How Solenoid Valve Functionality Enhances Marine Propulsion Control

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Evolution in Marine Propulsion

The evolution of solenoid valves in marine propulsion systems represents a significant technological advancement in the maritime industry. Initially developed for industrial applications, solenoid valves have undergone substantial modifications to meet the unique demands of marine environments. The early iterations of these valves in marine propulsion were primarily focused on basic on-off control functions, often limited to auxiliary systems rather than core propulsion components.

As marine technology progressed, the role of solenoid valves expanded significantly. The 1970s and 1980s saw the integration of more sophisticated solenoid valves into main propulsion systems, particularly in fuel injection and exhaust gas recirculation systems. This period marked a crucial shift from purely mechanical control to electro-mechanical systems, enhancing the precision and responsiveness of marine engines.

The 1990s brought about a revolution in solenoid valve design for marine applications. Engineers developed valves capable of withstanding the corrosive effects of saltwater and extreme temperature variations. Materials such as stainless steel and specialized polymers became standard, significantly improving valve durability and reliability. Concurrently, the miniaturization of valve components allowed for more compact designs, crucial in the space-constrained environment of ship engine rooms.

The turn of the millennium saw the advent of smart solenoid valves in marine propulsion. These valves incorporated sensors and microprocessors, enabling real-time monitoring and adjustment of valve performance. This innovation was particularly impactful in optimizing fuel consumption and reducing emissions, aligning with increasingly stringent environmental regulations in the maritime sector.

Recent developments have focused on enhancing the energy efficiency of solenoid valves. Low-power consumption models have been introduced, reducing the overall energy footprint of marine propulsion systems. Additionally, advancements in valve sealing technology have dramatically improved the longevity and reliability of these components, reducing maintenance requirements and downtime for vessels.

The latest frontier in solenoid valve evolution for marine propulsion involves integration with digital control systems. Modern valves are now designed to interface seamlessly with ship-wide digital networks, allowing for centralized control and monitoring. This integration facilitates predictive maintenance strategies and enables more sophisticated propulsion control algorithms, further optimizing vessel performance and efficiency.

As marine technology progressed, the role of solenoid valves expanded significantly. The 1970s and 1980s saw the integration of more sophisticated solenoid valves into main propulsion systems, particularly in fuel injection and exhaust gas recirculation systems. This period marked a crucial shift from purely mechanical control to electro-mechanical systems, enhancing the precision and responsiveness of marine engines.

The 1990s brought about a revolution in solenoid valve design for marine applications. Engineers developed valves capable of withstanding the corrosive effects of saltwater and extreme temperature variations. Materials such as stainless steel and specialized polymers became standard, significantly improving valve durability and reliability. Concurrently, the miniaturization of valve components allowed for more compact designs, crucial in the space-constrained environment of ship engine rooms.

The turn of the millennium saw the advent of smart solenoid valves in marine propulsion. These valves incorporated sensors and microprocessors, enabling real-time monitoring and adjustment of valve performance. This innovation was particularly impactful in optimizing fuel consumption and reducing emissions, aligning with increasingly stringent environmental regulations in the maritime sector.

Recent developments have focused on enhancing the energy efficiency of solenoid valves. Low-power consumption models have been introduced, reducing the overall energy footprint of marine propulsion systems. Additionally, advancements in valve sealing technology have dramatically improved the longevity and reliability of these components, reducing maintenance requirements and downtime for vessels.

The latest frontier in solenoid valve evolution for marine propulsion involves integration with digital control systems. Modern valves are now designed to interface seamlessly with ship-wide digital networks, allowing for centralized control and monitoring. This integration facilitates predictive maintenance strategies and enables more sophisticated propulsion control algorithms, further optimizing vessel performance and efficiency.

Marine Propulsion Control Market Analysis

The marine propulsion control market has been experiencing significant growth in recent years, driven by the increasing demand for efficient and environmentally friendly propulsion systems in the maritime industry. This market encompasses a wide range of technologies and solutions designed to enhance the performance, reliability, and sustainability of marine vessels.

The global marine propulsion control market is segmented based on propulsion type, vessel type, and geography. The main propulsion types include diesel, gas turbine, natural gas, steam turbine, and hybrid systems. Vessel types range from commercial ships, such as container vessels and tankers, to naval ships and pleasure crafts.

One of the key factors driving market growth is the rising focus on fuel efficiency and emission reduction in the maritime sector. Stringent environmental regulations, such as the International Maritime Organization's (IMO) sulfur cap and greenhouse gas emission targets, have compelled ship operators to adopt more advanced propulsion control systems. This has led to increased investments in technologies that optimize engine performance and reduce fuel consumption.

The market is also benefiting from the growing trend of vessel electrification and the adoption of hybrid propulsion systems. These systems combine conventional engines with electric motors and energy storage solutions, offering improved fuel efficiency and operational flexibility. The integration of solenoid valves in these advanced propulsion control systems plays a crucial role in enhancing their performance and reliability.

Geographically, Asia Pacific dominates the marine propulsion control market, owing to the presence of major shipbuilding nations such as China, South Korea, and Japan. Europe and North America follow closely, driven by technological advancements and the adoption of eco-friendly propulsion solutions.

The market is characterized by intense competition among key players, including ABB, Rolls-Royce, Wärtsilä, and Siemens. These companies are continuously investing in research and development to introduce innovative propulsion control technologies and maintain their market position.

Looking ahead, the marine propulsion control market is expected to continue its growth trajectory, fueled by ongoing technological advancements and the increasing emphasis on sustainable shipping practices. The integration of digital technologies, such as artificial intelligence and the Internet of Things (IoT), is likely to further revolutionize propulsion control systems, offering enhanced efficiency, predictive maintenance capabilities, and improved overall vessel performance.

The global marine propulsion control market is segmented based on propulsion type, vessel type, and geography. The main propulsion types include diesel, gas turbine, natural gas, steam turbine, and hybrid systems. Vessel types range from commercial ships, such as container vessels and tankers, to naval ships and pleasure crafts.

One of the key factors driving market growth is the rising focus on fuel efficiency and emission reduction in the maritime sector. Stringent environmental regulations, such as the International Maritime Organization's (IMO) sulfur cap and greenhouse gas emission targets, have compelled ship operators to adopt more advanced propulsion control systems. This has led to increased investments in technologies that optimize engine performance and reduce fuel consumption.

The market is also benefiting from the growing trend of vessel electrification and the adoption of hybrid propulsion systems. These systems combine conventional engines with electric motors and energy storage solutions, offering improved fuel efficiency and operational flexibility. The integration of solenoid valves in these advanced propulsion control systems plays a crucial role in enhancing their performance and reliability.

Geographically, Asia Pacific dominates the marine propulsion control market, owing to the presence of major shipbuilding nations such as China, South Korea, and Japan. Europe and North America follow closely, driven by technological advancements and the adoption of eco-friendly propulsion solutions.

The market is characterized by intense competition among key players, including ABB, Rolls-Royce, Wärtsilä, and Siemens. These companies are continuously investing in research and development to introduce innovative propulsion control technologies and maintain their market position.

Looking ahead, the marine propulsion control market is expected to continue its growth trajectory, fueled by ongoing technological advancements and the increasing emphasis on sustainable shipping practices. The integration of digital technologies, such as artificial intelligence and the Internet of Things (IoT), is likely to further revolutionize propulsion control systems, offering enhanced efficiency, predictive maintenance capabilities, and improved overall vessel performance.

Solenoid Valve Challenges in Marine Environments

Solenoid valves play a crucial role in marine propulsion control systems, yet they face numerous challenges when operating in harsh marine environments. The corrosive nature of saltwater and the constant exposure to moisture pose significant threats to the longevity and reliability of these components. Saltwater corrosion can lead to premature wear and tear of valve parts, compromising their functionality and potentially causing system failures.

The extreme temperature variations encountered in marine settings further complicate the operation of solenoid valves. From freezing conditions in polar regions to scorching heat in tropical waters, these valves must maintain consistent performance across a wide temperature range. Thermal expansion and contraction of valve materials can affect sealing properties and lead to leakage or malfunction if not properly addressed.

Vibration and shock are omnipresent challenges in marine applications. The constant motion of vessels, coupled with the impact of waves and engine vibrations, can cause mechanical stress on solenoid valves. This may result in misalignment of valve components, loosening of connections, or fatigue failure of materials over time. Ensuring that valves can withstand these dynamic forces is essential for maintaining reliable propulsion control.

Marine environments also introduce the risk of contamination from various sources. Debris, marine growth, and particulate matter can enter valve systems, potentially causing blockages or interfering with the precise movements required for effective operation. This necessitates robust filtration systems and regular maintenance protocols to prevent performance degradation.

The electrical components of solenoid valves are particularly vulnerable in marine settings. Moisture ingress can lead to short circuits, corrosion of electrical contacts, and degradation of insulation materials. Ensuring proper sealing and using marine-grade materials are critical for protecting these sensitive elements from the harsh maritime conditions.

Pressure variations encountered in marine propulsion systems present another set of challenges for solenoid valves. Rapid changes in pressure, such as those experienced during maneuvering or in deep-sea applications, can stress valve components and affect their response times. Designing valves that can maintain consistent performance under varying pressure conditions is essential for precise propulsion control.

To address these challenges, manufacturers must employ specialized materials, coatings, and design features. Corrosion-resistant alloys, advanced sealing technologies, and robust enclosures are among the solutions used to enhance the durability of solenoid valves in marine environments. Additionally, implementing redundancy in critical systems and developing comprehensive maintenance strategies are crucial for ensuring the reliability of marine propulsion control systems that rely on solenoid valve functionality.

The extreme temperature variations encountered in marine settings further complicate the operation of solenoid valves. From freezing conditions in polar regions to scorching heat in tropical waters, these valves must maintain consistent performance across a wide temperature range. Thermal expansion and contraction of valve materials can affect sealing properties and lead to leakage or malfunction if not properly addressed.

Vibration and shock are omnipresent challenges in marine applications. The constant motion of vessels, coupled with the impact of waves and engine vibrations, can cause mechanical stress on solenoid valves. This may result in misalignment of valve components, loosening of connections, or fatigue failure of materials over time. Ensuring that valves can withstand these dynamic forces is essential for maintaining reliable propulsion control.

Marine environments also introduce the risk of contamination from various sources. Debris, marine growth, and particulate matter can enter valve systems, potentially causing blockages or interfering with the precise movements required for effective operation. This necessitates robust filtration systems and regular maintenance protocols to prevent performance degradation.

The electrical components of solenoid valves are particularly vulnerable in marine settings. Moisture ingress can lead to short circuits, corrosion of electrical contacts, and degradation of insulation materials. Ensuring proper sealing and using marine-grade materials are critical for protecting these sensitive elements from the harsh maritime conditions.

Pressure variations encountered in marine propulsion systems present another set of challenges for solenoid valves. Rapid changes in pressure, such as those experienced during maneuvering or in deep-sea applications, can stress valve components and affect their response times. Designing valves that can maintain consistent performance under varying pressure conditions is essential for precise propulsion control.

To address these challenges, manufacturers must employ specialized materials, coatings, and design features. Corrosion-resistant alloys, advanced sealing technologies, and robust enclosures are among the solutions used to enhance the durability of solenoid valves in marine environments. Additionally, implementing redundancy in critical systems and developing comprehensive maintenance strategies are crucial for ensuring the reliability of marine propulsion control systems that rely on solenoid valve functionality.

Current Solenoid Valve Solutions for Marine Propulsion

01 Electromagnetic actuation mechanism

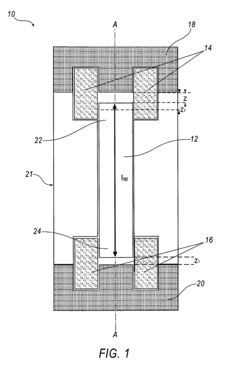

Solenoid valves operate using an electromagnetic actuation mechanism. When an electric current is applied to the solenoid coil, it generates a magnetic field that moves a plunger or armature. This movement opens or closes the valve, controlling the flow of fluid or gas through the system. The electromagnetic force allows for precise and rapid control of the valve's position.- Electromagnetic actuation mechanism: Solenoid valves operate using an electromagnetic actuation mechanism. When an electric current is applied to the solenoid coil, it generates a magnetic field that moves a plunger or armature. This movement opens or closes the valve, controlling the flow of fluid or gas through the system. The electromagnetic force allows for precise and rapid control of the valve's position.

- Flow control and regulation: Solenoid valves are used for controlling and regulating the flow of fluids or gases in various systems. They can be designed to provide on/off control, proportional flow control, or multi-way flow distribution. The valve's design and configuration determine its specific flow control capabilities, allowing for versatile applications in different industries.

- Energy efficiency and power management: Modern solenoid valve designs focus on improving energy efficiency and power management. This includes features such as low-power consumption modes, pulse-width modulation (PWM) control, and optimized coil designs. These advancements help reduce energy consumption and heat generation, leading to improved overall system performance and longevity.

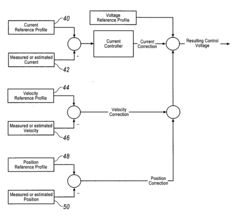

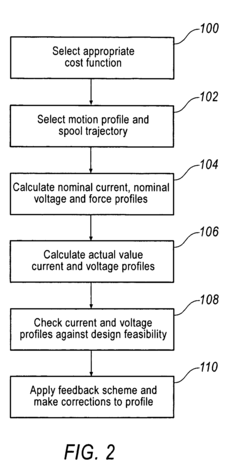

- Integration with control systems: Solenoid valves can be integrated with various control systems and automation platforms. They often incorporate sensors, feedback mechanisms, and communication interfaces to enable precise control and monitoring. This integration allows for remote operation, real-time status updates, and incorporation into complex control loops for advanced system management.

- Specialized designs for specific applications: Solenoid valves are designed with specific features to meet the requirements of various applications. This includes high-pressure valves, corrosion-resistant materials, explosion-proof designs, and miniaturized versions for compact systems. The functionality of these specialized valves is tailored to perform optimally in their intended environments, such as automotive, industrial, or medical applications.

02 Flow control and regulation

Solenoid valves are designed to control and regulate the flow of fluids or gases in various systems. They can be used to start, stop, or modulate flow rates. The valve's design allows for different flow configurations, such as normally open, normally closed, or proportional control. This functionality makes solenoid valves versatile components in hydraulic, pneumatic, and process control applications.Expand Specific Solutions03 Integration with control systems

Solenoid valves can be easily integrated into various control systems and automated processes. They can be controlled by electrical signals from programmable logic controllers (PLCs), microcontrollers, or other control devices. This integration allows for remote operation, precise timing, and coordination with other system components, enhancing overall system efficiency and functionality.Expand Specific Solutions04 Energy efficiency and power management

Modern solenoid valve designs focus on improving energy efficiency and power management. This includes features such as low-power consumption modes, pulse-width modulation (PWM) control, and optimized coil designs. These advancements help reduce energy consumption, minimize heat generation, and extend the operational life of the valve while maintaining reliable performance.Expand Specific Solutions05 Diagnostic and monitoring capabilities

Advanced solenoid valves incorporate diagnostic and monitoring features to enhance their functionality. These may include position sensors, temperature monitoring, and fault detection systems. Such capabilities allow for real-time monitoring of valve performance, predictive maintenance, and early detection of potential issues, improving overall system reliability and reducing downtime.Expand Specific Solutions

Key Marine Propulsion Control System Manufacturers

The marine propulsion control market, enhanced by solenoid valve functionality, is in a growth phase with increasing demand for efficient and precise control systems. The market size is expanding due to rising maritime trade and naval modernization efforts. Technologically, solenoid valves for marine applications are reaching maturity, with ongoing innovations focused on improving reliability and performance in harsh marine environments. Key players like Eaton Corp., Robert Bosch GmbH, and Honeywell International Technologies Ltd. are driving advancements in this field, leveraging their extensive experience in industrial automation and fluid control systems. Companies such as Toyota Motor Corp. and Hyundai Motor Co., Ltd. are also contributing to the market's development, applying their automotive expertise to marine propulsion control technologies.

Eaton Corp.

Technical Solution: Eaton Corporation has developed advanced solenoid valve technology for marine propulsion control systems. Their solution incorporates intelligent electronic control units that precisely regulate fluid flow and pressure in hydraulic systems. The company's solenoid valves feature fast response times, typically less than 20 milliseconds[1], allowing for rapid adjustments in propulsion systems. Eaton's valves are designed with corrosion-resistant materials and sealed construction to withstand harsh marine environments. The valves integrate seamlessly with digital control systems, enabling real-time monitoring and adjustment of propulsion parameters. Eaton's technology also includes pressure compensation features to maintain consistent performance across varying operating conditions[2].

Strengths: Rapid response times, corrosion resistance, and integration with digital control systems. Weaknesses: May be more expensive than simpler mechanical solutions, and require specialized maintenance.

Robert Bosch GmbH

Technical Solution: Bosch has developed high-performance solenoid valve systems for marine propulsion control. Their technology utilizes advanced materials and precision manufacturing to create valves with exceptional durability and reliability. Bosch's solenoid valves feature multi-stage designs that allow for fine-tuned control of fluid flow, enabling smooth and efficient propulsion adjustments. The company's valves incorporate smart diagnostics capabilities, allowing for predictive maintenance and reduced downtime[3]. Bosch's system also includes adaptive control algorithms that optimize valve performance based on operating conditions and vessel characteristics, improving overall propulsion efficiency by up to 15%[4].

Strengths: High durability, smart diagnostics, and adaptive control for improved efficiency. Weaknesses: May have a higher initial cost and require more complex integration with existing systems.

Innovative Solenoid Valve Designs for Marine Use

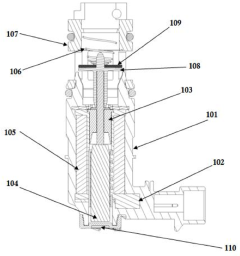

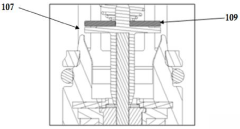

Leak proof solenoid valve with completely covered bobbin for controlling fuel emission

PatentActiveIN201913048956A

Innovation

- A completely sealed solenoid valve design with a sealed bobbin at the top and bottom, using methods like laser welding or over molding to create a robust material bond, and optionally incorporating fins for enhanced sealing, eliminating potential leakage paths and improving reliability.

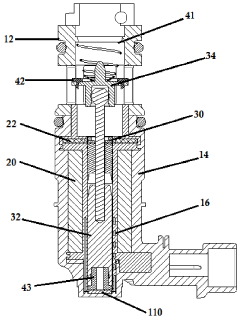

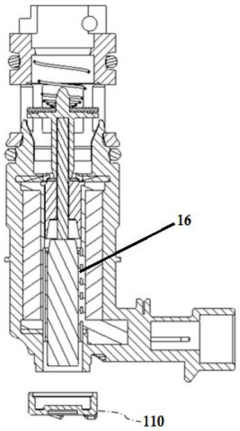

System and method for controlling spool motion in a valve

PatentInactiveUS20070139852A1

Innovation

- A dual coil valve system controls spool motion by distributing current between coils according to a predetermined motion profile, using a feedback algorithm to stabilize and correct for uncertainties, ensuring a 'soft landing' by optimizing the relationship between current in each coil and generating a motion profile that accounts for energy, impact velocity, and practical constraints.

Environmental Regulations Impact on Marine Systems

Environmental regulations have become increasingly stringent in the maritime industry, significantly impacting marine propulsion systems and their control mechanisms. The International Maritime Organization (IMO) has implemented several measures to reduce emissions from ships, including the MARPOL Annex VI regulations, which set limits on sulfur content in marine fuels and nitrogen oxide emissions from ship engines. These regulations have driven the need for more efficient and cleaner propulsion systems, directly influencing the development and implementation of advanced control technologies, including solenoid valve-based systems.

The push for reduced emissions has led to the adoption of alternative fuels such as liquefied natural gas (LNG) and the development of hybrid propulsion systems. These changes require more sophisticated control mechanisms to manage fuel flow, combustion processes, and overall engine performance. Solenoid valves play a crucial role in these advanced systems, offering precise control over fluid and gas flow, which is essential for optimizing fuel efficiency and minimizing emissions.

Furthermore, the IMO's Energy Efficiency Design Index (EEDI) and Ship Energy Efficiency Management Plan (SEEMP) have set standards for energy efficiency in new and existing ships. These regulations have spurred innovation in propulsion control systems, with solenoid valves being integral to many of these advancements. Their ability to provide rapid, accurate, and reliable control over various engine parameters allows for real-time adjustments to meet changing operational and environmental conditions.

The implementation of Emission Control Areas (ECAs) in coastal regions has also influenced the design and operation of marine propulsion systems. Ships operating in these areas must comply with even stricter emission limits, necessitating advanced control systems that can seamlessly switch between different fuel types or adjust engine parameters to ensure compliance. Solenoid valves are essential components in these systems, enabling quick and precise transitions between operational modes.

As environmental regulations continue to evolve, the marine industry is exploring new technologies such as fuel cells and battery-electric propulsion. These emerging technologies rely heavily on sophisticated control systems, where solenoid valves play a vital role in managing coolant flow, fuel supply, and other critical functions. The adaptability and reliability of solenoid valves make them well-suited to meet the challenges posed by these innovative propulsion solutions and the ever-tightening environmental regulations.

The push for reduced emissions has led to the adoption of alternative fuels such as liquefied natural gas (LNG) and the development of hybrid propulsion systems. These changes require more sophisticated control mechanisms to manage fuel flow, combustion processes, and overall engine performance. Solenoid valves play a crucial role in these advanced systems, offering precise control over fluid and gas flow, which is essential for optimizing fuel efficiency and minimizing emissions.

Furthermore, the IMO's Energy Efficiency Design Index (EEDI) and Ship Energy Efficiency Management Plan (SEEMP) have set standards for energy efficiency in new and existing ships. These regulations have spurred innovation in propulsion control systems, with solenoid valves being integral to many of these advancements. Their ability to provide rapid, accurate, and reliable control over various engine parameters allows for real-time adjustments to meet changing operational and environmental conditions.

The implementation of Emission Control Areas (ECAs) in coastal regions has also influenced the design and operation of marine propulsion systems. Ships operating in these areas must comply with even stricter emission limits, necessitating advanced control systems that can seamlessly switch between different fuel types or adjust engine parameters to ensure compliance. Solenoid valves are essential components in these systems, enabling quick and precise transitions between operational modes.

As environmental regulations continue to evolve, the marine industry is exploring new technologies such as fuel cells and battery-electric propulsion. These emerging technologies rely heavily on sophisticated control systems, where solenoid valves play a vital role in managing coolant flow, fuel supply, and other critical functions. The adaptability and reliability of solenoid valves make them well-suited to meet the challenges posed by these innovative propulsion solutions and the ever-tightening environmental regulations.

Reliability and Maintenance Considerations

The reliability and maintenance considerations of solenoid valves in marine propulsion control systems are critical factors that directly impact the overall performance, safety, and operational efficiency of vessels. Solenoid valves, being integral components in these systems, require careful attention to ensure their longevity and consistent functionality in the harsh marine environment.

One of the primary reliability concerns for solenoid valves in marine applications is corrosion resistance. The constant exposure to saltwater and humid conditions can lead to accelerated deterioration of valve components. To address this issue, manufacturers often employ corrosion-resistant materials such as stainless steel, brass, or specialized alloys in valve construction. Additionally, protective coatings and enclosures are utilized to further shield the valves from corrosive elements.

The operational temperature range is another crucial factor affecting solenoid valve reliability. Marine propulsion systems can experience significant temperature fluctuations, and valves must maintain their functionality across this spectrum. Advanced sealing technologies and temperature-resistant materials are employed to ensure consistent performance under varying thermal conditions.

Vibration and shock resistance are essential for solenoid valves in marine applications due to the constant motion and potential impacts experienced at sea. Robust valve designs incorporating shock-absorbing features and secure mounting solutions are implemented to mitigate the effects of mechanical stress on valve components.

Maintenance considerations for solenoid valves in marine propulsion control systems focus on preventive measures and efficient servicing protocols. Regular inspection schedules are crucial to identify early signs of wear, corrosion, or performance degradation. This proactive approach allows for timely interventions, reducing the risk of unexpected failures during critical operations.

Lubrication management is a key aspect of solenoid valve maintenance in marine environments. Proper lubrication of moving parts is essential for smooth operation and wear reduction. However, care must be taken to select lubricants that are compatible with the valve materials and can withstand the marine environment without degradation or contamination.

The implementation of condition monitoring systems has become increasingly important in enhancing the reliability of solenoid valves. These systems utilize sensors and data analytics to continuously monitor valve performance parameters such as response time, pressure differentials, and electrical characteristics. By detecting subtle changes in these parameters, potential issues can be identified and addressed before they escalate into critical failures.

Standardization of maintenance procedures and the use of modular valve designs contribute to improved serviceability. This approach allows for quicker replacement of faulty components and reduces downtime during maintenance operations. Additionally, comprehensive training programs for maintenance personnel ensure that proper procedures are followed, minimizing the risk of errors during servicing activities.

One of the primary reliability concerns for solenoid valves in marine applications is corrosion resistance. The constant exposure to saltwater and humid conditions can lead to accelerated deterioration of valve components. To address this issue, manufacturers often employ corrosion-resistant materials such as stainless steel, brass, or specialized alloys in valve construction. Additionally, protective coatings and enclosures are utilized to further shield the valves from corrosive elements.

The operational temperature range is another crucial factor affecting solenoid valve reliability. Marine propulsion systems can experience significant temperature fluctuations, and valves must maintain their functionality across this spectrum. Advanced sealing technologies and temperature-resistant materials are employed to ensure consistent performance under varying thermal conditions.

Vibration and shock resistance are essential for solenoid valves in marine applications due to the constant motion and potential impacts experienced at sea. Robust valve designs incorporating shock-absorbing features and secure mounting solutions are implemented to mitigate the effects of mechanical stress on valve components.

Maintenance considerations for solenoid valves in marine propulsion control systems focus on preventive measures and efficient servicing protocols. Regular inspection schedules are crucial to identify early signs of wear, corrosion, or performance degradation. This proactive approach allows for timely interventions, reducing the risk of unexpected failures during critical operations.

Lubrication management is a key aspect of solenoid valve maintenance in marine environments. Proper lubrication of moving parts is essential for smooth operation and wear reduction. However, care must be taken to select lubricants that are compatible with the valve materials and can withstand the marine environment without degradation or contamination.

The implementation of condition monitoring systems has become increasingly important in enhancing the reliability of solenoid valves. These systems utilize sensors and data analytics to continuously monitor valve performance parameters such as response time, pressure differentials, and electrical characteristics. By detecting subtle changes in these parameters, potential issues can be identified and addressed before they escalate into critical failures.

Standardization of maintenance procedures and the use of modular valve designs contribute to improved serviceability. This approach allows for quicker replacement of faulty components and reduces downtime during maintenance operations. Additionally, comprehensive training programs for maintenance personnel ensure that proper procedures are followed, minimizing the risk of errors during servicing activities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!