How to Accelerate Silicon Anode Development with High-Throughput Electrochemical Screening

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicon Anode Evolution and Objectives

Silicon anodes have emerged as a promising technology in the field of lithium-ion batteries, offering the potential for significantly higher energy density compared to traditional graphite anodes. The evolution of silicon anodes can be traced back to the early 2000s when researchers first recognized the theoretical capacity of silicon to store lithium ions. However, initial attempts to utilize silicon as an anode material were plagued by rapid capacity fading due to the material's substantial volume expansion during lithiation.

Over the past two decades, intensive research efforts have focused on addressing these challenges. Key milestones in silicon anode development include the introduction of nanostructured silicon materials, such as silicon nanowires and nanoparticles, which better accommodate volume changes. The development of silicon-carbon composites marked another significant advancement, combining the high capacity of silicon with the stability of carbon materials.

Recent years have seen a shift towards more sophisticated engineering approaches, including the design of porous silicon structures, core-shell architectures, and the incorporation of functional coatings. These strategies aim to mitigate the detrimental effects of volume expansion while maintaining high capacity and cycle life.

The primary objective in silicon anode development is to create a commercially viable anode material that can significantly enhance the energy density of lithium-ion batteries without compromising cycle life or safety. Specific goals include achieving a stable capacity of over 1000 mAh/g for thousands of cycles, reducing the first-cycle irreversible capacity loss, and ensuring compatibility with existing battery manufacturing processes.

To accelerate silicon anode development, high-throughput electrochemical screening has emerged as a powerful tool. This approach allows researchers to rapidly evaluate multiple material compositions, structures, and electrolyte formulations simultaneously. The objective of implementing high-throughput screening is to expedite the discovery and optimization of silicon anode materials by orders of magnitude compared to traditional methods.

Key aims of high-throughput screening in this context include identifying optimal silicon-based compositions, evaluating the effectiveness of various additives and coatings, and assessing the impact of different electrolyte formulations on anode performance. By systematically exploring a vast parameter space, researchers hope to uncover novel material combinations and processing techniques that can overcome the persistent challenges associated with silicon anodes.

Ultimately, the goal is to translate these high-throughput screening results into practical, scalable solutions that can be integrated into next-generation lithium-ion batteries. Success in this endeavor could lead to electric vehicles with significantly increased range, longer-lasting consumer electronics, and more efficient energy storage systems for renewable energy integration.

Over the past two decades, intensive research efforts have focused on addressing these challenges. Key milestones in silicon anode development include the introduction of nanostructured silicon materials, such as silicon nanowires and nanoparticles, which better accommodate volume changes. The development of silicon-carbon composites marked another significant advancement, combining the high capacity of silicon with the stability of carbon materials.

Recent years have seen a shift towards more sophisticated engineering approaches, including the design of porous silicon structures, core-shell architectures, and the incorporation of functional coatings. These strategies aim to mitigate the detrimental effects of volume expansion while maintaining high capacity and cycle life.

The primary objective in silicon anode development is to create a commercially viable anode material that can significantly enhance the energy density of lithium-ion batteries without compromising cycle life or safety. Specific goals include achieving a stable capacity of over 1000 mAh/g for thousands of cycles, reducing the first-cycle irreversible capacity loss, and ensuring compatibility with existing battery manufacturing processes.

To accelerate silicon anode development, high-throughput electrochemical screening has emerged as a powerful tool. This approach allows researchers to rapidly evaluate multiple material compositions, structures, and electrolyte formulations simultaneously. The objective of implementing high-throughput screening is to expedite the discovery and optimization of silicon anode materials by orders of magnitude compared to traditional methods.

Key aims of high-throughput screening in this context include identifying optimal silicon-based compositions, evaluating the effectiveness of various additives and coatings, and assessing the impact of different electrolyte formulations on anode performance. By systematically exploring a vast parameter space, researchers hope to uncover novel material combinations and processing techniques that can overcome the persistent challenges associated with silicon anodes.

Ultimately, the goal is to translate these high-throughput screening results into practical, scalable solutions that can be integrated into next-generation lithium-ion batteries. Success in this endeavor could lead to electric vehicles with significantly increased range, longer-lasting consumer electronics, and more efficient energy storage systems for renewable energy integration.

Market Demand for Advanced Battery Technologies

The demand for advanced battery technologies has been experiencing exponential growth, driven by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronic devices. Silicon anodes have emerged as a promising solution to meet the increasing energy density requirements of these applications. The market for silicon anode batteries is projected to grow significantly in the coming years, with major automotive manufacturers and consumer electronics companies showing keen interest in this technology.

In the EV sector, the push for longer driving ranges and faster charging times has created a strong demand for high-capacity anodes. Silicon anodes offer theoretical capacities up to ten times higher than traditional graphite anodes, making them an attractive option for next-generation EV batteries. This potential for increased energy density aligns with consumer expectations for EVs with ranges comparable to or exceeding those of conventional internal combustion engine vehicles.

The renewable energy sector also presents a substantial market opportunity for advanced battery technologies. As countries worldwide transition to cleaner energy sources, the need for efficient and high-capacity energy storage systems becomes critical. Silicon anode batteries could play a crucial role in grid-scale storage applications, helping to balance supply and demand in renewable energy systems and improving overall grid stability.

In the consumer electronics market, the ever-increasing functionality of smartphones, laptops, and wearable devices demands batteries with higher energy density and longer life cycles. Silicon anodes could enable smaller, lighter devices with extended battery life, meeting consumer expectations for improved portability and reduced charging frequency.

The industrial and aerospace sectors are also showing interest in silicon anode technology. The potential for lighter, more energy-dense batteries could lead to significant advancements in electric aircraft, drones, and other weight-sensitive applications. This expanding range of potential applications further underscores the market demand for silicon anode development.

However, the market adoption of silicon anode batteries faces challenges related to performance, durability, and cost. The industry requires accelerated development and optimization of silicon anode technology to overcome these hurdles. High-throughput electrochemical screening offers a promising approach to expedite this process, potentially reducing development timelines and costs while improving the overall performance of silicon anodes.

As the global focus on sustainability and electrification intensifies, the demand for advanced battery technologies, particularly those incorporating silicon anodes, is expected to continue its upward trajectory. This growing market presents significant opportunities for companies that can successfully develop and commercialize silicon anode batteries, making the acceleration of silicon anode development through high-throughput electrochemical screening a critical area of focus for the battery industry.

In the EV sector, the push for longer driving ranges and faster charging times has created a strong demand for high-capacity anodes. Silicon anodes offer theoretical capacities up to ten times higher than traditional graphite anodes, making them an attractive option for next-generation EV batteries. This potential for increased energy density aligns with consumer expectations for EVs with ranges comparable to or exceeding those of conventional internal combustion engine vehicles.

The renewable energy sector also presents a substantial market opportunity for advanced battery technologies. As countries worldwide transition to cleaner energy sources, the need for efficient and high-capacity energy storage systems becomes critical. Silicon anode batteries could play a crucial role in grid-scale storage applications, helping to balance supply and demand in renewable energy systems and improving overall grid stability.

In the consumer electronics market, the ever-increasing functionality of smartphones, laptops, and wearable devices demands batteries with higher energy density and longer life cycles. Silicon anodes could enable smaller, lighter devices with extended battery life, meeting consumer expectations for improved portability and reduced charging frequency.

The industrial and aerospace sectors are also showing interest in silicon anode technology. The potential for lighter, more energy-dense batteries could lead to significant advancements in electric aircraft, drones, and other weight-sensitive applications. This expanding range of potential applications further underscores the market demand for silicon anode development.

However, the market adoption of silicon anode batteries faces challenges related to performance, durability, and cost. The industry requires accelerated development and optimization of silicon anode technology to overcome these hurdles. High-throughput electrochemical screening offers a promising approach to expedite this process, potentially reducing development timelines and costs while improving the overall performance of silicon anodes.

As the global focus on sustainability and electrification intensifies, the demand for advanced battery technologies, particularly those incorporating silicon anodes, is expected to continue its upward trajectory. This growing market presents significant opportunities for companies that can successfully develop and commercialize silicon anode batteries, making the acceleration of silicon anode development through high-throughput electrochemical screening a critical area of focus for the battery industry.

Silicon Anode Challenges and Current Limitations

Silicon anodes have garnered significant attention in the battery industry due to their potential to dramatically increase the energy density of lithium-ion batteries. However, the development and commercialization of silicon anodes face several critical challenges that have hindered their widespread adoption.

One of the primary obstacles is the substantial volume expansion of silicon during lithiation, which can reach up to 300-400%. This expansion leads to mechanical stress and strain, causing the anode to crack and pulverize. As a result, the electrode structure degrades rapidly, leading to capacity fading and shortened battery life. This issue is particularly pronounced in high-capacity silicon anodes, where the volume changes are more severe.

Another significant challenge is the formation of an unstable solid-electrolyte interphase (SEI) layer on the silicon surface. The continuous expansion and contraction of silicon during cycling cause repeated breaking and reforming of the SEI layer. This process consumes electrolyte and lithium ions, leading to irreversible capacity loss and increased internal resistance of the battery.

The high reactivity of silicon with electrolytes poses additional complications. Silicon readily forms silicon oxide layers when exposed to air or electrolytes, which can impede lithium-ion transport and contribute to capacity loss. Moreover, the formation of lithium silicides during cycling can further exacerbate the structural instability of the anode.

Current silicon anodes also suffer from low initial Coulombic efficiency, typically around 70-80%, compared to the 90-95% efficiency of graphite anodes. This low efficiency is primarily due to the irreversible consumption of lithium in forming the SEI layer and trapping of lithium in the silicon structure.

The electrical conductivity of silicon is another limitation. Silicon has relatively low electrical conductivity compared to graphite, which can lead to increased internal resistance and reduced power performance in batteries. This issue necessitates the use of conductive additives or the development of silicon-carbon composite materials.

Scalability and cost-effectiveness remain significant hurdles in silicon anode production. Many promising silicon nanostructures or composites that show excellent performance in laboratory settings are challenging to produce at scale or are prohibitively expensive for commercial applications.

Lastly, the long-term cycling stability of silicon anodes is still inferior to that of traditional graphite anodes. While significant progress has been made, achieving thousands of cycles with high capacity retention remains a challenge, particularly for high-silicon-content anodes.

These challenges collectively contribute to the current limitations in silicon anode technology, necessitating innovative approaches and intensive research efforts to overcome them and realize the full potential of silicon in next-generation battery systems.

One of the primary obstacles is the substantial volume expansion of silicon during lithiation, which can reach up to 300-400%. This expansion leads to mechanical stress and strain, causing the anode to crack and pulverize. As a result, the electrode structure degrades rapidly, leading to capacity fading and shortened battery life. This issue is particularly pronounced in high-capacity silicon anodes, where the volume changes are more severe.

Another significant challenge is the formation of an unstable solid-electrolyte interphase (SEI) layer on the silicon surface. The continuous expansion and contraction of silicon during cycling cause repeated breaking and reforming of the SEI layer. This process consumes electrolyte and lithium ions, leading to irreversible capacity loss and increased internal resistance of the battery.

The high reactivity of silicon with electrolytes poses additional complications. Silicon readily forms silicon oxide layers when exposed to air or electrolytes, which can impede lithium-ion transport and contribute to capacity loss. Moreover, the formation of lithium silicides during cycling can further exacerbate the structural instability of the anode.

Current silicon anodes also suffer from low initial Coulombic efficiency, typically around 70-80%, compared to the 90-95% efficiency of graphite anodes. This low efficiency is primarily due to the irreversible consumption of lithium in forming the SEI layer and trapping of lithium in the silicon structure.

The electrical conductivity of silicon is another limitation. Silicon has relatively low electrical conductivity compared to graphite, which can lead to increased internal resistance and reduced power performance in batteries. This issue necessitates the use of conductive additives or the development of silicon-carbon composite materials.

Scalability and cost-effectiveness remain significant hurdles in silicon anode production. Many promising silicon nanostructures or composites that show excellent performance in laboratory settings are challenging to produce at scale or are prohibitively expensive for commercial applications.

Lastly, the long-term cycling stability of silicon anodes is still inferior to that of traditional graphite anodes. While significant progress has been made, achieving thousands of cycles with high capacity retention remains a challenge, particularly for high-silicon-content anodes.

These challenges collectively contribute to the current limitations in silicon anode technology, necessitating innovative approaches and intensive research efforts to overcome them and realize the full potential of silicon in next-generation battery systems.

High-Throughput Screening Methodologies

01 Nanostructured silicon anodes

Developing nanostructured silicon anodes, such as silicon nanowires or nanoparticles, to improve the performance and stability of lithium-ion batteries. These nanostructures can accommodate volume changes during charging and discharging, leading to better cycle life and capacity retention.- Nanostructured silicon anodes: Developing nanostructured silicon anodes, such as silicon nanowires or nanoparticles, to improve the performance and stability of lithium-ion batteries. These nanostructures can accommodate volume changes during charging and discharging, leading to better cycle life and capacity retention.

- Silicon-carbon composite anodes: Creating silicon-carbon composite anodes to combine the high capacity of silicon with the stability of carbon materials. This approach can help mitigate the volume expansion issues associated with pure silicon anodes and improve overall battery performance.

- Electrolyte optimization for silicon anodes: Developing specialized electrolytes or electrolyte additives that are compatible with silicon anodes. These optimized electrolytes can help form stable solid electrolyte interphase (SEI) layers, reducing capacity fade and improving the long-term stability of silicon-based batteries.

- Binder and conductive additive innovations: Exploring novel binder materials and conductive additives specifically designed for silicon anodes. These components can help maintain the structural integrity of the electrode during cycling and improve the overall conductivity and performance of silicon-based batteries.

- Pre-lithiation techniques: Developing pre-lithiation methods for silicon anodes to compensate for initial capacity loss and improve first-cycle efficiency. This can involve chemical or electrochemical pre-lithiation processes to introduce lithium into the silicon structure before battery assembly.

02 Silicon-carbon composite anodes

Creating silicon-carbon composite anodes to enhance conductivity and structural stability. This approach combines the high capacity of silicon with the stability of carbon materials, potentially accelerating the development of high-performance anodes for next-generation batteries.Expand Specific Solutions03 Electrolyte optimization for silicon anodes

Developing specialized electrolytes or electrolyte additives that are compatible with silicon anodes. These optimized electrolytes can help form stable solid electrolyte interphase (SEI) layers, reducing capacity fade and improving the overall performance of silicon-based anodes.Expand Specific Solutions04 Binder and conductive additive innovations

Exploring novel binders and conductive additives specifically designed for silicon anodes. These materials can help maintain the structural integrity of the anode during cycling and improve electron transport, leading to better overall battery performance and longevity.Expand Specific Solutions05 Advanced manufacturing techniques

Implementing advanced manufacturing techniques, such as 3D printing or roll-to-roll processing, to fabricate silicon anodes with precise control over structure and composition. These methods can potentially accelerate the development and scale-up of silicon anode production for commercial applications.Expand Specific Solutions

Key Players in Silicon Anode Development

The development of silicon anodes for lithium-ion batteries is in a dynamic growth phase, with significant market potential driven by the demand for higher energy density batteries in electric vehicles and consumer electronics. The market is characterized by intense competition among established players and innovative startups. Companies like Micron Technology, NanoGraf, and Enevate are at the forefront of silicon anode technology development, leveraging their expertise in materials science and battery engineering. The technology is approaching commercial viability, with several firms demonstrating promising results in high-throughput electrochemical screening. However, challenges remain in scaling production and ensuring long-term stability, indicating that the technology is still evolving towards full maturity.

NanoGraf Corp.

Technical Solution: NanoGraf has developed a high-throughput screening platform for silicon anode materials, focusing on their proprietary silicon alloy technology. Their approach utilizes a combination of computational modeling and rapid experimental validation. NanoGraf's screening process involves the synthesis of silicon-based nanocomposites with varying compositions and surface treatments. The company employs automated cell assembly and testing systems capable of evaluating hundreds of material combinations simultaneously[5]. NanoGraf's high-throughput methods have led to the development of silicon anodes with energy densities up to 50% higher than traditional graphite anodes, while maintaining good cycle life[6].

Strengths: High energy density, advanced computational modeling, and rapid experimental validation. Weaknesses: Potential challenges in scaling up production and maintaining performance at larger cell formats.

Ningde Amperex Technology Ltd.

Technical Solution: CATL (Ningde Amperex Technology Ltd.) has developed a high-throughput electrochemical screening platform for silicon anode materials. The system utilizes automated cell assembly, testing, and data analysis to rapidly evaluate various silicon-based anode formulations. CATL's approach incorporates machine learning algorithms to predict performance based on material properties and processing parameters[1]. The platform can screen hundreds of material combinations per week, significantly accelerating the development cycle. CATL also employs in-situ characterization techniques to monitor structural changes during cycling, providing insights into degradation mechanisms[3].

Strengths: Rapid screening capability, advanced data analytics, and in-situ characterization. Weaknesses: High initial investment cost and potential oversimplification of complex electrochemical processes.

Innovations in Electrochemical Screening Techniques

Silicon anode for use in an electrochemical cell

PatentPendingUS20240030420A1

Innovation

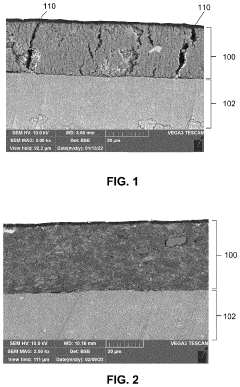

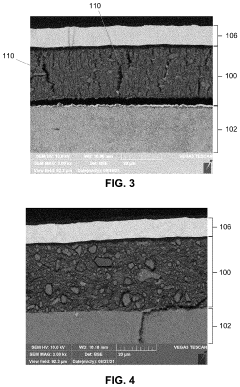

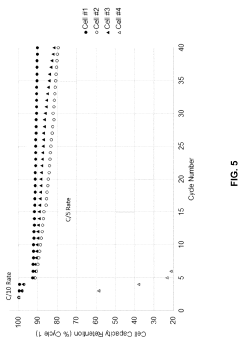

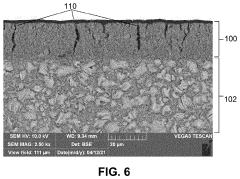

- An anode layer comprising silicon with an average particle size of less than 1 μm, a binder, and a solid-state electrolyte, characterized by the formation of vertical cracks with a thickness of less than 5 μm after a first cell cycle, and a stack pressure of 100 psi to 2500 psi, which enhances mechanical robustness and lithium transport.

Scalability and Manufacturing Considerations

Scaling up silicon anode production for commercial applications presents significant challenges that require careful consideration. The high-throughput electrochemical screening approach offers promising avenues for accelerating silicon anode development, but translating these laboratory-scale discoveries into large-scale manufacturing processes demands a comprehensive strategy.

One of the primary considerations is the adaptation of screening methodologies to industrial-scale production. While high-throughput techniques can rapidly identify promising silicon anode compositions and structures, replicating these results in large-scale batches requires precise control over synthesis parameters. Manufacturers must develop robust processes that maintain the desired nanostructure and composition of silicon anodes across larger production volumes.

Material sourcing and quality control become critical factors as production scales up. Ensuring a consistent supply of high-purity silicon precursors and other raw materials is essential for maintaining product quality. Implementing stringent quality assurance protocols throughout the supply chain and manufacturing process is necessary to minimize batch-to-batch variations that could impact anode performance.

The integration of silicon anodes into existing lithium-ion battery production lines presents another scalability challenge. Manufacturers may need to modify current electrode coating and assembly processes to accommodate the unique properties of silicon anodes, such as their volume expansion characteristics. This may require investments in new equipment or the adaptation of existing machinery to handle silicon-based slurries and electrode structures.

Energy and resource efficiency in large-scale production is another crucial consideration. Developing eco-friendly and cost-effective methods for silicon anode synthesis and processing is essential for long-term sustainability. This may involve optimizing reaction conditions, exploring alternative precursors, or implementing recycling strategies for silicon-rich waste streams.

Addressing the stability and cycle life of silicon anodes at commercial scales is paramount. While high-throughput screening can identify promising formulations, ensuring that these performance metrics are maintained in full-size battery cells and over extended cycling is critical. Manufacturers must develop accelerated testing protocols that can accurately predict long-term performance and reliability of silicon anodes in real-world applications.

Lastly, the economic viability of scaled-up silicon anode production must be carefully evaluated. While silicon offers significant advantages in terms of energy density, the cost of production must be competitive with existing graphite anodes. This requires a holistic approach to cost optimization, considering factors such as raw material costs, processing expenses, and potential economies of scale.

One of the primary considerations is the adaptation of screening methodologies to industrial-scale production. While high-throughput techniques can rapidly identify promising silicon anode compositions and structures, replicating these results in large-scale batches requires precise control over synthesis parameters. Manufacturers must develop robust processes that maintain the desired nanostructure and composition of silicon anodes across larger production volumes.

Material sourcing and quality control become critical factors as production scales up. Ensuring a consistent supply of high-purity silicon precursors and other raw materials is essential for maintaining product quality. Implementing stringent quality assurance protocols throughout the supply chain and manufacturing process is necessary to minimize batch-to-batch variations that could impact anode performance.

The integration of silicon anodes into existing lithium-ion battery production lines presents another scalability challenge. Manufacturers may need to modify current electrode coating and assembly processes to accommodate the unique properties of silicon anodes, such as their volume expansion characteristics. This may require investments in new equipment or the adaptation of existing machinery to handle silicon-based slurries and electrode structures.

Energy and resource efficiency in large-scale production is another crucial consideration. Developing eco-friendly and cost-effective methods for silicon anode synthesis and processing is essential for long-term sustainability. This may involve optimizing reaction conditions, exploring alternative precursors, or implementing recycling strategies for silicon-rich waste streams.

Addressing the stability and cycle life of silicon anodes at commercial scales is paramount. While high-throughput screening can identify promising formulations, ensuring that these performance metrics are maintained in full-size battery cells and over extended cycling is critical. Manufacturers must develop accelerated testing protocols that can accurately predict long-term performance and reliability of silicon anodes in real-world applications.

Lastly, the economic viability of scaled-up silicon anode production must be carefully evaluated. While silicon offers significant advantages in terms of energy density, the cost of production must be competitive with existing graphite anodes. This requires a holistic approach to cost optimization, considering factors such as raw material costs, processing expenses, and potential economies of scale.

Environmental Impact of Silicon Anode Production

The environmental impact of silicon anode production is a critical consideration in the development of advanced lithium-ion batteries. As the demand for high-performance energy storage solutions continues to grow, the need for sustainable manufacturing processes becomes increasingly important. Silicon anodes offer significant advantages in terms of energy density and battery life, but their production can have substantial environmental implications.

The primary environmental concerns associated with silicon anode production stem from the energy-intensive processes required to manufacture high-purity silicon materials. Traditional methods of silicon purification, such as the Siemens process, consume large amounts of electricity and generate significant greenhouse gas emissions. Additionally, the use of hazardous chemicals in the etching and doping processes can lead to potential environmental contamination if not properly managed.

Water consumption is another significant factor in silicon anode production. The manufacturing process requires large volumes of ultra-pure water for cleaning and processing, which can strain local water resources, particularly in water-scarce regions. Furthermore, the wastewater generated during production often contains toxic chemicals and heavy metals, necessitating extensive treatment before release.

The extraction of raw materials for silicon anodes, primarily quartz, can also have detrimental effects on local ecosystems. Mining operations can lead to habitat destruction, soil erosion, and water pollution if not conducted responsibly. The transportation of raw materials and finished products contributes to the overall carbon footprint of silicon anode production.

However, recent advancements in manufacturing techniques offer promising solutions to mitigate these environmental impacts. For instance, the development of low-temperature silicon purification methods and the use of recycled silicon from the semiconductor industry can significantly reduce energy consumption and emissions. Additionally, closed-loop water recycling systems and more efficient chemical recovery processes are being implemented to minimize water usage and reduce waste.

The adoption of renewable energy sources in silicon anode production facilities is another crucial step towards reducing the environmental footprint. Solar and wind power can offset the high energy demands of manufacturing processes, aligning production with sustainable energy practices. Moreover, the implementation of advanced filtration and treatment technologies can help minimize the release of pollutants into the environment.

As the industry moves towards more sustainable practices, life cycle assessments (LCAs) are becoming increasingly important in evaluating the overall environmental impact of silicon anode production. These comprehensive analyses consider all stages of the product lifecycle, from raw material extraction to end-of-life disposal, providing valuable insights for optimizing production processes and reducing environmental burdens.

The primary environmental concerns associated with silicon anode production stem from the energy-intensive processes required to manufacture high-purity silicon materials. Traditional methods of silicon purification, such as the Siemens process, consume large amounts of electricity and generate significant greenhouse gas emissions. Additionally, the use of hazardous chemicals in the etching and doping processes can lead to potential environmental contamination if not properly managed.

Water consumption is another significant factor in silicon anode production. The manufacturing process requires large volumes of ultra-pure water for cleaning and processing, which can strain local water resources, particularly in water-scarce regions. Furthermore, the wastewater generated during production often contains toxic chemicals and heavy metals, necessitating extensive treatment before release.

The extraction of raw materials for silicon anodes, primarily quartz, can also have detrimental effects on local ecosystems. Mining operations can lead to habitat destruction, soil erosion, and water pollution if not conducted responsibly. The transportation of raw materials and finished products contributes to the overall carbon footprint of silicon anode production.

However, recent advancements in manufacturing techniques offer promising solutions to mitigate these environmental impacts. For instance, the development of low-temperature silicon purification methods and the use of recycled silicon from the semiconductor industry can significantly reduce energy consumption and emissions. Additionally, closed-loop water recycling systems and more efficient chemical recovery processes are being implemented to minimize water usage and reduce waste.

The adoption of renewable energy sources in silicon anode production facilities is another crucial step towards reducing the environmental footprint. Solar and wind power can offset the high energy demands of manufacturing processes, aligning production with sustainable energy practices. Moreover, the implementation of advanced filtration and treatment technologies can help minimize the release of pollutants into the environment.

As the industry moves towards more sustainable practices, life cycle assessments (LCAs) are becoming increasingly important in evaluating the overall environmental impact of silicon anode production. These comprehensive analyses consider all stages of the product lifecycle, from raw material extraction to end-of-life disposal, providing valuable insights for optimizing production processes and reducing environmental burdens.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!