How Solenoid Valve Noise Reduction Paves the way for New Applications

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Noise Reduction Background and Objectives

Solenoid valves have been a cornerstone in fluid control systems for decades, playing crucial roles in various industries such as automotive, aerospace, medical, and industrial automation. However, the noise generated by these valves has long been a significant concern, limiting their application in noise-sensitive environments. The evolution of solenoid valve technology has been driven by the increasing demand for quieter, more efficient, and more reliable fluid control solutions.

The primary objective of solenoid valve noise reduction is to expand the application scope of these devices while maintaining or improving their performance characteristics. This goal aligns with the broader industry trends of miniaturization, energy efficiency, and enhanced user experience. By addressing the noise issue, manufacturers aim to unlock new markets and applications where traditional solenoid valves were previously unsuitable due to their acoustic footprint.

Historically, solenoid valve noise has been attributed to several factors, including the rapid movement of the valve's plunger, fluid turbulence, and mechanical vibrations. As the technology has progressed, researchers and engineers have focused on understanding these noise sources and developing innovative solutions to mitigate them. This has led to a multidisciplinary approach, combining principles from fluid dynamics, materials science, and acoustic engineering.

The journey of solenoid valve noise reduction has seen several key milestones. Early efforts focused on passive noise reduction techniques, such as improved valve designs and the use of sound-absorbing materials. As technology advanced, more sophisticated active noise control methods emerged, leveraging electronic systems to counteract valve-generated noise. Recent developments have explored the potential of smart materials and advanced manufacturing techniques to create inherently quieter valve designs.

Looking ahead, the field of solenoid valve noise reduction is poised for further innovation. Emerging technologies such as artificial intelligence and machine learning are expected to play a significant role in optimizing valve designs and control strategies for noise minimization. Additionally, the integration of IoT capabilities may enable real-time monitoring and adaptive noise control in complex systems.

The pursuit of quieter solenoid valves is not merely about noise reduction; it represents a broader technological evolution aimed at creating more versatile, efficient, and user-friendly fluid control solutions. As noise barriers are overcome, solenoid valves are expected to find new applications in areas such as residential appliances, medical devices, and advanced robotics, where silent operation is paramount.

The primary objective of solenoid valve noise reduction is to expand the application scope of these devices while maintaining or improving their performance characteristics. This goal aligns with the broader industry trends of miniaturization, energy efficiency, and enhanced user experience. By addressing the noise issue, manufacturers aim to unlock new markets and applications where traditional solenoid valves were previously unsuitable due to their acoustic footprint.

Historically, solenoid valve noise has been attributed to several factors, including the rapid movement of the valve's plunger, fluid turbulence, and mechanical vibrations. As the technology has progressed, researchers and engineers have focused on understanding these noise sources and developing innovative solutions to mitigate them. This has led to a multidisciplinary approach, combining principles from fluid dynamics, materials science, and acoustic engineering.

The journey of solenoid valve noise reduction has seen several key milestones. Early efforts focused on passive noise reduction techniques, such as improved valve designs and the use of sound-absorbing materials. As technology advanced, more sophisticated active noise control methods emerged, leveraging electronic systems to counteract valve-generated noise. Recent developments have explored the potential of smart materials and advanced manufacturing techniques to create inherently quieter valve designs.

Looking ahead, the field of solenoid valve noise reduction is poised for further innovation. Emerging technologies such as artificial intelligence and machine learning are expected to play a significant role in optimizing valve designs and control strategies for noise minimization. Additionally, the integration of IoT capabilities may enable real-time monitoring and adaptive noise control in complex systems.

The pursuit of quieter solenoid valves is not merely about noise reduction; it represents a broader technological evolution aimed at creating more versatile, efficient, and user-friendly fluid control solutions. As noise barriers are overcome, solenoid valves are expected to find new applications in areas such as residential appliances, medical devices, and advanced robotics, where silent operation is paramount.

Market Demand for Quiet Solenoid Valve Solutions

The market demand for quiet solenoid valve solutions has been steadily increasing across various industries, driven by the growing emphasis on noise reduction in industrial and consumer applications. This trend is particularly evident in sectors such as automotive, healthcare, and smart home technologies, where the need for silent operation is paramount.

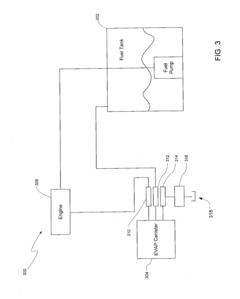

In the automotive industry, the push for electric and hybrid vehicles has intensified the focus on noise reduction. Solenoid valves are crucial components in these vehicles' brake systems, fuel injection systems, and climate control units. As consumers expect quieter and more comfortable driving experiences, manufacturers are actively seeking solenoid valves that can operate with minimal noise, creating a significant market opportunity for innovative solutions.

The healthcare sector presents another substantial market for quiet solenoid valve technologies. In hospital environments and medical devices, noise reduction is essential for patient comfort and the overall quality of care. Silent solenoid valves are in high demand for applications such as ventilators, anesthesia machines, and infusion pumps. The COVID-19 pandemic has further accelerated this demand, highlighting the importance of quiet and efficient medical equipment.

Smart home technologies represent a rapidly expanding market segment where noise reduction is a key selling point. As homes become increasingly automated, the demand for quiet solenoid valves in applications such as smart irrigation systems, HVAC controls, and water management systems has surged. Consumers are willing to pay a premium for devices that operate silently, enhancing their living environment without disruption.

The industrial sector also shows a growing interest in noise-reduced solenoid valves. In manufacturing facilities, where multiple valves operate simultaneously, the cumulative noise can be significant. Quieter valves contribute to improved working conditions and compliance with occupational health and safety regulations. This has led to increased adoption in pneumatic systems, process control equipment, and fluid handling applications.

Market research indicates that the global solenoid valve market is expected to grow substantially in the coming years, with a significant portion of this growth attributed to the demand for quieter solutions. Companies investing in noise reduction technologies for solenoid valves are likely to gain a competitive edge, as they address a critical pain point for end-users across multiple industries.

The demand is not limited to specific geographical regions but is observed globally. Developed markets in North America and Europe are at the forefront of adopting noise-reduced solenoid valves, particularly in high-end applications. However, emerging economies in Asia-Pacific and Latin America are also showing increased interest, driven by rapid industrialization and growing consumer awareness of product quality and environmental impact.

In the automotive industry, the push for electric and hybrid vehicles has intensified the focus on noise reduction. Solenoid valves are crucial components in these vehicles' brake systems, fuel injection systems, and climate control units. As consumers expect quieter and more comfortable driving experiences, manufacturers are actively seeking solenoid valves that can operate with minimal noise, creating a significant market opportunity for innovative solutions.

The healthcare sector presents another substantial market for quiet solenoid valve technologies. In hospital environments and medical devices, noise reduction is essential for patient comfort and the overall quality of care. Silent solenoid valves are in high demand for applications such as ventilators, anesthesia machines, and infusion pumps. The COVID-19 pandemic has further accelerated this demand, highlighting the importance of quiet and efficient medical equipment.

Smart home technologies represent a rapidly expanding market segment where noise reduction is a key selling point. As homes become increasingly automated, the demand for quiet solenoid valves in applications such as smart irrigation systems, HVAC controls, and water management systems has surged. Consumers are willing to pay a premium for devices that operate silently, enhancing their living environment without disruption.

The industrial sector also shows a growing interest in noise-reduced solenoid valves. In manufacturing facilities, where multiple valves operate simultaneously, the cumulative noise can be significant. Quieter valves contribute to improved working conditions and compliance with occupational health and safety regulations. This has led to increased adoption in pneumatic systems, process control equipment, and fluid handling applications.

Market research indicates that the global solenoid valve market is expected to grow substantially in the coming years, with a significant portion of this growth attributed to the demand for quieter solutions. Companies investing in noise reduction technologies for solenoid valves are likely to gain a competitive edge, as they address a critical pain point for end-users across multiple industries.

The demand is not limited to specific geographical regions but is observed globally. Developed markets in North America and Europe are at the forefront of adopting noise-reduced solenoid valves, particularly in high-end applications. However, emerging economies in Asia-Pacific and Latin America are also showing increased interest, driven by rapid industrialization and growing consumer awareness of product quality and environmental impact.

Current Challenges in Solenoid Valve Noise Reduction

Despite significant advancements in solenoid valve technology, noise reduction remains a critical challenge in the industry. The primary source of noise in solenoid valves is the rapid movement of the plunger and its impact on the valve body. This mechanical action generates vibrations that propagate through the valve structure and surrounding fluid, resulting in audible noise.

One of the main challenges is balancing noise reduction with valve performance. Attempts to dampen the plunger's movement often lead to slower response times and reduced flow rates, which can be detrimental in applications requiring precise and rapid control. Engineers must find innovative ways to minimize noise without compromising the valve's core functionality.

Material selection presents another significant hurdle. While softer materials can help absorb vibrations, they may not withstand the high pressures and temperatures often encountered in industrial applications. Conversely, harder materials that offer durability tend to transmit vibrations more readily, exacerbating the noise issue.

The complexity of fluid dynamics within the valve adds another layer of difficulty. Turbulent flow patterns can create additional noise, particularly in high-pressure systems. Designing valve geometries that promote laminar flow while maintaining efficiency is a delicate balance that requires advanced computational fluid dynamics modeling and extensive testing.

Miniaturization trends in various industries pose unique challenges for noise reduction. As valves become smaller to fit into compact systems, the space available for implementing noise-reduction features becomes limited. This constraint forces engineers to develop increasingly creative and efficient solutions within tight spatial confines.

Environmental factors also play a role in the noise reduction challenge. Valves often operate in diverse conditions, from extreme temperatures to corrosive environments. Noise reduction solutions must be robust enough to maintain their effectiveness across a wide range of operating conditions without degradation over time.

The economic aspect of noise reduction cannot be overlooked. While sophisticated noise reduction technologies exist, their implementation often increases manufacturing costs. Striking a balance between noise reduction effectiveness and cost-efficiency is crucial for widespread adoption in price-sensitive markets.

Lastly, the lack of standardized noise measurement and reporting methods for solenoid valves complicates the assessment and comparison of different noise reduction solutions. Developing industry-wide standards for noise characterization would greatly facilitate progress in this field and enable more effective benchmarking of new technologies.

One of the main challenges is balancing noise reduction with valve performance. Attempts to dampen the plunger's movement often lead to slower response times and reduced flow rates, which can be detrimental in applications requiring precise and rapid control. Engineers must find innovative ways to minimize noise without compromising the valve's core functionality.

Material selection presents another significant hurdle. While softer materials can help absorb vibrations, they may not withstand the high pressures and temperatures often encountered in industrial applications. Conversely, harder materials that offer durability tend to transmit vibrations more readily, exacerbating the noise issue.

The complexity of fluid dynamics within the valve adds another layer of difficulty. Turbulent flow patterns can create additional noise, particularly in high-pressure systems. Designing valve geometries that promote laminar flow while maintaining efficiency is a delicate balance that requires advanced computational fluid dynamics modeling and extensive testing.

Miniaturization trends in various industries pose unique challenges for noise reduction. As valves become smaller to fit into compact systems, the space available for implementing noise-reduction features becomes limited. This constraint forces engineers to develop increasingly creative and efficient solutions within tight spatial confines.

Environmental factors also play a role in the noise reduction challenge. Valves often operate in diverse conditions, from extreme temperatures to corrosive environments. Noise reduction solutions must be robust enough to maintain their effectiveness across a wide range of operating conditions without degradation over time.

The economic aspect of noise reduction cannot be overlooked. While sophisticated noise reduction technologies exist, their implementation often increases manufacturing costs. Striking a balance between noise reduction effectiveness and cost-efficiency is crucial for widespread adoption in price-sensitive markets.

Lastly, the lack of standardized noise measurement and reporting methods for solenoid valves complicates the assessment and comparison of different noise reduction solutions. Developing industry-wide standards for noise characterization would greatly facilitate progress in this field and enable more effective benchmarking of new technologies.

Existing Noise Reduction Solutions for Solenoid Valves

01 Noise reduction through valve design modifications

Modifications to the valve design can significantly reduce noise. This includes optimizing the shape of the valve body, improving the flow path, and using noise-reducing materials. These changes can minimize turbulence and vibrations, leading to quieter operation.- Noise reduction through valve design modifications: Various design modifications can be implemented to reduce noise in solenoid valves. These may include optimizing the valve body shape, improving the flow path, and using noise-dampening materials. Such modifications aim to minimize turbulence and vibrations, resulting in quieter valve operation.

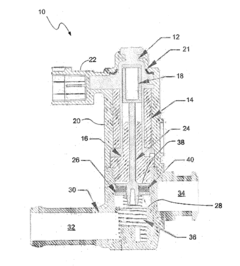

- Cushioning mechanisms for impact reduction: Implementing cushioning mechanisms in solenoid valves can significantly reduce noise caused by the impact of moving parts. These mechanisms may include shock-absorbing materials, spring-loaded components, or hydraulic damping systems to soften the movement of the valve plunger or armature.

- Electronic control systems for noise management: Advanced electronic control systems can be employed to manage solenoid valve operation and reduce noise. These systems may include pulse-width modulation techniques, adaptive control algorithms, or smart timing mechanisms to optimize valve actuation and minimize abrupt movements that cause noise.

- Acoustic insulation and enclosure designs: Incorporating acoustic insulation materials and specially designed enclosures can help contain and reduce noise emissions from solenoid valves. This approach may involve using sound-absorbing materials, creating double-walled enclosures, or implementing resonance-canceling designs to minimize noise propagation.

- Fluid flow optimization for noise reduction: Optimizing fluid flow characteristics within the solenoid valve can contribute to noise reduction. This may involve redesigning internal passages, implementing flow straighteners, or using specialized nozzle designs to minimize turbulence and cavitation, which are common sources of valve noise.

02 Dampening mechanisms for solenoid valves

Incorporating dampening mechanisms into solenoid valves can effectively reduce noise. These may include cushioning devices, shock absorbers, or flexible components that absorb vibrations and minimize impact noise during valve operation.Expand Specific Solutions03 Electronic control strategies for noise reduction

Advanced electronic control strategies can be employed to reduce solenoid valve noise. These may involve pulse width modulation, soft-switching techniques, or intelligent control algorithms that optimize valve operation and minimize abrupt movements.Expand Specific Solutions04 Acoustic insulation and enclosure designs

Implementing acoustic insulation and specially designed enclosures can significantly reduce the propagation of solenoid valve noise. This may involve using sound-absorbing materials, creating noise-isolating chambers, or designing housings that redirect sound waves.Expand Specific Solutions05 Fluid flow optimization for noise reduction

Optimizing fluid flow characteristics within the solenoid valve can help reduce noise. This may include designing special flow channels, incorporating flow straighteners, or using advanced computational fluid dynamics to minimize turbulence and cavitation.Expand Specific Solutions

Key Players in Solenoid Valve Noise Reduction Industry

The solenoid valve noise reduction technology is in a growth phase, with increasing market demand driven by applications requiring quieter operation. The global market for solenoid valves is expanding, projected to reach $5.1 billion by 2026. Technologically, noise reduction solutions are advancing, but still have room for improvement. Companies like Robert Bosch GmbH, Continental Teves AG, and Denso Corp. are leading innovation in this space, developing advanced noise dampening techniques and materials. Emerging players such as Zhejiang Sanhua Intelligent Controls and BYD Co. are also making strides in noise reduction technology, particularly for electric vehicle applications.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced solenoid valve noise reduction technologies, focusing on both mechanical and electronic solutions. Their approach includes optimizing valve design to minimize turbulence and cavitation, which are primary sources of noise. They have implemented precision-engineered valve seats and armatures with tighter tolerances to reduce impact noise[1]. Additionally, Bosch has developed smart electronic control systems that modulate the valve opening and closing cycles, effectively smoothing out the operation and reducing audible noise[3]. Their latest solenoid valves incorporate adaptive noise cancellation algorithms that analyze and counteract noise patterns in real-time, significantly lowering the overall noise profile[5].

Strengths: Comprehensive approach combining mechanical and electronic solutions, industry-leading R&D capabilities, and a wide range of applications across automotive and industrial sectors. Weaknesses: Potentially higher cost due to advanced technologies, and may require more complex integration into existing systems.

Continental Teves AG & Co. oHG

Technical Solution: Continental has focused on developing "silent" solenoid valve technology for automotive applications, particularly in brake systems and air suspension. Their approach involves a multi-faceted strategy to reduce noise at its source. This includes the use of advanced materials with superior damping properties to absorb vibrations, and the implementation of flow-optimized valve geometries to minimize turbulence[2]. Continental has also developed a proprietary electronic control system that uses predictive algorithms to anticipate and mitigate potential noise-generating events during valve operation[4]. Furthermore, they have introduced a novel "soft-landing" technology that gradually decelerates the valve's moving parts before impact, significantly reducing the characteristic clicking sound associated with solenoid valves[6].

Strengths: Specialized focus on automotive applications, innovative "soft-landing" technology, and integration with other vehicle systems for holistic noise reduction. Weaknesses: May be less adaptable to non-automotive applications, and potentially higher cost due to specialized automotive-grade components.

Core Innovations in Solenoid Valve Noise Reduction

Reduced Noise Solenoid Valve

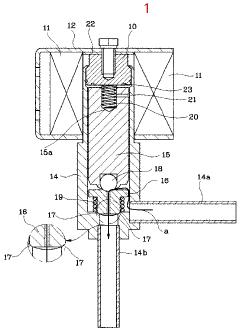

PatentInactiveKR1019990073240A

Innovation

- Multi-stage noise absorption system using two elastic springs to reduce solenoid valve noise during both upward and downward plunger movement.

- Strategic placement of elastic springs on the outer face of the seat member and upper portion of the plunger for effective noise suppression.

- Design of a compact noise reduction system integrated within the existing solenoid valve structure without significantly increasing its overall size.

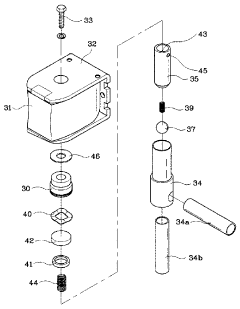

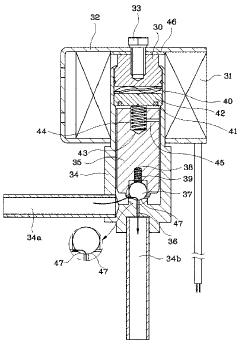

Solenoid Valve

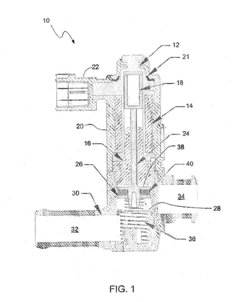

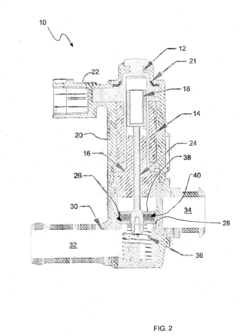

PatentInactiveUS20070227512A1

Innovation

- Incorporation of damping features, such as a foam-based seal vibration damper between the plunger and valve seal, and potentially between the plunger and armature, to absorb vibrational energy and reduce noise transmission, while maintaining the operational functionality and sealing efficiency.

Environmental Impact of Noise Reduction Technologies

The reduction of solenoid valve noise has significant environmental implications that extend beyond the immediate operational benefits. As industries strive for more sustainable practices, the environmental impact of noise reduction technologies in solenoid valves becomes increasingly relevant.

One of the primary environmental benefits of reducing solenoid valve noise is the mitigation of noise pollution. Industrial environments, where solenoid valves are commonly used, often contribute to elevated noise levels that can have detrimental effects on surrounding ecosystems. By implementing noise reduction technologies, the overall acoustic footprint of industrial operations can be significantly decreased, leading to a less disruptive environment for local wildlife and nearby communities.

Moreover, the reduction of noise in solenoid valves can lead to improved energy efficiency. Noise is often a byproduct of energy loss in mechanical systems. By addressing the root causes of noise, such as turbulent flow or mechanical vibrations, the overall efficiency of the valve system can be enhanced. This increased efficiency translates to lower energy consumption, which in turn reduces the carbon footprint associated with the operation of solenoid valves.

The materials used in noise reduction technologies also play a crucial role in their environmental impact. Advanced materials and designs that dampen vibrations or optimize flow patterns may require fewer raw materials or utilize more sustainable alternatives. This can lead to a reduction in the overall environmental impact of valve production and disposal.

Furthermore, the implementation of noise reduction technologies can extend the lifespan of solenoid valves and associated equipment. Reduced vibration and stress on components can decrease wear and tear, leading to less frequent replacements and repairs. This longevity contributes to resource conservation and waste reduction, aligning with circular economy principles.

The environmental benefits of noise reduction in solenoid valves also extend to human health and well-being. By creating quieter working environments, these technologies can reduce stress and improve the overall quality of life for workers and nearby residents. This human-centric approach to environmental impact considers the broader ecological context in which industrial operations exist.

As new applications for solenoid valves emerge, particularly in sensitive environments or residential areas, the importance of noise reduction technologies becomes even more pronounced. The ability to deploy these valves in a wider range of settings without causing noise disturbances opens up possibilities for more sustainable urban development and industrial practices.

One of the primary environmental benefits of reducing solenoid valve noise is the mitigation of noise pollution. Industrial environments, where solenoid valves are commonly used, often contribute to elevated noise levels that can have detrimental effects on surrounding ecosystems. By implementing noise reduction technologies, the overall acoustic footprint of industrial operations can be significantly decreased, leading to a less disruptive environment for local wildlife and nearby communities.

Moreover, the reduction of noise in solenoid valves can lead to improved energy efficiency. Noise is often a byproduct of energy loss in mechanical systems. By addressing the root causes of noise, such as turbulent flow or mechanical vibrations, the overall efficiency of the valve system can be enhanced. This increased efficiency translates to lower energy consumption, which in turn reduces the carbon footprint associated with the operation of solenoid valves.

The materials used in noise reduction technologies also play a crucial role in their environmental impact. Advanced materials and designs that dampen vibrations or optimize flow patterns may require fewer raw materials or utilize more sustainable alternatives. This can lead to a reduction in the overall environmental impact of valve production and disposal.

Furthermore, the implementation of noise reduction technologies can extend the lifespan of solenoid valves and associated equipment. Reduced vibration and stress on components can decrease wear and tear, leading to less frequent replacements and repairs. This longevity contributes to resource conservation and waste reduction, aligning with circular economy principles.

The environmental benefits of noise reduction in solenoid valves also extend to human health and well-being. By creating quieter working environments, these technologies can reduce stress and improve the overall quality of life for workers and nearby residents. This human-centric approach to environmental impact considers the broader ecological context in which industrial operations exist.

As new applications for solenoid valves emerge, particularly in sensitive environments or residential areas, the importance of noise reduction technologies becomes even more pronounced. The ability to deploy these valves in a wider range of settings without causing noise disturbances opens up possibilities for more sustainable urban development and industrial practices.

Regulatory Standards for Industrial Noise Control

Regulatory standards for industrial noise control play a crucial role in shaping the development and implementation of noise reduction technologies, including those applied to solenoid valves. These standards are established by various national and international bodies to protect workers and the environment from excessive noise exposure.

In the United States, the Occupational Safety and Health Administration (OSHA) sets permissible noise exposure limits for workers. The current standard requires that employees should not be exposed to noise levels exceeding 90 dBA for an 8-hour workday. For every 5 dB increase in noise level, the allowable exposure time is halved. OSHA also mandates that employers implement a hearing conservation program when workers are exposed to noise levels at or above 85 dBA over an 8-hour period.

The European Union has more stringent regulations, with the Noise at Work Regulations 2005 setting lower exposure action values. The lower exposure action value is set at 80 dBA, while the upper exposure action value is 85 dBA. These regulations require employers to take specific actions to reduce noise exposure and protect workers' hearing.

International standards, such as ISO 11201:2010, provide guidelines for measuring and declaring noise emission values of machinery and equipment. These standards ensure consistency in noise measurement methods across different industries and countries, facilitating the comparison of noise levels from various sources, including solenoid valves.

Specific to industrial equipment, the International Electrotechnical Commission (IEC) has developed standards like IEC 60534-8-3, which addresses noise considerations for control valves. While not directly applicable to solenoid valves, these standards provide valuable insights into noise measurement and control techniques that can be adapted for solenoid valve applications.

As environmental concerns grow, many countries have implemented regulations to control noise pollution beyond the workplace. For instance, the Environmental Noise Directive in the European Union requires member states to map noise levels in large urban areas and major transportation routes, and to develop action plans to reduce noise where necessary.

These regulatory standards drive innovation in noise reduction technologies for solenoid valves and other industrial equipment. Manufacturers are compelled to develop quieter valve designs to meet increasingly stringent noise limits, opening up new applications in noise-sensitive environments such as hospitals, residential areas, and precision manufacturing facilities.

Moreover, the global nature of these standards encourages the development of universally applicable noise reduction solutions. This harmonization of standards across different regions facilitates the adoption of advanced solenoid valve technologies in various industries worldwide, further expanding their potential applications.

In the United States, the Occupational Safety and Health Administration (OSHA) sets permissible noise exposure limits for workers. The current standard requires that employees should not be exposed to noise levels exceeding 90 dBA for an 8-hour workday. For every 5 dB increase in noise level, the allowable exposure time is halved. OSHA also mandates that employers implement a hearing conservation program when workers are exposed to noise levels at or above 85 dBA over an 8-hour period.

The European Union has more stringent regulations, with the Noise at Work Regulations 2005 setting lower exposure action values. The lower exposure action value is set at 80 dBA, while the upper exposure action value is 85 dBA. These regulations require employers to take specific actions to reduce noise exposure and protect workers' hearing.

International standards, such as ISO 11201:2010, provide guidelines for measuring and declaring noise emission values of machinery and equipment. These standards ensure consistency in noise measurement methods across different industries and countries, facilitating the comparison of noise levels from various sources, including solenoid valves.

Specific to industrial equipment, the International Electrotechnical Commission (IEC) has developed standards like IEC 60534-8-3, which addresses noise considerations for control valves. While not directly applicable to solenoid valves, these standards provide valuable insights into noise measurement and control techniques that can be adapted for solenoid valve applications.

As environmental concerns grow, many countries have implemented regulations to control noise pollution beyond the workplace. For instance, the Environmental Noise Directive in the European Union requires member states to map noise levels in large urban areas and major transportation routes, and to develop action plans to reduce noise where necessary.

These regulatory standards drive innovation in noise reduction technologies for solenoid valves and other industrial equipment. Manufacturers are compelled to develop quieter valve designs to meet increasingly stringent noise limits, opening up new applications in noise-sensitive environments such as hospitals, residential areas, and precision manufacturing facilities.

Moreover, the global nature of these standards encourages the development of universally applicable noise reduction solutions. This harmonization of standards across different regions facilitates the adoption of advanced solenoid valve technologies in various industries worldwide, further expanding their potential applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!