How to Measure First-Cycle Irreversible Capacity Loss for Silicon-Based Anodes (Protocols)

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicon Anode Background

Silicon-based anodes have emerged as a promising alternative to traditional graphite anodes in lithium-ion batteries due to their significantly higher theoretical capacity. Silicon can theoretically store up to 4,200 mAh/g of lithium, which is more than ten times the capacity of graphite (372 mAh/g). This high capacity potential has driven extensive research and development efforts in the field of silicon anodes over the past two decades.

The interest in silicon anodes stems from the growing demand for higher energy density batteries in various applications, including electric vehicles, portable electronics, and renewable energy storage systems. As these technologies advance, the limitations of conventional graphite anodes become more apparent, necessitating the exploration of alternative materials like silicon.

However, the implementation of silicon anodes faces several challenges. The most significant issue is the large volume expansion (up to 300%) that silicon undergoes during lithiation, which leads to mechanical stress, pulverization of the active material, and loss of electrical contact. This volume change also causes the continuous formation and reformation of the solid electrolyte interphase (SEI), resulting in irreversible capacity loss and rapid capacity fade over cycling.

To address these challenges, researchers have explored various strategies. These include nanostructuring silicon to better accommodate volume changes, developing silicon-carbon composites to improve conductivity and stability, and engineering binders and electrolytes to enhance the overall performance of silicon anodes. Despite these efforts, the first-cycle irreversible capacity loss remains a critical issue that needs to be addressed for the successful commercialization of silicon anodes.

The first-cycle irreversible capacity loss in silicon anodes is primarily attributed to the formation of the SEI layer and the trapping of lithium in the anode structure. This loss can be substantial, often ranging from 10% to 50% of the initial capacity, depending on the specific silicon anode design and electrolyte composition. Understanding and mitigating this initial capacity loss is crucial for improving the overall performance and longevity of silicon-based anodes.

Measuring the first-cycle irreversible capacity loss accurately is essential for evaluating the effectiveness of different silicon anode designs and optimization strategies. It provides valuable insights into the initial SEI formation process, the extent of lithium trapping, and the overall efficiency of the electrode. This measurement serves as a critical performance indicator and guides further development efforts in silicon anode technology.

The interest in silicon anodes stems from the growing demand for higher energy density batteries in various applications, including electric vehicles, portable electronics, and renewable energy storage systems. As these technologies advance, the limitations of conventional graphite anodes become more apparent, necessitating the exploration of alternative materials like silicon.

However, the implementation of silicon anodes faces several challenges. The most significant issue is the large volume expansion (up to 300%) that silicon undergoes during lithiation, which leads to mechanical stress, pulverization of the active material, and loss of electrical contact. This volume change also causes the continuous formation and reformation of the solid electrolyte interphase (SEI), resulting in irreversible capacity loss and rapid capacity fade over cycling.

To address these challenges, researchers have explored various strategies. These include nanostructuring silicon to better accommodate volume changes, developing silicon-carbon composites to improve conductivity and stability, and engineering binders and electrolytes to enhance the overall performance of silicon anodes. Despite these efforts, the first-cycle irreversible capacity loss remains a critical issue that needs to be addressed for the successful commercialization of silicon anodes.

The first-cycle irreversible capacity loss in silicon anodes is primarily attributed to the formation of the SEI layer and the trapping of lithium in the anode structure. This loss can be substantial, often ranging from 10% to 50% of the initial capacity, depending on the specific silicon anode design and electrolyte composition. Understanding and mitigating this initial capacity loss is crucial for improving the overall performance and longevity of silicon-based anodes.

Measuring the first-cycle irreversible capacity loss accurately is essential for evaluating the effectiveness of different silicon anode designs and optimization strategies. It provides valuable insights into the initial SEI formation process, the extent of lithium trapping, and the overall efficiency of the electrode. This measurement serves as a critical performance indicator and guides further development efforts in silicon anode technology.

Market Demand Analysis

The market demand for accurate measurement protocols for first-cycle irreversible capacity loss in silicon-based anodes is driven by the growing interest in high-capacity lithium-ion batteries for electric vehicles and portable electronics. Silicon anodes offer significantly higher theoretical capacity compared to traditional graphite anodes, making them a promising candidate for next-generation energy storage solutions. However, the substantial irreversible capacity loss during the first charge-discharge cycle remains a major challenge, necessitating reliable measurement techniques to assess and mitigate this issue.

The automotive industry, in particular, is a key driver of this demand. As electric vehicle adoption accelerates globally, manufacturers are seeking ways to improve battery performance and longevity. Accurate measurement of first-cycle capacity loss is crucial for optimizing silicon-based anode materials and battery designs, ultimately leading to increased driving range and reduced costs. This has created a significant market for advanced testing equipment and protocols tailored specifically for silicon anode characterization.

Consumer electronics manufacturers are also contributing to the market demand for these measurement protocols. With the ever-increasing power requirements of smartphones, tablets, and laptops, there is a push for higher capacity batteries in smaller form factors. Silicon-based anodes offer a potential solution, but manufacturers need reliable methods to evaluate and minimize first-cycle capacity loss to ensure product performance and customer satisfaction.

The energy storage sector, including grid-scale applications and renewable energy integration, represents another growing market for silicon anode technology and associated measurement protocols. As the world transitions towards cleaner energy sources, the need for high-capacity, long-lasting batteries becomes more pressing. Accurate assessment of first-cycle irreversible capacity loss is essential for developing silicon-based batteries suitable for these large-scale applications.

Research institutions and material science companies are also driving demand for standardized measurement protocols. As they work on developing new silicon-based anode materials and composites, there is a need for consistent and reliable methods to compare different formulations and assess improvements in first-cycle performance. This has led to increased collaboration between academia and industry to establish standardized testing procedures and benchmarks.

The market for silicon anode materials is projected to grow significantly in the coming years, with some estimates suggesting a compound annual growth rate of over 20%. This growth is expected to directly correlate with an increased demand for sophisticated measurement protocols and equipment. As the technology matures and moves towards commercialization, the need for accurate and reproducible first-cycle capacity loss measurements will become even more critical for quality control and performance validation in mass production settings.

The automotive industry, in particular, is a key driver of this demand. As electric vehicle adoption accelerates globally, manufacturers are seeking ways to improve battery performance and longevity. Accurate measurement of first-cycle capacity loss is crucial for optimizing silicon-based anode materials and battery designs, ultimately leading to increased driving range and reduced costs. This has created a significant market for advanced testing equipment and protocols tailored specifically for silicon anode characterization.

Consumer electronics manufacturers are also contributing to the market demand for these measurement protocols. With the ever-increasing power requirements of smartphones, tablets, and laptops, there is a push for higher capacity batteries in smaller form factors. Silicon-based anodes offer a potential solution, but manufacturers need reliable methods to evaluate and minimize first-cycle capacity loss to ensure product performance and customer satisfaction.

The energy storage sector, including grid-scale applications and renewable energy integration, represents another growing market for silicon anode technology and associated measurement protocols. As the world transitions towards cleaner energy sources, the need for high-capacity, long-lasting batteries becomes more pressing. Accurate assessment of first-cycle irreversible capacity loss is essential for developing silicon-based batteries suitable for these large-scale applications.

Research institutions and material science companies are also driving demand for standardized measurement protocols. As they work on developing new silicon-based anode materials and composites, there is a need for consistent and reliable methods to compare different formulations and assess improvements in first-cycle performance. This has led to increased collaboration between academia and industry to establish standardized testing procedures and benchmarks.

The market for silicon anode materials is projected to grow significantly in the coming years, with some estimates suggesting a compound annual growth rate of over 20%. This growth is expected to directly correlate with an increased demand for sophisticated measurement protocols and equipment. As the technology matures and moves towards commercialization, the need for accurate and reproducible first-cycle capacity loss measurements will become even more critical for quality control and performance validation in mass production settings.

Current Challenges

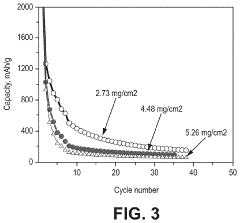

The measurement of first-cycle irreversible capacity loss for silicon-based anodes faces several significant challenges that hinder accurate and consistent evaluation. One of the primary obstacles is the high volume expansion of silicon during lithiation, which can reach up to 300%. This expansion leads to mechanical stress and strain, causing particle fracture and electrode degradation. Consequently, the irreversible capacity loss becomes difficult to distinguish from capacity fading due to structural changes.

Another challenge lies in the formation of the solid electrolyte interphase (SEI) layer on silicon anodes. The dynamic nature of the SEI formation process, coupled with the continuous expansion and contraction of silicon particles, results in an unstable interface. This instability makes it challenging to determine the exact contribution of SEI formation to the irreversible capacity loss during the first cycle.

The high reactivity of silicon with electrolytes poses an additional complication. Silicon anodes tend to consume electrolyte components rapidly, leading to continuous SEI growth and reformation. This ongoing process can mask the true first-cycle irreversible capacity loss, as subsequent cycles may also contribute to capacity loss through similar mechanisms.

Furthermore, the lack of standardized protocols for measuring first-cycle irreversible capacity loss in silicon-based anodes presents a significant hurdle. Different research groups and manufacturers employ varying testing conditions, such as voltage windows, current densities, and electrolyte compositions. This inconsistency makes it challenging to compare results across studies and establish reliable benchmarks for silicon anode performance.

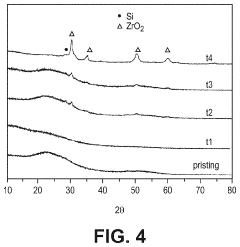

The presence of surface oxides on silicon particles adds another layer of complexity to the measurement process. These native oxides can participate in irreversible reactions during the first cycle, contributing to capacity loss that is not directly related to the silicon anode's intrinsic properties. Distinguishing between the capacity loss due to surface oxide reactions and that of the silicon core becomes a critical challenge in accurate measurements.

Lastly, the influence of electrode preparation methods on the first-cycle irreversible capacity loss cannot be overlooked. Factors such as particle size distribution, binder selection, conductive additive content, and electrode porosity can significantly impact the initial cycling behavior. Developing protocols that account for these variables while maintaining reproducibility across different laboratory settings remains a considerable challenge in the field of silicon-based anode research.

Another challenge lies in the formation of the solid electrolyte interphase (SEI) layer on silicon anodes. The dynamic nature of the SEI formation process, coupled with the continuous expansion and contraction of silicon particles, results in an unstable interface. This instability makes it challenging to determine the exact contribution of SEI formation to the irreversible capacity loss during the first cycle.

The high reactivity of silicon with electrolytes poses an additional complication. Silicon anodes tend to consume electrolyte components rapidly, leading to continuous SEI growth and reformation. This ongoing process can mask the true first-cycle irreversible capacity loss, as subsequent cycles may also contribute to capacity loss through similar mechanisms.

Furthermore, the lack of standardized protocols for measuring first-cycle irreversible capacity loss in silicon-based anodes presents a significant hurdle. Different research groups and manufacturers employ varying testing conditions, such as voltage windows, current densities, and electrolyte compositions. This inconsistency makes it challenging to compare results across studies and establish reliable benchmarks for silicon anode performance.

The presence of surface oxides on silicon particles adds another layer of complexity to the measurement process. These native oxides can participate in irreversible reactions during the first cycle, contributing to capacity loss that is not directly related to the silicon anode's intrinsic properties. Distinguishing between the capacity loss due to surface oxide reactions and that of the silicon core becomes a critical challenge in accurate measurements.

Lastly, the influence of electrode preparation methods on the first-cycle irreversible capacity loss cannot be overlooked. Factors such as particle size distribution, binder selection, conductive additive content, and electrode porosity can significantly impact the initial cycling behavior. Developing protocols that account for these variables while maintaining reproducibility across different laboratory settings remains a considerable challenge in the field of silicon-based anode research.

Existing Protocols

01 Nanostructured silicon-based anodes

Utilizing nanostructured silicon-based materials, such as silicon nanowires or nanoparticles, can help mitigate first-cycle irreversible capacity loss. These nanostructures provide better accommodation for volume changes during cycling and improve electron transport, leading to enhanced capacity retention and reduced irreversible capacity loss.- Nanostructured silicon-based anodes: Utilizing nanostructured silicon-based materials, such as silicon nanowires or nanoparticles, can help mitigate first-cycle irreversible capacity loss. These nanostructures provide better accommodation for volume changes during cycling and improve the overall electrochemical performance of the anode.

- Surface modification of silicon anodes: Modifying the surface of silicon anodes through various treatments or coatings can reduce the first-cycle irreversible capacity loss. These modifications can include carbon coatings, oxide layers, or other functional groups that stabilize the solid electrolyte interphase (SEI) and improve the overall cycling stability.

- Composite materials with silicon: Developing composite materials that combine silicon with other elements or compounds can help address the first-cycle irreversible capacity loss. These composites may include silicon-carbon, silicon-metal alloys, or silicon-oxide materials that provide better structural stability and electrochemical performance.

- Electrolyte additives and formulations: Optimizing electrolyte compositions and incorporating specific additives can significantly reduce the first-cycle irreversible capacity loss in silicon-based anodes. These additives can help form a more stable SEI layer and improve the overall cycling efficiency of the battery.

- Pre-lithiation techniques: Implementing pre-lithiation techniques for silicon-based anodes can effectively reduce the first-cycle irreversible capacity loss. These methods involve introducing lithium into the anode material before cell assembly, compensating for the initial lithium loss and improving the overall capacity retention of the battery.

02 Surface modification of silicon anodes

Modifying the surface of silicon-based anodes through coatings or treatments can significantly reduce first-cycle irreversible capacity loss. These modifications can include carbon coatings, oxide layers, or functional groups that stabilize the solid electrolyte interphase (SEI) and prevent excessive electrolyte decomposition during the initial charge-discharge cycle.Expand Specific Solutions03 Electrolyte additives for SEI formation

Incorporating specific additives into the electrolyte can promote the formation of a stable and thin SEI layer on silicon-based anodes. These additives help reduce the irreversible capacity loss by minimizing electrolyte decomposition and improving the passivation of the anode surface during the first cycle.Expand Specific Solutions04 Composite anodes with silicon and carbon

Developing composite anodes that combine silicon with carbon materials can help address first-cycle irreversible capacity loss. The carbon component provides structural stability and improved conductivity, while the silicon offers high capacity. This combination can lead to reduced volume expansion and better cycling performance, minimizing irreversible capacity loss.Expand Specific Solutions05 Pre-lithiation techniques

Implementing pre-lithiation techniques for silicon-based anodes can compensate for the initial lithium loss during SEI formation. This approach involves introducing lithium into the anode structure before cell assembly, effectively reducing the first-cycle irreversible capacity loss and improving the overall energy density of the battery.Expand Specific Solutions

Key Industry Players

The competition landscape for measuring first-cycle irreversible capacity loss in silicon-based anodes is in a growth phase, with increasing market size driven by the expanding electric vehicle and energy storage sectors. The technology is maturing, but still evolving, as evidenced by ongoing research and development efforts. Key players like Contemporary Amperex Technology Co., Ltd., Toyota Motor Corp., and LG Chem Ltd. are investing heavily in this area, leveraging their expertise in battery technology. Smaller specialized firms such as NanoGraf Corp. and Faradion Ltd. are also making significant contributions, focusing on innovative silicon-based anode materials. The involvement of research institutions like the Industrial Technology Research Institute and Swiss Federal Institute of Technology indicates the technology's potential for further advancement and commercialization.

Contemporary Amperex Technology Co., Ltd.

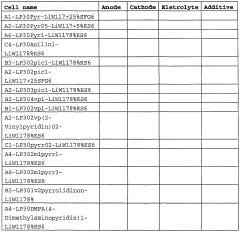

Technical Solution: CATL has developed a comprehensive protocol for measuring first-cycle irreversible capacity loss in silicon-based anodes, focusing on industrial relevance. Their method involves full cell testing with commercial-grade cathode materials and electrolytes[7]. CATL's protocol includes a formation cycle at elevated temperature to accelerate SEI formation, followed by multiple charge-discharge cycles at various rates to separate rate-dependent and intrinsic irreversible capacity losses[9]. They employ coulombic efficiency analysis and post-mortem characterization techniques such as TEM and XPS to provide a holistic view of capacity loss mechanisms[11].

Strengths: Industrially relevant conditions, comprehensive characterization. Weaknesses: May not capture subtle differences between experimental materials, time-consuming.

Toyota Motor Corp.

Technical Solution: Toyota has developed a protocol for measuring first-cycle irreversible capacity loss in silicon-based anodes with a focus on automotive applications. Their method involves testing in pouch cell format with automotive-grade electrolytes and separators[13]. Toyota's protocol includes a series of partial charge-discharge cycles before the full first cycle to mimic real-world usage patterns[15]. They employ differential voltage analysis and incremental capacity analysis to separate different contributions to irreversible capacity loss[17]. Toyota's method also incorporates gas evolution measurements during the first cycle to quantify electrolyte decomposition.

Strengths: Automotive-relevant conditions, detailed analysis of capacity loss mechanisms. Weaknesses: May not be suitable for early-stage materials screening, requires specialized gas analysis equipment.

Core Innovations

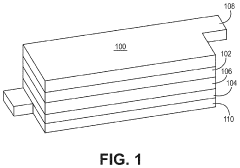

Silicon oxide based high capacity anode materials for lithium ion batteries

PatentPendingUS20230290925A1

Innovation

- The use of silicon oxide based composite materials with conductive components, high energy mechanical milling, and supplemental lithium to stabilize the negative electrode and balance electrode capacities, along with halogenated carbonate additives in the electrolyte, improves cycling performance and maintains high specific capacity.

A non-aqueous electrolyte for a rechargeable electrochemical cell and non-aqueous electrolyte rechargeable electrochemical cell

PatentWO2005081355A1

Innovation

- Incorporating a nitrogen-containing hetero-aromate or its derivatives, such as aniline and pyrrole, along with a film-forming organic component and an alkali metal salt, into the non-aqueous electrolyte to enhance the formation of a superior solid electrolyte interphase (SEI) on the carbon anode, reducing irreversible capacity loss and maintaining low temperature performance.

Standardization Efforts

Standardization efforts in measuring first-cycle irreversible capacity loss for silicon-based anodes have become increasingly important as the technology advances. Various organizations and research institutions have recognized the need for consistent protocols to ensure reliable and comparable results across different studies and applications.

The International Electrotechnical Commission (IEC) has been at the forefront of these efforts, working on developing standardized testing procedures for lithium-ion batteries, including those with silicon-based anodes. Their Technical Committee 21 on Secondary Cells and Batteries has been actively involved in creating guidelines for performance testing and safety requirements.

In parallel, the United States Advanced Battery Consortium (USABC) has also contributed significantly to the standardization process. They have published manuals and guidelines for electric vehicle battery testing, which include protocols for measuring capacity loss in various battery chemistries, including those with silicon anodes.

The National Institute of Standards and Technology (NIST) has been collaborating with industry partners to develop reference materials and measurement protocols specifically for silicon-based anodes. Their efforts aim to provide a common basis for comparing results across different laboratories and research groups.

Several academic institutions and industry consortia have also been working on establishing best practices for measuring first-cycle irreversible capacity loss. These include the Battery500 Consortium, which focuses on developing next-generation lithium-metal batteries, and the Faraday Institution in the UK, which has dedicated research programs on silicon anodes.

Standardization efforts have focused on several key aspects of the measurement process. These include defining consistent cycling conditions, such as voltage ranges, current rates, and temperature controls. Efforts have also been made to standardize sample preparation methods, electrode composition, and electrolyte formulations to ensure reproducibility.

Another important area of standardization has been the development of agreed-upon metrics for quantifying irreversible capacity loss. This includes defining how to calculate and report the first-cycle coulombic efficiency, as well as methods for separating different contributions to capacity loss, such as SEI formation and lithium trapping.

Despite these efforts, challenges remain in achieving full standardization. The diversity of silicon anode materials and their rapid evolution make it difficult to establish universal protocols. Additionally, the complex interplay between silicon anodes and other battery components necessitates ongoing refinement of measurement techniques.

The International Electrotechnical Commission (IEC) has been at the forefront of these efforts, working on developing standardized testing procedures for lithium-ion batteries, including those with silicon-based anodes. Their Technical Committee 21 on Secondary Cells and Batteries has been actively involved in creating guidelines for performance testing and safety requirements.

In parallel, the United States Advanced Battery Consortium (USABC) has also contributed significantly to the standardization process. They have published manuals and guidelines for electric vehicle battery testing, which include protocols for measuring capacity loss in various battery chemistries, including those with silicon anodes.

The National Institute of Standards and Technology (NIST) has been collaborating with industry partners to develop reference materials and measurement protocols specifically for silicon-based anodes. Their efforts aim to provide a common basis for comparing results across different laboratories and research groups.

Several academic institutions and industry consortia have also been working on establishing best practices for measuring first-cycle irreversible capacity loss. These include the Battery500 Consortium, which focuses on developing next-generation lithium-metal batteries, and the Faraday Institution in the UK, which has dedicated research programs on silicon anodes.

Standardization efforts have focused on several key aspects of the measurement process. These include defining consistent cycling conditions, such as voltage ranges, current rates, and temperature controls. Efforts have also been made to standardize sample preparation methods, electrode composition, and electrolyte formulations to ensure reproducibility.

Another important area of standardization has been the development of agreed-upon metrics for quantifying irreversible capacity loss. This includes defining how to calculate and report the first-cycle coulombic efficiency, as well as methods for separating different contributions to capacity loss, such as SEI formation and lithium trapping.

Despite these efforts, challenges remain in achieving full standardization. The diversity of silicon anode materials and their rapid evolution make it difficult to establish universal protocols. Additionally, the complex interplay between silicon anodes and other battery components necessitates ongoing refinement of measurement techniques.

Environmental Impact

The environmental impact of measuring first-cycle irreversible capacity loss for silicon-based anodes is an important consideration in the development and implementation of these protocols. The process involves the use of various materials and equipment, which can have both direct and indirect environmental consequences.

One of the primary environmental concerns is the use of electrolytes and other chemicals in the testing process. Many of these substances are potentially hazardous and require careful handling and disposal. Improper management of these materials can lead to soil and water contamination, posing risks to local ecosystems and human health. Additionally, the production and transportation of these chemicals contribute to carbon emissions and resource depletion.

The manufacturing and operation of testing equipment also have environmental implications. The production of specialized instruments and devices used in capacity loss measurements requires energy and raw materials, contributing to industrial emissions and resource consumption. Furthermore, the energy consumption during the testing process itself, particularly for long-duration cycling experiments, can be significant, especially if the power source is not from renewable energy.

Silicon-based anodes, while promising for improved battery performance, present their own environmental challenges. The production of silicon nanoparticles or other engineered silicon materials for anodes often involves energy-intensive processes and potentially hazardous chemicals. The environmental impact of scaling up these production methods for commercial use must be carefully evaluated.

Recycling and waste management are crucial aspects to consider. As research and development in this field progress, there will be an increasing amount of spent materials, including test cells and electrolytes. Developing efficient recycling protocols for these materials is essential to minimize waste and recover valuable resources, thereby reducing the overall environmental footprint of the research and development process.

On a broader scale, the advancement of silicon-based anode technology has the potential to significantly improve battery performance, which could lead to positive environmental outcomes. More efficient batteries could enhance the viability of electric vehicles and renewable energy storage systems, contributing to reduced greenhouse gas emissions and fossil fuel dependence. However, this potential benefit must be balanced against the immediate environmental impacts of the research and development process.

Researchers and industry professionals must prioritize the development of environmentally friendly testing protocols. This includes optimizing processes to reduce chemical usage, implementing energy-efficient testing equipment, and exploring green chemistry alternatives for electrolytes and other materials. Additionally, life cycle assessments should be conducted to comprehensively evaluate the environmental impact of these measurement techniques from raw material extraction to final disposal.

One of the primary environmental concerns is the use of electrolytes and other chemicals in the testing process. Many of these substances are potentially hazardous and require careful handling and disposal. Improper management of these materials can lead to soil and water contamination, posing risks to local ecosystems and human health. Additionally, the production and transportation of these chemicals contribute to carbon emissions and resource depletion.

The manufacturing and operation of testing equipment also have environmental implications. The production of specialized instruments and devices used in capacity loss measurements requires energy and raw materials, contributing to industrial emissions and resource consumption. Furthermore, the energy consumption during the testing process itself, particularly for long-duration cycling experiments, can be significant, especially if the power source is not from renewable energy.

Silicon-based anodes, while promising for improved battery performance, present their own environmental challenges. The production of silicon nanoparticles or other engineered silicon materials for anodes often involves energy-intensive processes and potentially hazardous chemicals. The environmental impact of scaling up these production methods for commercial use must be carefully evaluated.

Recycling and waste management are crucial aspects to consider. As research and development in this field progress, there will be an increasing amount of spent materials, including test cells and electrolytes. Developing efficient recycling protocols for these materials is essential to minimize waste and recover valuable resources, thereby reducing the overall environmental footprint of the research and development process.

On a broader scale, the advancement of silicon-based anode technology has the potential to significantly improve battery performance, which could lead to positive environmental outcomes. More efficient batteries could enhance the viability of electric vehicles and renewable energy storage systems, contributing to reduced greenhouse gas emissions and fossil fuel dependence. However, this potential benefit must be balanced against the immediate environmental impacts of the research and development process.

Researchers and industry professionals must prioritize the development of environmentally friendly testing protocols. This includes optimizing processes to reduce chemical usage, implementing energy-efficient testing equipment, and exploring green chemistry alternatives for electrolytes and other materials. Additionally, life cycle assessments should be conducted to comprehensively evaluate the environmental impact of these measurement techniques from raw material extraction to final disposal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!