Synchronous Rectifier In Flyback: DCM/QR/CCM Modes, Peak Current And Stress

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flyback SR Technology Evolution and Objectives

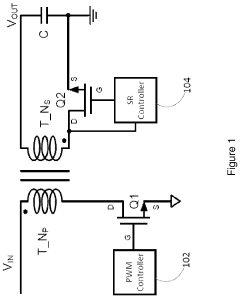

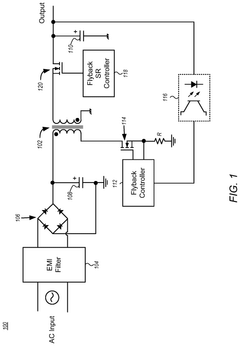

Flyback converters have evolved significantly since their inception in the 1970s as simple isolated power supply topologies. Initially designed for low-power applications with minimal efficiency requirements, these converters have transformed into sophisticated power management solutions capable of addressing modern electronic demands. The evolution trajectory has been primarily driven by the need for higher efficiency, smaller form factors, and improved reliability across various operating conditions.

The introduction of synchronous rectification (SR) in flyback converters marked a pivotal advancement in the late 1990s, replacing traditional Schottky diodes with MOSFETs to significantly reduce conduction losses. Early SR implementations were limited to simple timing control mechanisms that struggled with varying operating conditions, particularly in discontinuous conduction mode (DCM).

By the mid-2000s, SR technology progressed to accommodate quasi-resonant (QR) operation, which offered improved efficiency through valley switching techniques. This period saw the development of more sophisticated control algorithms that could better predict optimal MOSFET turn-on and turn-off timing based on transformer voltage sensing.

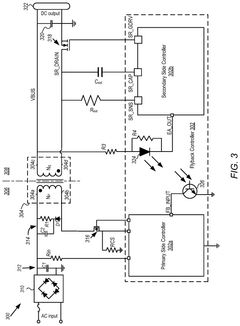

The most recent evolutionary phase has focused on continuous conduction mode (CCM) operation with SR, presenting unique challenges due to the continuous current flow and the critical timing requirements for MOSFET switching. Advanced controllers now incorporate multiple detection methods including primary-side sensing, secondary-side sensing, and hybrid approaches to optimize SR operation across all three modes: DCM, QR, and CCM.

Peak current management has emerged as a critical focus area, with modern SR controllers implementing sophisticated current sensing and limiting features to protect against transient conditions while maintaining optimal efficiency. Stress management techniques have also evolved to address thermal, voltage, and current stresses that can compromise reliability and performance.

The primary objectives of contemporary flyback SR technology development include achieving ultra-high efficiency (>95%) across wide load ranges, enabling higher power density through reduced thermal dissipation, ensuring robust operation across all conduction modes, and simplifying implementation to reduce component count and system cost. Additionally, there is a growing emphasis on adaptive control algorithms that can automatically optimize SR timing based on real-time operating conditions.

Future development goals include seamless mode transition capabilities, enhanced protection features for abnormal operating conditions, and integration with digital control systems to enable predictive maintenance and system optimization. The convergence of SR technology with wide-bandgap semiconductors (SiC and GaN) represents another frontier, promising further efficiency improvements and higher switching frequencies.

The introduction of synchronous rectification (SR) in flyback converters marked a pivotal advancement in the late 1990s, replacing traditional Schottky diodes with MOSFETs to significantly reduce conduction losses. Early SR implementations were limited to simple timing control mechanisms that struggled with varying operating conditions, particularly in discontinuous conduction mode (DCM).

By the mid-2000s, SR technology progressed to accommodate quasi-resonant (QR) operation, which offered improved efficiency through valley switching techniques. This period saw the development of more sophisticated control algorithms that could better predict optimal MOSFET turn-on and turn-off timing based on transformer voltage sensing.

The most recent evolutionary phase has focused on continuous conduction mode (CCM) operation with SR, presenting unique challenges due to the continuous current flow and the critical timing requirements for MOSFET switching. Advanced controllers now incorporate multiple detection methods including primary-side sensing, secondary-side sensing, and hybrid approaches to optimize SR operation across all three modes: DCM, QR, and CCM.

Peak current management has emerged as a critical focus area, with modern SR controllers implementing sophisticated current sensing and limiting features to protect against transient conditions while maintaining optimal efficiency. Stress management techniques have also evolved to address thermal, voltage, and current stresses that can compromise reliability and performance.

The primary objectives of contemporary flyback SR technology development include achieving ultra-high efficiency (>95%) across wide load ranges, enabling higher power density through reduced thermal dissipation, ensuring robust operation across all conduction modes, and simplifying implementation to reduce component count and system cost. Additionally, there is a growing emphasis on adaptive control algorithms that can automatically optimize SR timing based on real-time operating conditions.

Future development goals include seamless mode transition capabilities, enhanced protection features for abnormal operating conditions, and integration with digital control systems to enable predictive maintenance and system optimization. The convergence of SR technology with wide-bandgap semiconductors (SiC and GaN) represents another frontier, promising further efficiency improvements and higher switching frequencies.

Market Demand for Efficient Power Conversion Solutions

The global power electronics market has witnessed substantial growth, reaching $41.1 billion in 2022, with projections indicating expansion to $65.7 billion by 2028, representing a CAGR of 8.2%. This growth is primarily driven by increasing demand for energy-efficient power conversion solutions across multiple sectors including consumer electronics, telecommunications, automotive, and industrial applications.

Synchronous rectification technology in flyback converters has emerged as a critical component in meeting market demands for higher efficiency power supplies. With global energy efficiency regulations becoming increasingly stringent, manufacturers are under pressure to develop power supplies that minimize conversion losses. The European Commission's ErP Directive and the U.S. Department of Energy's efficiency standards have established minimum performance requirements that necessitate advanced solutions like synchronous rectification.

Consumer electronics represents the largest market segment for efficient power conversion solutions, accounting for approximately 32% of the total market share. The proliferation of smartphones, tablets, and laptops has created substantial demand for compact, efficient chargers and adapters. Market research indicates that consumers are increasingly willing to pay premium prices for fast-charging solutions that maintain high efficiency, creating a significant opportunity for synchronous rectifier implementations.

The automotive sector presents another rapidly growing market for synchronous rectification technology, particularly with the electric vehicle (EV) market expanding at 25% annually. On-board chargers and DC-DC converters in EVs require high-efficiency power conversion to maximize battery life and driving range. This application demands robust synchronous rectifier solutions capable of handling various operating modes (DCM/QR/CCM) under fluctuating load conditions.

Data centers and telecommunications infrastructure collectively consume over 3% of global electricity production, creating substantial demand for efficiency improvements in power supplies. Even marginal efficiency gains of 1-2% can translate to millions in energy cost savings for large-scale operations. This sector particularly values synchronous rectifier solutions that can maintain high efficiency across varying load conditions, making adaptive control methods for different operating modes increasingly important.

The industrial power supply market segment values reliability and robustness alongside efficiency. This sector shows growing interest in synchronous rectifier solutions that can handle high peak currents and voltage stress while maintaining stable operation across multiple operating modes. Market analysis reveals that industrial customers prioritize total cost of ownership over initial investment, creating opportunities for premium synchronous rectifier solutions that offer superior long-term performance.

Regional analysis shows Asia-Pacific leading the market with 45% share, followed by North America (28%) and Europe (22%). China and Taiwan dominate manufacturing, while design innovation centers remain concentrated in the United States, Germany, and Japan.

Synchronous rectification technology in flyback converters has emerged as a critical component in meeting market demands for higher efficiency power supplies. With global energy efficiency regulations becoming increasingly stringent, manufacturers are under pressure to develop power supplies that minimize conversion losses. The European Commission's ErP Directive and the U.S. Department of Energy's efficiency standards have established minimum performance requirements that necessitate advanced solutions like synchronous rectification.

Consumer electronics represents the largest market segment for efficient power conversion solutions, accounting for approximately 32% of the total market share. The proliferation of smartphones, tablets, and laptops has created substantial demand for compact, efficient chargers and adapters. Market research indicates that consumers are increasingly willing to pay premium prices for fast-charging solutions that maintain high efficiency, creating a significant opportunity for synchronous rectifier implementations.

The automotive sector presents another rapidly growing market for synchronous rectification technology, particularly with the electric vehicle (EV) market expanding at 25% annually. On-board chargers and DC-DC converters in EVs require high-efficiency power conversion to maximize battery life and driving range. This application demands robust synchronous rectifier solutions capable of handling various operating modes (DCM/QR/CCM) under fluctuating load conditions.

Data centers and telecommunications infrastructure collectively consume over 3% of global electricity production, creating substantial demand for efficiency improvements in power supplies. Even marginal efficiency gains of 1-2% can translate to millions in energy cost savings for large-scale operations. This sector particularly values synchronous rectifier solutions that can maintain high efficiency across varying load conditions, making adaptive control methods for different operating modes increasingly important.

The industrial power supply market segment values reliability and robustness alongside efficiency. This sector shows growing interest in synchronous rectifier solutions that can handle high peak currents and voltage stress while maintaining stable operation across multiple operating modes. Market analysis reveals that industrial customers prioritize total cost of ownership over initial investment, creating opportunities for premium synchronous rectifier solutions that offer superior long-term performance.

Regional analysis shows Asia-Pacific leading the market with 45% share, followed by North America (28%) and Europe (22%). China and Taiwan dominate manufacturing, while design innovation centers remain concentrated in the United States, Germany, and Japan.

Current SR Implementation Challenges Across Operating Modes

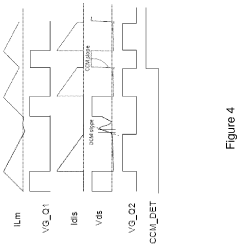

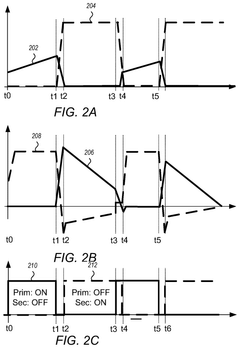

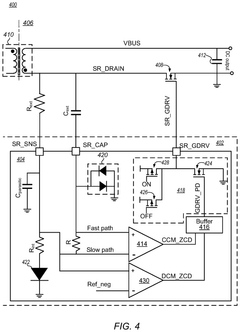

Implementing Synchronous Rectification (SR) in flyback converters presents distinct challenges across different operating modes. In Discontinuous Conduction Mode (DCM), the primary challenge lies in accurately detecting the zero-current crossing point. Since current falls to zero during each switching cycle, the SR MOSFET must turn off precisely at this moment to prevent reverse current flow. Timing errors as small as tens of nanoseconds can lead to significant efficiency losses or even circuit damage.

For Quasi-Resonant (QR) mode operation, the variable switching frequency complicates SR timing control. As the controller adjusts switching frequency based on load conditions, the SR driver must dynamically adapt its timing parameters. The resonant behavior creates voltage oscillations that can interfere with accurate current sensing, making it difficult to determine optimal turn-off points for the SR MOSFET.

Continuous Conduction Mode (CCM) presents perhaps the most complex SR implementation challenges. Unlike DCM, the current never reaches zero, requiring sophisticated current-direction detection methods. The lack of a natural zero-current point eliminates the clear turn-off signal present in other modes. Additionally, CCM operation typically involves higher RMS currents, increasing thermal management requirements for SR MOSFETs.

Peak current handling represents another significant challenge across all operating modes. SR MOSFETs must be properly sized to handle current spikes that can be 2-3 times the average current. These transients create thermal stress and potential reliability issues, particularly in high-power applications. The gate driver design must also account for these current peaks to ensure proper switching under worst-case conditions.

Voltage stress management presents additional complications. In flyback topologies, the SR MOSFET experiences voltage stresses related to both input voltage and reflected output voltage, plus spikes from leakage inductance. These voltage transients can exceed device ratings without proper snubber circuits, leading to premature failure.

Cross-mode operation presents perhaps the most demanding challenge. Many modern power supplies must seamlessly transition between DCM, QR, and CCM modes depending on load conditions. Designing an SR controller that functions optimally across all these modes requires sophisticated adaptive algorithms that can detect operating mode transitions and adjust timing parameters accordingly.

Temperature variations further complicate SR implementation, as MOSFET characteristics change significantly with temperature. The on-resistance typically increases with temperature, while switching speeds decrease, requiring compensation mechanisms in the control algorithm to maintain efficiency across the operating temperature range.

For Quasi-Resonant (QR) mode operation, the variable switching frequency complicates SR timing control. As the controller adjusts switching frequency based on load conditions, the SR driver must dynamically adapt its timing parameters. The resonant behavior creates voltage oscillations that can interfere with accurate current sensing, making it difficult to determine optimal turn-off points for the SR MOSFET.

Continuous Conduction Mode (CCM) presents perhaps the most complex SR implementation challenges. Unlike DCM, the current never reaches zero, requiring sophisticated current-direction detection methods. The lack of a natural zero-current point eliminates the clear turn-off signal present in other modes. Additionally, CCM operation typically involves higher RMS currents, increasing thermal management requirements for SR MOSFETs.

Peak current handling represents another significant challenge across all operating modes. SR MOSFETs must be properly sized to handle current spikes that can be 2-3 times the average current. These transients create thermal stress and potential reliability issues, particularly in high-power applications. The gate driver design must also account for these current peaks to ensure proper switching under worst-case conditions.

Voltage stress management presents additional complications. In flyback topologies, the SR MOSFET experiences voltage stresses related to both input voltage and reflected output voltage, plus spikes from leakage inductance. These voltage transients can exceed device ratings without proper snubber circuits, leading to premature failure.

Cross-mode operation presents perhaps the most demanding challenge. Many modern power supplies must seamlessly transition between DCM, QR, and CCM modes depending on load conditions. Designing an SR controller that functions optimally across all these modes requires sophisticated adaptive algorithms that can detect operating mode transitions and adjust timing parameters accordingly.

Temperature variations further complicate SR implementation, as MOSFET characteristics change significantly with temperature. The on-resistance typically increases with temperature, while switching speeds decrease, requiring compensation mechanisms in the control algorithm to maintain efficiency across the operating temperature range.

Comparative Analysis of DCM/QR/CCM Implementation Approaches

01 Peak current control in synchronous rectifier flyback converters

Synchronous rectifier flyback converters employ peak current control mechanisms to regulate output voltage and prevent component stress. These systems monitor the primary side current and use feedback loops to adjust the switching timing. Advanced control algorithms can detect when the current reaches predetermined thresholds and modify the duty cycle accordingly, ensuring optimal performance while preventing excessive current stress on the synchronous rectifier MOSFETs.- Synchronous rectifier control techniques for peak current management: Various control techniques are employed in synchronous rectifiers for flyback converters to manage peak current. These include adaptive timing control, zero-voltage detection, and current sensing methods that optimize the switching timing of the synchronous rectifier. These techniques help reduce current stress by ensuring proper turn-on and turn-off timing, preventing reverse current flow, and maintaining efficient operation across varying load conditions.

- Circuit designs for reducing voltage and current stress in synchronous rectifiers: Specialized circuit designs are implemented to reduce voltage and current stress in synchronous rectifiers used in flyback converters. These designs include snubber circuits, resonant switching networks, and optimized gate drive circuits that minimize voltage spikes and current surges during switching transitions. By controlling the rate of change in current and voltage, these circuits protect the synchronous rectifier from excessive stress while improving overall converter efficiency.

- Peak current mode control in flyback converters with synchronous rectification: Peak current mode control schemes are implemented in flyback converters with synchronous rectification to regulate and limit peak currents. These control methods monitor the primary or secondary current and adjust the duty cycle accordingly to prevent current from exceeding safe operating limits. Advanced implementations include slope compensation, predictive control algorithms, and adaptive current limiting that respond to varying input voltages and load conditions while maintaining optimal efficiency.

- Timing optimization for synchronous rectifier switching to reduce stress: Precise timing optimization techniques are employed for synchronous rectifier switching to minimize current and voltage stress. These include predictive timing algorithms, delay compensation methods, and adaptive dead-time control that ensure optimal turn-on and turn-off timing of the synchronous rectifier. By precisely controlling the switching transitions based on operating conditions, these techniques reduce current spikes, prevent shoot-through current, and minimize switching losses.

- Integration of protection features for synchronous rectifiers under peak current conditions: Protection features are integrated into synchronous rectifier designs to safeguard against excessive peak current conditions. These include overcurrent detection circuits, thermal shutdown mechanisms, and fault management systems that prevent damage during abnormal operating conditions. Advanced protection schemes implement cycle-by-cycle current limiting, soft-start procedures, and recovery modes that allow the converter to safely resume operation after fault conditions have been cleared.

02 Voltage stress reduction techniques for synchronous rectifiers

Various techniques are employed to reduce voltage stress on synchronous rectifiers in flyback converters. These include snubber circuits, clamp circuits, and resonant switching methods that limit voltage spikes during switching transitions. By controlling the rate of change in current and voltage, these techniques prevent excessive voltage stress that could damage the synchronous rectifier components, while maintaining high efficiency operation.Expand Specific Solutions03 Timing control for synchronous rectifier turn-on/off

Precise timing control for synchronous rectifier switching is critical to minimize losses and stress in flyback converters. Advanced gate drive circuits detect optimal turn-on and turn-off moments by monitoring voltage or current conditions. These systems can predict the zero-voltage or zero-current crossing points to achieve soft switching, reducing peak current stress and electromagnetic interference while improving overall efficiency.Expand Specific Solutions04 Current sensing and protection mechanisms

Flyback converters with synchronous rectification implement various current sensing and protection mechanisms to prevent damage from overcurrent conditions. These include primary-side sensing, secondary-side sensing, and integrated current monitoring circuits. When excessive peak currents are detected, protection circuits can temporarily disable switching, adjust duty cycles, or implement cycle-by-cycle current limiting to protect the synchronous rectifier and other components from thermal and electrical stress.Expand Specific Solutions05 Resonant and quasi-resonant techniques for stress reduction

Resonant and quasi-resonant switching techniques are implemented in flyback converters to reduce peak current and voltage stress on synchronous rectifiers. These approaches utilize the natural resonance between inductive and capacitive elements to achieve soft switching transitions. By ensuring that switching occurs at zero voltage or zero current points, these techniques significantly reduce switching losses and stress, allowing for higher frequency operation and improved power density while maintaining component reliability.Expand Specific Solutions

Key Industry Players in SR Controller and Power IC Markets

The synchronous rectifier in flyback converter market is currently in a growth phase, with increasing demand driven by power efficiency requirements across various applications. The market size is expanding due to the proliferation of power-efficient devices in consumer electronics, automotive, and industrial sectors. Technologically, the field shows moderate maturity with ongoing innovations in DCM/QR/CCM modes and stress management. Leading players include established semiconductor manufacturers like Infineon Technologies, STMicroelectronics, and ON Semiconductor, alongside specialized power management companies such as Silergy, Richtek Technology, and Monolithic Power Systems. Academic institutions like Southeast University and Hangzhou Dianzi University contribute significant research. Companies like JoulWatt, Alpha & Omega Semiconductor, and Nexperia are advancing synchronous rectification technologies to address peak current challenges and improve efficiency in various operating modes.

Stmicroelectronics Srl

Technical Solution: STMicroelectronics has developed comprehensive synchronous rectification solutions for flyback converters addressing all operating modes (DCM/QR/CCM). Their technology employs a dual-detection approach combining both voltage and current sensing to optimize SR MOSFET timing across different operating conditions. For DCM/QR operation, ST's controllers implement precise zero-voltage detection with adaptive blanking time to prevent false triggering, while in CCM mode, their solution utilizes secondary-side current sensing with fast-response comparators featuring propagation delays under 50ns. ST's integrated SR controllers include sophisticated peak current management with programmable thresholds that can be adjusted based on application requirements. Their technology features advanced protection mechanisms including cycle-by-cycle current limiting, thermal shutdown, and undervoltage lockout to ensure reliable operation under all conditions. ST's SR controllers also implement adaptive gate drive strength that adjusts based on the detected MOSFET characteristics, optimizing switching performance while minimizing losses and EMI generation across varying load conditions and operating frequencies.

Strengths: Comprehensive solution with excellent integration of protection features; adaptive gate drive capability optimizes performance with different MOSFET types. Weaknesses: May require more complex implementation with additional sensing components; potentially higher system cost for full-featured implementations.

Infineon Technologies Americas Corp.

Technical Solution: Infineon Technologies has developed advanced synchronous rectification solutions for flyback converters that operate efficiently across DCM, QR, and CCM modes. Their technology combines specialized SR MOSFETs featuring ultra-low RDS(on) characteristics with sophisticated controller ICs designed specifically for synchronous rectification applications. For DCM/QR operation, Infineon's solution implements precise transformer demagnetization detection with adaptive blanking time to optimize turn-on timing, while in CCM mode, their controllers utilize secondary-side current sensing with proprietary fast-response comparators featuring propagation delays under 40ns. Infineon's integrated SR controllers include comprehensive peak current management with programmable thresholds and response times that can be tailored to specific application requirements. Their technology features sophisticated protection mechanisms including cycle-by-cycle current limiting with adjustable thresholds, thermal shutdown with hysteresis, and undervoltage lockout to ensure reliable operation under all conditions. Infineon's solution also implements adaptive dead-time control that minimizes body diode conduction losses while preventing shoot-through current, significantly improving efficiency across varying load conditions.

Strengths: Excellent integration between MOSFET characteristics and controller features; comprehensive protection features with programmable thresholds for application-specific optimization. Weaknesses: May require more complex implementation with additional configuration; potentially higher initial cost compared to simpler solutions.

Critical SR Timing Control and Current Sensing Technologies

Synchronous rectifier continuous conduction mode detection apparatus and control method

PatentActiveUS11606041B2

Innovation

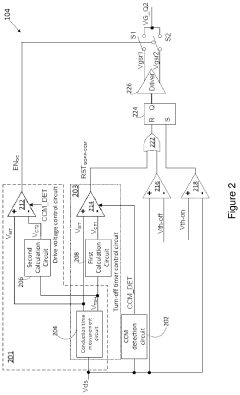

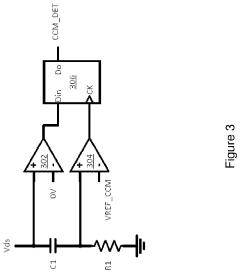

- A synchronous rectifier control apparatus and method that includes a continuous conduction mode detection circuit, a turn-off timer control circuit, and a drive voltage control circuit to determine the conduction time of the synchronous rectifier switch and adjust the gate drive voltage, thereby reducing the inrush current and improving reliability.

Synchronous rectifier scheme for continuous conduction mode in primary side controlled fly-back converter

PatentActiveUS12119755B2

Innovation

- Incorporating a secondary-side-controller with a CCM zero-crossing detector comparator that detects sharp changes in voltage during primary switch activation, enabling timely turn-off of the synchronous rectifier to minimize cross-conduction, utilizing a combination of capacitive and resistive paths for voltage sensing to enhance detection speed.

Thermal Management Strategies for SR MOSFETs

Thermal management is a critical aspect of synchronous rectifier (SR) MOSFET implementation in flyback converters across all operating modes (DCM, QR, and CCM). As power density requirements increase in modern power supply designs, effective thermal management becomes essential for ensuring reliability and optimal performance.

The thermal challenges for SR MOSFETs vary significantly across different operating modes. In DCM (Discontinuous Conduction Mode), the intermittent current flow creates thermal cycling that can stress package connections over time. QR (Quasi-Resonant) mode presents moderate but consistent thermal loads, while CCM (Continuous Conduction Mode) operation generates the highest continuous thermal stress due to constant current flow through the SR MOSFET.

Peak current handling capability directly impacts thermal management requirements. Higher peak currents in flyback converters, particularly during transient load conditions, generate significant I²R losses in the SR MOSFET's RDS(on) resistance. These losses manifest as heat that must be efficiently dissipated to prevent thermal runaway and device failure.

Advanced package technologies play a crucial role in thermal management strategies. DirectFET, PQFN, and other thermally enhanced packages offer superior thermal resistance paths compared to traditional packages. These packages feature exposed metal pads that directly connect to the PCB's thermal planes, reducing junction-to-ambient thermal resistance by up to 50%.

PCB layout optimization represents another critical thermal management strategy. Implementing copper pour areas directly connected to SR MOSFET thermal pads, utilizing thermal vias arrays to transfer heat to inner and bottom copper layers, and ensuring proper spacing between heat-generating components all contribute to effective thermal management.

Active cooling solutions become necessary in high-power density applications. Small form-factor heatsinks with forced air cooling can reduce thermal resistance by 30-40% compared to passive solutions. In space-constrained designs, thermally conductive gap fillers and phase-change materials provide effective thermal interfaces between MOSFETs and nearby metal structures that serve as heat spreaders.

Thermal simulation and validation using computational fluid dynamics (CFD) tools enable designers to identify potential hotspots before physical prototyping. These simulations can predict junction temperatures under various operating conditions, allowing for optimization of thermal management strategies before finalizing designs.

Dynamic thermal management through intelligent gate driving represents an emerging approach. Advanced SR controllers can monitor MOSFET temperature and dynamically adjust switching parameters to balance performance and thermal stress, particularly valuable in applications with varying load profiles.

The thermal challenges for SR MOSFETs vary significantly across different operating modes. In DCM (Discontinuous Conduction Mode), the intermittent current flow creates thermal cycling that can stress package connections over time. QR (Quasi-Resonant) mode presents moderate but consistent thermal loads, while CCM (Continuous Conduction Mode) operation generates the highest continuous thermal stress due to constant current flow through the SR MOSFET.

Peak current handling capability directly impacts thermal management requirements. Higher peak currents in flyback converters, particularly during transient load conditions, generate significant I²R losses in the SR MOSFET's RDS(on) resistance. These losses manifest as heat that must be efficiently dissipated to prevent thermal runaway and device failure.

Advanced package technologies play a crucial role in thermal management strategies. DirectFET, PQFN, and other thermally enhanced packages offer superior thermal resistance paths compared to traditional packages. These packages feature exposed metal pads that directly connect to the PCB's thermal planes, reducing junction-to-ambient thermal resistance by up to 50%.

PCB layout optimization represents another critical thermal management strategy. Implementing copper pour areas directly connected to SR MOSFET thermal pads, utilizing thermal vias arrays to transfer heat to inner and bottom copper layers, and ensuring proper spacing between heat-generating components all contribute to effective thermal management.

Active cooling solutions become necessary in high-power density applications. Small form-factor heatsinks with forced air cooling can reduce thermal resistance by 30-40% compared to passive solutions. In space-constrained designs, thermally conductive gap fillers and phase-change materials provide effective thermal interfaces between MOSFETs and nearby metal structures that serve as heat spreaders.

Thermal simulation and validation using computational fluid dynamics (CFD) tools enable designers to identify potential hotspots before physical prototyping. These simulations can predict junction temperatures under various operating conditions, allowing for optimization of thermal management strategies before finalizing designs.

Dynamic thermal management through intelligent gate driving represents an emerging approach. Advanced SR controllers can monitor MOSFET temperature and dynamically adjust switching parameters to balance performance and thermal stress, particularly valuable in applications with varying load profiles.

EMI Considerations in SR Flyback Design

Electromagnetic Interference (EMI) represents a significant challenge in Synchronous Rectifier (SR) Flyback converter designs across all operational modes (DCM, QR, and CCM). The high-speed switching nature of SR MOSFETs creates substantial electromagnetic noise that can compromise system performance and regulatory compliance if not properly addressed.

In SR Flyback converters, the primary EMI sources include the high dv/dt transitions during MOSFET switching, parasitic oscillations in the transformer windings, and current spikes during mode transitions. These phenomena generate both conducted and radiated emissions across a wide frequency spectrum. The EMI profile varies significantly between operational modes, with CCM typically exhibiting lower high-frequency noise but more challenging low-frequency harmonics compared to DCM and QR modes.

The gate driver circuitry for synchronous rectifiers introduces additional EMI concerns. Fast switching transitions necessary for efficient operation create high-frequency noise components that can couple into sensitive control circuits. This is particularly problematic in QR mode where variable switching frequencies can spread EMI across wider frequency bands, complicating filtering strategies.

Peak current handling in SR Flyback designs presents unique EMI challenges. The current stress during turn-off events creates significant di/dt rates that generate magnetic field transients. These transients can couple into nearby circuits and radiate from PCB traces acting as unintentional antennas. Proper layout techniques including minimized loop areas and strategic component placement are essential for mitigating these effects.

Practical EMI mitigation strategies for SR Flyback converters include optimized gate drive slew rate control to balance switching losses against EMI generation. Snubber networks across primary and secondary windings help dampen parasitic oscillations, though they introduce efficiency penalties that must be carefully managed. Spread spectrum techniques prove particularly effective in QR mode implementations by distributing noise energy across frequency bands rather than concentrating it at specific frequencies.

Transformer design significantly impacts EMI performance, with interleaved windings reducing leakage inductance and associated voltage spikes. Shielding layers between primary and secondary windings minimize capacitive coupling paths for common-mode noise. The physical PCB layout demands careful attention to ground plane integrity, with separate power and signal grounds connected at a single point to prevent ground loops that would otherwise amplify EMI issues.

Regulatory compliance testing for SR Flyback converters typically follows standards like CISPR 22/EN 55022 for information technology equipment or CISPR 11/EN 55011 for industrial equipment. These standards establish limits for both conducted and radiated emissions across specified frequency ranges, with different limits applying to various application environments.

In SR Flyback converters, the primary EMI sources include the high dv/dt transitions during MOSFET switching, parasitic oscillations in the transformer windings, and current spikes during mode transitions. These phenomena generate both conducted and radiated emissions across a wide frequency spectrum. The EMI profile varies significantly between operational modes, with CCM typically exhibiting lower high-frequency noise but more challenging low-frequency harmonics compared to DCM and QR modes.

The gate driver circuitry for synchronous rectifiers introduces additional EMI concerns. Fast switching transitions necessary for efficient operation create high-frequency noise components that can couple into sensitive control circuits. This is particularly problematic in QR mode where variable switching frequencies can spread EMI across wider frequency bands, complicating filtering strategies.

Peak current handling in SR Flyback designs presents unique EMI challenges. The current stress during turn-off events creates significant di/dt rates that generate magnetic field transients. These transients can couple into nearby circuits and radiate from PCB traces acting as unintentional antennas. Proper layout techniques including minimized loop areas and strategic component placement are essential for mitigating these effects.

Practical EMI mitigation strategies for SR Flyback converters include optimized gate drive slew rate control to balance switching losses against EMI generation. Snubber networks across primary and secondary windings help dampen parasitic oscillations, though they introduce efficiency penalties that must be carefully managed. Spread spectrum techniques prove particularly effective in QR mode implementations by distributing noise energy across frequency bands rather than concentrating it at specific frequencies.

Transformer design significantly impacts EMI performance, with interleaved windings reducing leakage inductance and associated voltage spikes. Shielding layers between primary and secondary windings minimize capacitive coupling paths for common-mode noise. The physical PCB layout demands careful attention to ground plane integrity, with separate power and signal grounds connected at a single point to prevent ground loops that would otherwise amplify EMI issues.

Regulatory compliance testing for SR Flyback converters typically follows standards like CISPR 22/EN 55022 for information technology equipment or CISPR 11/EN 55011 for industrial equipment. These standards establish limits for both conducted and radiated emissions across specified frequency ranges, with different limits applying to various application environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!