Silicon Anode Safety Considerations: Thermal Runaway Risk, Mixing & Handling Protocols

AUG 21, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicon Anode Evolution

The evolution of silicon anodes in lithium-ion batteries represents a significant advancement in energy storage technology. Initially, graphite anodes dominated the market due to their stability and relatively high capacity. However, the theoretical capacity of graphite (372 mAh/g) limited further improvements in battery energy density.

Silicon emerged as a promising alternative due to its exceptionally high theoretical capacity of 4200 mAh/g. Early research in the 1990s focused on pure silicon anodes, but these suffered from rapid capacity fading due to extreme volume changes during charge-discharge cycles. This led to the development of silicon-carbon composite anodes in the early 2000s, which aimed to mitigate the volume expansion issues.

By the mid-2000s, nanostructured silicon anodes gained attention. Silicon nanowires, nanoparticles, and porous structures were explored to accommodate volume changes and improve cycling stability. These approaches showed promising results in laboratory settings but faced challenges in scalable manufacturing.

The late 2000s and early 2010s saw the introduction of silicon-graphene composites. Graphene's excellent conductivity and mechanical properties complemented silicon's high capacity, resulting in improved performance and stability. This period also witnessed the development of various silicon alloys and compounds, such as silicon oxides and silicon-carbon alloys, which offered better stability than pure silicon.

In recent years, the focus has shifted towards optimizing electrolyte formulations and surface coatings for silicon anodes. Advanced binders and conductive additives have been developed to enhance the mechanical and electrical properties of silicon-based electrodes. Additionally, pre-lithiation techniques have been explored to mitigate the initial capacity loss associated with silicon anodes.

The latest developments include the commercialization of silicon-dominant anodes, with several companies introducing products containing up to 30% silicon. These advancements have led to batteries with higher energy densities and faster charging capabilities. However, challenges related to long-term cycling stability and safety considerations, particularly thermal runaway risks, remain active areas of research and development.

As the technology continues to evolve, researchers are exploring novel silicon anode architectures, advanced manufacturing techniques, and innovative electrolyte systems to further improve performance and address safety concerns. The ongoing evolution of silicon anodes holds promise for next-generation high-energy batteries, with potential applications in electric vehicles, consumer electronics, and grid-scale energy storage.

Silicon emerged as a promising alternative due to its exceptionally high theoretical capacity of 4200 mAh/g. Early research in the 1990s focused on pure silicon anodes, but these suffered from rapid capacity fading due to extreme volume changes during charge-discharge cycles. This led to the development of silicon-carbon composite anodes in the early 2000s, which aimed to mitigate the volume expansion issues.

By the mid-2000s, nanostructured silicon anodes gained attention. Silicon nanowires, nanoparticles, and porous structures were explored to accommodate volume changes and improve cycling stability. These approaches showed promising results in laboratory settings but faced challenges in scalable manufacturing.

The late 2000s and early 2010s saw the introduction of silicon-graphene composites. Graphene's excellent conductivity and mechanical properties complemented silicon's high capacity, resulting in improved performance and stability. This period also witnessed the development of various silicon alloys and compounds, such as silicon oxides and silicon-carbon alloys, which offered better stability than pure silicon.

In recent years, the focus has shifted towards optimizing electrolyte formulations and surface coatings for silicon anodes. Advanced binders and conductive additives have been developed to enhance the mechanical and electrical properties of silicon-based electrodes. Additionally, pre-lithiation techniques have been explored to mitigate the initial capacity loss associated with silicon anodes.

The latest developments include the commercialization of silicon-dominant anodes, with several companies introducing products containing up to 30% silicon. These advancements have led to batteries with higher energy densities and faster charging capabilities. However, challenges related to long-term cycling stability and safety considerations, particularly thermal runaway risks, remain active areas of research and development.

As the technology continues to evolve, researchers are exploring novel silicon anode architectures, advanced manufacturing techniques, and innovative electrolyte systems to further improve performance and address safety concerns. The ongoing evolution of silicon anodes holds promise for next-generation high-energy batteries, with potential applications in electric vehicles, consumer electronics, and grid-scale energy storage.

Market Demand Analysis

The market demand for silicon anodes in lithium-ion batteries has been growing rapidly, driven by the increasing need for higher energy density and longer-lasting batteries in various applications. The automotive industry, particularly the electric vehicle (EV) sector, is a primary driver of this demand. As governments worldwide push for electrification to reduce carbon emissions, the EV market is expected to expand significantly, creating a substantial demand for advanced battery technologies.

Silicon anodes offer the potential to dramatically increase the energy density of lithium-ion batteries, with theoretical capacities up to ten times that of traditional graphite anodes. This improvement could lead to EVs with longer ranges and consumer electronics with extended battery life, addressing key consumer concerns and market needs.

However, the safety considerations associated with silicon anodes, particularly the risk of thermal runaway, have created a complex market dynamic. On one hand, battery manufacturers and OEMs are eager to adopt silicon anode technology to gain a competitive edge. On the other hand, concerns about safety and reliability have led to cautious approaches and increased demand for robust safety protocols and testing procedures.

The market for silicon anode materials and related safety technologies is expected to grow significantly. This includes demand for advanced mixing and handling equipment, specialized safety monitoring systems, and thermal management solutions. Companies that can provide comprehensive safety solutions alongside silicon anode technology are likely to see increased market interest.

In the consumer electronics sector, the demand for silicon anodes is also rising, albeit with different safety considerations due to the smaller scale and different usage patterns compared to EVs. Manufacturers of smartphones, laptops, and wearables are exploring silicon anode technology to create devices with longer battery life without increasing battery size.

The industrial and grid storage sectors represent another growing market for silicon anode technology. These applications often require high-capacity, long-lasting batteries, making silicon anodes an attractive option. However, the safety considerations in these sectors are particularly critical, given the large scale of energy storage systems and the potential consequences of thermal events.

As awareness of the thermal runaway risk associated with silicon anodes grows, there is an emerging market for specialized insurance products and risk management services. This ancillary market is expected to develop alongside the primary silicon anode market, providing comprehensive risk mitigation strategies for manufacturers and end-users.

Silicon anodes offer the potential to dramatically increase the energy density of lithium-ion batteries, with theoretical capacities up to ten times that of traditional graphite anodes. This improvement could lead to EVs with longer ranges and consumer electronics with extended battery life, addressing key consumer concerns and market needs.

However, the safety considerations associated with silicon anodes, particularly the risk of thermal runaway, have created a complex market dynamic. On one hand, battery manufacturers and OEMs are eager to adopt silicon anode technology to gain a competitive edge. On the other hand, concerns about safety and reliability have led to cautious approaches and increased demand for robust safety protocols and testing procedures.

The market for silicon anode materials and related safety technologies is expected to grow significantly. This includes demand for advanced mixing and handling equipment, specialized safety monitoring systems, and thermal management solutions. Companies that can provide comprehensive safety solutions alongside silicon anode technology are likely to see increased market interest.

In the consumer electronics sector, the demand for silicon anodes is also rising, albeit with different safety considerations due to the smaller scale and different usage patterns compared to EVs. Manufacturers of smartphones, laptops, and wearables are exploring silicon anode technology to create devices with longer battery life without increasing battery size.

The industrial and grid storage sectors represent another growing market for silicon anode technology. These applications often require high-capacity, long-lasting batteries, making silicon anodes an attractive option. However, the safety considerations in these sectors are particularly critical, given the large scale of energy storage systems and the potential consequences of thermal events.

As awareness of the thermal runaway risk associated with silicon anodes grows, there is an emerging market for specialized insurance products and risk management services. This ancillary market is expected to develop alongside the primary silicon anode market, providing comprehensive risk mitigation strategies for manufacturers and end-users.

Safety Challenges

Silicon anodes in lithium-ion batteries present significant safety challenges that require careful consideration and management. The primary concern is the increased risk of thermal runaway, a process where the battery's temperature rises uncontrollably, potentially leading to fire or explosion. This risk is exacerbated by the large volume expansion of silicon during lithiation, which can cause mechanical stress and electrode degradation.

The formation of a stable solid-electrolyte interphase (SEI) layer is crucial for battery safety, but silicon anodes struggle to maintain a consistent SEI due to their volume changes. This instability can lead to continuous electrolyte decomposition, increasing the risk of thermal runaway and reducing battery life. Additionally, the high reactivity of silicon with electrolytes can generate heat and gas, further compromising safety.

Handling and mixing protocols for silicon-based materials pose their own set of challenges. Silicon nanoparticles, often used to mitigate volume expansion issues, can be pyrophoric and react violently with air or moisture. This necessitates stringent handling procedures in inert atmospheres, complicating manufacturing processes and increasing production costs.

The potential for silicon dust explosions during material processing and electrode fabrication is another significant safety concern. Fine silicon particles can form explosive mixtures with air, requiring specialized equipment and safety measures to prevent ignition sources and contain potential explosions.

Electrolyte compatibility is a critical factor in silicon anode safety. Traditional electrolytes may not be suitable for the highly reactive silicon surface, leading to accelerated degradation and increased safety risks. Developing electrolyte formulations that can form stable interfaces with silicon while maintaining high ionic conductivity is essential for improving battery safety.

The integration of silicon anodes into existing battery manufacturing processes presents additional safety challenges. The sensitivity of silicon materials to environmental conditions requires careful control of humidity, oxygen levels, and temperature throughout the production line. This may necessitate significant modifications to current manufacturing facilities and protocols.

Addressing these safety challenges requires a multifaceted approach, including materials engineering to improve silicon anode stability, advanced electrolyte designs, and the development of robust safety systems. Innovations in battery management systems that can detect and mitigate potential thermal runaway events are crucial for the safe implementation of silicon anode technology in commercial applications.

The formation of a stable solid-electrolyte interphase (SEI) layer is crucial for battery safety, but silicon anodes struggle to maintain a consistent SEI due to their volume changes. This instability can lead to continuous electrolyte decomposition, increasing the risk of thermal runaway and reducing battery life. Additionally, the high reactivity of silicon with electrolytes can generate heat and gas, further compromising safety.

Handling and mixing protocols for silicon-based materials pose their own set of challenges. Silicon nanoparticles, often used to mitigate volume expansion issues, can be pyrophoric and react violently with air or moisture. This necessitates stringent handling procedures in inert atmospheres, complicating manufacturing processes and increasing production costs.

The potential for silicon dust explosions during material processing and electrode fabrication is another significant safety concern. Fine silicon particles can form explosive mixtures with air, requiring specialized equipment and safety measures to prevent ignition sources and contain potential explosions.

Electrolyte compatibility is a critical factor in silicon anode safety. Traditional electrolytes may not be suitable for the highly reactive silicon surface, leading to accelerated degradation and increased safety risks. Developing electrolyte formulations that can form stable interfaces with silicon while maintaining high ionic conductivity is essential for improving battery safety.

The integration of silicon anodes into existing battery manufacturing processes presents additional safety challenges. The sensitivity of silicon materials to environmental conditions requires careful control of humidity, oxygen levels, and temperature throughout the production line. This may necessitate significant modifications to current manufacturing facilities and protocols.

Addressing these safety challenges requires a multifaceted approach, including materials engineering to improve silicon anode stability, advanced electrolyte designs, and the development of robust safety systems. Innovations in battery management systems that can detect and mitigate potential thermal runaway events are crucial for the safe implementation of silicon anode technology in commercial applications.

Current Safety Protocols

01 Protective coatings for silicon anodes

Applying protective coatings to silicon anodes can enhance their safety and stability. These coatings help prevent direct contact between the silicon and the electrolyte, reducing unwanted side reactions and improving the overall performance and longevity of the battery. Various materials such as carbon-based compounds or metal oxides can be used as protective coatings.- Protective coatings for silicon anodes: Applying protective coatings to silicon anodes can enhance their safety and stability. These coatings help prevent direct contact between the silicon and the electrolyte, reducing unwanted side reactions and improving the overall performance and longevity of the battery. Various materials such as carbon-based compounds or metal oxides can be used as protective layers.

- Nanostructured silicon anodes: Developing nanostructured silicon anodes can improve safety by accommodating volume changes during charging and discharging. These structures, such as silicon nanowires or nanoparticles, provide better mechanical stability and reduce the risk of anode degradation, leading to safer and more reliable battery performance.

- Electrolyte additives for silicon anodes: Incorporating specific additives into the electrolyte can enhance the safety of silicon anodes. These additives can form stable solid electrolyte interphase (SEI) layers, prevent electrolyte decomposition, and mitigate unwanted side reactions. This approach helps maintain the integrity of the silicon anode and improves overall battery safety.

- Silicon-carbon composite anodes: Developing silicon-carbon composite anodes can enhance safety by combining the high capacity of silicon with the stability of carbon materials. These composites help mitigate volume expansion issues, improve conductivity, and provide better structural integrity, resulting in safer and more reliable battery performance.

- Advanced battery management systems: Implementing advanced battery management systems can significantly improve the safety of silicon anode batteries. These systems monitor and control various parameters such as temperature, voltage, and current to prevent overcharging, overheating, and other potentially hazardous conditions. This approach ensures safer operation and extends the lifespan of silicon anode batteries.

02 Nanostructured silicon anodes

Developing nanostructured silicon anodes can improve safety by accommodating volume changes during charging and discharging. These structures, such as silicon nanowires or nanoparticles, provide better mechanical stability and reduce the risk of anode degradation, leading to safer and more reliable battery performance.Expand Specific Solutions03 Electrolyte additives for silicon anodes

Incorporating specific additives into the electrolyte can enhance the safety of silicon anodes. These additives can form a stable solid electrolyte interphase (SEI) layer, preventing excessive electrolyte decomposition and reducing the risk of thermal runaway. Carefully selected additives can also improve the cycling stability of silicon anodes.Expand Specific Solutions04 Silicon-carbon composite anodes

Developing silicon-carbon composite anodes can enhance safety by combining the high capacity of silicon with the stability of carbon materials. These composites help mitigate the volume expansion issues associated with pure silicon anodes, leading to improved cycling performance and reduced risk of mechanical failure.Expand Specific Solutions05 Advanced battery management systems

Implementing advanced battery management systems can significantly improve the safety of batteries with silicon anodes. These systems monitor various parameters such as temperature, voltage, and current to prevent overcharging, overheating, and other potentially hazardous conditions. They can also incorporate safety features like shutdown mechanisms in case of abnormal behavior.Expand Specific Solutions

Key Industry Players

The silicon anode safety considerations market is in a growth phase, driven by increasing demand for high-energy-density batteries in electric vehicles and consumer electronics. The market size is expanding rapidly, with major players like Tesla, LG Energy Solution, and CATL investing heavily in research and development. Technologically, silicon anodes are still evolving, with companies focusing on addressing challenges such as volume expansion and thermal stability. Ningde Amperex Technology, LG Chem, and Contemporary Amperex Technology are at the forefront of developing advanced silicon anode technologies, while startups like Enevate and Cadenza Innovation are introducing innovative solutions to improve safety and performance.

Ningde Amperex Technology Ltd.

Technical Solution: CATL (Ningde Amperex Technology Ltd.) has developed a novel silicon-carbon composite anode material that addresses thermal runaway risks in silicon anodes. Their approach involves encapsulating silicon nanoparticles within a carbon matrix, which helps to mitigate volume expansion during charging and discharging. This composite structure also improves thermal stability by creating a barrier against electrolyte decomposition[1]. CATL has implemented advanced mixing protocols that ensure uniform distribution of silicon particles, reducing hotspot formation. Their handling procedures include strict moisture control and inert atmosphere processing to prevent silicon oxidation[2]. To further enhance safety, CATL has integrated smart battery management systems that can detect early signs of thermal runaway and initiate preventive measures[3].

Strengths: Advanced composite structure mitigates volume expansion and improves thermal stability. Smart BMS enhances safety. Weaknesses: Potentially higher production costs due to complex manufacturing processes. May have lower energy density compared to pure silicon anodes.

LG Chem Ltd.

Technical Solution: LG Chem has developed a proprietary silicon-carbon composite anode technology that addresses thermal runaway risks. Their approach involves using a silicon-carbon nanocomposite with a core-shell structure, where silicon nanoparticles are encapsulated within a conductive carbon shell[1]. This structure helps to accommodate volume changes during cycling and improve thermal stability. LG Chem has also implemented advanced electrolyte formulations that form a stable solid electrolyte interphase (SEI) on the silicon surface, reducing side reactions that can lead to thermal runaway[2]. Their manufacturing process includes precise control of silicon particle size distribution and carbon coating thickness to optimize performance and safety. LG Chem has developed specialized mixing and handling protocols that minimize exposure to moisture and air, reducing the risk of silicon oxidation and degradation[3].

Strengths: Core-shell nanocomposite structure improves cycling stability and thermal performance. Advanced electrolyte formulations enhance safety. Weaknesses: Potentially higher production costs. May have lower initial capacity compared to pure silicon anodes.

Thermal Runaway Research

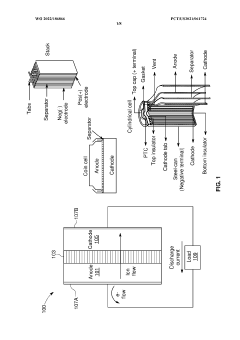

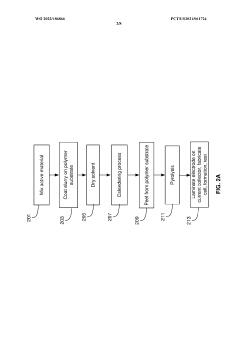

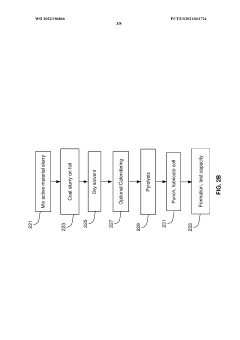

Method and system for safety of silicon dominant anodes

PatentWO2022186866A1

Innovation

- The development of silicon-dominant anodes with a pyrolyzed binder and conductive additives, combined with a ceramic-coated separator and specific electrolyte composition, enhances thermal conductivity and stability, increasing thermal runaway temperatures and preventing cell failure during nail penetration tests.

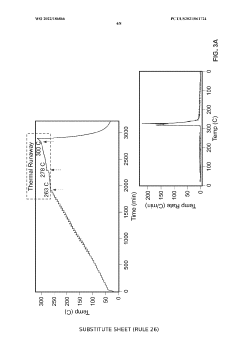

Thermally responsive electrolytes

PatentActiveUS20160126590A1

Innovation

- The introduction of a thermally responsive electrolyte that undergoes a reversible phase transition between 50° C to 160° C, inhibiting conductivity and charge transfer, comprising a thermally responsive polymer, an ionic liquid, and a lithium salt, which can control lithium-ion cell operation and prevent thermal runaway.

Regulatory Compliance

The regulatory landscape for silicon anode battery technology is rapidly evolving to address the unique safety considerations associated with this emerging energy storage solution. Compliance with existing and upcoming regulations is crucial for manufacturers and users of silicon anode batteries, particularly in light of the thermal runaway risks and specific handling protocols required.

Current regulations primarily focus on lithium-ion battery safety, with standards such as IEC 62133 and UN 38.3 serving as benchmarks for battery safety and transportation. However, these standards are being reevaluated and updated to incorporate the specific characteristics of silicon anode batteries. The U.S. Department of Transportation (DOT) and the International Air Transport Association (IATA) are actively working on new guidelines for the safe transport of silicon anode batteries, considering their higher energy density and potential for thermal events.

In the manufacturing sector, occupational safety regulations are being adapted to address the unique handling requirements of silicon materials. The Occupational Safety and Health Administration (OSHA) in the United States is developing new guidelines for worker protection during the mixing and handling of silicon-based anode materials, focusing on dust control measures and proper personal protective equipment (PPE).

Environmental regulations are also evolving to encompass the lifecycle management of silicon anode batteries. The European Union's Battery Directive is undergoing revisions to include specific provisions for the recycling and disposal of silicon-rich battery components. Similarly, the U.S. Environmental Protection Agency (EPA) is considering new rules under the Resource Conservation and Recovery Act (RCRA) to classify and manage silicon anode battery waste.

Product safety certifications are being updated to reflect the unique characteristics of silicon anode batteries. Underwriters Laboratories (UL) is developing new test protocols specifically for silicon anode batteries, focusing on thermal stability and cycle life under various conditions. These certifications will be crucial for market acceptance and regulatory compliance in consumer electronics and electric vehicle applications.

As the technology matures, it is anticipated that a more comprehensive regulatory framework will emerge. This framework will likely include specific safety standards for silicon anode battery design, manufacturing processes, and end-use applications. Manufacturers and researchers in this field must stay abreast of these regulatory developments and actively participate in shaping future standards to ensure the safe and widespread adoption of silicon anode battery technology.

Current regulations primarily focus on lithium-ion battery safety, with standards such as IEC 62133 and UN 38.3 serving as benchmarks for battery safety and transportation. However, these standards are being reevaluated and updated to incorporate the specific characteristics of silicon anode batteries. The U.S. Department of Transportation (DOT) and the International Air Transport Association (IATA) are actively working on new guidelines for the safe transport of silicon anode batteries, considering their higher energy density and potential for thermal events.

In the manufacturing sector, occupational safety regulations are being adapted to address the unique handling requirements of silicon materials. The Occupational Safety and Health Administration (OSHA) in the United States is developing new guidelines for worker protection during the mixing and handling of silicon-based anode materials, focusing on dust control measures and proper personal protective equipment (PPE).

Environmental regulations are also evolving to encompass the lifecycle management of silicon anode batteries. The European Union's Battery Directive is undergoing revisions to include specific provisions for the recycling and disposal of silicon-rich battery components. Similarly, the U.S. Environmental Protection Agency (EPA) is considering new rules under the Resource Conservation and Recovery Act (RCRA) to classify and manage silicon anode battery waste.

Product safety certifications are being updated to reflect the unique characteristics of silicon anode batteries. Underwriters Laboratories (UL) is developing new test protocols specifically for silicon anode batteries, focusing on thermal stability and cycle life under various conditions. These certifications will be crucial for market acceptance and regulatory compliance in consumer electronics and electric vehicle applications.

As the technology matures, it is anticipated that a more comprehensive regulatory framework will emerge. This framework will likely include specific safety standards for silicon anode battery design, manufacturing processes, and end-use applications. Manufacturers and researchers in this field must stay abreast of these regulatory developments and actively participate in shaping future standards to ensure the safe and widespread adoption of silicon anode battery technology.

Environmental Impact

The environmental impact of silicon anode technology in lithium-ion batteries is a critical consideration as the industry moves towards more sustainable energy storage solutions. While silicon anodes offer significant improvements in battery capacity and performance, their production and use raise several environmental concerns.

The manufacturing process of silicon anodes requires substantial energy input, potentially leading to increased carbon emissions if not sourced from renewable energy. The extraction and processing of silicon, typically from quartz, involves high-temperature reduction processes that are energy-intensive. This energy demand could offset some of the environmental benefits gained from improved battery performance if not managed sustainably.

Water usage is another significant environmental factor in silicon anode production. The purification of silicon to battery-grade quality requires large volumes of water, which can strain local water resources, especially in water-scarce regions. Proper water management and recycling systems are essential to mitigate this impact.

The use of hydrofluoric acid in silicon etching processes poses potential environmental risks. If not properly handled and disposed of, this highly corrosive substance can contaminate soil and water sources, causing severe ecological damage. Stringent safety protocols and waste treatment procedures are necessary to prevent environmental contamination.

On the positive side, silicon anodes contribute to the overall improvement of battery efficiency and lifespan. This enhancement can lead to reduced electronic waste, as fewer batteries need to be produced and disposed of over time. Additionally, the increased energy density of silicon anode batteries could accelerate the adoption of electric vehicles and renewable energy storage systems, indirectly reducing greenhouse gas emissions from transportation and energy sectors.

End-of-life considerations for silicon anode batteries are crucial. While silicon itself is not toxic, the composite materials used in anode construction may complicate recycling processes. Developing efficient recycling methods for these batteries is essential to minimize waste and recover valuable materials, thereby reducing the environmental footprint of battery production.

The thermal runaway risk associated with silicon anodes also has environmental implications. In the event of a battery failure or fire, the release of toxic gases and materials can have localized environmental impacts. Proper safety measures and containment strategies are necessary to mitigate these risks and protect surrounding ecosystems.

The manufacturing process of silicon anodes requires substantial energy input, potentially leading to increased carbon emissions if not sourced from renewable energy. The extraction and processing of silicon, typically from quartz, involves high-temperature reduction processes that are energy-intensive. This energy demand could offset some of the environmental benefits gained from improved battery performance if not managed sustainably.

Water usage is another significant environmental factor in silicon anode production. The purification of silicon to battery-grade quality requires large volumes of water, which can strain local water resources, especially in water-scarce regions. Proper water management and recycling systems are essential to mitigate this impact.

The use of hydrofluoric acid in silicon etching processes poses potential environmental risks. If not properly handled and disposed of, this highly corrosive substance can contaminate soil and water sources, causing severe ecological damage. Stringent safety protocols and waste treatment procedures are necessary to prevent environmental contamination.

On the positive side, silicon anodes contribute to the overall improvement of battery efficiency and lifespan. This enhancement can lead to reduced electronic waste, as fewer batteries need to be produced and disposed of over time. Additionally, the increased energy density of silicon anode batteries could accelerate the adoption of electric vehicles and renewable energy storage systems, indirectly reducing greenhouse gas emissions from transportation and energy sectors.

End-of-life considerations for silicon anode batteries are crucial. While silicon itself is not toxic, the composite materials used in anode construction may complicate recycling processes. Developing efficient recycling methods for these batteries is essential to minimize waste and recover valuable materials, thereby reducing the environmental footprint of battery production.

The thermal runaway risk associated with silicon anodes also has environmental implications. In the event of a battery failure or fire, the release of toxic gases and materials can have localized environmental impacts. Proper safety measures and containment strategies are necessary to mitigate these risks and protect surrounding ecosystems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!