How Solenoid Valve Miniaturization Improves Portable Medical Device Functionality

JUL 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Miniaturization Background and Objectives

Solenoid valves have been integral components in fluid control systems for decades, with applications spanning various industries. In recent years, the miniaturization of solenoid valves has emerged as a significant technological trend, particularly in the realm of portable medical devices. This advancement has been driven by the increasing demand for compact, efficient, and reliable medical equipment that can be easily transported and used in diverse healthcare settings.

The evolution of solenoid valve technology has been closely tied to advancements in materials science, precision manufacturing techniques, and electronic control systems. Early solenoid valves were bulky and power-hungry, limiting their use in portable applications. However, continuous improvements in design and manufacturing processes have led to the development of increasingly smaller and more efficient valves.

The primary objective of solenoid valve miniaturization in portable medical devices is to enhance functionality while reducing overall device size and weight. This goal aligns with the broader trend towards more patient-centric healthcare solutions that prioritize mobility, ease of use, and accessibility. By shrinking the size of solenoid valves, manufacturers can create medical devices that are not only more compact but also more energy-efficient and responsive.

Miniaturization efforts have focused on several key areas, including the reduction of valve body size, optimization of electromagnetic coil design, and the integration of advanced control electronics. These improvements have enabled the creation of solenoid valves that can operate with lower power consumption, faster response times, and improved precision in fluid control.

The impact of solenoid valve miniaturization extends beyond mere size reduction. It has opened up new possibilities for medical device design, allowing for the development of innovative products that were previously impractical or impossible. For instance, miniaturized solenoid valves have played a crucial role in the advancement of portable infusion pumps, ventilators, and diagnostic equipment.

As we look towards the future, the objectives for further miniaturization of solenoid valves in medical devices are multifaceted. Researchers and engineers are striving to push the boundaries of size reduction while simultaneously improving performance metrics such as flow rate, pressure handling capabilities, and longevity. Additionally, there is a growing emphasis on developing valves that can operate with even lower power requirements, potentially enabling the creation of self-powered or energy-harvesting medical devices.

The pursuit of these objectives is expected to drive continued innovation in materials, manufacturing processes, and control technologies. As solenoid valve miniaturization progresses, it promises to revolutionize the landscape of portable medical devices, ultimately leading to more accessible, efficient, and patient-friendly healthcare solutions.

The evolution of solenoid valve technology has been closely tied to advancements in materials science, precision manufacturing techniques, and electronic control systems. Early solenoid valves were bulky and power-hungry, limiting their use in portable applications. However, continuous improvements in design and manufacturing processes have led to the development of increasingly smaller and more efficient valves.

The primary objective of solenoid valve miniaturization in portable medical devices is to enhance functionality while reducing overall device size and weight. This goal aligns with the broader trend towards more patient-centric healthcare solutions that prioritize mobility, ease of use, and accessibility. By shrinking the size of solenoid valves, manufacturers can create medical devices that are not only more compact but also more energy-efficient and responsive.

Miniaturization efforts have focused on several key areas, including the reduction of valve body size, optimization of electromagnetic coil design, and the integration of advanced control electronics. These improvements have enabled the creation of solenoid valves that can operate with lower power consumption, faster response times, and improved precision in fluid control.

The impact of solenoid valve miniaturization extends beyond mere size reduction. It has opened up new possibilities for medical device design, allowing for the development of innovative products that were previously impractical or impossible. For instance, miniaturized solenoid valves have played a crucial role in the advancement of portable infusion pumps, ventilators, and diagnostic equipment.

As we look towards the future, the objectives for further miniaturization of solenoid valves in medical devices are multifaceted. Researchers and engineers are striving to push the boundaries of size reduction while simultaneously improving performance metrics such as flow rate, pressure handling capabilities, and longevity. Additionally, there is a growing emphasis on developing valves that can operate with even lower power requirements, potentially enabling the creation of self-powered or energy-harvesting medical devices.

The pursuit of these objectives is expected to drive continued innovation in materials, manufacturing processes, and control technologies. As solenoid valve miniaturization progresses, it promises to revolutionize the landscape of portable medical devices, ultimately leading to more accessible, efficient, and patient-friendly healthcare solutions.

Market Demand for Portable Medical Devices

The market demand for portable medical devices has been experiencing significant growth in recent years, driven by several key factors. The aging global population, coupled with the increasing prevalence of chronic diseases, has created a pressing need for accessible and convenient healthcare solutions. Portable medical devices offer patients the ability to monitor and manage their health conditions from the comfort of their homes, reducing the frequency of hospital visits and improving overall quality of life.

The COVID-19 pandemic has further accelerated this trend, as healthcare systems worldwide have been strained, leading to a surge in demand for remote patient monitoring and telemedicine solutions. Portable medical devices play a crucial role in enabling these services, allowing healthcare providers to track patients' vital signs and health metrics remotely, thus reducing the risk of virus transmission and alleviating pressure on healthcare facilities.

In addition to patient care, the healthcare industry itself is undergoing a shift towards more efficient and cost-effective solutions. Portable medical devices contribute to this goal by enabling early detection of health issues, facilitating preventive care, and reducing the need for lengthy hospital stays. This not only improves patient outcomes but also helps in managing healthcare costs, making it an attractive option for both healthcare providers and insurance companies.

The miniaturization of components, including solenoid valves, has been a key enabler in the development of more compact and user-friendly portable medical devices. Smaller, lighter devices are easier for patients to carry and use in their daily lives, increasing compliance with treatment regimens and improving overall health management. This trend towards miniaturization aligns with the growing consumer demand for sleek, unobtrusive medical devices that seamlessly integrate into their lifestyles.

Market research indicates that the global portable medical devices market is poised for substantial growth. Factors such as technological advancements, increasing healthcare expenditure, and growing awareness about personal health monitoring are expected to drive this expansion. The market encompasses a wide range of devices, including blood glucose monitors, insulin pumps, portable oxygen concentrators, and wearable ECG monitors, among others.

As the demand for portable medical devices continues to rise, manufacturers are focusing on developing innovative solutions that offer improved functionality, accuracy, and connectivity. The integration of IoT and AI technologies is opening up new possibilities for data analysis and personalized healthcare, further enhancing the appeal of these devices to both patients and healthcare professionals.

The COVID-19 pandemic has further accelerated this trend, as healthcare systems worldwide have been strained, leading to a surge in demand for remote patient monitoring and telemedicine solutions. Portable medical devices play a crucial role in enabling these services, allowing healthcare providers to track patients' vital signs and health metrics remotely, thus reducing the risk of virus transmission and alleviating pressure on healthcare facilities.

In addition to patient care, the healthcare industry itself is undergoing a shift towards more efficient and cost-effective solutions. Portable medical devices contribute to this goal by enabling early detection of health issues, facilitating preventive care, and reducing the need for lengthy hospital stays. This not only improves patient outcomes but also helps in managing healthcare costs, making it an attractive option for both healthcare providers and insurance companies.

The miniaturization of components, including solenoid valves, has been a key enabler in the development of more compact and user-friendly portable medical devices. Smaller, lighter devices are easier for patients to carry and use in their daily lives, increasing compliance with treatment regimens and improving overall health management. This trend towards miniaturization aligns with the growing consumer demand for sleek, unobtrusive medical devices that seamlessly integrate into their lifestyles.

Market research indicates that the global portable medical devices market is poised for substantial growth. Factors such as technological advancements, increasing healthcare expenditure, and growing awareness about personal health monitoring are expected to drive this expansion. The market encompasses a wide range of devices, including blood glucose monitors, insulin pumps, portable oxygen concentrators, and wearable ECG monitors, among others.

As the demand for portable medical devices continues to rise, manufacturers are focusing on developing innovative solutions that offer improved functionality, accuracy, and connectivity. The integration of IoT and AI technologies is opening up new possibilities for data analysis and personalized healthcare, further enhancing the appeal of these devices to both patients and healthcare professionals.

Current Challenges in Solenoid Valve Miniaturization

The miniaturization of solenoid valves for portable medical devices faces several significant challenges that require innovative solutions. One of the primary obstacles is the reduction of overall valve size while maintaining or improving performance. As the dimensions decrease, it becomes increasingly difficult to achieve the same level of flow control and precision as larger valves. This challenge is compounded by the need to maintain reliability and durability in a compact form factor.

Material selection presents another hurdle in the miniaturization process. Engineers must identify materials that can withstand the rigors of medical applications, including sterilization processes and exposure to various fluids, while also being suitable for small-scale manufacturing. The use of advanced materials, such as high-performance polymers or specialized alloys, may be necessary but can increase production costs.

Power consumption is a critical concern in portable medical devices. Miniaturized solenoid valves must operate efficiently to conserve battery life, which is essential for the overall functionality and usability of the device. Achieving this balance between power efficiency and performance in a smaller package requires sophisticated design and control strategies.

Heat dissipation becomes more challenging as valve size decreases. The compact nature of miniaturized valves can lead to heat buildup, potentially affecting both the valve's performance and the surrounding components. Developing effective thermal management solutions within the confined space is crucial for maintaining optimal operation and ensuring patient safety.

Manufacturing processes also present significant challenges. Producing intricate components at a smaller scale demands high-precision manufacturing techniques, which can be both complex and costly. Ensuring consistent quality and reliability in mass production of miniaturized valves requires advanced manufacturing capabilities and stringent quality control measures.

Integration with other components in portable medical devices poses another challenge. Miniaturized valves must be designed to interface seamlessly with other small-scale components, such as sensors, pumps, and control systems. This integration requires careful consideration of factors like electromagnetic compatibility, vibration resistance, and overall system architecture.

Regulatory compliance adds an additional layer of complexity to the miniaturization process. Solenoid valves used in medical devices must meet stringent regulatory standards, which can be more challenging to achieve with smaller components. Demonstrating the safety and efficacy of miniaturized valves may require extensive testing and documentation.

Lastly, cost considerations remain a significant challenge. While miniaturization can potentially reduce material costs, the increased complexity in design, manufacturing, and quality control can offset these savings. Balancing the benefits of miniaturization with the associated costs is crucial for the commercial viability of portable medical devices incorporating these advanced valves.

Material selection presents another hurdle in the miniaturization process. Engineers must identify materials that can withstand the rigors of medical applications, including sterilization processes and exposure to various fluids, while also being suitable for small-scale manufacturing. The use of advanced materials, such as high-performance polymers or specialized alloys, may be necessary but can increase production costs.

Power consumption is a critical concern in portable medical devices. Miniaturized solenoid valves must operate efficiently to conserve battery life, which is essential for the overall functionality and usability of the device. Achieving this balance between power efficiency and performance in a smaller package requires sophisticated design and control strategies.

Heat dissipation becomes more challenging as valve size decreases. The compact nature of miniaturized valves can lead to heat buildup, potentially affecting both the valve's performance and the surrounding components. Developing effective thermal management solutions within the confined space is crucial for maintaining optimal operation and ensuring patient safety.

Manufacturing processes also present significant challenges. Producing intricate components at a smaller scale demands high-precision manufacturing techniques, which can be both complex and costly. Ensuring consistent quality and reliability in mass production of miniaturized valves requires advanced manufacturing capabilities and stringent quality control measures.

Integration with other components in portable medical devices poses another challenge. Miniaturized valves must be designed to interface seamlessly with other small-scale components, such as sensors, pumps, and control systems. This integration requires careful consideration of factors like electromagnetic compatibility, vibration resistance, and overall system architecture.

Regulatory compliance adds an additional layer of complexity to the miniaturization process. Solenoid valves used in medical devices must meet stringent regulatory standards, which can be more challenging to achieve with smaller components. Demonstrating the safety and efficacy of miniaturized valves may require extensive testing and documentation.

Lastly, cost considerations remain a significant challenge. While miniaturization can potentially reduce material costs, the increased complexity in design, manufacturing, and quality control can offset these savings. Balancing the benefits of miniaturization with the associated costs is crucial for the commercial viability of portable medical devices incorporating these advanced valves.

Existing Miniaturization Techniques for Solenoid Valves

01 Compact solenoid valve design

Miniaturization of solenoid valves can be achieved through compact design strategies. This includes optimizing the arrangement of components, reducing the size of individual parts, and integrating multiple functions into a single unit. Such designs can significantly decrease the overall dimensions of the valve while maintaining its performance.- Compact valve design: Miniaturization of solenoid valves can be achieved through compact design strategies. This includes optimizing the internal structure, reducing the size of components, and integrating multiple functions into a single unit. Such designs allow for smaller overall valve dimensions while maintaining performance.

- Advanced materials and manufacturing techniques: Utilizing advanced materials and manufacturing techniques can contribute to solenoid valve miniaturization. This may involve using lightweight yet durable materials, precision manufacturing methods, and innovative assembly techniques to reduce the overall size and weight of the valve while ensuring reliability.

- Electromagnetic optimization: Optimizing the electromagnetic components of solenoid valves is crucial for miniaturization. This includes designing more efficient coils, using advanced magnetic materials, and improving the magnetic circuit to achieve the required force in a smaller package.

- Integrated control systems: Incorporating integrated control systems can help reduce the overall size of solenoid valve assemblies. This may involve embedding electronic controls, sensors, and actuators directly into the valve body, eliminating the need for separate control components.

- Modular and stackable designs: Developing modular and stackable solenoid valve designs can contribute to miniaturization in complex systems. These designs allow for compact arrangement of multiple valves, shared components, and efficient use of space in multi-valve applications.

02 Advanced materials for miniaturization

Utilizing advanced materials in solenoid valve construction can contribute to miniaturization. High-strength, lightweight materials allow for thinner walls and smaller components without compromising structural integrity. Additionally, materials with improved magnetic properties can enhance the efficiency of the solenoid, enabling size reduction.Expand Specific Solutions03 Innovative actuation mechanisms

Developing innovative actuation mechanisms can lead to more compact solenoid valve designs. This may include novel electromagnetic configurations, piezoelectric actuators, or shape memory alloys. These alternative mechanisms can potentially reduce the size of the actuation component, contributing to overall valve miniaturization.Expand Specific Solutions04 Microfluidic solenoid valve technology

Incorporating microfluidic technology into solenoid valve design can result in significant size reduction. Microfluidic channels and components can be fabricated on a much smaller scale, allowing for extremely compact valve designs suitable for applications requiring minimal space.Expand Specific Solutions05 Integration of electronic controls

Integrating electronic controls directly into the solenoid valve can contribute to miniaturization. By incorporating miniaturized electronic components and sensors within the valve housing, external control units can be eliminated, reducing the overall footprint of the valve system.Expand Specific Solutions

Key Players in Miniature Solenoid Valve Industry

The miniaturization of solenoid valves in portable medical devices represents a competitive landscape in a rapidly evolving market. The industry is in a growth phase, with increasing demand for compact, efficient medical equipment. Market size is expanding as healthcare becomes more mobile and personalized. Technologically, companies like OMRON HEALTHCARE, Baxter International, and Parker-Hannifin are at the forefront, developing advanced miniaturized valves. These firms, along with others like Bürkert Werke and Fluid Automation Systems, are driving innovation in precision engineering and materials science to create smaller, more reliable valves. The competition is fierce, with companies racing to achieve the optimal balance between size reduction and performance enhancement in their valve designs.

OMRON HEALTHCARE Co., Ltd.

Technical Solution: OMRON Healthcare has focused on miniaturizing solenoid valves for their portable blood pressure monitors and nebulizers. Their approach involves integrating microfluidic channels directly into the valve body, reducing the overall size by up to 40% compared to traditional designs [4]. OMRON's miniaturized valves incorporate a proprietary magnetic circuit that optimizes the force-to-size ratio, allowing for efficient operation in battery-powered devices. The company has also developed a novel actuation mechanism that reduces power consumption by up to 30%, extending the battery life of portable medical devices [5]. Additionally, OMRON's valves feature a multi-layer silicone diaphragm that enhances durability and reduces the risk of particulate contamination [6].

Strengths: Significant size reduction, improved energy efficiency, and enhanced durability. Weaknesses: May have limitations in high-pressure applications, potentially higher unit cost for complex designs.

Bürkert Werke GmbH & Co. KG

Technical Solution: Bürkert has developed a range of miniaturized solenoid valves tailored for portable medical devices. Their latest innovation is a modular valve system that allows for customizable configurations within a compact footprint. The company utilizes advanced 3D printing techniques to create complex internal geometries that optimize flow characteristics while minimizing overall size [7]. Bürkert's miniaturized valves incorporate a unique bistable solenoid design, which requires power only during switching states, significantly reducing energy consumption in intermittent-use medical devices [8]. The company has also implemented a novel sealing concept using fluoropolymer materials, ensuring compatibility with a wide range of medical fluids and gases while maintaining a compact form factor [9].

Strengths: Modular design for flexibility, extremely low power consumption, and broad media compatibility. Weaknesses: Potentially higher initial cost, may require specialized design support for integration.

Innovative Designs for Compact Solenoid Valves

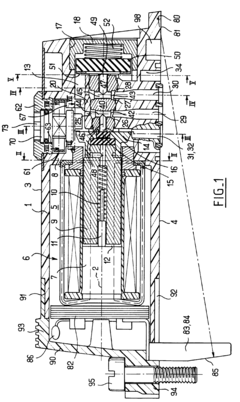

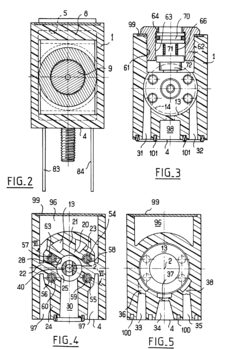

Miniature electromagnetic valve and assembling procedure

PatentInactiveEP1103992A1

Innovation

- A miniature solenoid valve design featuring a solenoid valve body with an integral electromagnet and plunger core, along with a pneumatic chamber and valve arrangement that allows for precise control of the pneumatic stroke through a combination of metallic and elastomeric components, enabling standardized manufacture and assembly, thus reducing costs and improving performance.

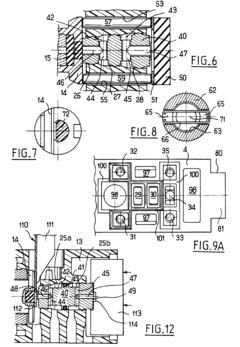

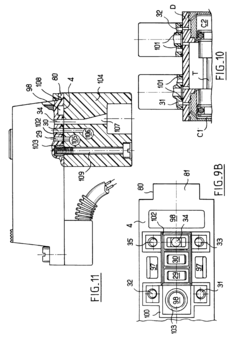

Miniaturized magnetic valve

PatentInactiveEP0916049A1

Innovation

- A miniaturized solenoid valve with soldering pins protruding from its base, allowing direct soldering onto a printed circuit board, combined with a magnetic drive and fluid connections on the opposite side of the housing, enabling pulse-controlled operation with a high transmission ratio actuating blade and a control circuit for optimized switching behavior.

Regulatory Compliance for Medical Device Components

Regulatory compliance is a critical aspect of medical device development, particularly when it comes to components like miniaturized solenoid valves in portable medical devices. The regulatory landscape for medical device components is complex and constantly evolving, requiring manufacturers to stay abreast of the latest standards and guidelines.

In the United States, the Food and Drug Administration (FDA) is the primary regulatory body overseeing medical devices. The FDA classifies medical devices into three categories based on their risk level and intended use. Miniaturized solenoid valves used in portable medical devices typically fall under Class II, which requires special controls to ensure safety and effectiveness. Manufacturers must comply with the FDA's Quality System Regulation (QSR) and follow Good Manufacturing Practices (GMP) to ensure consistent quality and performance of their components.

In the European Union, medical devices are regulated under the Medical Device Regulation (MDR), which came into effect in May 2021. The MDR places a strong emphasis on post-market surveillance and clinical evidence, requiring manufacturers to demonstrate ongoing safety and performance of their devices and components. Miniaturized solenoid valves must meet the essential requirements outlined in the MDR, including biocompatibility, durability, and reliability standards.

International standards also play a crucial role in regulatory compliance for medical device components. ISO 13485, the international standard for quality management systems in the medical device industry, provides a framework for ensuring consistent quality and meeting regulatory requirements. Additionally, IEC 60601-1 sets safety and performance standards for medical electrical equipment, which may apply to portable medical devices incorporating miniaturized solenoid valves.

Material selection is another critical aspect of regulatory compliance for medical device components. Materials used in miniaturized solenoid valves must meet biocompatibility requirements as outlined in ISO 10993. This standard provides guidelines for evaluating the biological safety of medical devices and their components, ensuring that materials do not cause adverse reactions when in contact with the human body.

Electromagnetic compatibility (EMC) is a key consideration for electronic components in medical devices. Miniaturized solenoid valves must comply with EMC standards such as IEC 60601-1-2, which specifies requirements for electromagnetic emissions and immunity in medical electrical equipment. This ensures that the valves do not interfere with other electronic devices or be susceptible to external electromagnetic interference.

As portable medical devices become more sophisticated and interconnected, cybersecurity regulations are increasingly relevant. While solenoid valves themselves may not be directly connected to networks, the overall device architecture must consider cybersecurity risks. Manufacturers should be aware of guidelines such as the FDA's "Content of Premarket Submissions for Management of Cybersecurity in Medical Devices" when designing and integrating components into connected medical devices.

In the United States, the Food and Drug Administration (FDA) is the primary regulatory body overseeing medical devices. The FDA classifies medical devices into three categories based on their risk level and intended use. Miniaturized solenoid valves used in portable medical devices typically fall under Class II, which requires special controls to ensure safety and effectiveness. Manufacturers must comply with the FDA's Quality System Regulation (QSR) and follow Good Manufacturing Practices (GMP) to ensure consistent quality and performance of their components.

In the European Union, medical devices are regulated under the Medical Device Regulation (MDR), which came into effect in May 2021. The MDR places a strong emphasis on post-market surveillance and clinical evidence, requiring manufacturers to demonstrate ongoing safety and performance of their devices and components. Miniaturized solenoid valves must meet the essential requirements outlined in the MDR, including biocompatibility, durability, and reliability standards.

International standards also play a crucial role in regulatory compliance for medical device components. ISO 13485, the international standard for quality management systems in the medical device industry, provides a framework for ensuring consistent quality and meeting regulatory requirements. Additionally, IEC 60601-1 sets safety and performance standards for medical electrical equipment, which may apply to portable medical devices incorporating miniaturized solenoid valves.

Material selection is another critical aspect of regulatory compliance for medical device components. Materials used in miniaturized solenoid valves must meet biocompatibility requirements as outlined in ISO 10993. This standard provides guidelines for evaluating the biological safety of medical devices and their components, ensuring that materials do not cause adverse reactions when in contact with the human body.

Electromagnetic compatibility (EMC) is a key consideration for electronic components in medical devices. Miniaturized solenoid valves must comply with EMC standards such as IEC 60601-1-2, which specifies requirements for electromagnetic emissions and immunity in medical electrical equipment. This ensures that the valves do not interfere with other electronic devices or be susceptible to external electromagnetic interference.

As portable medical devices become more sophisticated and interconnected, cybersecurity regulations are increasingly relevant. While solenoid valves themselves may not be directly connected to networks, the overall device architecture must consider cybersecurity risks. Manufacturers should be aware of guidelines such as the FDA's "Content of Premarket Submissions for Management of Cybersecurity in Medical Devices" when designing and integrating components into connected medical devices.

Energy Efficiency in Miniaturized Solenoid Valves

Energy efficiency is a critical factor in the miniaturization of solenoid valves for portable medical devices. As these devices become smaller and more compact, the need for efficient power consumption becomes increasingly important. Miniaturized solenoid valves offer significant advantages in terms of energy efficiency compared to their larger counterparts.

One of the primary ways miniaturization improves energy efficiency is through reduced power requirements. Smaller solenoid valves typically require less electrical current to operate, resulting in lower overall power consumption. This is achieved through the use of advanced materials and optimized electromagnetic designs that maximize the magnetic field strength while minimizing the size of the coil and core.

The reduced mass of miniaturized solenoid valves also contributes to improved energy efficiency. With less material to move, these valves require less force to actuate, further reducing power requirements. This is particularly beneficial in applications where rapid cycling is necessary, as the lower inertia allows for faster response times with less energy input.

Advancements in manufacturing techniques have enabled the production of more precise and tightly toleranced components for miniaturized solenoid valves. This precision results in improved sealing and reduced internal leakage, which in turn leads to better overall system efficiency. By minimizing fluid loss and maintaining consistent pressure, these valves help conserve energy throughout the entire medical device system.

The integration of smart control systems in miniaturized solenoid valves further enhances their energy efficiency. These systems can optimize valve operation based on real-time demand, adjusting power input to match the required flow rate or pressure. This dynamic control ensures that energy is not wasted during periods of low demand or inactivity.

Thermal management is another area where miniaturization contributes to improved energy efficiency. Smaller valves have a higher surface area to volume ratio, allowing for more effective heat dissipation. This reduces the energy lost to heat and helps maintain consistent performance, even in continuous operation scenarios.

The use of low-power materials and coatings in miniaturized solenoid valves also plays a role in enhancing energy efficiency. For example, the incorporation of rare earth magnets can provide stronger magnetic fields with less power input, while specialized coatings can reduce friction and wear, maintaining efficiency over the valve's lifetime.

In conclusion, the miniaturization of solenoid valves significantly improves energy efficiency in portable medical devices through reduced power requirements, optimized designs, precision manufacturing, smart control systems, improved thermal management, and advanced materials. These enhancements not only contribute to longer battery life and improved portability but also align with the broader trend towards more sustainable and environmentally friendly medical technologies.

One of the primary ways miniaturization improves energy efficiency is through reduced power requirements. Smaller solenoid valves typically require less electrical current to operate, resulting in lower overall power consumption. This is achieved through the use of advanced materials and optimized electromagnetic designs that maximize the magnetic field strength while minimizing the size of the coil and core.

The reduced mass of miniaturized solenoid valves also contributes to improved energy efficiency. With less material to move, these valves require less force to actuate, further reducing power requirements. This is particularly beneficial in applications where rapid cycling is necessary, as the lower inertia allows for faster response times with less energy input.

Advancements in manufacturing techniques have enabled the production of more precise and tightly toleranced components for miniaturized solenoid valves. This precision results in improved sealing and reduced internal leakage, which in turn leads to better overall system efficiency. By minimizing fluid loss and maintaining consistent pressure, these valves help conserve energy throughout the entire medical device system.

The integration of smart control systems in miniaturized solenoid valves further enhances their energy efficiency. These systems can optimize valve operation based on real-time demand, adjusting power input to match the required flow rate or pressure. This dynamic control ensures that energy is not wasted during periods of low demand or inactivity.

Thermal management is another area where miniaturization contributes to improved energy efficiency. Smaller valves have a higher surface area to volume ratio, allowing for more effective heat dissipation. This reduces the energy lost to heat and helps maintain consistent performance, even in continuous operation scenarios.

The use of low-power materials and coatings in miniaturized solenoid valves also plays a role in enhancing energy efficiency. For example, the incorporation of rare earth magnets can provide stronger magnetic fields with less power input, while specialized coatings can reduce friction and wear, maintaining efficiency over the valve's lifetime.

In conclusion, the miniaturization of solenoid valves significantly improves energy efficiency in portable medical devices through reduced power requirements, optimized designs, precision manufacturing, smart control systems, improved thermal management, and advanced materials. These enhancements not only contribute to longer battery life and improved portability but also align with the broader trend towards more sustainable and environmentally friendly medical technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!