How Solenoid Valves Contribute to Building Automation and Control Systems

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Evolution

The evolution of solenoid valves in building automation and control systems has been marked by significant technological advancements and increasing integration with smart building technologies. Initially developed in the early 20th century, solenoid valves have undergone substantial improvements in design, materials, and functionality over the decades.

In the 1950s and 1960s, solenoid valves began to find applications in basic building systems, primarily for controlling water and gas flow. These early models were relatively simple, with limited control options and reliability issues. The 1970s saw the introduction of more robust designs, incorporating improved materials such as corrosion-resistant alloys and enhanced sealing technologies.

The 1980s marked a turning point with the advent of microprocessors and digital control systems. This led to the development of solenoid valves with electronic controls, enabling more precise and programmable operation. These advancements allowed for better integration with emerging building management systems, laying the groundwork for more sophisticated automation.

During the 1990s and early 2000s, solenoid valve technology experienced rapid progress. Manufacturers introduced low-power consumption models, addressing energy efficiency concerns in buildings. The miniaturization of components allowed for more compact designs, facilitating installation in space-constrained areas. Additionally, the development of multi-way valves expanded the range of applications in complex HVAC and plumbing systems.

The rise of the Internet of Things (IoT) in the 2010s revolutionized solenoid valve technology in building automation. Smart solenoid valves equipped with sensors and network connectivity emerged, enabling real-time monitoring, remote control, and predictive maintenance. These IoT-enabled valves became integral components of intelligent building systems, contributing to enhanced energy management and occupant comfort.

Recent years have seen further refinements in solenoid valve technology. Advanced materials like high-performance polymers have improved durability and chemical resistance. The integration of artificial intelligence and machine learning algorithms has enhanced the decision-making capabilities of valve control systems, optimizing performance based on usage patterns and environmental conditions.

Looking ahead, the evolution of solenoid valves in building automation is likely to focus on increased sustainability, energy efficiency, and seamless integration with smart building ecosystems. Developments in energy harvesting technologies may lead to self-powered solenoid valves, reducing wiring complexity and installation costs. Furthermore, the ongoing trend towards modular and scalable building systems will drive the development of more flexible and adaptable solenoid valve solutions, capable of meeting the dynamic needs of modern smart buildings.

In the 1950s and 1960s, solenoid valves began to find applications in basic building systems, primarily for controlling water and gas flow. These early models were relatively simple, with limited control options and reliability issues. The 1970s saw the introduction of more robust designs, incorporating improved materials such as corrosion-resistant alloys and enhanced sealing technologies.

The 1980s marked a turning point with the advent of microprocessors and digital control systems. This led to the development of solenoid valves with electronic controls, enabling more precise and programmable operation. These advancements allowed for better integration with emerging building management systems, laying the groundwork for more sophisticated automation.

During the 1990s and early 2000s, solenoid valve technology experienced rapid progress. Manufacturers introduced low-power consumption models, addressing energy efficiency concerns in buildings. The miniaturization of components allowed for more compact designs, facilitating installation in space-constrained areas. Additionally, the development of multi-way valves expanded the range of applications in complex HVAC and plumbing systems.

The rise of the Internet of Things (IoT) in the 2010s revolutionized solenoid valve technology in building automation. Smart solenoid valves equipped with sensors and network connectivity emerged, enabling real-time monitoring, remote control, and predictive maintenance. These IoT-enabled valves became integral components of intelligent building systems, contributing to enhanced energy management and occupant comfort.

Recent years have seen further refinements in solenoid valve technology. Advanced materials like high-performance polymers have improved durability and chemical resistance. The integration of artificial intelligence and machine learning algorithms has enhanced the decision-making capabilities of valve control systems, optimizing performance based on usage patterns and environmental conditions.

Looking ahead, the evolution of solenoid valves in building automation is likely to focus on increased sustainability, energy efficiency, and seamless integration with smart building ecosystems. Developments in energy harvesting technologies may lead to self-powered solenoid valves, reducing wiring complexity and installation costs. Furthermore, the ongoing trend towards modular and scalable building systems will drive the development of more flexible and adaptable solenoid valve solutions, capable of meeting the dynamic needs of modern smart buildings.

Market Demand Analysis

The market demand for solenoid valves in building automation and control systems has been experiencing significant growth in recent years. This surge is primarily driven by the increasing focus on energy efficiency, smart building technologies, and the need for more precise control over various building systems.

In the commercial building sector, there is a growing emphasis on optimizing HVAC (Heating, Ventilation, and Air Conditioning) systems to reduce energy consumption and improve occupant comfort. Solenoid valves play a crucial role in these systems by controlling the flow of refrigerants, water, and other fluids with high precision. The ability to automate and remotely control these valves contributes to more efficient building management, leading to reduced operational costs and improved sustainability.

The residential market is also showing increased interest in smart home technologies, where solenoid valves are integral components in automated irrigation systems, water leak detection, and smart plumbing solutions. As homeowners become more conscious of water conservation and seek convenience through automation, the demand for these valve-integrated systems continues to rise.

In the industrial sector, the adoption of Industry 4.0 principles is driving the integration of solenoid valves into more sophisticated control systems. These valves are essential in process automation, where they control the flow of various fluids and gases in manufacturing processes, contributing to improved efficiency and reduced waste.

The healthcare industry represents another significant market for solenoid valves in building automation. Hospitals and medical facilities require precise control over air quality, temperature, and humidity in different areas. Solenoid valves are crucial in maintaining these controlled environments, especially in critical areas such as operating rooms and isolation wards.

The global trend towards green building certifications, such as LEED (Leadership in Energy and Environmental Design), is further propelling the demand for advanced building automation systems that incorporate solenoid valves. These certifications often require sophisticated control systems to optimize resource usage and minimize environmental impact.

As cities worldwide move towards becoming "smart cities," the integration of building automation systems into larger urban management networks is creating new opportunities for solenoid valve applications. These valves are becoming part of interconnected systems that manage not just individual buildings, but entire districts or cities, contributing to more efficient resource allocation and improved urban living conditions.

The market for solenoid valves in building automation is also benefiting from advancements in valve technology. Newer models offer improved energy efficiency, longer lifespan, and enhanced compatibility with digital control systems. These improvements are making solenoid valves more attractive for both new construction projects and retrofitting existing buildings with smart technologies.

In the commercial building sector, there is a growing emphasis on optimizing HVAC (Heating, Ventilation, and Air Conditioning) systems to reduce energy consumption and improve occupant comfort. Solenoid valves play a crucial role in these systems by controlling the flow of refrigerants, water, and other fluids with high precision. The ability to automate and remotely control these valves contributes to more efficient building management, leading to reduced operational costs and improved sustainability.

The residential market is also showing increased interest in smart home technologies, where solenoid valves are integral components in automated irrigation systems, water leak detection, and smart plumbing solutions. As homeowners become more conscious of water conservation and seek convenience through automation, the demand for these valve-integrated systems continues to rise.

In the industrial sector, the adoption of Industry 4.0 principles is driving the integration of solenoid valves into more sophisticated control systems. These valves are essential in process automation, where they control the flow of various fluids and gases in manufacturing processes, contributing to improved efficiency and reduced waste.

The healthcare industry represents another significant market for solenoid valves in building automation. Hospitals and medical facilities require precise control over air quality, temperature, and humidity in different areas. Solenoid valves are crucial in maintaining these controlled environments, especially in critical areas such as operating rooms and isolation wards.

The global trend towards green building certifications, such as LEED (Leadership in Energy and Environmental Design), is further propelling the demand for advanced building automation systems that incorporate solenoid valves. These certifications often require sophisticated control systems to optimize resource usage and minimize environmental impact.

As cities worldwide move towards becoming "smart cities," the integration of building automation systems into larger urban management networks is creating new opportunities for solenoid valve applications. These valves are becoming part of interconnected systems that manage not just individual buildings, but entire districts or cities, contributing to more efficient resource allocation and improved urban living conditions.

The market for solenoid valves in building automation is also benefiting from advancements in valve technology. Newer models offer improved energy efficiency, longer lifespan, and enhanced compatibility with digital control systems. These improvements are making solenoid valves more attractive for both new construction projects and retrofitting existing buildings with smart technologies.

Technical Challenges

The integration of solenoid valves in building automation and control systems presents several technical challenges that need to be addressed for optimal performance and reliability. One of the primary challenges is ensuring precise control and accuracy in valve operation. Solenoid valves must respond quickly and consistently to electrical signals, maintaining tight tolerances in flow control across various pressure and temperature conditions. This requires advanced manufacturing techniques and materials to minimize hysteresis and improve repeatability.

Another significant challenge is power consumption and heat dissipation. Solenoid valves require electrical energy to operate, and in large-scale building systems, the cumulative power usage can be substantial. Developing energy-efficient solenoid valves that maintain performance while reducing power consumption is crucial. Additionally, managing heat generation during prolonged operation is essential to prevent valve degradation and ensure long-term reliability.

Compatibility and integration with diverse building management systems pose another set of challenges. Solenoid valves must interface seamlessly with various control protocols and communication standards used in building automation. This necessitates the development of versatile valve designs and control interfaces that can adapt to different system architectures and software platforms.

Durability and maintenance requirements present ongoing challenges in solenoid valve implementation. Building systems often operate continuously, subjecting valves to frequent cycling and potential wear. Designing valves that can withstand millions of cycles while maintaining consistent performance is critical. Moreover, developing predictive maintenance strategies and incorporating self-diagnostic capabilities into valve systems can help prevent unexpected failures and reduce downtime.

Environmental factors also contribute to the technical challenges faced by solenoid valves in building applications. Valves must operate reliably across a wide range of temperatures, humidity levels, and potentially corrosive environments. This requires careful material selection and protective measures to ensure longevity and consistent performance under varying conditions.

Lastly, the miniaturization of solenoid valves for space-constrained applications in modern buildings presents design and manufacturing challenges. Reducing valve size while maintaining flow capacity and control precision requires innovative engineering solutions and advanced manufacturing processes. Balancing size reduction with performance and reliability is an ongoing area of development in solenoid valve technology for building automation systems.

Another significant challenge is power consumption and heat dissipation. Solenoid valves require electrical energy to operate, and in large-scale building systems, the cumulative power usage can be substantial. Developing energy-efficient solenoid valves that maintain performance while reducing power consumption is crucial. Additionally, managing heat generation during prolonged operation is essential to prevent valve degradation and ensure long-term reliability.

Compatibility and integration with diverse building management systems pose another set of challenges. Solenoid valves must interface seamlessly with various control protocols and communication standards used in building automation. This necessitates the development of versatile valve designs and control interfaces that can adapt to different system architectures and software platforms.

Durability and maintenance requirements present ongoing challenges in solenoid valve implementation. Building systems often operate continuously, subjecting valves to frequent cycling and potential wear. Designing valves that can withstand millions of cycles while maintaining consistent performance is critical. Moreover, developing predictive maintenance strategies and incorporating self-diagnostic capabilities into valve systems can help prevent unexpected failures and reduce downtime.

Environmental factors also contribute to the technical challenges faced by solenoid valves in building applications. Valves must operate reliably across a wide range of temperatures, humidity levels, and potentially corrosive environments. This requires careful material selection and protective measures to ensure longevity and consistent performance under varying conditions.

Lastly, the miniaturization of solenoid valves for space-constrained applications in modern buildings presents design and manufacturing challenges. Reducing valve size while maintaining flow capacity and control precision requires innovative engineering solutions and advanced manufacturing processes. Balancing size reduction with performance and reliability is an ongoing area of development in solenoid valve technology for building automation systems.

Current Solutions

01 Solenoid valve design for fluid control

Solenoid valves are designed for precise control of fluid flow in various applications. They utilize electromagnetic force to open or close a valve, allowing or restricting fluid passage. These valves can be customized for different pressure ranges, flow rates, and fluid types, making them versatile components in hydraulic and pneumatic systems.- Design and structure of solenoid valves: Solenoid valves are designed with specific structures to control fluid flow. They typically consist of a coil, plunger, and valve body. The design may include features for improved performance, such as optimized magnetic circuits, sealing mechanisms, and flow paths. Various configurations are used to suit different applications and operating conditions.

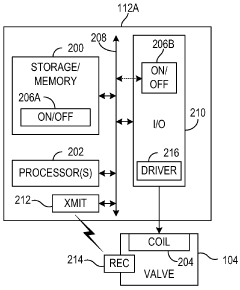

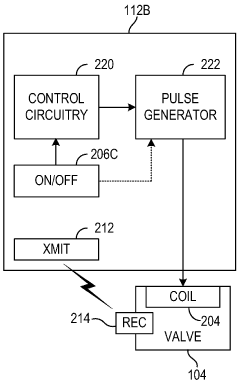

- Control systems for solenoid valves: Control systems are crucial for the operation of solenoid valves. These systems may include electronic controllers, sensors, and feedback mechanisms to regulate valve operation. Advanced control systems can provide precise timing, variable flow control, and integration with larger automation systems. Some designs incorporate multiple valves for complex fluid control scenarios.

- Applications of solenoid valves: Solenoid valves find applications in various industries and systems. They are used in automotive systems, industrial processes, irrigation systems, and household appliances. Specific applications include fuel injection systems, pneumatic controls, hydraulic systems, and water management. The versatility of solenoid valves makes them suitable for a wide range of fluid control needs.

- Energy efficiency and power management: Improving energy efficiency is a key focus in solenoid valve design. This includes developing low-power consumption valves, optimizing coil designs for reduced energy use, and implementing power management strategies. Some designs incorporate energy recovery systems or use alternative actuation methods to minimize power requirements while maintaining performance.

- Materials and manufacturing techniques: The choice of materials and manufacturing techniques plays a crucial role in solenoid valve performance and durability. Advanced materials may be used for improved magnetic properties, wear resistance, or chemical compatibility. Manufacturing techniques such as precision machining, 3D printing, or advanced molding processes can enhance valve quality and consistency. Innovations in this area focus on improving reliability, reducing costs, and extending valve lifespan.

02 Solenoid valves in automotive applications

Solenoid valves play a crucial role in automotive systems, particularly in engine management and emission control. They are used in fuel injection systems, transmission control, and exhaust gas recirculation. These valves help improve engine efficiency, reduce emissions, and enhance overall vehicle performance by precisely controlling fluid and gas flow.Expand Specific Solutions03 Miniaturization and integration of solenoid valves

Advancements in solenoid valve technology focus on miniaturization and integration. Compact designs allow for easier installation in space-constrained applications. Integrated solenoid valves combine multiple functions into a single unit, reducing system complexity and improving reliability. These developments enable more efficient and cost-effective fluid control solutions across various industries.Expand Specific Solutions04 Energy-efficient solenoid valve systems

Energy efficiency is a key consideration in modern solenoid valve design. Innovations include low-power consumption coils, improved magnetic circuit designs, and smart control systems. These advancements reduce energy usage while maintaining reliable operation, making solenoid valves more sustainable and cost-effective for long-term use in industrial and commercial applications.Expand Specific Solutions05 Solenoid valve maintenance and diagnostics

Maintenance and diagnostic features are increasingly incorporated into solenoid valve designs. These include self-diagnostic capabilities, condition monitoring sensors, and predictive maintenance algorithms. Such features help identify potential issues before they lead to system failures, reducing downtime and maintenance costs. Advanced diagnostics also facilitate easier troubleshooting and valve performance optimization.Expand Specific Solutions

Key Industry Players

The solenoid valve market in building automation and control systems is in a mature growth phase, with increasing demand driven by smart building trends and energy efficiency requirements. The global market size is projected to reach several billion dollars by 2025, growing at a CAGR of 3-5%. Technologically, solenoid valves are well-established, with ongoing innovations in materials, miniaturization, and IoT integration. Key players like Eaton Corp., Robert Bosch GmbH, and Honeywell International Technologies Ltd. are leading the market with advanced product offerings, while companies such as Festo SE & Co. KG and Emerson Electric Co. are focusing on smart, energy-efficient solutions to maintain their competitive edge in this evolving landscape.

Eaton Corp.

Technical Solution: Eaton Corporation has developed innovative solenoid valve solutions for building automation and control systems. Their AxisPro™ series of proportional valves utilize advanced digital control technology to provide precise flow regulation in HVAC and other building applications[13]. These valves feature Eaton's proprietary Valve-in-Valve design, which allows for redundancy and fail-safe operation, critical for maintaining building safety and comfort[14]. Eaton has also implemented their SmartWire-DT communication technology, enabling seamless integration with building management systems and providing real-time diagnostics and predictive maintenance capabilities[15]. The company's valves are designed with energy efficiency in mind, incorporating low-power coils and optimized flow paths to reduce energy consumption in building systems[16].

Strengths: Advanced digital control, fail-safe operation, and integrated diagnostics. Weaknesses: May require specialized training for installation and configuration, potentially higher initial cost.

Robert Bosch GmbH

Technical Solution: Bosch has developed a range of solenoid valves tailored for building automation and control systems. Their Rexroth series of hydraulic and pneumatic valves incorporate advanced spool designs that provide precise control and fast response times in various building applications[17]. Bosch's valves feature their proprietary Sercos automation bus, allowing for real-time communication and seamless integration with building management systems[18]. The company has also implemented IoT-enabled capabilities in their valves, enabling remote monitoring, predictive maintenance, and energy optimization in building control systems[19]. Bosch's valves are designed with sustainability in mind, utilizing eco-friendly materials and energy-efficient actuation technologies to reduce the environmental impact of building operations[20].

Strengths: Precise control, IoT integration, and sustainability focus. Weaknesses: May have a steeper learning curve for implementation, potentially higher cost for advanced features.

Core Innovations

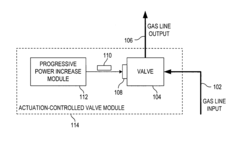

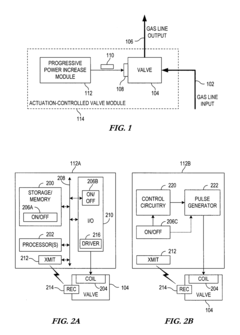

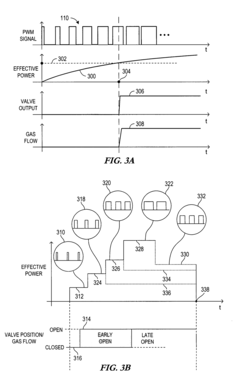

System, apparatus and method for controlling valves

PatentActiveUS7950622B2

Innovation

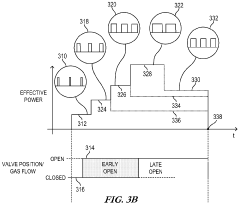

- A system and method that progressively increase the power signal to the valve control input, starting below the actuation threshold and gradually increasing until the valve is actuated, reducing the force required to open or close the valve, thus minimizing strain on mechanical components.

System, apparatus and method for controlling valves

PatentWO2009015155A1

Innovation

- A system and method that progressively increases the power signal to the valve control input, starting below the actuation threshold and gradually increasing the duty cycle or amplitude until the valve is actuated, reducing the force required to open or close the valve, thus minimizing strain on mechanical components.

Energy Efficiency

Solenoid valves play a crucial role in enhancing energy efficiency within building automation and control systems. These electromechanical devices contribute significantly to reducing energy consumption and optimizing resource utilization in various building applications. By precisely controlling the flow of fluids and gases, solenoid valves enable smart management of heating, ventilation, and air conditioning (HVAC) systems, which are major energy consumers in buildings.

In HVAC systems, solenoid valves regulate the flow of refrigerants, water, and air, allowing for precise temperature control and zoning. This granular control ensures that energy is not wasted on heating or cooling unoccupied spaces. Moreover, when integrated with occupancy sensors and building management systems, solenoid valves can automatically adjust the HVAC output based on real-time occupancy and usage patterns, further minimizing energy waste.

The rapid response time of solenoid valves also contributes to energy savings. Unlike manual valves, solenoid valves can quickly react to changes in demand or environmental conditions, preventing overcooling or overheating scenarios that lead to unnecessary energy consumption. This responsiveness is particularly valuable in variable air volume (VAV) systems, where airflow needs to be constantly adjusted to maintain optimal comfort levels while minimizing energy use.

In water management systems, solenoid valves help reduce water consumption by preventing leaks and controlling water flow in irrigation systems, toilets, and other water-dependent applications. By integrating these valves with smart sensors and timers, buildings can implement efficient watering schedules and detect abnormal water usage patterns, leading to substantial water and energy savings.

Furthermore, solenoid valves contribute to energy efficiency in lighting control systems. By regulating the flow of gases in certain types of lighting fixtures, such as neon signs or specialized architectural lighting, these valves can help optimize power consumption and extend the lifespan of lighting elements. This not only reduces direct energy consumption but also decreases the frequency of maintenance and replacement, indirectly contributing to overall energy efficiency.

The integration of solenoid valves with building automation systems allows for centralized control and monitoring of various building functions. This integration enables facility managers to implement sophisticated energy-saving strategies, such as demand-based ventilation, thermal energy storage, and load shedding during peak energy demand periods. By leveraging the precise control offered by solenoid valves, buildings can achieve a more balanced and efficient use of energy resources across different systems and time periods.

In HVAC systems, solenoid valves regulate the flow of refrigerants, water, and air, allowing for precise temperature control and zoning. This granular control ensures that energy is not wasted on heating or cooling unoccupied spaces. Moreover, when integrated with occupancy sensors and building management systems, solenoid valves can automatically adjust the HVAC output based on real-time occupancy and usage patterns, further minimizing energy waste.

The rapid response time of solenoid valves also contributes to energy savings. Unlike manual valves, solenoid valves can quickly react to changes in demand or environmental conditions, preventing overcooling or overheating scenarios that lead to unnecessary energy consumption. This responsiveness is particularly valuable in variable air volume (VAV) systems, where airflow needs to be constantly adjusted to maintain optimal comfort levels while minimizing energy use.

In water management systems, solenoid valves help reduce water consumption by preventing leaks and controlling water flow in irrigation systems, toilets, and other water-dependent applications. By integrating these valves with smart sensors and timers, buildings can implement efficient watering schedules and detect abnormal water usage patterns, leading to substantial water and energy savings.

Furthermore, solenoid valves contribute to energy efficiency in lighting control systems. By regulating the flow of gases in certain types of lighting fixtures, such as neon signs or specialized architectural lighting, these valves can help optimize power consumption and extend the lifespan of lighting elements. This not only reduces direct energy consumption but also decreases the frequency of maintenance and replacement, indirectly contributing to overall energy efficiency.

The integration of solenoid valves with building automation systems allows for centralized control and monitoring of various building functions. This integration enables facility managers to implement sophisticated energy-saving strategies, such as demand-based ventilation, thermal energy storage, and load shedding during peak energy demand periods. By leveraging the precise control offered by solenoid valves, buildings can achieve a more balanced and efficient use of energy resources across different systems and time periods.

Integration Strategies

The integration of solenoid valves into building automation and control systems requires a strategic approach to ensure seamless operation and optimal performance. One key strategy is to implement a centralized control system that can manage multiple solenoid valves across different building systems. This approach allows for coordinated operation of HVAC, plumbing, and fire suppression systems, enhancing overall building efficiency and safety.

Another crucial integration strategy involves the use of standardized communication protocols. By adopting protocols such as BACnet, Modbus, or LonWorks, solenoid valves can effectively communicate with other components of the building automation system. This standardization ensures interoperability between devices from different manufacturers and simplifies system expansion and maintenance.

Implementing a robust network infrastructure is essential for reliable solenoid valve integration. This may involve the use of wired or wireless networks, depending on the building's layout and requirements. Ethernet-based networks are increasingly popular due to their high bandwidth and ability to support Power over Ethernet (PoE) for powering solenoid valves directly through the network cable.

To maximize the benefits of solenoid valves in building automation, it is crucial to integrate them with advanced sensing and monitoring systems. This integration allows for real-time data collection on valve performance, fluid flow rates, and system pressures. By analyzing this data, building managers can optimize system operation, predict maintenance needs, and identify potential issues before they escalate.

Energy efficiency is a key consideration in solenoid valve integration strategies. By incorporating smart control algorithms and machine learning techniques, building automation systems can dynamically adjust valve operations based on occupancy patterns, weather conditions, and energy consumption data. This adaptive approach can significantly reduce energy waste and improve overall building sustainability.

Lastly, successful integration of solenoid valves requires careful consideration of system redundancy and fail-safe mechanisms. Implementing backup power supplies, redundant valve configurations, and automated fault detection systems ensures that critical building functions remain operational even in the event of component failures or power outages. This approach enhances the reliability and resilience of the entire building automation system.

Another crucial integration strategy involves the use of standardized communication protocols. By adopting protocols such as BACnet, Modbus, or LonWorks, solenoid valves can effectively communicate with other components of the building automation system. This standardization ensures interoperability between devices from different manufacturers and simplifies system expansion and maintenance.

Implementing a robust network infrastructure is essential for reliable solenoid valve integration. This may involve the use of wired or wireless networks, depending on the building's layout and requirements. Ethernet-based networks are increasingly popular due to their high bandwidth and ability to support Power over Ethernet (PoE) for powering solenoid valves directly through the network cable.

To maximize the benefits of solenoid valves in building automation, it is crucial to integrate them with advanced sensing and monitoring systems. This integration allows for real-time data collection on valve performance, fluid flow rates, and system pressures. By analyzing this data, building managers can optimize system operation, predict maintenance needs, and identify potential issues before they escalate.

Energy efficiency is a key consideration in solenoid valve integration strategies. By incorporating smart control algorithms and machine learning techniques, building automation systems can dynamically adjust valve operations based on occupancy patterns, weather conditions, and energy consumption data. This adaptive approach can significantly reduce energy waste and improve overall building sustainability.

Lastly, successful integration of solenoid valves requires careful consideration of system redundancy and fail-safe mechanisms. Implementing backup power supplies, redundant valve configurations, and automated fault detection systems ensures that critical building functions remain operational even in the event of component failures or power outages. This approach enhances the reliability and resilience of the entire building automation system.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!