How Solenoid Valves Enhance Safety Mechanisms in Nuclear Power Plants

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Evolution in Nuclear Safety

The evolution of solenoid valves in nuclear safety has been a critical aspect of enhancing the overall safety mechanisms in nuclear power plants. Over the years, these valves have undergone significant improvements to meet the stringent safety requirements of the nuclear industry.

In the early stages of nuclear power plant development, solenoid valves were primarily used for basic on-off control functions. However, as the understanding of nuclear safety grew, so did the demands placed on these crucial components. The 1970s saw a shift towards more robust and reliable solenoid valve designs, with increased focus on fail-safe operations and radiation resistance.

The Three Mile Island accident in 1979 marked a turning point in nuclear safety, leading to a comprehensive reassessment of safety systems, including solenoid valves. This event catalyzed the development of advanced solenoid valve technologies specifically tailored for nuclear applications. Manufacturers began incorporating redundancy features and improved materials to enhance valve reliability under extreme conditions.

During the 1980s and 1990s, digital control systems were increasingly integrated into nuclear power plants, necessitating the evolution of solenoid valves to interface with these new technologies. This period saw the introduction of smart solenoid valves with built-in diagnostics and remote monitoring capabilities, allowing for predictive maintenance and real-time performance assessment.

The Fukushima Daiichi disaster in 2011 further emphasized the importance of robust safety systems in nuclear power plants. In response, solenoid valve designs were further refined to withstand severe accident scenarios, including extended loss of power and exposure to extreme environmental conditions. This led to the development of passive solenoid valve systems that could operate without external power sources for extended periods.

Recent advancements in solenoid valve technology for nuclear safety applications have focused on enhancing reliability, extending operational lifespans, and improving resistance to harsh environments. Modern solenoid valves now incorporate advanced materials such as high-performance polymers and corrosion-resistant alloys, ensuring longevity and consistent performance under challenging conditions.

The integration of Industry 4.0 concepts has also influenced solenoid valve evolution in nuclear safety. Today's valves often feature advanced sensors and communication capabilities, enabling seamless integration with plant-wide safety systems and facilitating comprehensive monitoring and control strategies.

In the early stages of nuclear power plant development, solenoid valves were primarily used for basic on-off control functions. However, as the understanding of nuclear safety grew, so did the demands placed on these crucial components. The 1970s saw a shift towards more robust and reliable solenoid valve designs, with increased focus on fail-safe operations and radiation resistance.

The Three Mile Island accident in 1979 marked a turning point in nuclear safety, leading to a comprehensive reassessment of safety systems, including solenoid valves. This event catalyzed the development of advanced solenoid valve technologies specifically tailored for nuclear applications. Manufacturers began incorporating redundancy features and improved materials to enhance valve reliability under extreme conditions.

During the 1980s and 1990s, digital control systems were increasingly integrated into nuclear power plants, necessitating the evolution of solenoid valves to interface with these new technologies. This period saw the introduction of smart solenoid valves with built-in diagnostics and remote monitoring capabilities, allowing for predictive maintenance and real-time performance assessment.

The Fukushima Daiichi disaster in 2011 further emphasized the importance of robust safety systems in nuclear power plants. In response, solenoid valve designs were further refined to withstand severe accident scenarios, including extended loss of power and exposure to extreme environmental conditions. This led to the development of passive solenoid valve systems that could operate without external power sources for extended periods.

Recent advancements in solenoid valve technology for nuclear safety applications have focused on enhancing reliability, extending operational lifespans, and improving resistance to harsh environments. Modern solenoid valves now incorporate advanced materials such as high-performance polymers and corrosion-resistant alloys, ensuring longevity and consistent performance under challenging conditions.

The integration of Industry 4.0 concepts has also influenced solenoid valve evolution in nuclear safety. Today's valves often feature advanced sensors and communication capabilities, enabling seamless integration with plant-wide safety systems and facilitating comprehensive monitoring and control strategies.

Nuclear Plant Safety Market Analysis

The nuclear plant safety market has witnessed significant growth in recent years, driven by increasing concerns over nuclear safety and stringent regulatory requirements. The global market for nuclear plant safety systems is projected to expand steadily, with a particular focus on advanced safety mechanisms such as solenoid valves. These valves play a crucial role in enhancing the overall safety and reliability of nuclear power plants.

The demand for solenoid valves in nuclear safety applications is primarily fueled by the need for precise control of fluid flow and pressure in various critical systems within nuclear power plants. As countries worldwide continue to invest in nuclear energy as a clean and efficient power source, the market for safety-related components, including solenoid valves, is expected to grow proportionally.

Key market drivers include the aging of existing nuclear facilities, which necessitates upgrades and replacements of safety systems, as well as the construction of new nuclear power plants in emerging economies. Additionally, the increasing emphasis on passive safety systems in Generation III+ and Generation IV nuclear reactors has created new opportunities for advanced solenoid valve technologies.

The market landscape is characterized by a mix of established players and innovative startups. Major companies in the nuclear safety market are investing heavily in research and development to improve the performance, reliability, and longevity of solenoid valves used in nuclear applications. These efforts are focused on developing valves that can withstand extreme conditions, operate with high precision, and provide fail-safe functionality.

Geographically, North America and Europe currently dominate the market for nuclear plant safety systems, including solenoid valves, due to their mature nuclear industries and stringent safety regulations. However, the Asia-Pacific region is expected to exhibit the highest growth rate in the coming years, driven by ambitious nuclear power expansion plans in countries like China and India.

The market for solenoid valves in nuclear safety applications faces certain challenges, including the high costs associated with nuclear-grade components and the long certification processes required for safety-critical equipment. However, these barriers also serve as entry deterrents, potentially benefiting established players in the long run.

Looking ahead, the nuclear plant safety market is poised for technological advancements, with a focus on digital control systems, smart sensors, and advanced materials for valve construction. These innovations are expected to further enhance the capabilities of solenoid valves in ensuring nuclear plant safety, potentially expanding their applications and market share within the broader nuclear safety ecosystem.

The demand for solenoid valves in nuclear safety applications is primarily fueled by the need for precise control of fluid flow and pressure in various critical systems within nuclear power plants. As countries worldwide continue to invest in nuclear energy as a clean and efficient power source, the market for safety-related components, including solenoid valves, is expected to grow proportionally.

Key market drivers include the aging of existing nuclear facilities, which necessitates upgrades and replacements of safety systems, as well as the construction of new nuclear power plants in emerging economies. Additionally, the increasing emphasis on passive safety systems in Generation III+ and Generation IV nuclear reactors has created new opportunities for advanced solenoid valve technologies.

The market landscape is characterized by a mix of established players and innovative startups. Major companies in the nuclear safety market are investing heavily in research and development to improve the performance, reliability, and longevity of solenoid valves used in nuclear applications. These efforts are focused on developing valves that can withstand extreme conditions, operate with high precision, and provide fail-safe functionality.

Geographically, North America and Europe currently dominate the market for nuclear plant safety systems, including solenoid valves, due to their mature nuclear industries and stringent safety regulations. However, the Asia-Pacific region is expected to exhibit the highest growth rate in the coming years, driven by ambitious nuclear power expansion plans in countries like China and India.

The market for solenoid valves in nuclear safety applications faces certain challenges, including the high costs associated with nuclear-grade components and the long certification processes required for safety-critical equipment. However, these barriers also serve as entry deterrents, potentially benefiting established players in the long run.

Looking ahead, the nuclear plant safety market is poised for technological advancements, with a focus on digital control systems, smart sensors, and advanced materials for valve construction. These innovations are expected to further enhance the capabilities of solenoid valves in ensuring nuclear plant safety, potentially expanding their applications and market share within the broader nuclear safety ecosystem.

Solenoid Valve Challenges in Nuclear Applications

Solenoid valves play a crucial role in enhancing safety mechanisms within nuclear power plants, yet they face several significant challenges in these demanding applications. The extreme conditions present in nuclear environments, including high temperatures, pressures, and radiation levels, pose substantial obstacles to the reliable operation of solenoid valves.

One of the primary challenges is material degradation. The intense radiation exposure can cause embrittlement and deterioration of valve components, particularly in elastomeric seals and electrical insulation materials. This degradation can lead to leaks, reduced performance, or complete valve failure, potentially compromising the safety systems they are designed to protect.

Thermal management presents another significant hurdle. Solenoid valves in nuclear applications must withstand elevated temperatures while maintaining precise control over fluid flow. The heat generated by both the nuclear processes and the valve's own operation can affect the solenoid's magnetic properties and the overall valve performance, necessitating advanced cooling solutions and thermally resilient materials.

The requirement for fail-safe operation adds complexity to solenoid valve design in nuclear settings. These valves must reliably return to a predetermined safe position in the event of power loss or system failure, ensuring that critical safety functions are maintained even under adverse conditions. This demand for unfailing reliability in emergency scenarios places additional stress on valve components and control systems.

Corrosion resistance is another critical factor, as solenoid valves in nuclear plants may be exposed to various corrosive fluids and environments. The valves must maintain their integrity and functionality over extended periods without succumbing to chemical attack or erosion, which could lead to premature failure or compromised performance.

The need for long-term reliability and minimal maintenance presents yet another challenge. Nuclear power plants operate on extended cycles, and frequent maintenance or replacement of components is often impractical or impossible due to radiation exposure risks. Solenoid valves must therefore be designed for exceptional durability and longevity, capable of functioning flawlessly for years without intervention.

Electromagnetic interference (EMI) and electromagnetic compatibility (EMC) issues also pose significant challenges in nuclear applications. The complex electrical systems and potential for electromagnetic disturbances in nuclear facilities require solenoid valves to be shielded and designed to operate reliably in the presence of EMI, without themselves becoming sources of interference that could affect other critical systems.

One of the primary challenges is material degradation. The intense radiation exposure can cause embrittlement and deterioration of valve components, particularly in elastomeric seals and electrical insulation materials. This degradation can lead to leaks, reduced performance, or complete valve failure, potentially compromising the safety systems they are designed to protect.

Thermal management presents another significant hurdle. Solenoid valves in nuclear applications must withstand elevated temperatures while maintaining precise control over fluid flow. The heat generated by both the nuclear processes and the valve's own operation can affect the solenoid's magnetic properties and the overall valve performance, necessitating advanced cooling solutions and thermally resilient materials.

The requirement for fail-safe operation adds complexity to solenoid valve design in nuclear settings. These valves must reliably return to a predetermined safe position in the event of power loss or system failure, ensuring that critical safety functions are maintained even under adverse conditions. This demand for unfailing reliability in emergency scenarios places additional stress on valve components and control systems.

Corrosion resistance is another critical factor, as solenoid valves in nuclear plants may be exposed to various corrosive fluids and environments. The valves must maintain their integrity and functionality over extended periods without succumbing to chemical attack or erosion, which could lead to premature failure or compromised performance.

The need for long-term reliability and minimal maintenance presents yet another challenge. Nuclear power plants operate on extended cycles, and frequent maintenance or replacement of components is often impractical or impossible due to radiation exposure risks. Solenoid valves must therefore be designed for exceptional durability and longevity, capable of functioning flawlessly for years without intervention.

Electromagnetic interference (EMI) and electromagnetic compatibility (EMC) issues also pose significant challenges in nuclear applications. The complex electrical systems and potential for electromagnetic disturbances in nuclear facilities require solenoid valves to be shielded and designed to operate reliably in the presence of EMI, without themselves becoming sources of interference that could affect other critical systems.

Current Solenoid Valve Safety Solutions

01 Fail-safe mechanisms for solenoid valves

Implementing fail-safe mechanisms in solenoid valves ensures that the valve defaults to a safe position in case of power failure or system malfunction. This can include spring-return designs, redundant solenoids, or mechanical interlocks that automatically close or open the valve as needed for safety.- Fail-safe mechanisms for solenoid valves: Implementing fail-safe mechanisms in solenoid valves ensures that the valve defaults to a safe position in case of power failure or system malfunction. This can include spring-return mechanisms or backup power systems to maintain safety in critical applications.

- Monitoring and diagnostic systems: Incorporating monitoring and diagnostic systems into solenoid valve assemblies allows for real-time detection of potential issues. These systems can track valve performance, detect leaks, and alert operators to maintenance needs, enhancing overall safety and reliability.

- Redundancy in solenoid valve systems: Implementing redundant solenoid valve systems provides an additional layer of safety. This approach involves using multiple valves in parallel or series configurations to ensure continued operation and safety even if one valve fails.

- Explosion-proof solenoid valve designs: Developing explosion-proof solenoid valve designs for use in hazardous environments. These valves are constructed with materials and features that prevent ignition of flammable gases or dust, ensuring safety in potentially explosive atmospheres.

- Integration with safety control systems: Integrating solenoid valves with broader safety control systems enhances overall process safety. This integration allows for coordinated emergency shutdowns, pressure relief, and other safety functions across multiple system components.

02 Monitoring and diagnostic systems

Incorporating monitoring and diagnostic systems into solenoid valve assemblies can enhance safety by detecting potential issues before they become critical. These systems may include sensors for pressure, temperature, or position, as well as electronic controllers that can analyze valve performance and alert operators to maintenance needs or impending failures.Expand Specific Solutions03 Explosion-proof solenoid valve designs

Developing explosion-proof solenoid valve designs is crucial for applications in hazardous environments. These designs may include sealed enclosures, flame-proof materials, and special electrical components that prevent sparks or excessive heat generation, reducing the risk of ignition in potentially explosive atmospheres.Expand Specific Solutions04 Redundancy and backup systems

Implementing redundancy and backup systems in solenoid valve installations can significantly improve safety. This may involve using multiple valves in parallel, backup power supplies, or alternative actuation methods to ensure continued operation or safe shutdown in case of primary system failure.Expand Specific Solutions05 Smart solenoid valve technology

Integrating smart technology into solenoid valves can enhance safety through improved control and communication capabilities. These advanced valves may feature built-in microprocessors, network connectivity, and self-diagnostic functions, allowing for real-time monitoring, remote operation, and predictive maintenance to prevent safety-related issues.Expand Specific Solutions

Key Nuclear Valve Manufacturers

The solenoid valve market for nuclear power plant safety mechanisms is in a mature growth stage, with a significant global market size driven by increasing nuclear power generation capacity. The technology is well-established, with major players like Robert Bosch GmbH, Eaton Corp., and Toshiba Corp. offering advanced solutions. Chinese companies such as China General Nuclear Power Corp. and CGN Power Co., Ltd. are also making significant strides in this sector. The competitive landscape is characterized by a mix of established industrial conglomerates and specialized nuclear technology firms, with ongoing innovation focused on enhancing reliability, safety, and efficiency of solenoid valve systems in nuclear applications.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has applied its extensive expertise in automotive and industrial technologies to develop advanced solenoid valve solutions for nuclear power plant safety systems. Their approach focuses on precision engineering and reliability. Bosch's nuclear-grade solenoid valves feature high-precision manufacturing techniques that ensure consistent performance under varying conditions. The company has implemented a unique modular design that allows for easy maintenance and replacement of components, reducing downtime and improving overall system reliability. Bosch's valves incorporate advanced sealing technologies that minimize the risk of leaks, a critical factor in nuclear applications. Additionally, they have developed a proprietary electronic control system that provides real-time monitoring and adjustment of valve performance, optimizing operation based on current plant conditions[11]. The system also includes predictive maintenance algorithms that can forecast potential valve failures, allowing for proactive maintenance scheduling.

Strengths: High-precision engineering, modular design for easy maintenance, and advanced electronic control systems. Weaknesses: Less specialized experience in nuclear applications compared to dedicated nuclear technology companies.

China General Nuclear Power Corp.

Technical Solution: China General Nuclear Power Corp. (CGN) has developed advanced solenoid valve systems for nuclear power plants, focusing on enhancing safety mechanisms. Their technology incorporates redundant valve configurations and fail-safe designs to ensure reliable operation during normal and emergency conditions. CGN's solenoid valves feature rapid response times, typically under 100 milliseconds[1], which is crucial for quick isolation of systems in case of anomalies. The company has also implemented smart diagnostic capabilities in their valve systems, allowing for real-time monitoring and predictive maintenance, significantly reducing the risk of unexpected failures[2]. CGN's valves are designed to withstand harsh environments, including high radiation and temperature conditions, with a lifespan exceeding 40 years in nuclear plant operations[3].

Strengths: Extensive experience in nuclear power, advanced fail-safe designs, and smart diagnostic capabilities. Weaknesses: Potential over-reliance on in-house technology, which may limit integration with other systems.

Innovative Solenoid Valve Technologies

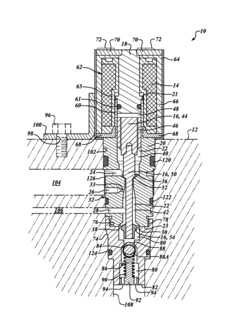

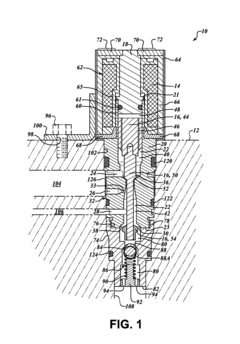

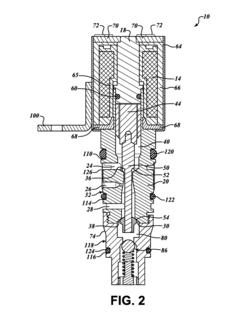

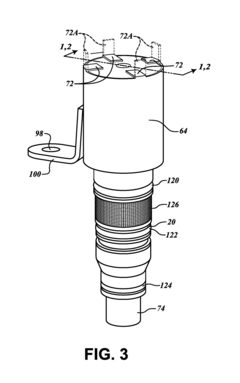

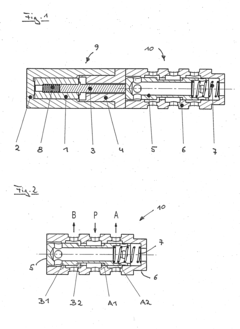

Solenoid valve assembly with pilot pressure control

PatentActiveUS20170074745A1

Innovation

- The solenoid valve assembly includes a selectively energizable coil, a valve body with primary and secondary supply ports, a control port, and an exhaust port, along with an armature assembly that moves within the valve body to regulate fluid flow. A regulator valve and pole piece with a fluid leak path are designed to maintain pilot pressure and prevent air leaks, ensuring continuous fluid flow and quick actuation.

Magnetic valve and method for controlling same

PatentInactiveEP2568204A1

Innovation

- The design incorporates an armature return spring to passively move the armature to its rear stop position when a jam is detected, and re-energizing the coil with an impulse force increases the piston's kinetic energy to dislodge stuck particles, with the force amplified by at least eight times, and anti-friction coatings to reduce friction and enhance sliding.

Regulatory Framework for Nuclear Safety

The regulatory framework for nuclear safety is a critical component in ensuring the safe operation of nuclear power plants, including the implementation of safety mechanisms such as solenoid valves. This framework is established and enforced by national and international regulatory bodies to maintain the highest standards of safety in the nuclear industry.

At the international level, the International Atomic Energy Agency (IAEA) plays a pivotal role in setting safety standards and guidelines. The IAEA's Safety Standards Series provides a comprehensive set of fundamental principles, requirements, and recommendations for nuclear safety. These standards are regularly updated to incorporate lessons learned from operational experience and advances in technology.

National regulatory bodies, such as the Nuclear Regulatory Commission (NRC) in the United States, the Office for Nuclear Regulation (ONR) in the United Kingdom, and the Nuclear Safety Authority (ASN) in France, are responsible for implementing and enforcing these international standards within their respective jurisdictions. These organizations develop specific regulations and guidelines tailored to their national context while adhering to international best practices.

The regulatory framework typically includes licensing requirements for nuclear power plants, which involve a rigorous review process of plant design, construction, and operational procedures. This process ensures that all safety systems, including those utilizing solenoid valves, meet stringent safety criteria. Regular inspections and audits are conducted to verify compliance with these regulations throughout the plant's operational lifetime.

Specific to solenoid valves and their role in enhancing safety mechanisms, regulations often focus on reliability, redundancy, and fail-safe operation. For instance, regulations may require multiple, independent solenoid valve systems to ensure that critical safety functions are maintained even in the event of a single failure. The regulatory framework also typically mandates regular testing and maintenance of these valves to ensure their continued reliability.

Furthermore, the regulatory framework addresses the qualification of equipment for nuclear applications. This includes requirements for environmental qualification, seismic qualification, and electromagnetic compatibility. Solenoid valves used in safety-critical systems must demonstrate their ability to function under various postulated accident conditions, including extreme temperatures, pressures, and radiation levels.

In recent years, regulatory bodies have placed increased emphasis on the concept of defense-in-depth, which involves multiple layers of protection against potential accidents. This approach has led to more stringent requirements for diverse and redundant safety systems, further enhancing the role of solenoid valves in nuclear safety mechanisms.

At the international level, the International Atomic Energy Agency (IAEA) plays a pivotal role in setting safety standards and guidelines. The IAEA's Safety Standards Series provides a comprehensive set of fundamental principles, requirements, and recommendations for nuclear safety. These standards are regularly updated to incorporate lessons learned from operational experience and advances in technology.

National regulatory bodies, such as the Nuclear Regulatory Commission (NRC) in the United States, the Office for Nuclear Regulation (ONR) in the United Kingdom, and the Nuclear Safety Authority (ASN) in France, are responsible for implementing and enforcing these international standards within their respective jurisdictions. These organizations develop specific regulations and guidelines tailored to their national context while adhering to international best practices.

The regulatory framework typically includes licensing requirements for nuclear power plants, which involve a rigorous review process of plant design, construction, and operational procedures. This process ensures that all safety systems, including those utilizing solenoid valves, meet stringent safety criteria. Regular inspections and audits are conducted to verify compliance with these regulations throughout the plant's operational lifetime.

Specific to solenoid valves and their role in enhancing safety mechanisms, regulations often focus on reliability, redundancy, and fail-safe operation. For instance, regulations may require multiple, independent solenoid valve systems to ensure that critical safety functions are maintained even in the event of a single failure. The regulatory framework also typically mandates regular testing and maintenance of these valves to ensure their continued reliability.

Furthermore, the regulatory framework addresses the qualification of equipment for nuclear applications. This includes requirements for environmental qualification, seismic qualification, and electromagnetic compatibility. Solenoid valves used in safety-critical systems must demonstrate their ability to function under various postulated accident conditions, including extreme temperatures, pressures, and radiation levels.

In recent years, regulatory bodies have placed increased emphasis on the concept of defense-in-depth, which involves multiple layers of protection against potential accidents. This approach has led to more stringent requirements for diverse and redundant safety systems, further enhancing the role of solenoid valves in nuclear safety mechanisms.

Environmental Impact Assessment

The implementation of solenoid valves in nuclear power plant safety mechanisms has significant environmental implications that warrant careful consideration. These valves play a crucial role in controlling the flow of coolant and other critical fluids within the plant, directly impacting the overall safety and efficiency of operations.

From an environmental perspective, the enhanced control provided by solenoid valves contributes to the prevention of potential leaks or releases of radioactive materials. By ensuring precise and rapid actuation of safety systems, these valves help maintain the integrity of containment structures and minimize the risk of environmental contamination. This is particularly important in the event of abnormal operating conditions or emergency situations.

The improved reliability and responsiveness of solenoid valves also contribute to more efficient plant operations. This efficiency translates to reduced energy consumption and, consequently, a lower carbon footprint associated with nuclear power generation. By optimizing coolant flow and other processes, solenoid valves help maximize the energy output while minimizing waste and resource consumption.

Furthermore, the integration of solenoid valves in safety mechanisms enhances the overall resilience of nuclear power plants against natural disasters and other external threats. This increased robustness reduces the likelihood of catastrophic events that could have severe and long-lasting environmental consequences.

However, it is important to note that the production and disposal of solenoid valves themselves have environmental considerations. The manufacturing process involves the use of various materials, including metals and plastics, which have their own environmental footprints. Additionally, the eventual decommissioning and replacement of these components must be managed responsibly to minimize waste and potential environmental impacts.

In the context of nuclear waste management, solenoid valves contribute to improved handling and storage processes. Their precise control capabilities enable more accurate monitoring and manipulation of radioactive materials, reducing the risk of accidental releases during waste processing and storage operations.

The implementation of solenoid valves also supports the development of advanced reactor designs, including small modular reactors (SMRs) and Generation IV reactors. These innovative designs often incorporate passive safety features that rely on natural phenomena like gravity and convection, which can be further enhanced by the precise control offered by solenoid valves. This evolution in reactor technology has the potential to reduce the environmental footprint of nuclear power generation significantly.

From an environmental perspective, the enhanced control provided by solenoid valves contributes to the prevention of potential leaks or releases of radioactive materials. By ensuring precise and rapid actuation of safety systems, these valves help maintain the integrity of containment structures and minimize the risk of environmental contamination. This is particularly important in the event of abnormal operating conditions or emergency situations.

The improved reliability and responsiveness of solenoid valves also contribute to more efficient plant operations. This efficiency translates to reduced energy consumption and, consequently, a lower carbon footprint associated with nuclear power generation. By optimizing coolant flow and other processes, solenoid valves help maximize the energy output while minimizing waste and resource consumption.

Furthermore, the integration of solenoid valves in safety mechanisms enhances the overall resilience of nuclear power plants against natural disasters and other external threats. This increased robustness reduces the likelihood of catastrophic events that could have severe and long-lasting environmental consequences.

However, it is important to note that the production and disposal of solenoid valves themselves have environmental considerations. The manufacturing process involves the use of various materials, including metals and plastics, which have their own environmental footprints. Additionally, the eventual decommissioning and replacement of these components must be managed responsibly to minimize waste and potential environmental impacts.

In the context of nuclear waste management, solenoid valves contribute to improved handling and storage processes. Their precise control capabilities enable more accurate monitoring and manipulation of radioactive materials, reducing the risk of accidental releases during waste processing and storage operations.

The implementation of solenoid valves also supports the development of advanced reactor designs, including small modular reactors (SMRs) and Generation IV reactors. These innovative designs often incorporate passive safety features that rely on natural phenomena like gravity and convection, which can be further enhanced by the precise control offered by solenoid valves. This evolution in reactor technology has the potential to reduce the environmental footprint of nuclear power generation significantly.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!