Synchronous Rectifier EMI/EMC: Common-Mode Currents, Layout And Snubbers

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Synchronous Rectifier EMI/EMC Background and Objectives

Synchronous rectification technology has evolved significantly over the past three decades, transforming power conversion efficiency in modern electronic systems. Initially developed in the 1990s as an alternative to traditional diode rectification, synchronous rectifiers (SRs) utilize MOSFETs to reduce conduction losses, achieving efficiency improvements of 2-5% in power conversion circuits. This technology has become increasingly critical as electronic devices continue to demand higher power density and efficiency.

The evolution of synchronous rectification has been marked by continuous improvements in semiconductor technology, control methodologies, and circuit design techniques. Early implementations faced challenges with timing control and parasitic effects, but advancements in integrated circuit technology have enabled more sophisticated solutions. The transition from discrete implementations to highly integrated modules has accelerated adoption across various applications including server power supplies, automotive systems, and consumer electronics.

However, as switching frequencies increase to reduce passive component sizes and improve power density, electromagnetic interference (EMI) and electromagnetic compatibility (EMC) concerns have emerged as significant challenges. Common-mode currents, in particular, have become a critical issue as they can propagate through parasitic capacitances and create conducted and radiated emissions that may interfere with nearby electronic systems.

The technical objective of this research is to comprehensively investigate EMI/EMC issues specific to synchronous rectifier implementations, with particular focus on common-mode current generation mechanisms, PCB layout optimization techniques, and snubber circuit designs. By understanding these phenomena, we aim to develop design methodologies that can mitigate EMI while maintaining the efficiency benefits of synchronous rectification.

This research seeks to establish clear correlations between circuit parameters, layout considerations, and resulting EMI profiles. Additionally, it aims to quantify the effectiveness of various snubber topologies in suppressing high-frequency noise without significantly compromising efficiency. The ultimate goal is to develop a systematic approach to synchronous rectifier design that balances performance, efficiency, and electromagnetic compatibility.

Recent regulatory changes have also increased the importance of this research. Standards such as CISPR 32/35 and automotive EMC requirements (ISO 11452) have become more stringent, requiring power conversion systems to meet lower emission limits across broader frequency ranges. This regulatory landscape necessitates a deeper understanding of EMI generation and suppression techniques specific to synchronous rectification.

By addressing these challenges, this research will contribute to the continued evolution of synchronous rectification technology, enabling its application in increasingly sensitive and demanding environments while maintaining compliance with global EMC standards.

The evolution of synchronous rectification has been marked by continuous improvements in semiconductor technology, control methodologies, and circuit design techniques. Early implementations faced challenges with timing control and parasitic effects, but advancements in integrated circuit technology have enabled more sophisticated solutions. The transition from discrete implementations to highly integrated modules has accelerated adoption across various applications including server power supplies, automotive systems, and consumer electronics.

However, as switching frequencies increase to reduce passive component sizes and improve power density, electromagnetic interference (EMI) and electromagnetic compatibility (EMC) concerns have emerged as significant challenges. Common-mode currents, in particular, have become a critical issue as they can propagate through parasitic capacitances and create conducted and radiated emissions that may interfere with nearby electronic systems.

The technical objective of this research is to comprehensively investigate EMI/EMC issues specific to synchronous rectifier implementations, with particular focus on common-mode current generation mechanisms, PCB layout optimization techniques, and snubber circuit designs. By understanding these phenomena, we aim to develop design methodologies that can mitigate EMI while maintaining the efficiency benefits of synchronous rectification.

This research seeks to establish clear correlations between circuit parameters, layout considerations, and resulting EMI profiles. Additionally, it aims to quantify the effectiveness of various snubber topologies in suppressing high-frequency noise without significantly compromising efficiency. The ultimate goal is to develop a systematic approach to synchronous rectifier design that balances performance, efficiency, and electromagnetic compatibility.

Recent regulatory changes have also increased the importance of this research. Standards such as CISPR 32/35 and automotive EMC requirements (ISO 11452) have become more stringent, requiring power conversion systems to meet lower emission limits across broader frequency ranges. This regulatory landscape necessitates a deeper understanding of EMI generation and suppression techniques specific to synchronous rectification.

By addressing these challenges, this research will contribute to the continued evolution of synchronous rectification technology, enabling its application in increasingly sensitive and demanding environments while maintaining compliance with global EMC standards.

Market Demand for Low-EMI Power Conversion Solutions

The global market for low-EMI power conversion solutions has experienced significant growth in recent years, driven by the increasing complexity of electronic systems and stricter regulatory requirements. The demand for synchronous rectifier technologies with enhanced EMI/EMC performance is particularly pronounced across multiple sectors including consumer electronics, automotive, industrial automation, and telecommunications.

In the consumer electronics segment, the proliferation of compact, high-performance devices has created a pressing need for power conversion solutions that minimize electromagnetic interference. Market research indicates that manufacturers are willing to pay a premium of 15-20% for components that can demonstrably reduce EMI issues, as this directly impacts product certification timelines and market entry speed.

The automotive industry represents one of the fastest-growing markets for low-EMI power conversion technologies. With the rapid expansion of electric vehicles and advanced driver assistance systems, automotive manufacturers face increasingly complex electromagnetic compatibility challenges. The market for automotive-grade synchronous rectifiers with superior EMI performance is projected to grow at a compound annual rate of 22% through 2028.

Industrial automation systems, particularly in smart manufacturing environments, require power conversion solutions that can operate reliably in electrically noisy environments without contributing to electromagnetic interference. Factory operators report that EMI-related downtime can cost between $10,000 and $30,000 per hour in high-volume manufacturing facilities, creating strong economic incentives for improved solutions.

The telecommunications sector, especially with the ongoing deployment of 5G infrastructure, demands power conversion technologies that minimize common-mode currents and other EMI sources. Network equipment providers increasingly specify enhanced EMI performance in their component requirements, with particular emphasis on layout optimization and effective snubber designs.

Regulatory trends are also driving market demand, with updates to standards like CISPR 32, FCC Part 15, and automotive-specific requirements becoming more stringent. Compliance with these evolving standards represents a significant competitive advantage for component manufacturers who can deliver effective EMI mitigation strategies.

Market surveys indicate that design engineers rank EMI/EMC performance among their top three selection criteria when choosing power conversion components, alongside efficiency and reliability. This represents a significant shift from five years ago when EMI considerations typically ranked sixth or seventh in importance.

The geographical distribution of demand shows particular strength in regions with dense electronic manufacturing and strict regulatory environments, including East Asia, Western Europe, and North America. Emerging markets are also showing increased sensitivity to EMI performance as they adopt more sophisticated electronic systems and align with international standards.

In the consumer electronics segment, the proliferation of compact, high-performance devices has created a pressing need for power conversion solutions that minimize electromagnetic interference. Market research indicates that manufacturers are willing to pay a premium of 15-20% for components that can demonstrably reduce EMI issues, as this directly impacts product certification timelines and market entry speed.

The automotive industry represents one of the fastest-growing markets for low-EMI power conversion technologies. With the rapid expansion of electric vehicles and advanced driver assistance systems, automotive manufacturers face increasingly complex electromagnetic compatibility challenges. The market for automotive-grade synchronous rectifiers with superior EMI performance is projected to grow at a compound annual rate of 22% through 2028.

Industrial automation systems, particularly in smart manufacturing environments, require power conversion solutions that can operate reliably in electrically noisy environments without contributing to electromagnetic interference. Factory operators report that EMI-related downtime can cost between $10,000 and $30,000 per hour in high-volume manufacturing facilities, creating strong economic incentives for improved solutions.

The telecommunications sector, especially with the ongoing deployment of 5G infrastructure, demands power conversion technologies that minimize common-mode currents and other EMI sources. Network equipment providers increasingly specify enhanced EMI performance in their component requirements, with particular emphasis on layout optimization and effective snubber designs.

Regulatory trends are also driving market demand, with updates to standards like CISPR 32, FCC Part 15, and automotive-specific requirements becoming more stringent. Compliance with these evolving standards represents a significant competitive advantage for component manufacturers who can deliver effective EMI mitigation strategies.

Market surveys indicate that design engineers rank EMI/EMC performance among their top three selection criteria when choosing power conversion components, alongside efficiency and reliability. This represents a significant shift from five years ago when EMI considerations typically ranked sixth or seventh in importance.

The geographical distribution of demand shows particular strength in regions with dense electronic manufacturing and strict regulatory environments, including East Asia, Western Europe, and North America. Emerging markets are also showing increased sensitivity to EMI performance as they adopt more sophisticated electronic systems and align with international standards.

Current Challenges in Common-Mode Current Suppression

Common-mode current suppression in synchronous rectifier circuits presents significant challenges that continue to impede optimal EMI/EMC performance. The primary difficulty lies in the high-speed switching nature of modern power conversion systems, where fast-rising edges (dv/dt) create displacement currents through parasitic capacitances. These parasitic paths, particularly between switching nodes and ground, form unintended common-mode current loops that radiate electromagnetic interference.

A major technical obstacle involves the inherent trade-off between switching speed and EMI performance. As synchronous rectifiers push toward higher frequencies to reduce passive component sizes, the resulting faster transitions exacerbate common-mode noise generation. Engineers face the dilemma of balancing efficiency gains from faster switching against deteriorating EMI performance.

The parasitic capacitance between semiconductor devices and heatsinks represents another persistent challenge. This capacitance creates a direct path for common-mode currents, especially problematic in high-power applications requiring substantial thermal management. Traditional isolation methods often introduce thermal resistance, creating an undesirable compromise between EMI suppression and thermal performance.

Layout-related challenges further complicate common-mode current suppression. The physical arrangement of components creates complex three-dimensional electromagnetic fields that are difficult to model accurately during the design phase. Parasitic inductances in PCB traces and ground planes can resonate with capacitive elements, amplifying common-mode noise at specific frequencies. These resonances often appear unexpectedly during testing phases, requiring costly redesigns.

Snubber circuit design presents its own set of challenges. While snubbers can effectively dampen switching transients, they introduce additional components that may create new parasitic paths. Optimizing snubber values requires complex analysis of the entire power conversion system, as improper values can actually worsen EMI performance or significantly reduce efficiency.

Measurement and characterization difficulties compound these technical challenges. Common-mode currents often manifest differently in laboratory settings versus real-world applications due to grounding differences and environmental factors. This makes validation of suppression techniques particularly challenging, as solutions that work in controlled environments may fail in actual deployments.

Regulatory compliance adds another layer of complexity, with increasingly stringent EMC standards across different regions and applications. Meeting these diverse requirements often necessitates multiple suppression techniques working in concert, increasing design complexity and potentially reducing reliability through component count increases.

A major technical obstacle involves the inherent trade-off between switching speed and EMI performance. As synchronous rectifiers push toward higher frequencies to reduce passive component sizes, the resulting faster transitions exacerbate common-mode noise generation. Engineers face the dilemma of balancing efficiency gains from faster switching against deteriorating EMI performance.

The parasitic capacitance between semiconductor devices and heatsinks represents another persistent challenge. This capacitance creates a direct path for common-mode currents, especially problematic in high-power applications requiring substantial thermal management. Traditional isolation methods often introduce thermal resistance, creating an undesirable compromise between EMI suppression and thermal performance.

Layout-related challenges further complicate common-mode current suppression. The physical arrangement of components creates complex three-dimensional electromagnetic fields that are difficult to model accurately during the design phase. Parasitic inductances in PCB traces and ground planes can resonate with capacitive elements, amplifying common-mode noise at specific frequencies. These resonances often appear unexpectedly during testing phases, requiring costly redesigns.

Snubber circuit design presents its own set of challenges. While snubbers can effectively dampen switching transients, they introduce additional components that may create new parasitic paths. Optimizing snubber values requires complex analysis of the entire power conversion system, as improper values can actually worsen EMI performance or significantly reduce efficiency.

Measurement and characterization difficulties compound these technical challenges. Common-mode currents often manifest differently in laboratory settings versus real-world applications due to grounding differences and environmental factors. This makes validation of suppression techniques particularly challenging, as solutions that work in controlled environments may fail in actual deployments.

Regulatory compliance adds another layer of complexity, with increasingly stringent EMC standards across different regions and applications. Meeting these diverse requirements often necessitates multiple suppression techniques working in concert, increasing design complexity and potentially reducing reliability through component count increases.

Existing Common-Mode Current Mitigation Techniques

01 Common-mode noise reduction techniques in synchronous rectifiers

Various techniques can be employed to reduce common-mode noise in synchronous rectifier circuits. These include implementing balanced circuit designs, using symmetrical layouts, and incorporating specialized filtering components. By minimizing the common-mode current paths and providing proper isolation between primary and secondary sides, EMI/EMC performance can be significantly improved. These approaches help to meet electromagnetic compatibility standards while maintaining high efficiency in power conversion systems.- EMI/EMC reduction techniques in synchronous rectifier circuits: Various techniques are employed to reduce electromagnetic interference (EMI) and improve electromagnetic compatibility (EMC) in synchronous rectifier circuits. These include specialized circuit designs, filtering components, and shielding methods that minimize noise generation and propagation. By implementing these techniques, common-mode currents that contribute to EMI can be significantly reduced, improving overall system performance and compliance with regulatory standards.

- Common-mode current suppression in power converters: Power converters with synchronous rectifiers often implement specific methods to suppress common-mode currents that cause EMI issues. These methods include balanced circuit topologies, common-mode chokes, and specialized grounding techniques. By addressing the root causes of common-mode currents, these solutions help maintain signal integrity while reducing electromagnetic emissions that could interfere with nearby electronic equipment.

- Gate driver optimization for EMI reduction: The gate driver circuits in synchronous rectifiers significantly impact EMI performance. Optimized gate drivers control the switching transitions with precise timing and slew rates, reducing high-frequency noise generation. Advanced gate driver designs incorporate features like adaptive dead-time control, soft switching techniques, and isolation methods that minimize parasitic oscillations and common-mode currents, resulting in improved EMC performance.

- PCB layout and component placement for EMC improvement: Proper PCB layout and component placement are crucial for minimizing EMI in synchronous rectifier applications. Techniques include optimized trace routing, strategic placement of decoupling capacitors, minimizing loop areas, and implementing ground planes. These design considerations help reduce parasitic inductances and capacitances that contribute to common-mode currents, resulting in improved EMC performance without requiring additional components.

- Integrated EMI filtering solutions for synchronous rectifiers: Integrated EMI filtering solutions combine multiple filtering techniques directly within synchronous rectifier designs. These solutions incorporate components like common-mode filters, differential-mode filters, and spread spectrum techniques to comprehensively address EMI issues. By integrating these filtering solutions at the design stage, common-mode currents can be effectively suppressed across a wide frequency range, meeting stringent EMC requirements while maintaining power conversion efficiency.

02 Gate driver optimization for EMI reduction

Optimizing gate driver circuits in synchronous rectifiers can substantially reduce electromagnetic interference. This includes controlling the slew rate of switching transitions, implementing precise timing control, and using specialized driver ICs with built-in EMI mitigation features. By carefully managing the switching behavior of power MOSFETs, common-mode currents can be minimized. Advanced gate driving techniques also help balance the trade-off between switching losses and EMI generation.Expand Specific Solutions03 Shielding and layout techniques for EMC compliance

Proper shielding and PCB layout techniques are crucial for achieving EMC compliance in synchronous rectifier designs. This includes strategic placement of components, optimized trace routing, ground plane design, and the use of shielding materials. By minimizing parasitic capacitances and inductances, common-mode current paths can be effectively controlled. Careful attention to physical design aspects helps prevent electromagnetic radiation and susceptibility issues in power conversion circuits.Expand Specific Solutions04 Filtering and passive component solutions

Implementing appropriate filtering and passive component solutions can significantly reduce EMI/EMC issues in synchronous rectifier circuits. This includes the use of common-mode chokes, Y-capacitors, ferrite beads, and specialized EMI filters. These components help suppress conducted and radiated emissions by providing high impedance paths for common-mode currents while maintaining low impedance for differential-mode currents. Proper selection and placement of these components is essential for effective EMI mitigation.Expand Specific Solutions05 Advanced control algorithms for EMI suppression

Advanced control algorithms can be implemented to suppress EMI in synchronous rectifier applications. These include spread spectrum techniques, soft-switching methods, and adaptive control strategies that dynamically adjust switching parameters based on operating conditions. By introducing controlled variations in switching frequency or implementing zero-voltage or zero-current switching, common-mode noise generation can be significantly reduced. These algorithmic approaches complement hardware solutions for comprehensive EMI management.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The synchronous rectifier EMI/EMC market is currently in a growth phase, with increasing demand driven by power efficiency requirements in electronic devices. The market is expanding rapidly as companies address electromagnetic interference challenges in power conversion systems. Leading players include Infineon Technologies and Huawei Technologies, who have established strong technical expertise in synchronous rectification solutions. Delta Electronics and Renesas Electronics have developed advanced snubber designs and layout optimization techniques to mitigate common-mode currents. Academic institutions like Beihang University and University of Florida are contributing significant research on EMI reduction techniques. The competitive landscape shows a mix of semiconductor manufacturers, electronics giants, and specialized power management companies working to advance synchronous rectifier technology while meeting stringent EMC standards.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed proprietary synchronous rectifier technology with advanced EMI/EMC suppression focusing on power supply applications in telecommunications equipment. Their approach incorporates multi-layer shielding techniques and specialized PCB layout methodologies that minimize common-mode current paths. Huawei's synchronous rectifier designs feature adaptive gate driving algorithms that dynamically adjust switching parameters based on load conditions to optimize the balance between efficiency and EMI performance. Their solutions implement distributed snubber networks strategically placed to address both differential and common-mode noise sources at multiple points in the circuit. Huawei has pioneered the use of embedded filtering structures within power conversion modules, integrating common-mode rejection directly into the power delivery architecture. Their designs incorporate specialized grounding schemes with star-point configurations and impedance-matched return paths to minimize ground bounce and common-mode current circulation. Additionally, Huawei employs advanced simulation techniques to model EMI propagation paths, allowing for optimization of component placement and routing before physical prototyping.

Strengths: Highly optimized solutions for telecommunications infrastructure with exceptional reliability and performance in dense electronic environments. Their designs achieve excellent EMI compliance while maintaining high power density. Weaknesses: Solutions are often highly customized for specific applications, potentially limiting broader applicability. Implementation typically requires specialized knowledge and tools developed within Huawei's ecosystem.

Delta Electronics, Inc.

Technical Solution: Delta Electronics has developed comprehensive synchronous rectifier solutions with integrated EMI/EMC mitigation strategies specifically targeting power supply applications. Their approach focuses on holistic system design that addresses common-mode currents through multiple complementary techniques. Delta's synchronous rectifier implementations feature carefully designed PCB layouts with symmetrical power traces, minimized loop areas, and strategic component placement to reduce parasitic inductances and capacitances that contribute to EMI. Their designs incorporate advanced multi-layer PCB structures with dedicated ground planes and shielding layers that provide controlled return paths for high-frequency currents. Delta has pioneered hybrid snubber networks that combine both passive and active elements to effectively dampen switching transients while minimizing power losses. Their solutions implement specialized gate drive circuits with optimized rise/fall times and propagation delays to control dv/dt and di/dt rates during switching transitions, significantly reducing EMI generation at the source. Additionally, Delta employs advanced filtering techniques including balanced line filters and common-mode chokes with optimized core materials specifically selected for high-frequency common-mode rejection.

Strengths: Exceptional balance between EMI performance and power conversion efficiency, with solutions that maintain high power density. Their designs demonstrate excellent thermal management and reliability in demanding applications. Weaknesses: Implementation often requires sophisticated design tools and expertise in power electronics. Their more advanced solutions may have higher component counts compared to simpler implementations.

Critical PCB Layout Strategies and Snubber Circuit Designs

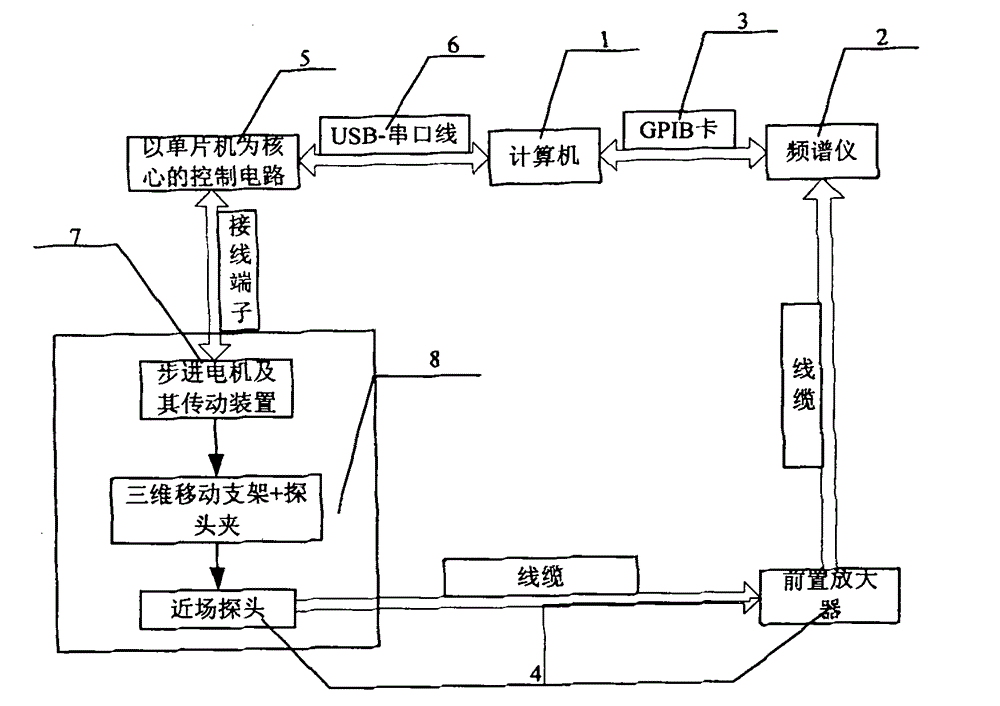

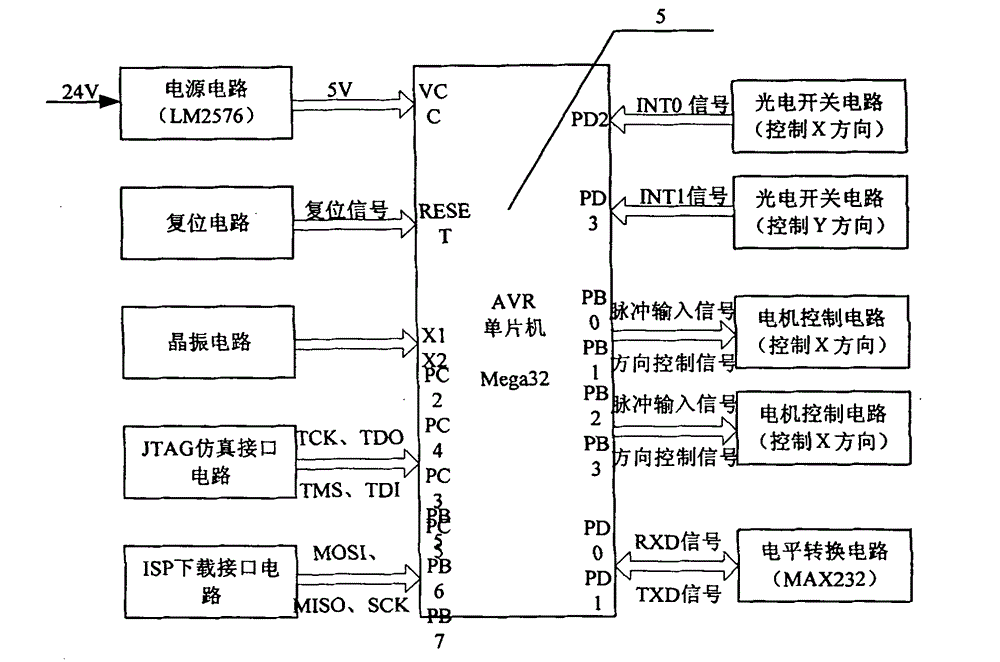

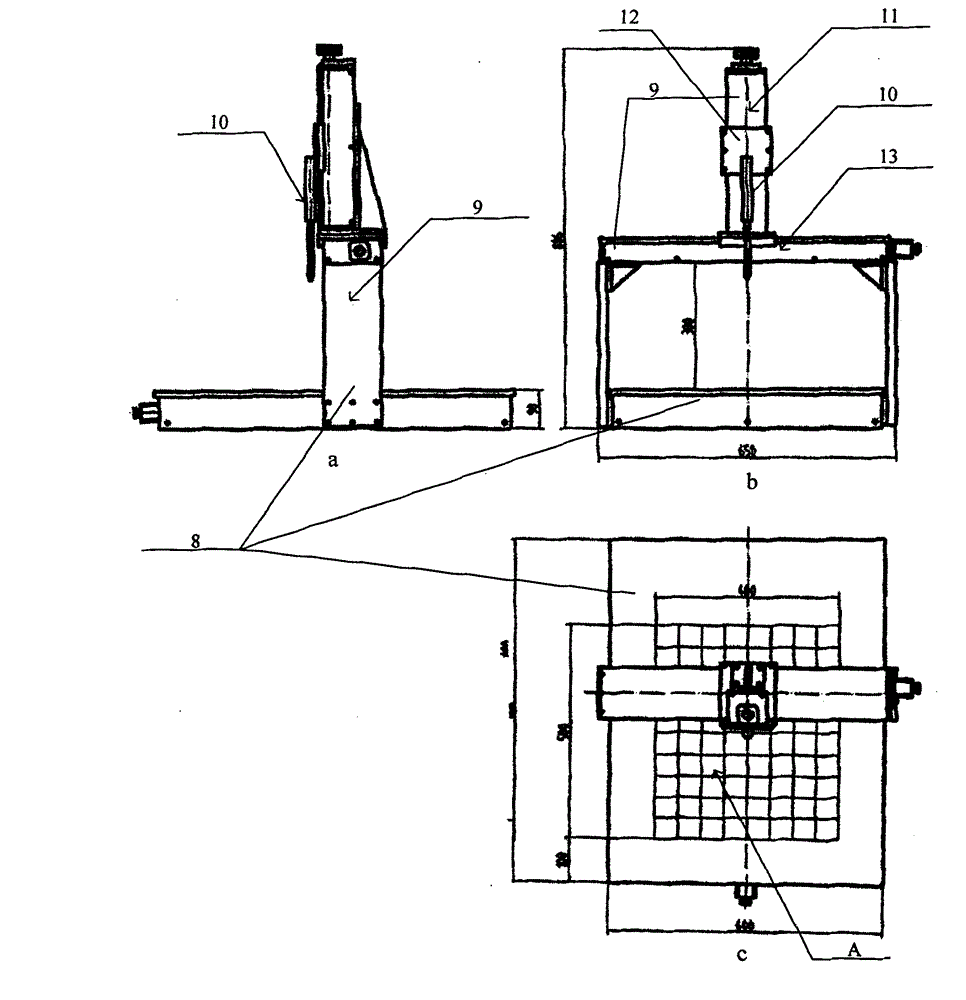

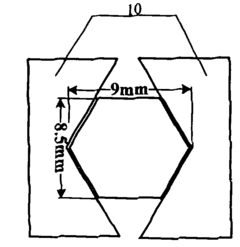

Self-adaptive scanning device with electromagnetic compatibility for near-field test

PatentInactiveCN101750546B

Innovation

- An electromagnetic compatibility adaptive scanning device for near-field testing is designed. It uses a precise moving near-field probe in a three-dimensional system, combined with a spectrum analyzer and a computer, to realize changes in electromagnetic radiation values by adaptively adjusting the step length. Dynamically responds, optimizing scan paths for increased efficiency and accuracy.

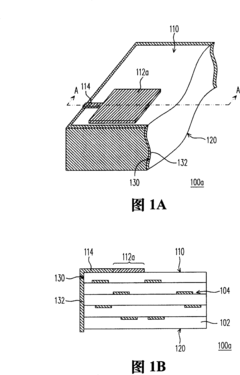

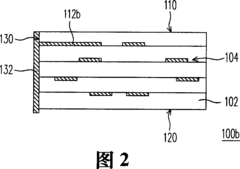

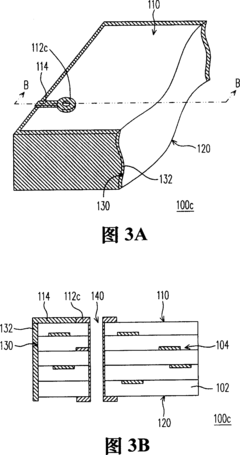

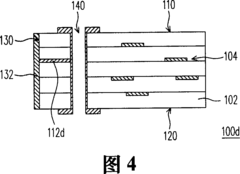

Circuit board

PatentInactiveCN101022694A

Innovation

- A second conductive area is formed on the third side of the circuit board as a metal shielding layer. The conductive layer is formed by printing, electroplating, sputtering or dipping to ensure that the signal is not subject to external interference and that the internal signal does not radiate to the outside.

Regulatory Standards and Compliance Requirements

Synchronous rectifier designs must comply with a comprehensive set of regulatory standards governing electromagnetic compatibility. The International Electrotechnical Commission (IEC) establishes the primary EMC standards, with IEC 61000 series being particularly relevant for power electronic systems. CISPR 22/EN 55022 standards specifically address information technology equipment emissions, categorizing limits into Class A (industrial) and more stringent Class B (residential) environments.

For synchronous rectifiers in power supplies, FCC Part 15 regulations in the United States mandate strict conducted and radiated emission limits across frequency ranges of 150 kHz to 30 MHz and 30 MHz to 1 GHz respectively. The European Union's EMC Directive 2014/30/EU enforces similar requirements through harmonized standards, making compliance mandatory for CE marking and market access.

Common-mode current mitigation in synchronous rectifiers must meet IEC 61000-3-2 standards for harmonic current emissions, particularly crucial for equipment drawing significant current from public low-voltage supply systems. Additionally, IEC 61000-4 series standards define immunity requirements against various electromagnetic disturbances, including electrostatic discharge (ESD), radiated fields, and electrical fast transients.

Layout design and snubber implementation must consider safety standards like IEC 62368-1 (for audio/video and IT equipment) or IEC 61558 (for power transformers), which specify creepage and clearance distances based on voltage levels, pollution degree, and insulation requirements. These standards ensure both functional performance and user safety.

Military and automotive applications face even more stringent requirements. MIL-STD-461G establishes EMI limits and test methods for military equipment, while automotive synchronous rectifiers must comply with CISPR 25 and ISO 7637 standards, addressing the challenging electromagnetic environment of vehicles.

Testing methodologies for synchronous rectifier compliance include conducted emission measurements using Line Impedance Stabilization Networks (LISN) per CISPR 16-1-2, and radiated emission testing in anechoic chambers according to CISPR 16-2-3. Common-mode current measurements typically employ current probes with spectrum analyzers to verify compliance with relevant standards.

Regulatory bodies increasingly focus on energy efficiency alongside EMC requirements. Standards like 80 PLUS certification and EU Ecodesign Directive 2009/125/EC establish minimum efficiency requirements for power supplies, directly impacting synchronous rectifier design parameters and the selection of snubber components that must balance EMI suppression with energy efficiency goals.

For synchronous rectifiers in power supplies, FCC Part 15 regulations in the United States mandate strict conducted and radiated emission limits across frequency ranges of 150 kHz to 30 MHz and 30 MHz to 1 GHz respectively. The European Union's EMC Directive 2014/30/EU enforces similar requirements through harmonized standards, making compliance mandatory for CE marking and market access.

Common-mode current mitigation in synchronous rectifiers must meet IEC 61000-3-2 standards for harmonic current emissions, particularly crucial for equipment drawing significant current from public low-voltage supply systems. Additionally, IEC 61000-4 series standards define immunity requirements against various electromagnetic disturbances, including electrostatic discharge (ESD), radiated fields, and electrical fast transients.

Layout design and snubber implementation must consider safety standards like IEC 62368-1 (for audio/video and IT equipment) or IEC 61558 (for power transformers), which specify creepage and clearance distances based on voltage levels, pollution degree, and insulation requirements. These standards ensure both functional performance and user safety.

Military and automotive applications face even more stringent requirements. MIL-STD-461G establishes EMI limits and test methods for military equipment, while automotive synchronous rectifiers must comply with CISPR 25 and ISO 7637 standards, addressing the challenging electromagnetic environment of vehicles.

Testing methodologies for synchronous rectifier compliance include conducted emission measurements using Line Impedance Stabilization Networks (LISN) per CISPR 16-1-2, and radiated emission testing in anechoic chambers according to CISPR 16-2-3. Common-mode current measurements typically employ current probes with spectrum analyzers to verify compliance with relevant standards.

Regulatory bodies increasingly focus on energy efficiency alongside EMC requirements. Standards like 80 PLUS certification and EU Ecodesign Directive 2009/125/EC establish minimum efficiency requirements for power supplies, directly impacting synchronous rectifier design parameters and the selection of snubber components that must balance EMI suppression with energy efficiency goals.

Thermal Management Considerations for SR Circuits

Thermal management is a critical aspect of synchronous rectifier (SR) circuit design, particularly when addressing EMI/EMC concerns. The switching behavior of SR MOSFETs generates significant heat that must be effectively dissipated to maintain optimal performance and reliability. Temperature rises in SR circuits directly impact conduction losses through increased RDS(on) values, with typical MOSFETs experiencing a 0.35-0.5% increase in on-resistance per degree Celsius above ambient temperature.

Common-mode current issues in SR circuits are exacerbated by thermal gradients, as temperature differences across circuit components can create uneven impedance paths that contribute to EMI generation. Proper thermal design therefore serves as an indirect but effective EMI mitigation strategy by maintaining consistent electrical characteristics throughout the circuit.

Heat dissipation in SR circuits follows multiple paths, with conduction through PCB copper layers being predominant in surface-mount designs. The thermal resistance junction-to-ambient (RθJA) typically ranges from 40-60°C/W for standard SO-8 packages without additional cooling measures. When addressing common-mode EMI concerns, thermal vias placement must be carefully balanced with EMI considerations, as poorly placed thermal structures can inadvertently create return paths for common-mode currents.

Layout techniques that optimize thermal performance while minimizing EMI include symmetrical thermal via patterns, strategic copper pour segmentation, and thermal isolation of noise-sensitive components. Research indicates that thermal vias placed in a grid pattern rather than a single cluster can reduce common-mode current paths by up to 30% while maintaining similar thermal performance.

Snubber circuits, while primarily designed to suppress voltage spikes and ringing, also impact thermal management. The resistive elements in RC snubbers dissipate energy that would otherwise manifest as EMI, but this creates additional thermal load that must be managed. Studies show that optimally designed snubbers can reduce switching losses by 15-25%, thereby improving overall thermal performance while simultaneously addressing EMI concerns.

Advanced cooling techniques for SR applications include integrated heat spreaders, phase-change materials, and forced-air cooling. These methods become particularly important in high-density applications where common-mode EMI issues are more pronounced due to parasitic capacitances. Thermal simulation tools that incorporate both electrical and thermal models are increasingly used to predict hotspots that might contribute to EMI problems through temperature-dependent parameter shifts.

The relationship between thermal cycling and long-term EMI performance stability represents an emerging research area, with evidence suggesting that repeated thermal stress can gradually alter circuit characteristics in ways that affect EMI profiles over time. This highlights the importance of robust thermal design not just for immediate performance but for sustained EMI compliance throughout the product lifecycle.

Common-mode current issues in SR circuits are exacerbated by thermal gradients, as temperature differences across circuit components can create uneven impedance paths that contribute to EMI generation. Proper thermal design therefore serves as an indirect but effective EMI mitigation strategy by maintaining consistent electrical characteristics throughout the circuit.

Heat dissipation in SR circuits follows multiple paths, with conduction through PCB copper layers being predominant in surface-mount designs. The thermal resistance junction-to-ambient (RθJA) typically ranges from 40-60°C/W for standard SO-8 packages without additional cooling measures. When addressing common-mode EMI concerns, thermal vias placement must be carefully balanced with EMI considerations, as poorly placed thermal structures can inadvertently create return paths for common-mode currents.

Layout techniques that optimize thermal performance while minimizing EMI include symmetrical thermal via patterns, strategic copper pour segmentation, and thermal isolation of noise-sensitive components. Research indicates that thermal vias placed in a grid pattern rather than a single cluster can reduce common-mode current paths by up to 30% while maintaining similar thermal performance.

Snubber circuits, while primarily designed to suppress voltage spikes and ringing, also impact thermal management. The resistive elements in RC snubbers dissipate energy that would otherwise manifest as EMI, but this creates additional thermal load that must be managed. Studies show that optimally designed snubbers can reduce switching losses by 15-25%, thereby improving overall thermal performance while simultaneously addressing EMI concerns.

Advanced cooling techniques for SR applications include integrated heat spreaders, phase-change materials, and forced-air cooling. These methods become particularly important in high-density applications where common-mode EMI issues are more pronounced due to parasitic capacitances. Thermal simulation tools that incorporate both electrical and thermal models are increasingly used to predict hotspots that might contribute to EMI problems through temperature-dependent parameter shifts.

The relationship between thermal cycling and long-term EMI performance stability represents an emerging research area, with evidence suggesting that repeated thermal stress can gradually alter circuit characteristics in ways that affect EMI profiles over time. This highlights the importance of robust thermal design not just for immediate performance but for sustained EMI compliance throughout the product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!