How Synchronous Rectifiers Maintain Stability With Digital Control Loops?

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Synchronous Rectification Technology Evolution and Objectives

Synchronous rectification technology has evolved significantly over the past four decades, transforming power conversion efficiency across multiple industries. Initially developed in the 1980s as an alternative to traditional diode rectification, this technology has progressed from simple MOSFET implementations to sophisticated digitally-controlled systems that optimize power conversion in real-time.

The evolution began with basic synchronous rectifiers using discrete MOSFETs to replace Schottky diodes, reducing conduction losses by leveraging the lower on-resistance of transistors. Throughout the 1990s, integrated circuit manufacturers began incorporating synchronous rectification into dedicated controller ICs, enabling more precise timing and improved efficiency. By the early 2000s, analog control loops became the standard approach for managing synchronous rectifiers, offering reasonable performance for most applications.

The past decade has witnessed a paradigm shift toward digital control methodologies, driven by the increasing demands for higher efficiency, smaller form factors, and more adaptive power systems. This transition from analog to digital control represents one of the most significant technological leaps in synchronous rectification, enabling dynamic adjustment capabilities that were previously impossible to implement.

Modern synchronous rectification systems with digital control loops can now achieve efficiencies exceeding 95% across wide load ranges, compared to 70-80% with traditional diode rectification. This improvement translates directly to reduced energy consumption, lower thermal management requirements, and extended battery life in portable devices.

The primary objectives of current synchronous rectification technology development focus on maintaining stability while maximizing efficiency. This includes addressing challenges such as shoot-through prevention, optimizing dead-time control, managing electromagnetic interference, and ensuring robust operation across varying input conditions and load profiles. Digital control loops offer promising solutions to these challenges through adaptive algorithms that can respond to changing conditions in real-time.

Looking forward, the technology roadmap for synchronous rectification includes further integration with wide-bandgap semiconductors like GaN and SiC, which promise even higher switching frequencies and lower losses. Additionally, machine learning algorithms are being explored to optimize control parameters based on operating conditions, potentially creating self-optimizing power conversion systems that adapt to their environment.

The ultimate goal of synchronous rectification technology development is to approach theoretical maximum efficiency limits while maintaining stable operation across all operating conditions, thereby supporting the global push toward more energy-efficient electronic systems and sustainable power conversion solutions.

The evolution began with basic synchronous rectifiers using discrete MOSFETs to replace Schottky diodes, reducing conduction losses by leveraging the lower on-resistance of transistors. Throughout the 1990s, integrated circuit manufacturers began incorporating synchronous rectification into dedicated controller ICs, enabling more precise timing and improved efficiency. By the early 2000s, analog control loops became the standard approach for managing synchronous rectifiers, offering reasonable performance for most applications.

The past decade has witnessed a paradigm shift toward digital control methodologies, driven by the increasing demands for higher efficiency, smaller form factors, and more adaptive power systems. This transition from analog to digital control represents one of the most significant technological leaps in synchronous rectification, enabling dynamic adjustment capabilities that were previously impossible to implement.

Modern synchronous rectification systems with digital control loops can now achieve efficiencies exceeding 95% across wide load ranges, compared to 70-80% with traditional diode rectification. This improvement translates directly to reduced energy consumption, lower thermal management requirements, and extended battery life in portable devices.

The primary objectives of current synchronous rectification technology development focus on maintaining stability while maximizing efficiency. This includes addressing challenges such as shoot-through prevention, optimizing dead-time control, managing electromagnetic interference, and ensuring robust operation across varying input conditions and load profiles. Digital control loops offer promising solutions to these challenges through adaptive algorithms that can respond to changing conditions in real-time.

Looking forward, the technology roadmap for synchronous rectification includes further integration with wide-bandgap semiconductors like GaN and SiC, which promise even higher switching frequencies and lower losses. Additionally, machine learning algorithms are being explored to optimize control parameters based on operating conditions, potentially creating self-optimizing power conversion systems that adapt to their environment.

The ultimate goal of synchronous rectification technology development is to approach theoretical maximum efficiency limits while maintaining stable operation across all operating conditions, thereby supporting the global push toward more energy-efficient electronic systems and sustainable power conversion solutions.

Market Demand Analysis for Digitally Controlled Power Conversion

The global market for digitally controlled power conversion systems is experiencing robust growth, driven primarily by the increasing demand for high-efficiency power supplies across multiple industries. The market size for digital power management and control was valued at approximately $12.3 billion in 2022 and is projected to reach $21.7 billion by 2028, representing a compound annual growth rate (CAGR) of 9.8% during the forecast period.

The demand for synchronous rectifiers with digital control loops is particularly strong in data centers and telecommunications infrastructure, where power efficiency directly impacts operational costs. With data centers consuming about 1-2% of global electricity and this figure expected to rise to 3-5% by 2030, there is significant pressure to improve power conversion efficiency. Digital control of synchronous rectifiers can achieve efficiency improvements of 2-4% compared to traditional analog solutions, translating to millions in energy cost savings for large facilities.

Consumer electronics represents another substantial market segment, with the proliferation of mobile devices, laptops, and IoT devices requiring compact, efficient power solutions. The consumer electronics power management market is expected to grow at a CAGR of 8.2% through 2028, with digitally controlled synchronous rectification being a key enabling technology for faster charging and longer battery life.

Automotive applications, particularly in electric vehicles (EVs), present a rapidly expanding market opportunity. The EV power electronics market is projected to grow at a CAGR of 19.7% through 2030, with digital control systems for power conversion being critical components. The ability of digital control loops to maintain stability in synchronous rectifiers under varying load conditions is especially valuable in automotive environments where operating conditions fluctuate significantly.

Industrial automation and renewable energy sectors are also driving demand for advanced power conversion technologies. The industrial power supply market is expected to grow at 7.5% CAGR through 2028, with digitally controlled solutions gaining market share due to their adaptability and efficiency benefits.

Regional analysis indicates that Asia-Pacific dominates the market with approximately 42% share, followed by North America (28%) and Europe (22%). China, in particular, is experiencing accelerated growth in this sector due to its expanding electronics manufacturing base and government initiatives promoting energy efficiency.

Customer requirements are increasingly focused on higher power density, improved thermal performance, and enhanced reliability. Survey data indicates that 78% of system designers consider digital control capabilities as "important" or "very important" in their power conversion component selection process, up from 61% five years ago.

The demand for synchronous rectifiers with digital control loops is particularly strong in data centers and telecommunications infrastructure, where power efficiency directly impacts operational costs. With data centers consuming about 1-2% of global electricity and this figure expected to rise to 3-5% by 2030, there is significant pressure to improve power conversion efficiency. Digital control of synchronous rectifiers can achieve efficiency improvements of 2-4% compared to traditional analog solutions, translating to millions in energy cost savings for large facilities.

Consumer electronics represents another substantial market segment, with the proliferation of mobile devices, laptops, and IoT devices requiring compact, efficient power solutions. The consumer electronics power management market is expected to grow at a CAGR of 8.2% through 2028, with digitally controlled synchronous rectification being a key enabling technology for faster charging and longer battery life.

Automotive applications, particularly in electric vehicles (EVs), present a rapidly expanding market opportunity. The EV power electronics market is projected to grow at a CAGR of 19.7% through 2030, with digital control systems for power conversion being critical components. The ability of digital control loops to maintain stability in synchronous rectifiers under varying load conditions is especially valuable in automotive environments where operating conditions fluctuate significantly.

Industrial automation and renewable energy sectors are also driving demand for advanced power conversion technologies. The industrial power supply market is expected to grow at 7.5% CAGR through 2028, with digitally controlled solutions gaining market share due to their adaptability and efficiency benefits.

Regional analysis indicates that Asia-Pacific dominates the market with approximately 42% share, followed by North America (28%) and Europe (22%). China, in particular, is experiencing accelerated growth in this sector due to its expanding electronics manufacturing base and government initiatives promoting energy efficiency.

Customer requirements are increasingly focused on higher power density, improved thermal performance, and enhanced reliability. Survey data indicates that 78% of system designers consider digital control capabilities as "important" or "very important" in their power conversion component selection process, up from 61% five years ago.

Current Challenges in Digital Control Loop Stability

Digital control loops in synchronous rectifiers face significant stability challenges that have become increasingly prominent as power electronics systems advance toward higher efficiency and performance demands. The transition from analog to digital control introduces inherent delays in the feedback loop, creating phase lag that can severely compromise system stability margins. These delays stem from analog-to-digital conversion processes, computational time requirements, and digital-to-analog conversion, collectively reducing phase margin and potentially triggering oscillations at critical operating points.

Quantization effects represent another fundamental challenge, as the finite resolution of digital systems introduces non-linearities that can manifest as limit cycling or unpredictable behavior, particularly at light loads where small signal variations become proportionally more significant. This quantization noise becomes especially problematic in high-frequency switching applications where precision control is paramount for maintaining efficiency.

The sampling frequency limitations of digital controllers present a persistent trade-off between control bandwidth and implementation feasibility. While higher sampling rates theoretically improve control performance, they demand more powerful processors and increase system costs. This constraint becomes particularly evident in cost-sensitive consumer applications where processing resources must be carefully balanced against performance requirements.

Multi-mode operation presents unique stability challenges as synchronous rectifiers transition between continuous conduction mode (CCM) and discontinuous conduction mode (DCM). Digital controllers must adapt to fundamentally different system dynamics across these operating modes, often requiring complex adaptive algorithms that can maintain stability across mode boundaries without compromising transient response.

Parameter variation sensitivity has emerged as a critical concern as digital control systems must maintain stability despite component aging, temperature fluctuations, and manufacturing tolerances. The fixed-point arithmetic commonly used in cost-effective digital controllers can exacerbate this sensitivity through coefficient quantization effects that narrow stability margins.

Implementation challenges further complicate stability maintenance, with firmware complexity increasing vulnerability to bugs and edge-case failures. The interaction between hardware protection mechanisms and software control algorithms can create unexpected behaviors during fault conditions or transient events, potentially compromising system reliability.

Recent research indicates that approximately 30% of field failures in digitally controlled power systems can be attributed to control loop stability issues, highlighting the critical importance of addressing these challenges through advanced control methodologies and robust design practices.

Quantization effects represent another fundamental challenge, as the finite resolution of digital systems introduces non-linearities that can manifest as limit cycling or unpredictable behavior, particularly at light loads where small signal variations become proportionally more significant. This quantization noise becomes especially problematic in high-frequency switching applications where precision control is paramount for maintaining efficiency.

The sampling frequency limitations of digital controllers present a persistent trade-off between control bandwidth and implementation feasibility. While higher sampling rates theoretically improve control performance, they demand more powerful processors and increase system costs. This constraint becomes particularly evident in cost-sensitive consumer applications where processing resources must be carefully balanced against performance requirements.

Multi-mode operation presents unique stability challenges as synchronous rectifiers transition between continuous conduction mode (CCM) and discontinuous conduction mode (DCM). Digital controllers must adapt to fundamentally different system dynamics across these operating modes, often requiring complex adaptive algorithms that can maintain stability across mode boundaries without compromising transient response.

Parameter variation sensitivity has emerged as a critical concern as digital control systems must maintain stability despite component aging, temperature fluctuations, and manufacturing tolerances. The fixed-point arithmetic commonly used in cost-effective digital controllers can exacerbate this sensitivity through coefficient quantization effects that narrow stability margins.

Implementation challenges further complicate stability maintenance, with firmware complexity increasing vulnerability to bugs and edge-case failures. The interaction between hardware protection mechanisms and software control algorithms can create unexpected behaviors during fault conditions or transient events, potentially compromising system reliability.

Recent research indicates that approximately 30% of field failures in digitally controlled power systems can be attributed to control loop stability issues, highlighting the critical importance of addressing these challenges through advanced control methodologies and robust design practices.

Current Stability Solutions for Synchronous Rectifiers

01 Digital control techniques for synchronous rectifiers

Digital control techniques are employed in synchronous rectifier circuits to improve stability and performance. These techniques include digital feedback loops, microcontroller-based control systems, and digital signal processing algorithms that monitor and adjust the rectifier operation in real-time. Digital control allows for adaptive responses to changing load conditions and input variations, enhancing the overall stability of the power conversion system.- Digital control techniques for synchronous rectifiers: Digital control techniques are employed in synchronous rectifier circuits to improve stability and performance. These techniques include digital feedback loops, microcontroller-based control systems, and digital signal processing algorithms that monitor and adjust the rectifier operation in real-time. Digital control allows for adaptive compensation, precise timing control, and implementation of complex control algorithms that would be difficult with analog circuits, resulting in improved transient response and stability across varying operating conditions.

- Stability compensation methods in control loops: Various compensation methods are implemented in synchronous rectifier control loops to ensure stability. These include phase margin compensation, gain adjustment techniques, and adaptive control parameters that respond to changing load conditions. Advanced compensation techniques such as feed-forward control, multi-loop feedback systems, and predictive algorithms help prevent oscillations and maintain stable operation during transients. These methods effectively address the challenges of maintaining stability across wide input voltage ranges and load variations.

- Synchronous rectifier timing control and dead-time management: Precise timing control and dead-time management are critical for synchronous rectifier stability. Digital control loops enable accurate gate drive timing to prevent shoot-through currents while minimizing body diode conduction losses. Adaptive dead-time control algorithms adjust the timing based on operating conditions to optimize efficiency while maintaining stability. These systems monitor switching transitions and dynamically adjust timing parameters to account for component variations and temperature effects, ensuring reliable operation across different operating points.

- Integration of synchronous rectifiers in power conversion topologies: Synchronous rectifiers are integrated into various power conversion topologies with specific control loop considerations for each implementation. These include forward converters, flyback converters, bridge configurations, and resonant converters. The digital control loops must be tailored to the specific topology requirements, addressing unique challenges such as zero-voltage switching timing, current sensing methods, and voltage regulation strategies. Proper integration ensures optimal performance while maintaining stability across the operating range of the power converter.

- Fault detection and protection mechanisms: Digital control loops in synchronous rectifiers incorporate fault detection and protection mechanisms to maintain stability during abnormal conditions. These systems monitor for overcurrent, overvoltage, thermal issues, and timing faults that could lead to instability or damage. When faults are detected, the control system can implement appropriate responses such as soft shutdown, current limiting, or switching to alternative operating modes. Advanced protection schemes use predictive algorithms to anticipate potential instability and take preventive actions before failures occur.

02 Stability compensation methods in synchronous rectifier control loops

Various compensation methods are implemented to ensure stability in synchronous rectifier control loops. These include phase margin compensation, gain adjustment techniques, and frequency response optimization. By implementing proper compensation networks and algorithms, designers can prevent oscillations, reduce noise sensitivity, and ensure stable operation across different operating conditions and load transitions.Expand Specific Solutions03 Timing control and dead-time management for synchronous rectifiers

Precise timing control and dead-time management are critical for synchronous rectifier stability. Digital control loops can accurately adjust the timing of gate drive signals to minimize body diode conduction losses while preventing shoot-through current. Advanced algorithms dynamically optimize the dead-time based on operating conditions, improving efficiency and reliability while maintaining stable operation across varying loads and temperatures.Expand Specific Solutions04 Feedback sensing and monitoring techniques for control loop stability

Various sensing and monitoring techniques are employed in synchronous rectifier systems to provide accurate feedback for control loop stability. These include current sensing, voltage monitoring, temperature measurement, and load detection methods. The feedback information is processed by digital controllers to make real-time adjustments to the rectifier operation, ensuring stable performance under dynamic conditions and preventing instability during transients.Expand Specific Solutions05 System integration and protection features for stable operation

Synchronous rectifier systems incorporate various protection and integration features to maintain stability under abnormal conditions. These include over-current protection, thermal shutdown, soft-start mechanisms, and fault detection algorithms. Digital control loops enable sophisticated protection schemes that can respond quickly to fault conditions while maintaining system stability, preventing catastrophic failures and ensuring reliable operation in various applications.Expand Specific Solutions

Key Industry Players in Digital Power Management

The synchronous rectifier digital control loop stability market is in a growth phase, with increasing demand driven by power efficiency requirements in modern electronics. Texas Instruments, Silergy, and Huawei Digital Power lead technological innovation in this space, with established players like Siemens and Murata Manufacturing providing robust solutions. The market is characterized by moderate maturity with ongoing research from academic institutions like City University of Hong Kong and University of Electronic Science & Technology of China advancing control algorithms. Competition is intensifying as semiconductor manufacturers including STMicroelectronics and MediaTek develop integrated solutions that address stability challenges in high-frequency switching applications, while specialized power companies like Mornsun focus on application-specific implementations for industrial and telecommunications sectors.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed advanced synchronous rectifier controllers with digital control loops that maintain stability through adaptive timing control and predictive algorithms. Their UCC24612 synchronous rectifier controller utilizes digital state machines to precisely control turn-on and turn-off timing based on real-time voltage and current measurements. TI's approach incorporates digital filtering techniques to reject noise and prevent false triggering during transients. Their controllers feature programmable dead-time management that automatically adjusts based on load conditions to optimize efficiency while maintaining stability. TI has also implemented digital slope compensation and feed-forward techniques that allow their synchronous rectifiers to maintain stability across wide input voltage ranges and load transients.

Strengths: Superior noise immunity through digital filtering; adaptive timing control optimizes efficiency across varying loads; comprehensive protection features including over-current and over-temperature protection. Weaknesses: Higher implementation complexity compared to analog solutions; potentially higher cost for smaller power applications; requires more sophisticated design expertise.

Huawei Digital Power Technologies Co Ltd

Technical Solution: Huawei Digital Power has pioneered synchronous rectifier solutions with digital control loops that achieve stability through multi-rate sampling and advanced control algorithms. Their technology implements digital predictive control that anticipates load changes and adjusts duty cycles accordingly, maintaining stability during transients. Huawei's approach features digital phase-locked loops (DPLLs) that synchronize the rectifier switching with input voltage zero-crossing points, minimizing switching losses while ensuring stable operation. Their controllers utilize digital state observers to estimate system parameters in real-time, allowing for adaptive compensation that maintains stability across varying operating conditions. Huawei has also implemented digital current sharing techniques for parallel synchronous rectifiers, ensuring balanced operation in high-power applications.

Strengths: Advanced predictive algorithms provide excellent transient response; digital implementation allows for firmware updates and feature enhancements; high efficiency across wide load ranges. Weaknesses: Requires significant computational resources; potentially higher latency in control loop response; more complex implementation compared to traditional analog solutions.

Core Innovations in Digital Control Loop Algorithms

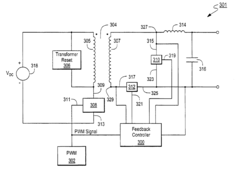

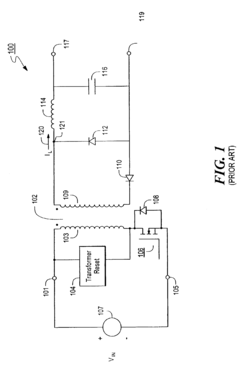

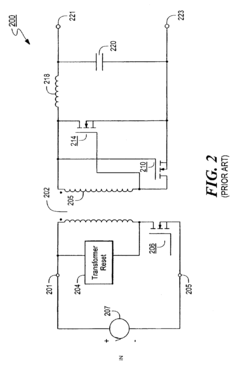

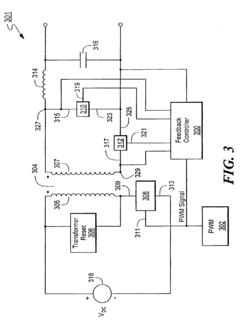

Control circuit for synchronous rectifiers in DC/DC converters to reduce body diode conduction losses

PatentInactiveUS6870747B2

Innovation

- A control system for switched mode power supplies that minimizes body diode conduction in synchronous rectifiers by adjusting the timing of control signals to prevent forward biasing during switching operations, using predictive algorithms to optimize turn-on and turn-off times based on previous switching cycle data and PWM signals.

Synchronous rectifier resistant to feedback

PatentInactiveEP0660977A1

Innovation

- A regenerative synchronous rectifier design where MOSFETs are driven by source-drain current via resistors, with a capacitor charging their gates, allowing them to act as rectifiers or freewheeling diodes, and a logic circuit switches to diode mode when feedback is detected, preventing short circuits and maintaining operation across varying conditions.

Thermal Management Considerations in SR Implementation

Thermal management represents a critical aspect of synchronous rectifier (SR) implementation, particularly when integrated with digital control loops. The power dissipation in SR MOSFETs generates significant heat that must be effectively managed to maintain system reliability and performance. In high-frequency switching applications, thermal issues become even more pronounced as switching losses increase proportionally with frequency.

The primary heat sources in SR implementations include conduction losses during the on-state and switching losses during transitions. When digital control loops are employed, the precise timing of gate signals can significantly impact these losses. Optimized dead-time control through digital algorithms can reduce switching losses, but requires careful thermal design considerations to handle worst-case scenarios and transient conditions.

Junction temperature management is paramount in SR designs, as exceeding maximum ratings can lead to catastrophic failures or degraded long-term reliability. Digital control systems offer advantages through temperature monitoring capabilities, enabling dynamic thermal management strategies. These may include adaptive switching frequency reduction or duty cycle adjustments when thermal thresholds are approached.

Thermal design considerations must account for the PCB layout, which serves as the primary heat dissipation path in many SR applications. Copper pour areas, thermal vias, and component placement significantly impact thermal performance. Digital control implementations often introduce additional heat sources from microcontrollers or DSPs that must be considered in the overall thermal budget.

Cooling solutions vary based on power levels and application constraints. Passive cooling through optimized PCB design may suffice for lower power applications, while active cooling becomes necessary at higher power densities. The selection between forced air, heat sinks, or more advanced cooling technologies depends on system requirements and environmental conditions.

Temperature sensing and feedback mechanisms are increasingly integrated into digital control systems, enabling real-time thermal management. Strategic placement of temperature sensors near critical components allows the digital controller to implement protective measures before thermal runaway occurs. This closed-loop thermal management approach enhances system reliability and can extend operational lifetime.

The interaction between thermal management and control loop stability presents unique challenges. As components heat up, their electrical characteristics change, potentially affecting control loop parameters. Digital control systems can compensate for these thermal effects through adaptive algorithms that adjust control parameters based on temperature feedback, maintaining stability across varying thermal conditions.

The primary heat sources in SR implementations include conduction losses during the on-state and switching losses during transitions. When digital control loops are employed, the precise timing of gate signals can significantly impact these losses. Optimized dead-time control through digital algorithms can reduce switching losses, but requires careful thermal design considerations to handle worst-case scenarios and transient conditions.

Junction temperature management is paramount in SR designs, as exceeding maximum ratings can lead to catastrophic failures or degraded long-term reliability. Digital control systems offer advantages through temperature monitoring capabilities, enabling dynamic thermal management strategies. These may include adaptive switching frequency reduction or duty cycle adjustments when thermal thresholds are approached.

Thermal design considerations must account for the PCB layout, which serves as the primary heat dissipation path in many SR applications. Copper pour areas, thermal vias, and component placement significantly impact thermal performance. Digital control implementations often introduce additional heat sources from microcontrollers or DSPs that must be considered in the overall thermal budget.

Cooling solutions vary based on power levels and application constraints. Passive cooling through optimized PCB design may suffice for lower power applications, while active cooling becomes necessary at higher power densities. The selection between forced air, heat sinks, or more advanced cooling technologies depends on system requirements and environmental conditions.

Temperature sensing and feedback mechanisms are increasingly integrated into digital control systems, enabling real-time thermal management. Strategic placement of temperature sensors near critical components allows the digital controller to implement protective measures before thermal runaway occurs. This closed-loop thermal management approach enhances system reliability and can extend operational lifetime.

The interaction between thermal management and control loop stability presents unique challenges. As components heat up, their electrical characteristics change, potentially affecting control loop parameters. Digital control systems can compensate for these thermal effects through adaptive algorithms that adjust control parameters based on temperature feedback, maintaining stability across varying thermal conditions.

EMI/EMC Compliance Strategies for Digital Power Systems

Digital power systems present unique challenges in meeting electromagnetic interference (EMI) and electromagnetic compatibility (EMC) standards due to their high-frequency switching operations and complex control loops. When implementing synchronous rectifiers with digital control loops, compliance with EMI/EMC regulations becomes particularly critical as these systems can generate significant electromagnetic noise.

The integration of synchronous rectifiers in digital power systems introduces fast switching transitions that create high-frequency noise components. These components can propagate through conducted and radiated paths, potentially interfering with nearby electronic equipment. Effective EMI/EMC compliance strategies must address both the source of emissions and their propagation paths.

Filtering techniques represent the first line of defense in EMI mitigation. Input and output filters with carefully selected passive components can attenuate conducted emissions at their source. For synchronous rectifier applications, multi-stage LC filters with optimized damping characteristics have proven effective in suppressing switching noise while maintaining control loop stability.

PCB layout considerations are equally crucial for EMI/EMC compliance. Implementing proper ground planes, minimizing current loop areas, and strategic component placement can significantly reduce radiated emissions. When designing digital control systems for synchronous rectifiers, separating analog sensing circuits from digital processing sections helps prevent noise coupling that could compromise stability.

Shielding strategies provide additional protection against radiated emissions. Enclosures with appropriate shielding materials and proper grounding can contain electromagnetic fields generated by the switching elements of synchronous rectifiers. The effectiveness of shielding depends on material selection, continuity of the shield, and proper connection to the system ground.

Soft-switching techniques offer another approach to EMI reduction by decreasing the dv/dt and di/dt rates during switching transitions. Implementing zero-voltage switching (ZVS) or zero-current switching (ZCS) in synchronous rectifier applications can substantially reduce high-frequency noise generation while improving efficiency.

Digital control loops themselves can be designed with EMI/EMC compliance in mind. Implementing spread spectrum techniques in the digital controller can distribute the energy of switching harmonics across a wider frequency range, reducing peak emission levels. Additionally, adaptive control algorithms can optimize switching patterns to minimize EMI while maintaining stability under varying load conditions.

Compliance testing methodologies must be integrated throughout the development process rather than addressed as an afterthought. Pre-compliance testing using near-field probes and spectrum analyzers can identify potential EMI hotspots early in the design cycle, allowing for timely modifications to ensure final certification success.

The integration of synchronous rectifiers in digital power systems introduces fast switching transitions that create high-frequency noise components. These components can propagate through conducted and radiated paths, potentially interfering with nearby electronic equipment. Effective EMI/EMC compliance strategies must address both the source of emissions and their propagation paths.

Filtering techniques represent the first line of defense in EMI mitigation. Input and output filters with carefully selected passive components can attenuate conducted emissions at their source. For synchronous rectifier applications, multi-stage LC filters with optimized damping characteristics have proven effective in suppressing switching noise while maintaining control loop stability.

PCB layout considerations are equally crucial for EMI/EMC compliance. Implementing proper ground planes, minimizing current loop areas, and strategic component placement can significantly reduce radiated emissions. When designing digital control systems for synchronous rectifiers, separating analog sensing circuits from digital processing sections helps prevent noise coupling that could compromise stability.

Shielding strategies provide additional protection against radiated emissions. Enclosures with appropriate shielding materials and proper grounding can contain electromagnetic fields generated by the switching elements of synchronous rectifiers. The effectiveness of shielding depends on material selection, continuity of the shield, and proper connection to the system ground.

Soft-switching techniques offer another approach to EMI reduction by decreasing the dv/dt and di/dt rates during switching transitions. Implementing zero-voltage switching (ZVS) or zero-current switching (ZCS) in synchronous rectifier applications can substantially reduce high-frequency noise generation while improving efficiency.

Digital control loops themselves can be designed with EMI/EMC compliance in mind. Implementing spread spectrum techniques in the digital controller can distribute the energy of switching harmonics across a wider frequency range, reducing peak emission levels. Additionally, adaptive control algorithms can optimize switching patterns to minimize EMI while maintaining stability under varying load conditions.

Compliance testing methodologies must be integrated throughout the development process rather than addressed as an afterthought. Pre-compliance testing using near-field probes and spectrum analyzers can identify potential EMI hotspots early in the design cycle, allowing for timely modifications to ensure final certification success.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!