Synchronous Rectifier Start-Up/Shutdown: Pre-Bias, Sequencing And Inrush

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Synchronous Rectifier Technology Background and Objectives

Synchronous rectification technology has evolved significantly over the past three decades, transforming power conversion efficiency in modern electronics. Originally developed in the 1990s as an alternative to traditional diode rectification, synchronous rectifiers (SRs) utilize MOSFETs to reduce conduction losses by replacing diodes with low-resistance switches. This technological advancement has been critical in meeting the increasing power density and efficiency demands of contemporary electronic systems.

The evolution of synchronous rectification has been driven by the exponential growth in computing power and the miniaturization of electronic devices. As processors and other components require lower voltages at higher currents, the efficiency limitations of conventional diode rectification became increasingly apparent. The forward voltage drop of diodes (typically 0.4-0.7V) represents a significant efficiency loss when converting to low output voltages, particularly in high-current applications.

Synchronous rectification addresses this challenge by reducing conduction losses by up to 70% compared to Schottky diodes. This improvement has enabled power supply efficiencies exceeding 95% in many applications, contributing significantly to energy conservation in data centers, telecommunications equipment, and consumer electronics.

However, the implementation of synchronous rectifiers introduces complex control challenges, particularly during startup and shutdown sequences. Pre-bias conditions, where voltage exists on the output before the converter starts, can cause significant current spikes and potential component damage if not properly managed. Similarly, inrush current during startup and sequencing issues in multi-rail power systems present substantial technical hurdles.

The industry trend toward higher switching frequencies to reduce component size has further complicated SR timing control, requiring nanosecond-level precision in gate drive signals. Additionally, the proliferation of distributed power architectures has increased the importance of proper SR behavior during abnormal operating conditions.

The primary technical objectives in synchronous rectifier startup/shutdown management include: developing robust control algorithms that prevent shoot-through currents during transitions; creating adaptive timing systems that accommodate varying load conditions; implementing effective pre-bias protection to prevent reverse current flow; designing intelligent sequencing protocols for multi-phase systems; and minimizing inrush current without compromising response time.

Future development in this field is expected to focus on integration of advanced sensing techniques, implementation of predictive control algorithms, and development of self-adaptive systems that can optimize performance across varying operating conditions. These advancements will be crucial for meeting the efficiency and reliability requirements of next-generation power systems in applications ranging from artificial intelligence processors to electric vehicle charging infrastructure.

The evolution of synchronous rectification has been driven by the exponential growth in computing power and the miniaturization of electronic devices. As processors and other components require lower voltages at higher currents, the efficiency limitations of conventional diode rectification became increasingly apparent. The forward voltage drop of diodes (typically 0.4-0.7V) represents a significant efficiency loss when converting to low output voltages, particularly in high-current applications.

Synchronous rectification addresses this challenge by reducing conduction losses by up to 70% compared to Schottky diodes. This improvement has enabled power supply efficiencies exceeding 95% in many applications, contributing significantly to energy conservation in data centers, telecommunications equipment, and consumer electronics.

However, the implementation of synchronous rectifiers introduces complex control challenges, particularly during startup and shutdown sequences. Pre-bias conditions, where voltage exists on the output before the converter starts, can cause significant current spikes and potential component damage if not properly managed. Similarly, inrush current during startup and sequencing issues in multi-rail power systems present substantial technical hurdles.

The industry trend toward higher switching frequencies to reduce component size has further complicated SR timing control, requiring nanosecond-level precision in gate drive signals. Additionally, the proliferation of distributed power architectures has increased the importance of proper SR behavior during abnormal operating conditions.

The primary technical objectives in synchronous rectifier startup/shutdown management include: developing robust control algorithms that prevent shoot-through currents during transitions; creating adaptive timing systems that accommodate varying load conditions; implementing effective pre-bias protection to prevent reverse current flow; designing intelligent sequencing protocols for multi-phase systems; and minimizing inrush current without compromising response time.

Future development in this field is expected to focus on integration of advanced sensing techniques, implementation of predictive control algorithms, and development of self-adaptive systems that can optimize performance across varying operating conditions. These advancements will be crucial for meeting the efficiency and reliability requirements of next-generation power systems in applications ranging from artificial intelligence processors to electric vehicle charging infrastructure.

Market Demand Analysis for SR Solutions

The global market for Synchronous Rectifier (SR) solutions has experienced significant growth in recent years, driven primarily by the increasing demand for high-efficiency power conversion systems across multiple industries. The power electronics market, within which SR technology plays a crucial role, is projected to reach $25 billion by 2025, with a compound annual growth rate of approximately 6.5%.

The demand for SR solutions is particularly strong in consumer electronics, telecommunications, automotive, and industrial sectors. Consumer electronics, including smartphones, tablets, and laptops, represent the largest market segment, accounting for nearly 40% of the total SR market. This is attributed to the continuous miniaturization of devices coupled with increasing power requirements, necessitating more efficient power conversion solutions.

Data center and server applications have emerged as the fastest-growing segment for SR technology, with an estimated growth rate of 9% annually. This surge is driven by the exponential increase in cloud computing services and the critical need to reduce power consumption in data centers, where even marginal efficiency improvements translate to significant operational cost savings.

The automotive sector presents another substantial growth opportunity for SR solutions, particularly with the rapid expansion of electric vehicles (EVs) and hybrid electric vehicles (HEVs). The EV charging infrastructure alone is expected to create a $2 billion market for advanced power conversion technologies by 2026, with SR solutions being integral components.

Market research indicates that customers across all segments are increasingly prioritizing specific performance aspects of SR solutions. These include higher efficiency at light loads, improved thermal performance, enhanced reliability during start-up and shutdown conditions, and better handling of pre-bias conditions. A survey of power supply designers revealed that 78% consider proper handling of pre-bias conditions and inrush current management as "very important" or "critical" features when selecting SR controllers.

Regional analysis shows that Asia-Pacific dominates the SR market with approximately 55% share, followed by North America and Europe. China, in particular, has seen tremendous growth in SR adoption, driven by its massive electronics manufacturing industry and government initiatives promoting energy efficiency.

The market is also witnessing increasing demand for integrated SR solutions that address the complex challenges of pre-bias conditions, sequencing, and inrush current management in a single package. This trend is reflected in the 35% premium that customers are willing to pay for SR solutions offering comprehensive protection features compared to basic alternatives.

The demand for SR solutions is particularly strong in consumer electronics, telecommunications, automotive, and industrial sectors. Consumer electronics, including smartphones, tablets, and laptops, represent the largest market segment, accounting for nearly 40% of the total SR market. This is attributed to the continuous miniaturization of devices coupled with increasing power requirements, necessitating more efficient power conversion solutions.

Data center and server applications have emerged as the fastest-growing segment for SR technology, with an estimated growth rate of 9% annually. This surge is driven by the exponential increase in cloud computing services and the critical need to reduce power consumption in data centers, where even marginal efficiency improvements translate to significant operational cost savings.

The automotive sector presents another substantial growth opportunity for SR solutions, particularly with the rapid expansion of electric vehicles (EVs) and hybrid electric vehicles (HEVs). The EV charging infrastructure alone is expected to create a $2 billion market for advanced power conversion technologies by 2026, with SR solutions being integral components.

Market research indicates that customers across all segments are increasingly prioritizing specific performance aspects of SR solutions. These include higher efficiency at light loads, improved thermal performance, enhanced reliability during start-up and shutdown conditions, and better handling of pre-bias conditions. A survey of power supply designers revealed that 78% consider proper handling of pre-bias conditions and inrush current management as "very important" or "critical" features when selecting SR controllers.

Regional analysis shows that Asia-Pacific dominates the SR market with approximately 55% share, followed by North America and Europe. China, in particular, has seen tremendous growth in SR adoption, driven by its massive electronics manufacturing industry and government initiatives promoting energy efficiency.

The market is also witnessing increasing demand for integrated SR solutions that address the complex challenges of pre-bias conditions, sequencing, and inrush current management in a single package. This trend is reflected in the 35% premium that customers are willing to pay for SR solutions offering comprehensive protection features compared to basic alternatives.

Current Challenges in SR Start-Up/Shutdown Operations

Synchronous rectifier (SR) technology has significantly improved power conversion efficiency in modern power supplies, but its start-up and shutdown operations present several critical challenges that impact system reliability and performance. One of the most significant issues is pre-bias handling, where a voltage exists at the output before the converter starts. When SR controllers fail to properly detect this condition, they may inadvertently enable the low-side MOSFET, creating a direct path to ground that discharges the output capacitors and potentially damages components.

Sequencing challenges represent another major concern in multi-rail power systems. When multiple voltage rails with synchronous rectifiers power up or down in incorrect order, cross-conduction between converters can occur. This phenomenon creates unwanted current paths that may lead to voltage spikes, excessive power dissipation, and even catastrophic failures in sensitive components. Current SR controllers often lack sophisticated sequencing capabilities to coordinate with other power rails.

Inrush current management during start-up poses a substantial challenge for SR implementations. The initial charging of output capacitors can draw excessive current through synchronous MOSFETs, potentially exceeding their safe operating area. This surge can trigger protection circuits, cause voltage droops, and in severe cases, damage the MOSFETs. Traditional solutions like soft-start mechanisms are often insufficient for SR applications due to their unique switching characteristics.

False triggering during transient events represents a persistent issue in SR operation. During start-up and shutdown, voltage and current waveforms contain noise and ringing that can cause SR controllers to incorrectly turn on MOSFETs at inappropriate times. This false triggering creates efficiency losses and potential reliability issues that are difficult to diagnose in field applications.

Temperature-dependent behavior further complicates SR operation. MOSFET characteristics vary significantly with temperature, affecting turn-on thresholds and timing parameters critical for safe start-up and shutdown. Current SR solutions often implement fixed timing parameters that cannot adapt to these temperature variations, leading to suboptimal performance across operating conditions.

Parasitic inductances in PCB layouts introduce additional complications during high-speed switching transitions typical in start-up and shutdown events. These inductances create voltage spikes that can falsely trigger SR gates or even damage gate drivers. As switching frequencies increase to improve efficiency, these parasitic effects become more pronounced and challenging to mitigate.

Addressing these challenges requires innovative approaches that combine advanced sensing techniques, adaptive control algorithms, and improved semiconductor technologies. The industry is actively seeking solutions that can provide robust operation across diverse operating conditions while maintaining the efficiency benefits that make synchronous rectification so valuable in modern power conversion systems.

Sequencing challenges represent another major concern in multi-rail power systems. When multiple voltage rails with synchronous rectifiers power up or down in incorrect order, cross-conduction between converters can occur. This phenomenon creates unwanted current paths that may lead to voltage spikes, excessive power dissipation, and even catastrophic failures in sensitive components. Current SR controllers often lack sophisticated sequencing capabilities to coordinate with other power rails.

Inrush current management during start-up poses a substantial challenge for SR implementations. The initial charging of output capacitors can draw excessive current through synchronous MOSFETs, potentially exceeding their safe operating area. This surge can trigger protection circuits, cause voltage droops, and in severe cases, damage the MOSFETs. Traditional solutions like soft-start mechanisms are often insufficient for SR applications due to their unique switching characteristics.

False triggering during transient events represents a persistent issue in SR operation. During start-up and shutdown, voltage and current waveforms contain noise and ringing that can cause SR controllers to incorrectly turn on MOSFETs at inappropriate times. This false triggering creates efficiency losses and potential reliability issues that are difficult to diagnose in field applications.

Temperature-dependent behavior further complicates SR operation. MOSFET characteristics vary significantly with temperature, affecting turn-on thresholds and timing parameters critical for safe start-up and shutdown. Current SR solutions often implement fixed timing parameters that cannot adapt to these temperature variations, leading to suboptimal performance across operating conditions.

Parasitic inductances in PCB layouts introduce additional complications during high-speed switching transitions typical in start-up and shutdown events. These inductances create voltage spikes that can falsely trigger SR gates or even damage gate drivers. As switching frequencies increase to improve efficiency, these parasitic effects become more pronounced and challenging to mitigate.

Addressing these challenges requires innovative approaches that combine advanced sensing techniques, adaptive control algorithms, and improved semiconductor technologies. The industry is actively seeking solutions that can provide robust operation across diverse operating conditions while maintaining the efficiency benefits that make synchronous rectification so valuable in modern power conversion systems.

Existing Solutions for Pre-Bias and Inrush Management

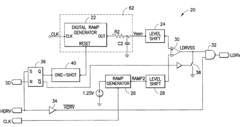

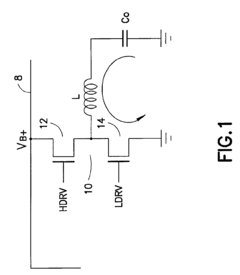

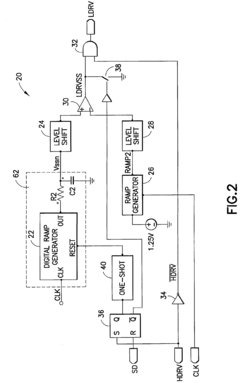

01 Synchronous rectifier control during startup/shutdown

Various control methods are implemented to manage synchronous rectifiers during startup and shutdown phases to prevent reverse current flow and ensure stable operation. These methods include timing control circuits, detection of voltage or current thresholds, and adaptive control algorithms that adjust gate drive signals based on operating conditions. Such control mechanisms help prevent shoot-through currents and improve overall efficiency during transient states.- Synchronous rectifier control during startup: Various techniques are employed to control synchronous rectifiers during the startup phase of power converters. These methods include delayed activation of synchronous rectifiers to prevent reverse current flow, soft-start mechanisms to gradually increase duty cycle, and detection circuits that monitor input voltage or primary side signals before enabling the synchronous rectifier. These approaches help prevent shoot-through currents and ensure stable operation during the critical startup period.

- Shutdown protection mechanisms: Shutdown protection mechanisms are implemented to safely disable synchronous rectifiers when the power converter is turned off or during fault conditions. These include circuits that detect decreasing output voltage, monitor primary side signals for shutdown indication, and implement fast turn-off capabilities to prevent reverse current flow. Some designs incorporate delay elements to ensure proper sequencing during shutdown, protecting the synchronous rectifier MOSFETs from damage.

- Gate drive optimization techniques: Gate drive optimization techniques focus on improving the switching performance of synchronous rectifiers during both startup and shutdown. These include adaptive gate drive circuits that adjust timing based on operating conditions, resonant gate drivers that reduce switching losses, and level-shifting circuits for high-side synchronous rectifiers. Some implementations use digital controllers to precisely time the gate signals, ensuring optimal efficiency across different operating modes.

- Sensing and detection circuits: Advanced sensing and detection circuits are employed to monitor operating conditions and control synchronous rectifiers accordingly. These include current sensing for overcurrent protection, voltage sensing for zero-voltage switching, and temperature monitoring to prevent thermal runaway. Some designs incorporate comparators with hysteresis to prevent oscillation during transitions, while others use digital signal processing for more sophisticated control algorithms.

- Integration with power management systems: Synchronous rectifier control is increasingly integrated with broader power management systems to enhance overall performance. These integrated solutions coordinate synchronous rectifier operation with other power conversion stages, implement power sequencing during startup and shutdown, and provide communication interfaces for system-level control. Some designs include programmable parameters that can be adjusted based on system requirements, enabling optimization for specific applications.

02 Protection circuits for synchronous rectifiers

Protection circuits are integrated into synchronous rectifier designs to prevent damage during startup and shutdown events. These circuits monitor operating parameters such as input voltage, output voltage, and current flow to detect abnormal conditions. When potential issues are detected, the protection circuits can disable the synchronous rectifier, implement soft-start procedures, or activate alternative operating modes to maintain safe operation and prevent component damage.Expand Specific Solutions03 Soft-start and soft-shutdown techniques

Soft-start and soft-shutdown techniques are employed to gradually enable or disable synchronous rectifiers, reducing stress on components and minimizing voltage/current spikes. These techniques often involve ramping gate drive voltages, implementing delay circuits, or using multi-stage activation sequences. By controlling the transition between operating states, these methods improve reliability and reduce electromagnetic interference during power cycling events.Expand Specific Solutions04 Gate drive optimization for transient states

Gate drive circuits for synchronous rectifiers are optimized to handle the unique requirements of startup and shutdown transitions. These optimizations include adaptive gate drive strength, variable timing control, and condition-based switching schemes. Advanced gate drivers may incorporate feedback mechanisms to adjust drive parameters based on load conditions, input voltage variations, or temperature changes, ensuring optimal performance during all operating phases.Expand Specific Solutions05 Dead-time management during transitions

Dead-time management techniques are implemented to prevent shoot-through currents during switching transitions in synchronous rectifiers. These techniques ensure that complementary switches are never simultaneously conducting by introducing precisely controlled delays between switching events. Advanced dead-time control may include adaptive algorithms that adjust timing based on operating conditions, improving efficiency while maintaining safe operation during startup and shutdown sequences.Expand Specific Solutions

Key Industry Players in SR Controller Market

The synchronous rectifier start-up/shutdown technology market is currently in a growth phase, with increasing demand driven by power efficiency requirements in modern electronics. The market size is expanding rapidly as power management becomes critical in various applications. Leading players include established semiconductor manufacturers like Texas Instruments, NXP Semiconductors, and Microchip Technology, who offer comprehensive solutions addressing pre-bias, sequencing, and inrush challenges. Asian companies such as Delta Electronics, Leadtrend Technology, and Huawei are gaining market share through specialized power management ICs. The technology is approaching maturity in consumer electronics but continues to evolve for industrial and automotive applications, with companies like BCD Micro-Electronics and Power LSI focusing on innovative synchronous rectification solutions for specific market segments.

Delta Electronics, Inc.

Technical Solution: Delta Electronics has developed comprehensive synchronous rectifier solutions that address pre-bias, sequencing and inrush current challenges across their power conversion product lines. Their synchronous rectifier controllers implement a sophisticated voltage sensing circuit that monitors output conditions before enabling synchronous MOSFETs, preventing reverse current flow during startup with pre-existing voltage conditions. Delta's approach incorporates adaptive gate drive technology that optimizes MOSFET switching characteristics based on load conditions, improving efficiency while maintaining robust protection against shoot-through currents. For managing inrush current, Delta has engineered a progressive soft-start implementation that gradually increases duty cycle while monitoring input current, effectively limiting peak current during startup to protect both the power supply and connected systems. Their power sequencing architecture utilizes a master controller with distributed execution nodes, enabling precise coordination of multiple power rails with timing accuracy of ±100μs. Delta's controllers also feature intelligent shutdown sequencing that ensures proper power-down order even during unexpected power loss events, protecting sensitive loads from potential damage.

Strengths: Highly optimized solutions for industrial and telecommunications applications; excellent thermal management capabilities; comprehensive protection features including input undervoltage, output short-circuit, and overtemperature; high reliability with extended operating temperature ranges. Weaknesses: Some solutions require more complex implementation with additional external components; higher cost for smaller-scale applications; limited configuration flexibility in some product lines.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed proprietary synchronous rectification technology for their power supply units that addresses pre-bias, sequencing and inrush current challenges. Their approach incorporates a dual-threshold detection system that monitors both primary and secondary voltages before enabling synchronous rectifiers, preventing reverse power flow during startup conditions with pre-existing voltage. Huawei's synchronous rectifier controllers implement adaptive gate drive technology that modulates MOSFET switching characteristics based on real-time load conditions, optimizing efficiency while maintaining robust protection. Their power sequencing architecture utilizes a centralized controller with distributed execution nodes, enabling precise coordination of multiple power rails with timing accuracy of ±50μs. For telecommunications and data center applications, Huawei has developed specialized inrush current management that implements a multi-stage soft-start with current monitoring feedback loops, gradually ramping up power while maintaining input current below specified thresholds. Their controllers also feature intelligent shutdown sequencing that ensures proper power-down order even during unexpected power loss events.

Strengths: Highly optimized for telecommunications and data center applications; excellent system integration capabilities with digital control interfaces; sophisticated thermal management; comprehensive protection features including input undervoltage, output short-circuit, and overtemperature. Weaknesses: Proprietary solutions with limited compatibility with third-party systems; higher implementation complexity requiring specialized knowledge; relatively higher cost for smaller-scale applications.

Critical Patents and Innovations in SR Control Techniques

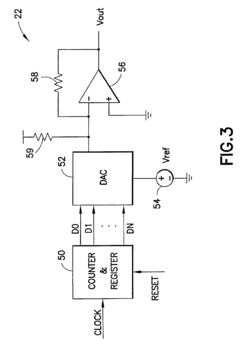

Pre-bias controller for switching power converters

PatentWO2020112174A1

Innovation

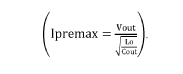

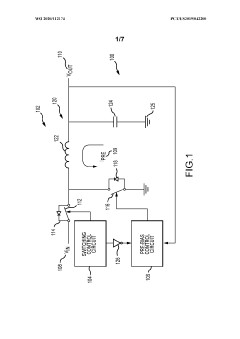

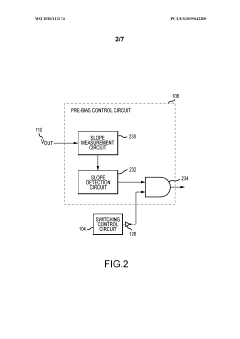

- A pre-bias control circuit that detects the slope of the output voltage over time and outputs an OPEN command when the slope is negative and the pre-charge current reaches a maximum value, overriding the typical control waveform to control energy flow back through the converter, using a slope measurement circuit, slope detection circuit, and an AND gate to manage the synchronous rectifier switch.

Pre-bias protection circuit for converter

PatentActiveUS7482795B2

Innovation

- A pre-bias protection circuit is implemented, which controls the duty cycle of the low-side switch control signal during startup, gradually increasing the duty cycle to prevent pre-bias voltage discharge by using a comparator circuit and pulse width modulation to manage the low-side switch operation, ensuring the pre-bias voltage is maintained.

Thermal Management Considerations in SR Applications

Thermal management is a critical aspect of synchronous rectifier (SR) applications, particularly during start-up and shutdown phases when pre-bias conditions, sequencing requirements, and inrush currents create unique thermal challenges. The power dissipation in SR MOSFETs during these transient states can significantly exceed steady-state operation, potentially leading to thermal runaway if not properly managed.

During start-up, inrush currents can cause momentary high conduction losses in SR MOSFETs, creating thermal hotspots that stress device junctions. These thermal transients are particularly concerning in applications with frequent start-up cycles, where cumulative thermal cycling can accelerate component aging and reduce system reliability. Pre-bias conditions further complicate thermal management by potentially causing shoot-through currents if SR timing is not properly controlled.

The thermal design of SR systems must account for both steady-state and transient thermal impedances. While steady-state thermal resistance (junction-to-ambient) is commonly specified, transient thermal impedance becomes the dominant factor during start-up and shutdown events. Proper thermal modeling requires consideration of the complete thermal network, including die attachment, package materials, PCB layout, and cooling mechanisms.

PCB layout plays a crucial role in SR thermal management. Copper pour areas, thermal vias, and component placement significantly impact heat dissipation pathways. For high-current applications, multilayer PCBs with dedicated thermal planes may be necessary to maintain acceptable junction temperatures during transient events. The placement of temperature-sensitive components relative to SR MOSFETs must also be carefully considered to prevent thermal coupling issues.

Active cooling solutions may be required for high-power SR applications, particularly those with challenging start-up profiles. These can range from forced-air cooling to more sophisticated liquid cooling systems for extreme power densities. Thermal sensors and protective shutdown mechanisms should be implemented to prevent catastrophic failures during abnormal operating conditions.

Thermal simulation tools have become essential for optimizing SR designs, allowing engineers to model complex thermal behaviors during start-up and shutdown sequences. These simulations can identify potential hotspots and verify that thermal design margins are adequate across all operating conditions, including worst-case inrush scenarios and ambient temperature extremes.

Advanced SR controller ICs now incorporate thermal protection features specifically designed to address start-up and shutdown challenges. These include programmable soft-start capabilities, thermal shutdown protection, and adaptive timing algorithms that minimize power dissipation during transient states while maintaining robust operation under pre-bias conditions.

During start-up, inrush currents can cause momentary high conduction losses in SR MOSFETs, creating thermal hotspots that stress device junctions. These thermal transients are particularly concerning in applications with frequent start-up cycles, where cumulative thermal cycling can accelerate component aging and reduce system reliability. Pre-bias conditions further complicate thermal management by potentially causing shoot-through currents if SR timing is not properly controlled.

The thermal design of SR systems must account for both steady-state and transient thermal impedances. While steady-state thermal resistance (junction-to-ambient) is commonly specified, transient thermal impedance becomes the dominant factor during start-up and shutdown events. Proper thermal modeling requires consideration of the complete thermal network, including die attachment, package materials, PCB layout, and cooling mechanisms.

PCB layout plays a crucial role in SR thermal management. Copper pour areas, thermal vias, and component placement significantly impact heat dissipation pathways. For high-current applications, multilayer PCBs with dedicated thermal planes may be necessary to maintain acceptable junction temperatures during transient events. The placement of temperature-sensitive components relative to SR MOSFETs must also be carefully considered to prevent thermal coupling issues.

Active cooling solutions may be required for high-power SR applications, particularly those with challenging start-up profiles. These can range from forced-air cooling to more sophisticated liquid cooling systems for extreme power densities. Thermal sensors and protective shutdown mechanisms should be implemented to prevent catastrophic failures during abnormal operating conditions.

Thermal simulation tools have become essential for optimizing SR designs, allowing engineers to model complex thermal behaviors during start-up and shutdown sequences. These simulations can identify potential hotspots and verify that thermal design margins are adequate across all operating conditions, including worst-case inrush scenarios and ambient temperature extremes.

Advanced SR controller ICs now incorporate thermal protection features specifically designed to address start-up and shutdown challenges. These include programmable soft-start capabilities, thermal shutdown protection, and adaptive timing algorithms that minimize power dissipation during transient states while maintaining robust operation under pre-bias conditions.

Safety and Reliability Standards for Power Conversion Systems

Power conversion systems in modern electronics must adhere to stringent safety and reliability standards, particularly when dealing with synchronous rectifier start-up/shutdown scenarios involving pre-bias conditions, sequencing, and inrush current management. These standards are established by various international organizations to ensure consistent safety levels across different applications and regions.

The International Electrotechnical Commission (IEC) provides comprehensive frameworks through standards like IEC 61000 for electromagnetic compatibility and IEC 62368 for audio/video equipment safety. These standards specifically address transient protection requirements that directly impact synchronous rectifier operation during critical power state transitions.

UL (Underwriters Laboratories) standards, particularly UL 60950 and UL 62368-1, outline specific requirements for power conversion systems regarding pre-bias handling and inrush current limitations. These standards mandate that synchronous rectifiers must maintain safe operation even when encountering pre-existing voltage conditions on output capacitors.

The automotive industry imposes additional requirements through standards like ISO 26262 and AEC-Q100, which demand robust synchronous rectifier designs capable of withstanding harsh environmental conditions while maintaining precise sequencing during power transitions. These standards emphasize functional safety aspects that prevent hazardous conditions during abnormal start-up or shutdown events.

For telecommunications and data center applications, ETSI EN 300 and NEBS compliance requirements specify strict parameters for inrush current management and sequencing to prevent network disruptions. These standards typically require controlled soft-start capabilities and protection against reverse current flow during pre-bias conditions.

Medical device standards (IEC 60601) impose particularly stringent requirements on power conversion systems used in healthcare settings, mandating multiple layers of protection against power sequencing failures that could potentially harm patients or compromise critical care equipment.

The aerospace and defense sectors follow standards like DO-160 and MIL-STD-461, which outline extreme reliability requirements for power systems operating in mission-critical environments. These standards specify comprehensive testing protocols for synchronous rectifiers under various start-up and shutdown scenarios.

Emerging standards addressing energy efficiency, such as 80 PLUS certification and Energy Star requirements, are increasingly incorporating specifications for transient behavior during power state changes, recognizing that efficient management of start-up/shutdown sequences contributes significantly to overall system efficiency.

Compliance with these standards requires comprehensive testing methodologies including pre-bias response evaluation, inrush current measurement, and sequence timing verification under various load conditions and temperatures. Documentation of these test results forms a critical component of the certification process for power conversion systems utilizing synchronous rectification technology.

The International Electrotechnical Commission (IEC) provides comprehensive frameworks through standards like IEC 61000 for electromagnetic compatibility and IEC 62368 for audio/video equipment safety. These standards specifically address transient protection requirements that directly impact synchronous rectifier operation during critical power state transitions.

UL (Underwriters Laboratories) standards, particularly UL 60950 and UL 62368-1, outline specific requirements for power conversion systems regarding pre-bias handling and inrush current limitations. These standards mandate that synchronous rectifiers must maintain safe operation even when encountering pre-existing voltage conditions on output capacitors.

The automotive industry imposes additional requirements through standards like ISO 26262 and AEC-Q100, which demand robust synchronous rectifier designs capable of withstanding harsh environmental conditions while maintaining precise sequencing during power transitions. These standards emphasize functional safety aspects that prevent hazardous conditions during abnormal start-up or shutdown events.

For telecommunications and data center applications, ETSI EN 300 and NEBS compliance requirements specify strict parameters for inrush current management and sequencing to prevent network disruptions. These standards typically require controlled soft-start capabilities and protection against reverse current flow during pre-bias conditions.

Medical device standards (IEC 60601) impose particularly stringent requirements on power conversion systems used in healthcare settings, mandating multiple layers of protection against power sequencing failures that could potentially harm patients or compromise critical care equipment.

The aerospace and defense sectors follow standards like DO-160 and MIL-STD-461, which outline extreme reliability requirements for power systems operating in mission-critical environments. These standards specify comprehensive testing protocols for synchronous rectifiers under various start-up and shutdown scenarios.

Emerging standards addressing energy efficiency, such as 80 PLUS certification and Energy Star requirements, are increasingly incorporating specifications for transient behavior during power state changes, recognizing that efficient management of start-up/shutdown sequences contributes significantly to overall system efficiency.

Compliance with these standards requires comprehensive testing methodologies including pre-bias response evaluation, inrush current measurement, and sequence timing verification under various load conditions and temperatures. Documentation of these test results forms a critical component of the certification process for power conversion systems utilizing synchronous rectification technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!