more substantial cooling, liquid cooling systems are often employed. These systems circulate a coolant through the device, efficiently removing heat from critical components. MRI machines, for instance, use liquid helium to cool superconducting magnets, maintaining the extremely low temperatures necessary for proper operation.

In portable medical devices, such as handheld ultrasound machines or mobile X-ray units, miniaturized fan-based cooling systems are commonly used. These systems incorporate small, high-efficiency fans to circulate air and dissipate heat, balancing cooling performance with size and power constraints.

Phase change materials (PCMs) represent an emerging cooling technology in medical devices. These materials absorb or release heat as they change phase, typically between solid and liquid states. PCMs are being explored for use in wearable medical devices and temperature-sensitive drug delivery systems, offering passive temperature regulation without the need for power sources.

Microfluidic cooling is another innovative approach gaining traction in medical device design. This technology utilizes microscale channels to circulate coolant, allowing for highly efficient heat removal in compact spaces. Microfluidic cooling shows promise in applications such as lab-on-a-chip devices and miniaturized diagnostic tools.

As medical devices continue to evolve, becoming smaller, more powerful, and more portable, the demand for advanced cooling technologies grows. Researchers and engineers are exploring novel materials and techniques, such as graphene-based heat spreaders and nanofluids, to push the boundaries of thermal management in medical devices. These advancements aim to improve device performance, extend operational lifetimes, and enhance patient safety across a wide range of medical applications.

One of the most common cooling technologies employed in medical devices is passive cooling. This approach relies on materials with high thermal conductivity to dissipate heat without the need for active components. Heat sinks, often made of aluminum or copper, are frequently used in devices such as diagnostic imaging equipment and surgical lights. These heat sinks efficiently transfer heat away from critical components, maintaining safe operating temperatures.

Active cooling systems, on the other hand, utilize powered components to remove heat more effectively. Thermoelectric cooling, based on the Peltier effect, is widely used in smaller medical devices. This technology employs semiconductor elements to create a temperature differential, allowing for precise temperature control. Thermoelectric coolers are found in applications such as blood analyzers and PCR machines, where maintaining specific temperatures is crucial for accurate results.

For larger medical devices or those requiring more substantial cooling, liquid cooling systems are often employed. These systems circulate a coolant through the device, efficiently removing heat from critical components. MRI machines, for instance, use liquid helium to cool superconducting magnets, maintaining the extremely low temperatures necessary for proper operation.

In portable medical devices, such as handheld ultrasound machines or mobile X-ray units, miniaturized fan-based cooling systems are commonly used. These systems incorporate small, high-efficiency fans to circulate air and dissipate heat, balancing cooling performance with size and power constraints.

Phase change materials (PCMs) represent an emerging cooling technology in medical devices. These materials absorb or release heat as they change phase, typically between solid and liquid states. PCMs are being explored for use in wearable medical devices and temperature-sensitive drug delivery systems, offering passive temperature regulation without the need for power sources.

Microfluidic cooling is another innovative approach gaining traction in medical device design. This technology utilizes microscale channels to circulate coolant, allowing for highly efficient heat removal in compact spaces. Microfluidic cooling shows promise in applications such as lab-on-a-chip devices and miniaturized diagnostic tools.

As medical devices continue to evolve, becoming smaller, more powerful, and more portable, the demand for advanced cooling technologies grows. Researchers and engineers are exploring novel materials and techniques, such as graphene-based heat spreaders and nanofluids, to push the boundaries of thermal management in medical devices. These advancements aim to improve device performance, extend operational lifetimes, and enhance patient safety across a wide range of medical applications.

Existing Cooling Solutions for Laryngoscope Handles

01 Heat dissipation mechanisms in laryngoscope handles

Various heat dissipation mechanisms are employed in laryngoscope handles to maintain a comfortable temperature during use. These include the use of heat sinks, thermal conductive materials, and passive cooling designs. Such mechanisms help to efficiently transfer heat away from the handle, improving user comfort and device longevity.- Heat dissipation mechanisms in laryngoscope handles: Various heat dissipation mechanisms are employed in laryngoscope handles to maintain a comfortable temperature during use. These include the use of heat sinks, thermal conductive materials, and passive cooling designs. Such mechanisms help to efficiently transfer heat away from the handle, ensuring user comfort and preventing overheating of internal components.

- Active cooling systems for laryngoscope handles: Active cooling systems are integrated into some laryngoscope handles to provide enhanced temperature control. These systems may include miniature fans, thermoelectric coolers, or liquid cooling circuits. Active cooling allows for more precise temperature management, especially in prolonged procedures or high-intensity light output scenarios.

- Temperature-sensitive materials in handle construction: Innovative materials with temperature-sensitive properties are used in the construction of laryngoscope handles. These materials may change color or texture in response to temperature variations, providing visual or tactile feedback to the user. This feature helps in monitoring the handle temperature and ensures safe operation.

- Ergonomic design for heat management: Laryngoscope handles are designed with ergonomic considerations to manage heat distribution. This includes the use of insulating materials, strategic placement of heat-generating components, and optimized grip designs. These ergonomic features help in minimizing heat transfer to the user's hand while maintaining functionality.

- Smart cooling control systems: Advanced laryngoscope handles incorporate smart cooling control systems. These systems use sensors to monitor handle temperature and automatically adjust cooling mechanisms. They may also include user-configurable settings and power management features to optimize cooling efficiency and battery life.

02 Active cooling systems for laryngoscope handles

Active cooling systems are integrated into some laryngoscope handles to provide enhanced temperature control. These systems may include miniature fans, thermoelectric coolers, or liquid cooling circuits. Active cooling allows for more precise temperature management, especially in prolonged procedures or high-intensity light settings.Expand Specific Solutions03 Temperature-sensitive materials in handle construction

Laryngoscope handles incorporate temperature-sensitive materials that respond to heat buildup. These materials may change properties or shape to facilitate heat dissipation or provide tactile feedback to the user. This approach helps in maintaining a safe and comfortable handle temperature without the need for complex cooling systems.Expand Specific Solutions04 Ergonomic design for improved heat management

The ergonomic design of laryngoscope handles plays a crucial role in heat management. Handles are shaped and structured to maximize surface area for heat dissipation while maintaining a comfortable grip. Some designs incorporate ventilation channels or textured surfaces to enhance air circulation and reduce heat retention.Expand Specific Solutions05 Smart cooling systems with temperature monitoring

Advanced laryngoscope handles feature smart cooling systems with integrated temperature monitoring. These systems use sensors to detect handle temperature and automatically adjust cooling mechanisms. Some designs include user alerts or automatic power reduction to prevent overheating, ensuring safe and efficient operation.Expand Specific Solutions

Key Players in Laryngoscope Manufacturing

The integration of cooling technologies in laryngoscope handles is in a growth phase, with increasing market demand driven by the need for improved patient comfort and procedural efficiency. The global market for advanced laryngoscopes is expanding, with a focus on innovative features like cooling systems. Companies such as Karl Storz, Covidien, and Olympus are leading the technological advancements in this field. The technology is maturing rapidly, with various players introducing novel cooling solutions. However, there is still room for innovation and market penetration, particularly in emerging economies. Smaller companies like Heine Optotechnik and Flexicare are also contributing to the competitive landscape with specialized offerings.

Karl Storz SE & Co. KG

Technical Solution: Karl Storz has developed an innovative cooling system for their laryngoscope handles, utilizing advanced heat dissipation materials and a miniaturized liquid cooling circuit. This system effectively manages heat generated by LED light sources, ensuring optimal performance and patient comfort during prolonged procedures. The company's C-MAC® video laryngoscope incorporates a passive cooling design with strategically placed heat sinks and thermal conductive pathways[1]. Additionally, Karl Storz has implemented a smart temperature control system that dynamically adjusts LED intensity based on handle temperature, preventing overheating while maintaining excellent illumination[2].

Strengths: Advanced thermal management, improved user comfort, and extended device lifespan. Weaknesses: Potentially higher manufacturing costs and increased complexity in maintenance.

Teleflex Life Sciences LLC

Technical Solution: Teleflex has integrated an innovative cooling technology in their laryngoscope handles, focusing on user comfort and device longevity. Their approach utilizes a combination of advanced materials and smart design principles to manage heat effectively. The company has developed a proprietary thermal management system that incorporates heat-dissipating alloys and micro-channeled structures within the handle to maximize surface area for cooling. Teleflex's laryngoscope handles also feature a dynamic power management system that adjusts LED output based on real-time temperature readings, preventing overheating while maintaining optimal illumination[7]. Additionally, some models incorporate a thin-film thermoelectric cooling element to actively remove heat from critical components[8].

Strengths: Enhanced user comfort, prolonged LED lifespan, and adaptive performance. Weaknesses: Increased production costs and potential for higher power consumption in active cooling models.

Innovative Cooling Technologies for Medical Instruments

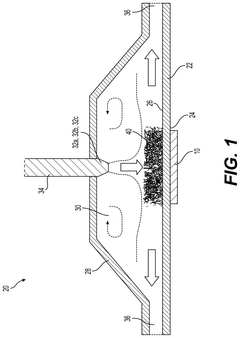

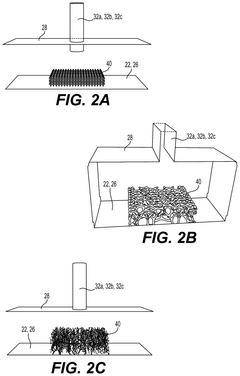

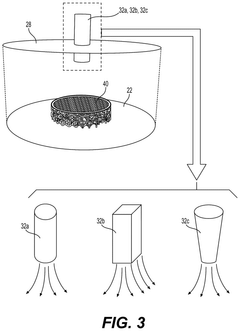

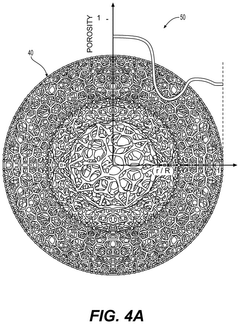

Porous spreader assisted jet and spray impingement cooling systems

PatentPendingUS20250008694A1

Innovation

- A hybrid thermal management system incorporating a porous heat spreader with spatially varying properties and multiple nozzles directing jets or sprays at different angles, enhancing heat transfer through increased turbulence and surface area, while minimizing pump work and coolant usage.

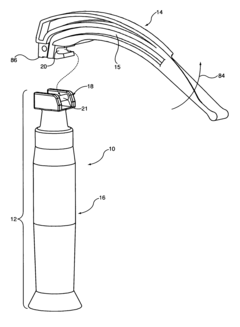

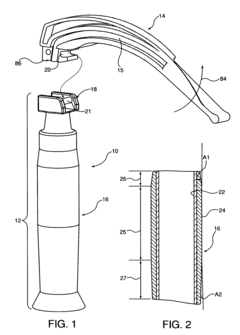

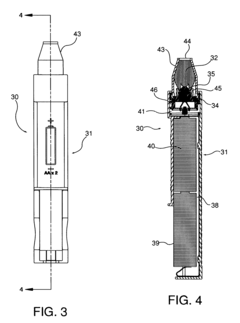

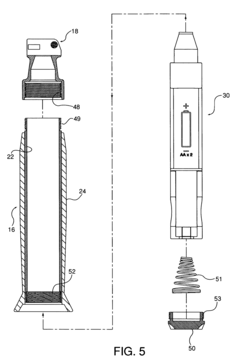

Laryngoscope and laryngoscope handle apparatus including an LED and which may include an ergonomic handle

PatentActiveUS7771350B2

Innovation

- The integration of an LED light source with an ergonomic handle and a battery/lens pack that includes a printed circuit board with an LED drive circuit, using DC batteries and a compression spring to maintain consistent light output and durability, along with an ergonomic design to reduce hand fatigue.

Regulatory Considerations for Cooled Medical Devices

The integration of cooling technologies in laryngoscope handles introduces unique regulatory considerations that must be carefully addressed to ensure patient safety and device efficacy. Medical device manufacturers must navigate a complex landscape of regulations and standards when incorporating cooling systems into laryngoscopes.

In the United States, the Food and Drug Administration (FDA) classifies laryngoscopes as Class I medical devices, which are subject to general controls. However, the addition of cooling technology may elevate the device to Class II, requiring a 510(k) premarket notification. Manufacturers must demonstrate that the cooled laryngoscope is substantially equivalent to a predicate device in terms of safety and effectiveness.

The FDA's guidance on thermal management in medical devices becomes particularly relevant for cooled laryngoscopes. Manufacturers must provide comprehensive data on heat dissipation, temperature control, and potential thermal risks to patients and healthcare providers. This includes thermal mapping of the device under various operating conditions and worst-case scenarios.

In the European Union, cooled laryngoscopes fall under the Medical Device Regulation (MDR). Manufacturers must obtain CE marking by demonstrating compliance with the Essential Requirements outlined in the MDR. This involves a thorough risk assessment, including the evaluation of potential hazards associated with the cooling system, such as electrical safety, biocompatibility of materials, and thermal effects on tissues.

International standards play a crucial role in regulatory compliance. IEC 60601-1, the general standard for medical electrical equipment, provides guidelines on safety and essential performance. Manufacturers must ensure that the integration of cooling technology does not compromise the device's compliance with this standard, particularly in areas such as electrical safety and electromagnetic compatibility.

ISO 14971, which outlines the application of risk management to medical devices, is another critical standard. Manufacturers must conduct a comprehensive risk analysis of the cooling system, identifying potential failure modes and their consequences. This includes assessing the risks associated with temperature fluctuations, coolant leakage, and system malfunction.

Biocompatibility testing, as outlined in ISO 10993, is essential for any new materials introduced by the cooling system that may come into contact with the patient. This ensures that the materials used do not cause adverse biological reactions.

Regulatory bodies also require manufacturers to establish robust quality management systems. For cooled laryngoscopes, this includes implementing stringent controls over the design, manufacture, and testing of the cooling components. Manufacturers must demonstrate the reliability and consistency of the cooling system's performance over the device's intended lifecycle.

In the United States, the Food and Drug Administration (FDA) classifies laryngoscopes as Class I medical devices, which are subject to general controls. However, the addition of cooling technology may elevate the device to Class II, requiring a 510(k) premarket notification. Manufacturers must demonstrate that the cooled laryngoscope is substantially equivalent to a predicate device in terms of safety and effectiveness.

The FDA's guidance on thermal management in medical devices becomes particularly relevant for cooled laryngoscopes. Manufacturers must provide comprehensive data on heat dissipation, temperature control, and potential thermal risks to patients and healthcare providers. This includes thermal mapping of the device under various operating conditions and worst-case scenarios.

In the European Union, cooled laryngoscopes fall under the Medical Device Regulation (MDR). Manufacturers must obtain CE marking by demonstrating compliance with the Essential Requirements outlined in the MDR. This involves a thorough risk assessment, including the evaluation of potential hazards associated with the cooling system, such as electrical safety, biocompatibility of materials, and thermal effects on tissues.

International standards play a crucial role in regulatory compliance. IEC 60601-1, the general standard for medical electrical equipment, provides guidelines on safety and essential performance. Manufacturers must ensure that the integration of cooling technology does not compromise the device's compliance with this standard, particularly in areas such as electrical safety and electromagnetic compatibility.

ISO 14971, which outlines the application of risk management to medical devices, is another critical standard. Manufacturers must conduct a comprehensive risk analysis of the cooling system, identifying potential failure modes and their consequences. This includes assessing the risks associated with temperature fluctuations, coolant leakage, and system malfunction.

Biocompatibility testing, as outlined in ISO 10993, is essential for any new materials introduced by the cooling system that may come into contact with the patient. This ensures that the materials used do not cause adverse biological reactions.

Regulatory bodies also require manufacturers to establish robust quality management systems. For cooled laryngoscopes, this includes implementing stringent controls over the design, manufacture, and testing of the cooling components. Manufacturers must demonstrate the reliability and consistency of the cooling system's performance over the device's intended lifecycle.

Ergonomic Impact of Cooling Integration

The integration of cooling technologies in laryngoscope handles has significant ergonomic implications for healthcare professionals. The primary goal of this integration is to enhance user comfort and performance during prolonged procedures. By effectively managing heat dissipation, these cooling systems can reduce hand fatigue and improve grip stability, crucial factors in maintaining precise control during intubation.

The ergonomic impact of cooling integration extends beyond mere comfort. It directly influences the user's ability to maintain a steady hand and clear view of the laryngeal structures. Reduced heat buildup in the handle can prevent sweating and slippage, which are common issues during extended use of traditional laryngoscopes. This improved grip stability translates to more accurate placement of the laryngoscope blade and potentially faster, more successful intubations.

From a design perspective, the integration of cooling technologies presents both challenges and opportunities. The additional components required for cooling must be seamlessly incorporated without significantly altering the handle's shape or weight distribution. Successful designs maintain or even enhance the ergonomic contours of the handle while accommodating the cooling mechanism. This balance is critical to ensure that the benefits of cooling do not come at the cost of compromised handling or increased user fatigue.

The impact on user experience is multifaceted. Healthcare professionals report increased comfort during lengthy procedures, which can lead to reduced physical strain and improved focus. This is particularly beneficial in high-stress scenarios where every second counts. The psychological comfort of knowing that the device will remain cool can also contribute to reduced anxiety and improved performance among less experienced users.

However, the ergonomic benefits must be weighed against potential drawbacks. The addition of cooling systems may increase the overall weight of the laryngoscope, which could counteract some of the ergonomic gains. Additionally, the complexity of the device may increase, potentially affecting its durability and maintenance requirements. These factors must be carefully considered in the design process to ensure that the ergonomic improvements truly enhance the overall usability of the laryngoscope.

In conclusion, the ergonomic impact of cooling integration in laryngoscope handles is predominantly positive, offering significant improvements in user comfort, grip stability, and potentially procedure outcomes. As this technology continues to evolve, further refinements in design and materials will likely lead to even greater ergonomic benefits, solidifying the role of cooled laryngoscopes in modern medical practice.

The ergonomic impact of cooling integration extends beyond mere comfort. It directly influences the user's ability to maintain a steady hand and clear view of the laryngeal structures. Reduced heat buildup in the handle can prevent sweating and slippage, which are common issues during extended use of traditional laryngoscopes. This improved grip stability translates to more accurate placement of the laryngoscope blade and potentially faster, more successful intubations.

From a design perspective, the integration of cooling technologies presents both challenges and opportunities. The additional components required for cooling must be seamlessly incorporated without significantly altering the handle's shape or weight distribution. Successful designs maintain or even enhance the ergonomic contours of the handle while accommodating the cooling mechanism. This balance is critical to ensure that the benefits of cooling do not come at the cost of compromised handling or increased user fatigue.

The impact on user experience is multifaceted. Healthcare professionals report increased comfort during lengthy procedures, which can lead to reduced physical strain and improved focus. This is particularly beneficial in high-stress scenarios where every second counts. The psychological comfort of knowing that the device will remain cool can also contribute to reduced anxiety and improved performance among less experienced users.

However, the ergonomic benefits must be weighed against potential drawbacks. The addition of cooling systems may increase the overall weight of the laryngoscope, which could counteract some of the ergonomic gains. Additionally, the complexity of the device may increase, potentially affecting its durability and maintenance requirements. These factors must be carefully considered in the design process to ensure that the ergonomic improvements truly enhance the overall usability of the laryngoscope.

In conclusion, the ergonomic impact of cooling integration in laryngoscope handles is predominantly positive, offering significant improvements in user comfort, grip stability, and potentially procedure outcomes. As this technology continues to evolve, further refinements in design and materials will likely lead to even greater ergonomic benefits, solidifying the role of cooled laryngoscopes in modern medical practice.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!