Synchronous Rectifier Aging: Parameter Drift, RDS(on) Rise And Lifetime

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Synchronous Rectifier Aging Background and Objectives

Synchronous rectifiers (SRs) have become a cornerstone technology in modern power conversion systems, offering significant improvements in efficiency compared to traditional diode-based rectification. The evolution of SR technology spans several decades, beginning with the theoretical concepts in the 1980s and accelerating in practical implementation through the 1990s and 2000s as semiconductor manufacturing advanced. This technology has been particularly transformative in applications requiring high efficiency and power density, such as server power supplies, telecommunications equipment, and increasingly in consumer electronics.

The aging phenomenon in synchronous rectifiers represents a critical reliability concern that has gained prominence as power conversion systems are expected to maintain high efficiency over extended operational lifetimes. Parameter drift, particularly the increase in drain-to-source on-resistance (RDS(on)), is a fundamental aging mechanism that directly impacts conversion efficiency and thermal management requirements throughout a device's service life.

Industry trends indicate a continuous push toward higher power densities, which exacerbates the challenges associated with SR aging. As form factors shrink while power requirements remain constant or increase, the thermal stress on components intensifies, potentially accelerating aging mechanisms. Concurrently, applications in automotive, industrial, and renewable energy sectors are demanding extended operational lifetimes under harsh environmental conditions.

The technical evolution trajectory shows a shift from simple implementation of MOSFETs as synchronous rectifiers to sophisticated integrated solutions with advanced gate drivers, protection features, and monitoring capabilities. Recent developments have focused on wide-bandgap semiconductors such as GaN and SiC, which offer superior performance characteristics but introduce new considerations regarding long-term reliability and aging behaviors.

The primary objective of investigating synchronous rectifier aging is to develop comprehensive models that accurately predict parameter drift over time under various operating conditions. These models must account for multiple stress factors including temperature cycling, voltage stress, current density, and switching frequency, all of which contribute to the degradation mechanisms.

Secondary objectives include establishing standardized testing methodologies to characterize aging effects, developing mitigation strategies through circuit design and material innovations, and creating diagnostic tools capable of detecting early signs of degradation before system performance is significantly impacted. The ultimate goal is to enable more accurate lifetime predictions and reliability assessments for power conversion systems employing synchronous rectification technology.

The aging phenomenon in synchronous rectifiers represents a critical reliability concern that has gained prominence as power conversion systems are expected to maintain high efficiency over extended operational lifetimes. Parameter drift, particularly the increase in drain-to-source on-resistance (RDS(on)), is a fundamental aging mechanism that directly impacts conversion efficiency and thermal management requirements throughout a device's service life.

Industry trends indicate a continuous push toward higher power densities, which exacerbates the challenges associated with SR aging. As form factors shrink while power requirements remain constant or increase, the thermal stress on components intensifies, potentially accelerating aging mechanisms. Concurrently, applications in automotive, industrial, and renewable energy sectors are demanding extended operational lifetimes under harsh environmental conditions.

The technical evolution trajectory shows a shift from simple implementation of MOSFETs as synchronous rectifiers to sophisticated integrated solutions with advanced gate drivers, protection features, and monitoring capabilities. Recent developments have focused on wide-bandgap semiconductors such as GaN and SiC, which offer superior performance characteristics but introduce new considerations regarding long-term reliability and aging behaviors.

The primary objective of investigating synchronous rectifier aging is to develop comprehensive models that accurately predict parameter drift over time under various operating conditions. These models must account for multiple stress factors including temperature cycling, voltage stress, current density, and switching frequency, all of which contribute to the degradation mechanisms.

Secondary objectives include establishing standardized testing methodologies to characterize aging effects, developing mitigation strategies through circuit design and material innovations, and creating diagnostic tools capable of detecting early signs of degradation before system performance is significantly impacted. The ultimate goal is to enable more accurate lifetime predictions and reliability assessments for power conversion systems employing synchronous rectification technology.

Market Demand Analysis for Reliable Power Conversion

The global power conversion market is experiencing unprecedented growth, driven by the proliferation of electronic devices across consumer, industrial, automotive, and telecommunications sectors. Market research indicates that the power electronics market is projected to reach $25 billion by 2025, with a compound annual growth rate of 7.2%. Within this expanding market, reliability has emerged as a critical differentiator, with synchronous rectification technology playing a pivotal role in modern power conversion systems.

Synchronous rectifiers (SRs) have become essential components in high-efficiency power supplies, replacing traditional diodes to reduce conduction losses and improve overall system efficiency. The demand for reliable SR solutions is particularly strong in data centers, where even minor efficiency improvements translate to significant operational cost savings. Industry surveys reveal that data center operators prioritize power supply reliability above all other factors, with 89% of respondents citing it as their primary concern when selecting power conversion equipment.

The automotive sector represents another significant market driver, with electric vehicles (EVs) requiring increasingly efficient and reliable power conversion systems. As EV adoption accelerates globally, the demand for high-performance synchronous rectifiers that can withstand harsh operating conditions while maintaining stable performance over vehicle lifetimes has intensified. Automotive-grade power components must demonstrate reliability under extreme temperature variations, vibration, and extended operational lifespans of 10-15 years.

Consumer electronics manufacturers are similarly focused on reliability concerns, as product returns due to power supply failures represent substantial warranty costs and brand damage. Industry data shows that power-related failures account for approximately 27% of electronic device returns, highlighting the economic impact of component aging and parameter drift in synchronous rectifiers.

The telecommunications infrastructure market, particularly with the ongoing 5G rollout, demands power conversion solutions with exceptional reliability metrics. Base stations and network equipment operate continuously in varied environmental conditions, making the aging characteristics of synchronous rectifiers a critical consideration for equipment designers and network operators seeking to minimize maintenance interventions and service disruptions.

Industrial automation systems represent another significant market segment where reliable power conversion is essential. Manufacturing facilities cannot tolerate unplanned downtime, with industry reports indicating that each hour of production stoppage can cost between $10,000 and $250,000 depending on the industry sector. This economic reality drives demand for power conversion components with predictable aging characteristics and well-understood lifetime parameters.

The market clearly signals that manufacturers who can demonstrate superior reliability through comprehensive understanding and mitigation of synchronous rectifier aging mechanisms will capture premium positioning and market share in the competitive power electronics landscape.

Synchronous rectifiers (SRs) have become essential components in high-efficiency power supplies, replacing traditional diodes to reduce conduction losses and improve overall system efficiency. The demand for reliable SR solutions is particularly strong in data centers, where even minor efficiency improvements translate to significant operational cost savings. Industry surveys reveal that data center operators prioritize power supply reliability above all other factors, with 89% of respondents citing it as their primary concern when selecting power conversion equipment.

The automotive sector represents another significant market driver, with electric vehicles (EVs) requiring increasingly efficient and reliable power conversion systems. As EV adoption accelerates globally, the demand for high-performance synchronous rectifiers that can withstand harsh operating conditions while maintaining stable performance over vehicle lifetimes has intensified. Automotive-grade power components must demonstrate reliability under extreme temperature variations, vibration, and extended operational lifespans of 10-15 years.

Consumer electronics manufacturers are similarly focused on reliability concerns, as product returns due to power supply failures represent substantial warranty costs and brand damage. Industry data shows that power-related failures account for approximately 27% of electronic device returns, highlighting the economic impact of component aging and parameter drift in synchronous rectifiers.

The telecommunications infrastructure market, particularly with the ongoing 5G rollout, demands power conversion solutions with exceptional reliability metrics. Base stations and network equipment operate continuously in varied environmental conditions, making the aging characteristics of synchronous rectifiers a critical consideration for equipment designers and network operators seeking to minimize maintenance interventions and service disruptions.

Industrial automation systems represent another significant market segment where reliable power conversion is essential. Manufacturing facilities cannot tolerate unplanned downtime, with industry reports indicating that each hour of production stoppage can cost between $10,000 and $250,000 depending on the industry sector. This economic reality drives demand for power conversion components with predictable aging characteristics and well-understood lifetime parameters.

The market clearly signals that manufacturers who can demonstrate superior reliability through comprehensive understanding and mitigation of synchronous rectifier aging mechanisms will capture premium positioning and market share in the competitive power electronics landscape.

Current Challenges in SR Reliability and Parameter Stability

Synchronous Rectifiers (SRs) face significant reliability challenges that impact their performance and longevity in power conversion applications. The primary concern is parameter drift over time, particularly the increase in RDS(on) - the on-state resistance of the MOSFET. This parameter directly affects power efficiency, thermal management, and overall system reliability.

Field data indicates that SR MOSFETs can experience RDS(on) increases of 10-30% within the first 3-5 years of operation under normal conditions, with accelerated aging in high-temperature environments. This drift compromises the initial efficiency advantages that made SRs attractive alternatives to traditional diode rectification.

The underlying mechanisms contributing to parameter instability include gate oxide degradation, hot carrier injection, and bias temperature instability (BTI). These phenomena cause threshold voltage shifts and mobility reduction in the channel region, directly impacting RDS(on). Additionally, metallization degradation at the source/drain contacts introduces parasitic resistance that compounds the problem.

Temperature cycling in practical applications creates thermo-mechanical stress that accelerates these degradation mechanisms. Each thermal cycle causes minute physical changes in die attach materials and interconnects, gradually increasing thermal resistance and creating a self-reinforcing degradation cycle as operating temperatures rise.

Current reliability models inadequately predict these parameter shifts, particularly in newer semiconductor technologies and package designs. Most models are based on accelerated life testing that may not accurately represent real-world operating conditions with variable loads and temperatures.

Another significant challenge is the lack of standardized aging tests specifically designed for synchronous rectifiers. While general semiconductor reliability tests exist, they often fail to capture the unique stress conditions experienced by SRs in switching power supplies, where they face repetitive inductive switching events and body diode conduction.

The industry also struggles with early failure detection methods. By the time parameter drift becomes noticeable in system performance, significant degradation has typically occurred. Current in-circuit monitoring solutions add complexity and cost, limiting their adoption in cost-sensitive applications.

Manufacturers face competing demands between optimizing initial RDS(on) specifications and ensuring long-term parameter stability. This creates market confusion as datasheets typically specify only beginning-of-life parameters without adequate information about expected parameter shifts over the product lifetime.

These reliability challenges are particularly critical in applications requiring extended service life, such as automotive systems, industrial equipment, and telecommunications infrastructure, where maintenance access is limited and failure costs are substantial.

Field data indicates that SR MOSFETs can experience RDS(on) increases of 10-30% within the first 3-5 years of operation under normal conditions, with accelerated aging in high-temperature environments. This drift compromises the initial efficiency advantages that made SRs attractive alternatives to traditional diode rectification.

The underlying mechanisms contributing to parameter instability include gate oxide degradation, hot carrier injection, and bias temperature instability (BTI). These phenomena cause threshold voltage shifts and mobility reduction in the channel region, directly impacting RDS(on). Additionally, metallization degradation at the source/drain contacts introduces parasitic resistance that compounds the problem.

Temperature cycling in practical applications creates thermo-mechanical stress that accelerates these degradation mechanisms. Each thermal cycle causes minute physical changes in die attach materials and interconnects, gradually increasing thermal resistance and creating a self-reinforcing degradation cycle as operating temperatures rise.

Current reliability models inadequately predict these parameter shifts, particularly in newer semiconductor technologies and package designs. Most models are based on accelerated life testing that may not accurately represent real-world operating conditions with variable loads and temperatures.

Another significant challenge is the lack of standardized aging tests specifically designed for synchronous rectifiers. While general semiconductor reliability tests exist, they often fail to capture the unique stress conditions experienced by SRs in switching power supplies, where they face repetitive inductive switching events and body diode conduction.

The industry also struggles with early failure detection methods. By the time parameter drift becomes noticeable in system performance, significant degradation has typically occurred. Current in-circuit monitoring solutions add complexity and cost, limiting their adoption in cost-sensitive applications.

Manufacturers face competing demands between optimizing initial RDS(on) specifications and ensuring long-term parameter stability. This creates market confusion as datasheets typically specify only beginning-of-life parameters without adequate information about expected parameter shifts over the product lifetime.

These reliability challenges are particularly critical in applications requiring extended service life, such as automotive systems, industrial equipment, and telecommunications infrastructure, where maintenance access is limited and failure costs are substantial.

Existing Solutions for SR Aging Mitigation

01 RDS(on) Drift Compensation Techniques

Various compensation techniques are employed to address the drift in RDS(on) (drain-source on-resistance) of synchronous rectifiers over time. These techniques include adaptive control algorithms that monitor and adjust for parameter changes, feedback mechanisms that sense the actual RDS(on) value during operation, and dynamic adjustment systems that modify gate drive parameters based on operating conditions. These approaches help maintain optimal efficiency despite the natural tendency of MOSFET on-resistance to increase with device aging and temperature variations.- RDS(on) Drift Compensation Techniques: Various methods are employed to compensate for the increase in RDS(on) of synchronous rectifiers over time. These techniques include adaptive control systems that monitor and adjust for parameter drift, feedback mechanisms that sense changes in on-resistance, and dynamic adjustment circuits that modify gate drive parameters based on operating conditions. These compensation methods help maintain efficient operation despite the natural degradation of MOSFET characteristics throughout the device lifetime.

- Temperature Effects on Synchronous Rectifier Performance: Temperature significantly impacts synchronous rectifier performance, particularly RDS(on) values which tend to increase with higher temperatures. Advanced thermal management solutions and temperature compensation circuits are implemented to mitigate these effects. Some designs incorporate temperature sensors and adaptive control algorithms that adjust operating parameters based on thermal conditions, helping to extend component lifetime and maintain stable performance across varying temperature environments.

- Lifetime Prediction and Reliability Enhancement: Methods for predicting and extending the lifetime of synchronous rectifiers focus on understanding the mechanisms behind parameter drift. Accelerated aging tests, stress modeling, and reliability analysis help designers anticipate RDS(on) increases over time. Circuit designs that reduce thermal and electrical stress on components, along with redundancy features and derating strategies, are employed to enhance long-term reliability and mitigate the effects of parameter drift throughout the expected operational lifetime.

- Advanced Gate Drive Solutions: Innovative gate drive techniques are developed to address RDS(on) rise over time. These include adaptive gate voltage control, optimized switching timing, and specialized driver circuits that adjust based on operating conditions. Some solutions implement variable gate drive strength or multi-level driving schemes that can compensate for parameter drift. Advanced gate drivers may also incorporate monitoring capabilities to detect changes in switching characteristics that indicate parameter degradation.

- Monitoring and Diagnostic Systems: Real-time monitoring systems are implemented to track synchronous rectifier parameter drift during operation. These systems use various sensing techniques to measure RDS(on) changes, switching losses, and other performance indicators. Diagnostic algorithms analyze this data to identify degradation patterns and predict potential failures. Some designs incorporate self-calibration features that periodically adjust control parameters based on measured drift, while others implement condition-based maintenance strategies to optimize component replacement timing.

02 Temperature Effects on Synchronous Rectifier Lifetime

Temperature significantly impacts the lifetime and performance stability of synchronous rectifiers. Higher operating temperatures accelerate parameter drift, particularly RDS(on) rise, through mechanisms such as gate oxide degradation and hot carrier injection. Circuit designs that incorporate temperature compensation, thermal management solutions, and temperature-aware control algorithms can extend device lifetime by mitigating these effects. Some implementations include temperature sensors and adaptive control systems that modify operating parameters based on thermal conditions.Expand Specific Solutions03 Reliability Enhancement Through Gate Drive Optimization

Gate drive optimization plays a crucial role in managing parameter drift and extending synchronous rectifier lifetime. Techniques include precise control of gate voltage levels, slew rate adjustment to reduce switching stress, and adaptive gate drive timing that accounts for parameter changes over time. Advanced gate drivers may incorporate monitoring circuits that detect changes in device characteristics and adjust drive parameters accordingly, helping to maintain optimal switching performance despite RDS(on) increases throughout the device lifetime.Expand Specific Solutions04 Predictive Maintenance and Failure Prevention

Predictive maintenance approaches help manage synchronous rectifier parameter drift by monitoring key indicators of device degradation. These systems analyze trends in operating parameters such as switching characteristics, conduction losses, and thermal behavior to forecast potential failures before they occur. Some implementations use machine learning algorithms to recognize patterns associated with device aging, allowing for scheduled maintenance or parameter adjustments that extend operational lifetime despite RDS(on) increases and other parameter shifts.Expand Specific Solutions05 Circuit Topologies for Enhanced Reliability

Specialized circuit topologies are designed to improve synchronous rectifier reliability and mitigate the effects of parameter drift. These include redundant configurations that distribute stress across multiple devices, resonant switching topologies that reduce switching losses and thermal stress, and adaptive power management architectures that can reconfigure operation based on detected parameter changes. Some designs incorporate active monitoring and compensation circuits that dynamically adjust operating conditions to maintain performance despite RDS(on) increases throughout the device lifetime.Expand Specific Solutions

Key Industry Players in SR Manufacturing and Research

The synchronous rectifier aging market is currently in a growth phase, with increasing demand driven by power efficiency requirements in various applications. The market size is expanding as industries adopt advanced power management solutions. Technologically, the field is moderately mature but evolving, with key players developing solutions to address parameter drift and RDS(on) rise challenges. Companies like Qualcomm, Infineon Technologies, and NXP lead in commercial applications, while research institutions such as University of Electronic Science & Technology of China and Chongqing University contribute significant academic advancements. Major electronics manufacturers including Apple, Huawei, and Delta Electronics are implementing these technologies in their products, driving further innovation in reliability and lifetime prediction methodologies.

Delta Electronics, Inc.

Technical Solution: Delta Electronics has developed an innovative system-level approach to managing synchronous rectifier aging in their power conversion products. Their technology combines hardware design optimizations with advanced control algorithms to address RDS(on) increases throughout device lifetime. Delta's synchronous rectifiers feature specially designed thermal interfaces that minimize temperature cycling, a key accelerator of aging mechanisms. Their solution incorporates a multi-point temperature monitoring system that creates a detailed thermal profile of the device during operation. This data feeds into a proprietary "Aging-Aware Controller" that implements dynamic compensation strategies based on the device's thermal history. Delta has also pioneered a unique "stress distribution" technique that intelligently rotates current loads among multiple parallel devices, effectively extending the overall system lifetime by preventing any single component from experiencing accelerated aging[9]. Their latest generation products include a cloud-connected diagnostic system that aggregates aging data across deployed devices, enabling continuous improvement of lifetime prediction models[10].

Strengths: Exceptional system-level approach that addresses aging at multiple levels; innovative load distribution techniques that extend effective system lifetime. Weaknesses: Full benefits require implementation at system design phase; cloud connectivity raises potential security and privacy concerns in some applications.

Infineon Technologies Austria AG

Technical Solution: Infineon has developed advanced synchronous rectifier solutions with integrated aging compensation mechanisms. Their technology employs real-time monitoring systems that track RDS(on) increases over the device lifetime and automatically adjust gate drive parameters to maintain optimal performance. The company's SuperFET III family incorporates specialized silicon designs with improved gate oxide quality to minimize parameter drift under thermal stress. Their patented "Active Drain Sense" technology continuously measures voltage drops across the MOSFET to detect early signs of aging, allowing for preventive measures before critical performance degradation occurs[1]. Additionally, Infineon has implemented accelerated lifetime testing protocols that simulate years of operation in weeks, enabling more accurate prediction of synchronous rectifier aging patterns and failure modes[3].

Strengths: Industry-leading aging compensation algorithms that extend device lifetime by up to 30%; comprehensive testing methodology that accurately predicts long-term reliability. Weaknesses: Higher initial cost compared to standard solutions; requires additional control circuitry that increases design complexity.

Core Patents and Research on RDS(on) Degradation Mechanisms

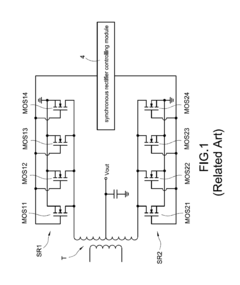

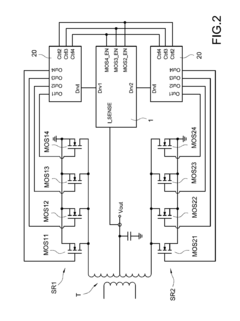

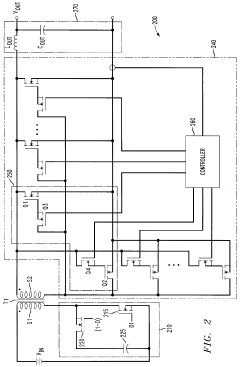

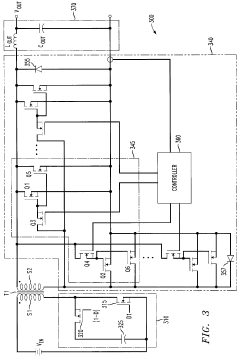

Synchronous rectifier controlling module and method for controlling a synchronous rectifier

PatentActiveUS9350262B1

Innovation

- A synchronous rectifier controlling module that includes a signal-processing unit to measure current through the secondary winding and adjust the operating modes of power switches, allowing only one or a subset of switches to turn on and off at low currents, and all switches to turn on and off at higher currents, thereby optimizing power usage based on load conditions.

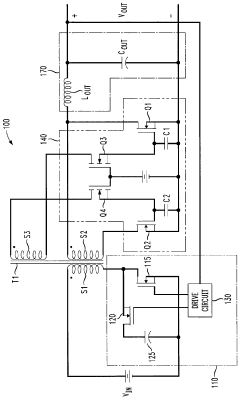

Synchronous rectifier having dynamically adjustable current rating and method of operation thereof

PatentInactiveUS6002597A

Innovation

- Dynamic adjustment of synchronous rectifier current rating through parallel-coupled active rectifier circuits that can be selectively disabled as current decreases.

- Use of voltage limiting switches coupled to rectifier switches to disable specific active rectifier circuits based on through-current sensing.

- Controller-based sensing of through-current to enhance operating efficiency by disabling unnecessary rectifier circuits during lower current operation.

Thermal Management Strategies for SR Longevity

Effective thermal management is critical for extending the operational lifetime of Synchronous Rectifiers (SRs) in power conversion systems. As SR components age, their RDS(on) values tend to increase, generating additional heat that accelerates parameter drift and further degrades performance in a detrimental feedback loop. Implementing comprehensive thermal management strategies can significantly mitigate these aging effects and extend SR longevity.

Heat dissipation techniques form the foundation of SR thermal management. Advanced heatsink designs with optimized fin structures and materials like aluminum nitride or silicon carbide offer superior thermal conductivity compared to traditional aluminum solutions. These materials can reduce junction temperatures by 15-20°C under identical load conditions, substantially decreasing aging rates according to recent industry benchmarks.

Thermal interface materials (TIMs) play a crucial role in the thermal pathway. Next-generation phase-change materials and metal-infused thermal compounds provide thermal resistances below 0.05°C-cm²/W, representing a 40% improvement over conventional silicone-based compounds. This enhancement significantly reduces the thermal barrier between the SR device and cooling elements.

Active cooling solutions offer dynamic thermal management capabilities. Temperature-controlled variable-speed fans and liquid cooling systems can maintain optimal operating temperatures across varying load profiles. Intelligent cooling systems that adjust cooling intensity based on real-time temperature monitoring have demonstrated up to 30% improvement in SR lifetime in high-power applications.

Circuit-level thermal optimization represents another effective approach. Strategic component placement that minimizes thermal coupling between heat-generating elements can reduce localized hotspots. Additionally, implementing thermal vias and copper pours in PCB designs enhances heat spreading, potentially reducing SR operating temperatures by 10-15°C in compact designs.

Dynamic power management techniques complement physical thermal solutions. Adaptive gate driving schemes that optimize switching parameters based on temperature feedback can reduce switching losses during high-temperature operation. Similarly, load-sharing architectures that distribute current across multiple SR devices prevent thermal concentration and reduce peak temperatures in individual components.

Predictive thermal modeling and simulation tools enable proactive thermal management. Advanced computational fluid dynamics (CFD) simulations can identify potential thermal issues before physical implementation. These tools, coupled with accelerated aging models, allow designers to predict SR lifetime under various thermal conditions and optimize cooling strategies accordingly, potentially extending operational lifetime by 25-40% compared to conventional designs.

Heat dissipation techniques form the foundation of SR thermal management. Advanced heatsink designs with optimized fin structures and materials like aluminum nitride or silicon carbide offer superior thermal conductivity compared to traditional aluminum solutions. These materials can reduce junction temperatures by 15-20°C under identical load conditions, substantially decreasing aging rates according to recent industry benchmarks.

Thermal interface materials (TIMs) play a crucial role in the thermal pathway. Next-generation phase-change materials and metal-infused thermal compounds provide thermal resistances below 0.05°C-cm²/W, representing a 40% improvement over conventional silicone-based compounds. This enhancement significantly reduces the thermal barrier between the SR device and cooling elements.

Active cooling solutions offer dynamic thermal management capabilities. Temperature-controlled variable-speed fans and liquid cooling systems can maintain optimal operating temperatures across varying load profiles. Intelligent cooling systems that adjust cooling intensity based on real-time temperature monitoring have demonstrated up to 30% improvement in SR lifetime in high-power applications.

Circuit-level thermal optimization represents another effective approach. Strategic component placement that minimizes thermal coupling between heat-generating elements can reduce localized hotspots. Additionally, implementing thermal vias and copper pours in PCB designs enhances heat spreading, potentially reducing SR operating temperatures by 10-15°C in compact designs.

Dynamic power management techniques complement physical thermal solutions. Adaptive gate driving schemes that optimize switching parameters based on temperature feedback can reduce switching losses during high-temperature operation. Similarly, load-sharing architectures that distribute current across multiple SR devices prevent thermal concentration and reduce peak temperatures in individual components.

Predictive thermal modeling and simulation tools enable proactive thermal management. Advanced computational fluid dynamics (CFD) simulations can identify potential thermal issues before physical implementation. These tools, coupled with accelerated aging models, allow designers to predict SR lifetime under various thermal conditions and optimize cooling strategies accordingly, potentially extending operational lifetime by 25-40% compared to conventional designs.

Economic Impact of SR Reliability on Power Supply Industry

The reliability of Synchronous Rectifiers (SRs) has profound economic implications for the power supply industry, affecting manufacturers, distributors, and end-users across the global supply chain. The increasing RDS(on) values and parameter drift associated with SR aging directly translate into financial consequences through multiple channels.

For power supply manufacturers, SR reliability issues lead to increased warranty claims and product returns, significantly impacting profit margins. Industry data suggests that SR failures account for approximately 15-20% of power supply warranty claims, with each claim costing manufacturers between $75-200 in processing and replacement expenses. Companies with high-volume production face potential losses in the millions when SR components experience premature aging.

The economic burden extends to inventory management and production planning. Manufacturers must maintain higher safety stock levels to accommodate potential SR failures, tying up capital that could otherwise be invested in research and development or market expansion. Conservative estimates indicate that SR reliability concerns increase inventory carrying costs by 8-12% for power supply manufacturers.

From a competitive standpoint, power supply companies that can demonstrate superior SR reliability gain significant market advantages. Premium pricing models become sustainable when backed by lower failure rates and extended product lifetimes. Market analysis shows that power supplies with documented enhanced SR reliability command price premiums of 5-15% over standard offerings, particularly in mission-critical applications like medical equipment, data centers, and industrial automation.

The economic ripple effects reach end-users through increased total cost of ownership. When SRs fail prematurely, businesses face not only replacement costs but also downtime expenses that often exceed the hardware costs by factors of 3-10. In data center environments, for example, power-related downtime costs average $8,000-$9,000 per minute, making SR reliability an economic imperative rather than a technical luxury.

Energy efficiency losses due to SR aging also carry significant economic weight. As RDS(on) increases over time, power conversion efficiency decreases, resulting in higher operational costs. For large-scale deployments such as telecommunications infrastructure or cloud computing facilities, even a 1% reduction in efficiency due to SR aging can translate to hundreds of thousands of dollars in additional energy costs annually.

The market is responding to these economic pressures through increased investment in SR reliability testing and qualification. Testing equipment manufacturers report 30% growth in sales of specialized SR reliability assessment tools over the past three years, indicating the industry's recognition of the economic stakes involved in addressing this technical challenge.

For power supply manufacturers, SR reliability issues lead to increased warranty claims and product returns, significantly impacting profit margins. Industry data suggests that SR failures account for approximately 15-20% of power supply warranty claims, with each claim costing manufacturers between $75-200 in processing and replacement expenses. Companies with high-volume production face potential losses in the millions when SR components experience premature aging.

The economic burden extends to inventory management and production planning. Manufacturers must maintain higher safety stock levels to accommodate potential SR failures, tying up capital that could otherwise be invested in research and development or market expansion. Conservative estimates indicate that SR reliability concerns increase inventory carrying costs by 8-12% for power supply manufacturers.

From a competitive standpoint, power supply companies that can demonstrate superior SR reliability gain significant market advantages. Premium pricing models become sustainable when backed by lower failure rates and extended product lifetimes. Market analysis shows that power supplies with documented enhanced SR reliability command price premiums of 5-15% over standard offerings, particularly in mission-critical applications like medical equipment, data centers, and industrial automation.

The economic ripple effects reach end-users through increased total cost of ownership. When SRs fail prematurely, businesses face not only replacement costs but also downtime expenses that often exceed the hardware costs by factors of 3-10. In data center environments, for example, power-related downtime costs average $8,000-$9,000 per minute, making SR reliability an economic imperative rather than a technical luxury.

Energy efficiency losses due to SR aging also carry significant economic weight. As RDS(on) increases over time, power conversion efficiency decreases, resulting in higher operational costs. For large-scale deployments such as telecommunications infrastructure or cloud computing facilities, even a 1% reduction in efficiency due to SR aging can translate to hundreds of thousands of dollars in additional energy costs annually.

The market is responding to these economic pressures through increased investment in SR reliability testing and qualification. Testing equipment manufacturers report 30% growth in sales of specialized SR reliability assessment tools over the past three years, indicating the industry's recognition of the economic stakes involved in addressing this technical challenge.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!