How to Implement Inline QC for Silicon Anode Slurries in Pilot Manufacturing

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicon Anode Slurry QC Background and Objectives

Silicon anode technology has emerged as a promising solution to enhance the energy density of lithium-ion batteries. As the demand for high-performance energy storage systems continues to grow, the development of silicon anodes has gained significant attention in recent years. The evolution of this technology can be traced back to the early 2000s when researchers first recognized the potential of silicon as an anode material due to its high theoretical capacity.

The primary objective of implementing inline quality control (QC) for silicon anode slurries in pilot manufacturing is to ensure consistent and high-quality production of battery components. This goal is driven by the need to address the challenges associated with silicon anodes, such as volume expansion during cycling and poor electrical conductivity. By integrating real-time QC measures, manufacturers aim to optimize the production process, reduce defects, and improve overall battery performance.

The technical landscape of silicon anode slurries has witnessed several key developments over the past decade. Initially, research focused on overcoming the volume expansion issue through nanostructured silicon materials. Subsequently, efforts shifted towards developing composite materials that combine silicon with carbon or other conductive additives to enhance stability and conductivity. Recent advancements have explored the use of silicon-graphite composites and silicon-carbon core-shell structures to further improve cycling performance.

As the technology progresses, the industry is moving towards large-scale production of silicon anode batteries. This transition necessitates the implementation of robust QC measures to ensure consistent quality and performance across batches. The integration of inline QC for silicon anode slurries represents a critical step in bridging the gap between laboratory-scale research and commercial-scale manufacturing.

The expected outcomes of implementing inline QC for silicon anode slurries include improved product consistency, reduced defect rates, and enhanced overall battery performance. By monitoring key parameters such as particle size distribution, viscosity, and composition in real-time, manufacturers can quickly identify and address any deviations from the desired specifications. This proactive approach is essential for maintaining high standards of quality and reliability in pilot-scale production.

Furthermore, the implementation of inline QC aligns with broader industry trends towards smart manufacturing and Industry 4.0 principles. By leveraging advanced sensors, data analytics, and machine learning algorithms, manufacturers can gain deeper insights into the production process and make data-driven decisions to optimize performance and efficiency.

The primary objective of implementing inline quality control (QC) for silicon anode slurries in pilot manufacturing is to ensure consistent and high-quality production of battery components. This goal is driven by the need to address the challenges associated with silicon anodes, such as volume expansion during cycling and poor electrical conductivity. By integrating real-time QC measures, manufacturers aim to optimize the production process, reduce defects, and improve overall battery performance.

The technical landscape of silicon anode slurries has witnessed several key developments over the past decade. Initially, research focused on overcoming the volume expansion issue through nanostructured silicon materials. Subsequently, efforts shifted towards developing composite materials that combine silicon with carbon or other conductive additives to enhance stability and conductivity. Recent advancements have explored the use of silicon-graphite composites and silicon-carbon core-shell structures to further improve cycling performance.

As the technology progresses, the industry is moving towards large-scale production of silicon anode batteries. This transition necessitates the implementation of robust QC measures to ensure consistent quality and performance across batches. The integration of inline QC for silicon anode slurries represents a critical step in bridging the gap between laboratory-scale research and commercial-scale manufacturing.

The expected outcomes of implementing inline QC for silicon anode slurries include improved product consistency, reduced defect rates, and enhanced overall battery performance. By monitoring key parameters such as particle size distribution, viscosity, and composition in real-time, manufacturers can quickly identify and address any deviations from the desired specifications. This proactive approach is essential for maintaining high standards of quality and reliability in pilot-scale production.

Furthermore, the implementation of inline QC aligns with broader industry trends towards smart manufacturing and Industry 4.0 principles. By leveraging advanced sensors, data analytics, and machine learning algorithms, manufacturers can gain deeper insights into the production process and make data-driven decisions to optimize performance and efficiency.

Market Demand for Inline QC in Battery Manufacturing

The demand for inline quality control (QC) in battery manufacturing, particularly for silicon anode slurries in pilot production, is driven by the increasing adoption of electric vehicles (EVs) and the growing energy storage market. As battery technology advances, manufacturers are seeking more efficient and reliable production processes to meet the rising demand for high-performance batteries.

Silicon anode technology has emerged as a promising solution to enhance battery capacity and performance. However, the production of silicon anode slurries presents unique challenges that require stringent quality control measures. Traditional offline QC methods are time-consuming and often result in production delays and increased costs. This has created a significant market need for inline QC solutions that can provide real-time monitoring and control of the manufacturing process.

The global lithium-ion battery market is projected to grow substantially in the coming years, with a compound annual growth rate (CAGR) exceeding 12% from 2021 to 2028. This growth is primarily driven by the automotive sector, where the demand for EVs is surging due to environmental concerns and government regulations. As a result, battery manufacturers are under pressure to increase production capacity while maintaining high quality standards.

Inline QC for silicon anode slurries addresses several critical market needs. First, it enables manufacturers to detect and correct quality issues in real-time, reducing waste and improving overall production yield. This is particularly important for pilot manufacturing, where process optimization and scalability are crucial for successful commercialization.

Second, inline QC helps ensure consistency in battery performance, which is essential for meeting the stringent requirements of automotive and energy storage applications. By continuously monitoring key parameters such as particle size distribution, viscosity, and homogeneity, manufacturers can maintain tight control over the production process and deliver high-quality anodes.

Third, the implementation of inline QC aligns with the industry's push towards smart manufacturing and Industry 4.0 principles. The ability to collect and analyze real-time data enables predictive maintenance, process optimization, and continuous improvement, leading to increased operational efficiency and reduced production costs.

Furthermore, the market demand for inline QC in battery manufacturing is driven by the need for faster time-to-market and increased production flexibility. As new battery chemistries and designs emerge, manufacturers require agile production systems that can quickly adapt to changing specifications. Inline QC provides the necessary feedback loop to support rapid process adjustments and validation of new manufacturing techniques.

In conclusion, the market demand for inline QC in battery manufacturing, specifically for silicon anode slurries in pilot production, is substantial and growing. As the industry continues to evolve and scale up production, the need for advanced quality control solutions will only intensify, creating significant opportunities for technology providers and equipment manufacturers in this space.

Silicon anode technology has emerged as a promising solution to enhance battery capacity and performance. However, the production of silicon anode slurries presents unique challenges that require stringent quality control measures. Traditional offline QC methods are time-consuming and often result in production delays and increased costs. This has created a significant market need for inline QC solutions that can provide real-time monitoring and control of the manufacturing process.

The global lithium-ion battery market is projected to grow substantially in the coming years, with a compound annual growth rate (CAGR) exceeding 12% from 2021 to 2028. This growth is primarily driven by the automotive sector, where the demand for EVs is surging due to environmental concerns and government regulations. As a result, battery manufacturers are under pressure to increase production capacity while maintaining high quality standards.

Inline QC for silicon anode slurries addresses several critical market needs. First, it enables manufacturers to detect and correct quality issues in real-time, reducing waste and improving overall production yield. This is particularly important for pilot manufacturing, where process optimization and scalability are crucial for successful commercialization.

Second, inline QC helps ensure consistency in battery performance, which is essential for meeting the stringent requirements of automotive and energy storage applications. By continuously monitoring key parameters such as particle size distribution, viscosity, and homogeneity, manufacturers can maintain tight control over the production process and deliver high-quality anodes.

Third, the implementation of inline QC aligns with the industry's push towards smart manufacturing and Industry 4.0 principles. The ability to collect and analyze real-time data enables predictive maintenance, process optimization, and continuous improvement, leading to increased operational efficiency and reduced production costs.

Furthermore, the market demand for inline QC in battery manufacturing is driven by the need for faster time-to-market and increased production flexibility. As new battery chemistries and designs emerge, manufacturers require agile production systems that can quickly adapt to changing specifications. Inline QC provides the necessary feedback loop to support rapid process adjustments and validation of new manufacturing techniques.

In conclusion, the market demand for inline QC in battery manufacturing, specifically for silicon anode slurries in pilot production, is substantial and growing. As the industry continues to evolve and scale up production, the need for advanced quality control solutions will only intensify, creating significant opportunities for technology providers and equipment manufacturers in this space.

Current Challenges in Silicon Anode Slurry QC

The implementation of inline quality control (QC) for silicon anode slurries in pilot manufacturing faces several significant challenges. One of the primary obstacles is the dynamic nature of silicon anode slurries during the manufacturing process. Unlike traditional graphite-based anodes, silicon anodes undergo substantial volume changes during charge and discharge cycles, which can lead to inconsistencies in slurry composition and properties throughout the production line.

Another major challenge is the sensitivity of silicon anode slurries to environmental factors. Temperature fluctuations, humidity levels, and exposure to air can all significantly impact the slurry's rheological properties and particle distribution. This sensitivity makes it difficult to maintain consistent quality standards across different batches and production runs.

The rapid sedimentation of silicon particles in the slurry poses an additional hurdle for inline QC. The tendency of silicon particles to settle quickly can lead to inhomogeneous mixtures, making it challenging to obtain representative samples for real-time analysis. This sedimentation issue also complicates the design and implementation of inline measurement techniques that rely on stable and uniform sample presentation.

Furthermore, the high reactivity of silicon with air and moisture introduces complexities in handling and measuring the slurry. Exposure to these elements can lead to oxidation and degradation of the silicon particles, altering the slurry's properties and potentially compromising the final product's performance. This reactivity necessitates the development of specialized inline QC methods that can operate in inert or controlled atmospheres.

The multifaceted nature of silicon anode slurry quality also presents a challenge for inline QC. Multiple parameters need to be monitored simultaneously, including viscosity, particle size distribution, solid content, and chemical composition. Developing inline measurement techniques capable of assessing all these parameters in real-time, without disrupting the production flow, remains a significant technical challenge.

Lastly, the lack of standardized methods and reference materials for silicon anode slurries complicates the establishment of reliable inline QC protocols. The relatively new and rapidly evolving nature of silicon anode technology means that industry-wide standards are still in development, making it difficult to validate and calibrate inline QC systems consistently across different manufacturing facilities.

Another major challenge is the sensitivity of silicon anode slurries to environmental factors. Temperature fluctuations, humidity levels, and exposure to air can all significantly impact the slurry's rheological properties and particle distribution. This sensitivity makes it difficult to maintain consistent quality standards across different batches and production runs.

The rapid sedimentation of silicon particles in the slurry poses an additional hurdle for inline QC. The tendency of silicon particles to settle quickly can lead to inhomogeneous mixtures, making it challenging to obtain representative samples for real-time analysis. This sedimentation issue also complicates the design and implementation of inline measurement techniques that rely on stable and uniform sample presentation.

Furthermore, the high reactivity of silicon with air and moisture introduces complexities in handling and measuring the slurry. Exposure to these elements can lead to oxidation and degradation of the silicon particles, altering the slurry's properties and potentially compromising the final product's performance. This reactivity necessitates the development of specialized inline QC methods that can operate in inert or controlled atmospheres.

The multifaceted nature of silicon anode slurry quality also presents a challenge for inline QC. Multiple parameters need to be monitored simultaneously, including viscosity, particle size distribution, solid content, and chemical composition. Developing inline measurement techniques capable of assessing all these parameters in real-time, without disrupting the production flow, remains a significant technical challenge.

Lastly, the lack of standardized methods and reference materials for silicon anode slurries complicates the establishment of reliable inline QC protocols. The relatively new and rapidly evolving nature of silicon anode technology means that industry-wide standards are still in development, making it difficult to validate and calibrate inline QC systems consistently across different manufacturing facilities.

Existing Inline QC Solutions for Battery Slurries

01 Composition control of silicon anode slurries

Quality control of silicon anode slurries involves careful management of their composition. This includes controlling the ratio of silicon particles, conductive additives, and binders. Proper composition ensures optimal electrical conductivity, mechanical stability, and electrochemical performance of the anode.- Composition control of silicon anode slurries: Quality control of silicon anode slurries involves careful management of their composition. This includes controlling the ratio of silicon particles, conductive additives, and binders. Proper composition ensures optimal electrical conductivity, mechanical stability, and electrochemical performance of the anode.

- Particle size and distribution analysis: Monitoring and controlling the particle size and distribution of silicon particles in the slurry is crucial for quality control. Techniques such as laser diffraction or dynamic light scattering are used to ensure uniform particle size distribution, which affects the anode's capacity and cycling stability.

- Viscosity and rheological properties measurement: The viscosity and rheological properties of silicon anode slurries are important quality control parameters. These properties affect the coating process and the final electrode structure. Rheometers are used to measure and control these properties to ensure consistent slurry quality.

- Impurity detection and control: Detecting and controlling impurities in silicon anode slurries is essential for maintaining high-quality anodes. Techniques such as inductively coupled plasma mass spectrometry (ICP-MS) or X-ray fluorescence (XRF) spectroscopy are used to identify and quantify impurities that could negatively impact battery performance.

- In-line monitoring and process control: Implementing in-line monitoring systems for continuous quality control of silicon anode slurries during production. This includes real-time measurements of key parameters such as solid content, temperature, and homogeneity. Advanced process control algorithms are used to maintain consistent slurry quality throughout the manufacturing process.

02 Particle size and distribution monitoring

Monitoring and controlling the particle size and distribution of silicon particles in the slurry is crucial for quality control. Uniform particle size distribution contributes to consistent electrode thickness and performance. Advanced techniques such as laser diffraction or dynamic light scattering may be employed for this purpose.Expand Specific Solutions03 Viscosity and rheological properties assessment

The viscosity and rheological properties of silicon anode slurries significantly impact coating quality and electrode performance. Regular assessment and adjustment of these properties ensure proper coating behavior and uniform electrode formation. Rheometers and viscometers are commonly used for these measurements.Expand Specific Solutions04 Impurity detection and control

Detecting and controlling impurities in silicon anode slurries is essential for maintaining high-quality anodes. Impurities can negatively affect the electrochemical performance and cycle life of batteries. Advanced analytical techniques such as ICP-MS or XRF spectroscopy may be used for impurity detection and quantification.Expand Specific Solutions05 In-line monitoring and process control

Implementing in-line monitoring systems and process control measures helps maintain consistent quality of silicon anode slurries during production. This may include real-time measurements of slurry properties, automated adjustments to process parameters, and statistical process control techniques to ensure batch-to-batch consistency.Expand Specific Solutions

Key Players in Battery QC and Slurry Manufacturing

The implementation of inline QC for silicon anode slurries in pilot manufacturing is at an early stage of development, with the market still emerging. The technology's maturity varies among key players, reflecting a competitive landscape in flux. Companies like GlobalWafers and SK Siltron CSS are leveraging their silicon expertise, while battery manufacturers such as EVE Energy and Guoxuan High-Tech are exploring integration possibilities. Research institutions like CEA and Korea Electrotechnology Research Institute are contributing to technological advancements. As the market grows, collaboration between semiconductor, battery, and equipment manufacturers is likely to accelerate innovation and standardization in this critical area of battery production.

EVE Energy Co., Ltd.

Technical Solution: EVE Energy has developed an advanced inline quality control (QC) system for silicon anode slurries in pilot manufacturing. Their approach utilizes real-time monitoring and artificial intelligence to analyze key parameters such as viscosity, particle size distribution, and homogeneity. The system employs in-situ sensors and spectroscopic techniques to continuously assess slurry properties during the production process[1]. Machine learning algorithms process the data to identify deviations from optimal specifications and automatically adjust process parameters to maintain consistency[3]. This enables rapid detection and correction of quality issues, reducing waste and improving overall production efficiency.

Strengths: Real-time monitoring and AI-driven process control allow for immediate adjustments, reducing defects and improving consistency. Weaknesses: High initial implementation cost and complexity in integrating with existing manufacturing systems.

Hefei Guoxuan High-Tech Power Energy Co., Ltd.

Technical Solution: Guoxuan has implemented an innovative inline QC system for silicon anode slurries that combines advanced sensing technologies with a closed-loop control system. Their approach utilizes ultrasonic sensors to measure slurry density and viscosity in real-time, while laser diffraction analysis monitors particle size distribution[2]. A proprietary algorithm processes this data to calculate key quality indicators. The system also incorporates inline rheological measurements to assess slurry flow properties[4]. When deviations are detected, the control system automatically adjusts mixing parameters, additive dosing, or temperature to bring the slurry back within specifications. This comprehensive approach ensures consistent quality throughout the pilot manufacturing process.

Strengths: Comprehensive multi-parameter monitoring and automated adjustments ensure high consistency. Weaknesses: System complexity may require specialized training for operators and maintenance personnel.

Core Innovations in Silicon Anode Slurry Analysis

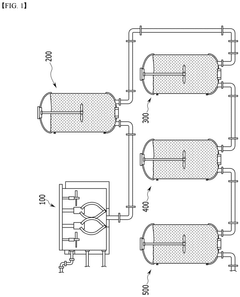

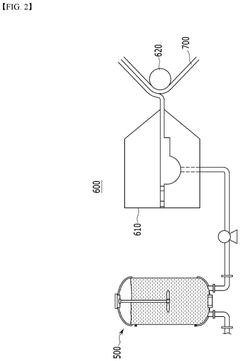

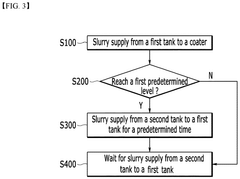

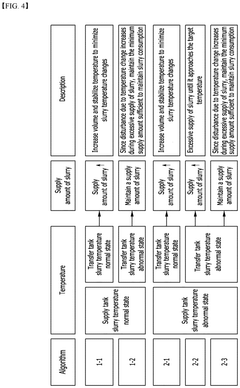

Method for controlling supply amount of electrode slurry and apparatus therefor

PatentPendingEP4557388A1

Innovation

- A method and apparatus for controlling the supply amount of electrode slurry by supplying slurry from a second tank to a first tank for a predetermined time when the first tank's level reaches a certain threshold, and automatically interrupting the supply when the time elapses, while also adjusting the supply based on the temperature of the tanks.

Regulatory Compliance for Battery Manufacturing QC

Regulatory compliance is a critical aspect of battery manufacturing quality control, especially when implementing inline QC for silicon anode slurries in pilot manufacturing. The battery industry is subject to stringent regulations due to the potential safety risks associated with lithium-ion batteries. Manufacturers must adhere to various standards and guidelines set by regulatory bodies such as the International Electrotechnical Commission (IEC), Underwriters Laboratories (UL), and regional authorities like the European Union's Battery Directive.

For silicon anode slurries, specific attention must be paid to material composition, particle size distribution, and contamination levels. The inline QC process must be designed to meet the requirements of ISO 9001 for quality management systems and ISO/IEC 17025 for testing and calibration laboratories. These standards ensure that the QC procedures are robust, repeatable, and traceable.

In the United States, the Department of Energy (DOE) has established guidelines for battery manufacturing through its Battery500 Consortium. These guidelines emphasize the importance of consistent quality control throughout the production process, including the preparation and application of electrode slurries. The Environmental Protection Agency (EPA) also regulates the handling and disposal of materials used in battery production, which must be considered in the QC process.

Manufacturers implementing inline QC for silicon anode slurries must also comply with workplace safety regulations set by the Occupational Safety and Health Administration (OSHA). This includes proper handling of nanomaterials, which are often present in advanced anode formulations. The National Institute for Occupational Safety and Health (NIOSH) provides specific guidelines for working with nanomaterials in the battery industry.

International standards such as IEC 62133 for safety requirements for portable batteries and IEC 61960 for performance testing must be considered when designing QC protocols. These standards outline specific tests and criteria that batteries must meet, which directly influence the quality requirements for anode materials.

To ensure regulatory compliance, manufacturers must implement a comprehensive documentation system that tracks all aspects of the QC process. This includes maintaining detailed records of raw material specifications, process parameters, and test results. The system should be capable of demonstrating compliance with all relevant regulations and standards during audits or inspections.

Furthermore, as the battery industry continues to evolve, manufacturers must stay informed about emerging regulations and standards. This may include new requirements for sustainability and recyclability, as well as updated safety standards in response to technological advancements in battery chemistry and design.

For silicon anode slurries, specific attention must be paid to material composition, particle size distribution, and contamination levels. The inline QC process must be designed to meet the requirements of ISO 9001 for quality management systems and ISO/IEC 17025 for testing and calibration laboratories. These standards ensure that the QC procedures are robust, repeatable, and traceable.

In the United States, the Department of Energy (DOE) has established guidelines for battery manufacturing through its Battery500 Consortium. These guidelines emphasize the importance of consistent quality control throughout the production process, including the preparation and application of electrode slurries. The Environmental Protection Agency (EPA) also regulates the handling and disposal of materials used in battery production, which must be considered in the QC process.

Manufacturers implementing inline QC for silicon anode slurries must also comply with workplace safety regulations set by the Occupational Safety and Health Administration (OSHA). This includes proper handling of nanomaterials, which are often present in advanced anode formulations. The National Institute for Occupational Safety and Health (NIOSH) provides specific guidelines for working with nanomaterials in the battery industry.

International standards such as IEC 62133 for safety requirements for portable batteries and IEC 61960 for performance testing must be considered when designing QC protocols. These standards outline specific tests and criteria that batteries must meet, which directly influence the quality requirements for anode materials.

To ensure regulatory compliance, manufacturers must implement a comprehensive documentation system that tracks all aspects of the QC process. This includes maintaining detailed records of raw material specifications, process parameters, and test results. The system should be capable of demonstrating compliance with all relevant regulations and standards during audits or inspections.

Furthermore, as the battery industry continues to evolve, manufacturers must stay informed about emerging regulations and standards. This may include new requirements for sustainability and recyclability, as well as updated safety standards in response to technological advancements in battery chemistry and design.

Cost-Benefit Analysis of Inline QC Implementation

Implementing inline quality control (QC) for silicon anode slurries in pilot manufacturing requires a thorough cost-benefit analysis to justify the investment and optimize the implementation strategy. The initial costs of implementing inline QC systems can be substantial, including equipment purchases, installation, and integration with existing manufacturing processes. These systems typically involve advanced sensors, real-time data analysis tools, and automated control mechanisms, which can range from $100,000 to $500,000 depending on the complexity and scale of the pilot manufacturing line.

However, the long-term benefits of inline QC implementation can significantly outweigh the initial costs. One of the primary advantages is the reduction in material waste. Traditional batch testing methods often result in the rejection of entire batches if quality issues are detected, whereas inline QC allows for immediate adjustments, potentially saving up to 15-20% in raw material costs. This is particularly crucial for silicon anode slurries, where the high cost of silicon-based materials makes waste reduction a priority.

Labor costs associated with quality control can also be substantially reduced through automation. Manual sampling and testing procedures typically require dedicated QC personnel, whereas inline systems can operate with minimal human intervention. This can lead to a 30-40% reduction in QC-related labor costs, allowing for the reallocation of skilled workers to more value-added tasks within the manufacturing process.

The improved product consistency achieved through inline QC can have far-reaching benefits. By ensuring that each batch of silicon anode slurry meets precise specifications, manufacturers can enhance the overall performance and reliability of the final battery products. This consistency can lead to increased customer satisfaction, reduced warranty claims, and potentially higher profit margins, with some studies suggesting a 5-10% improvement in overall product quality.

Time-to-market is another critical factor to consider. Inline QC systems can significantly reduce the time required for quality assurance processes, potentially shortening production cycles by 20-30%. This acceleration can provide a competitive edge in the rapidly evolving battery technology market, allowing manufacturers to respond more quickly to market demands and technological advancements.

While the upfront costs of implementing inline QC for silicon anode slurries are considerable, the long-term financial benefits are compelling. ROI calculations typically show a payback period of 18-24 months for most pilot manufacturing operations, with ongoing savings and efficiency gains continuing to accrue thereafter. Additionally, the scalability of these systems means that the benefits can be amplified as production volumes increase, making inline QC an essential investment for manufacturers looking to transition from pilot to full-scale production in the future.

However, the long-term benefits of inline QC implementation can significantly outweigh the initial costs. One of the primary advantages is the reduction in material waste. Traditional batch testing methods often result in the rejection of entire batches if quality issues are detected, whereas inline QC allows for immediate adjustments, potentially saving up to 15-20% in raw material costs. This is particularly crucial for silicon anode slurries, where the high cost of silicon-based materials makes waste reduction a priority.

Labor costs associated with quality control can also be substantially reduced through automation. Manual sampling and testing procedures typically require dedicated QC personnel, whereas inline systems can operate with minimal human intervention. This can lead to a 30-40% reduction in QC-related labor costs, allowing for the reallocation of skilled workers to more value-added tasks within the manufacturing process.

The improved product consistency achieved through inline QC can have far-reaching benefits. By ensuring that each batch of silicon anode slurry meets precise specifications, manufacturers can enhance the overall performance and reliability of the final battery products. This consistency can lead to increased customer satisfaction, reduced warranty claims, and potentially higher profit margins, with some studies suggesting a 5-10% improvement in overall product quality.

Time-to-market is another critical factor to consider. Inline QC systems can significantly reduce the time required for quality assurance processes, potentially shortening production cycles by 20-30%. This acceleration can provide a competitive edge in the rapidly evolving battery technology market, allowing manufacturers to respond more quickly to market demands and technological advancements.

While the upfront costs of implementing inline QC for silicon anode slurries are considerable, the long-term financial benefits are compelling. ROI calculations typically show a payback period of 18-24 months for most pilot manufacturing operations, with ongoing savings and efficiency gains continuing to accrue thereafter. Additionally, the scalability of these systems means that the benefits can be amplified as production volumes increase, making inline QC an essential investment for manufacturers looking to transition from pilot to full-scale production in the future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!