How to Reduce Volume-Change Degradation in Silicon Anodes: Design & Modeling Approaches

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicon Anode Evolution

The evolution of silicon anodes in lithium-ion batteries represents a significant milestone in energy storage technology. Initially, graphite anodes dominated the market due to their stability and relatively high capacity. However, the pursuit of higher energy density led researchers to explore silicon as a potential anode material.

Silicon anodes emerged as a promising alternative due to their theoretical capacity, which is nearly ten times that of graphite. The early stages of silicon anode development focused on understanding the fundamental properties of silicon in lithium-ion batteries. Researchers discovered that silicon could alloy with lithium to form Li15Si4, offering a theoretical capacity of 3579 mAh/g.

As the potential of silicon anodes became apparent, the research community faced significant challenges. The primary obstacle was the enormous volume expansion of silicon during lithiation, reaching up to 300%. This volume change led to severe mechanical stress, resulting in particle fracture and electrode pulverization. Consequently, rapid capacity fading and poor cycle life became major hurdles in the commercialization of silicon anodes.

To address these issues, researchers explored various strategies. One of the early approaches involved the use of nanostructured silicon, such as silicon nanowires and nanoparticles. These structures provided better accommodation for volume changes and improved electronic conductivity. However, the high surface area of nanostructures led to increased side reactions with the electrolyte, creating new challenges.

Another significant development was the introduction of silicon-carbon composites. By combining silicon with carbon materials, researchers aimed to buffer the volume expansion and enhance the overall conductivity of the electrode. This approach led to improved cycling stability and paved the way for further advancements in silicon anode technology.

The evolution of silicon anodes also saw the development of novel binder systems. Traditional binders used in graphite anodes proved inadequate for silicon due to the extreme volume changes. This led to the exploration of elastic binders and three-dimensional conductive networks to maintain electrode integrity during cycling.

Recent years have witnessed a shift towards silicon-dominant composite anodes, where silicon content exceeds 50% of the active material. This approach aims to maximize the benefits of silicon while mitigating its drawbacks through careful material design and engineering. Advanced coating technologies and electrolyte additives have also played crucial roles in improving the performance and longevity of silicon anodes.

As the field progresses, researchers are now focusing on understanding the complex interplay between silicon particles, binders, conductive additives, and electrolytes at the nanoscale. This holistic approach is essential for developing next-generation silicon anodes that can meet the demanding requirements of high-energy density batteries for electric vehicles and grid storage applications.

Silicon anodes emerged as a promising alternative due to their theoretical capacity, which is nearly ten times that of graphite. The early stages of silicon anode development focused on understanding the fundamental properties of silicon in lithium-ion batteries. Researchers discovered that silicon could alloy with lithium to form Li15Si4, offering a theoretical capacity of 3579 mAh/g.

As the potential of silicon anodes became apparent, the research community faced significant challenges. The primary obstacle was the enormous volume expansion of silicon during lithiation, reaching up to 300%. This volume change led to severe mechanical stress, resulting in particle fracture and electrode pulverization. Consequently, rapid capacity fading and poor cycle life became major hurdles in the commercialization of silicon anodes.

To address these issues, researchers explored various strategies. One of the early approaches involved the use of nanostructured silicon, such as silicon nanowires and nanoparticles. These structures provided better accommodation for volume changes and improved electronic conductivity. However, the high surface area of nanostructures led to increased side reactions with the electrolyte, creating new challenges.

Another significant development was the introduction of silicon-carbon composites. By combining silicon with carbon materials, researchers aimed to buffer the volume expansion and enhance the overall conductivity of the electrode. This approach led to improved cycling stability and paved the way for further advancements in silicon anode technology.

The evolution of silicon anodes also saw the development of novel binder systems. Traditional binders used in graphite anodes proved inadequate for silicon due to the extreme volume changes. This led to the exploration of elastic binders and three-dimensional conductive networks to maintain electrode integrity during cycling.

Recent years have witnessed a shift towards silicon-dominant composite anodes, where silicon content exceeds 50% of the active material. This approach aims to maximize the benefits of silicon while mitigating its drawbacks through careful material design and engineering. Advanced coating technologies and electrolyte additives have also played crucial roles in improving the performance and longevity of silicon anodes.

As the field progresses, researchers are now focusing on understanding the complex interplay between silicon particles, binders, conductive additives, and electrolytes at the nanoscale. This holistic approach is essential for developing next-generation silicon anodes that can meet the demanding requirements of high-energy density batteries for electric vehicles and grid storage applications.

Market Demand Analysis

The market demand for silicon anodes in lithium-ion batteries has been steadily increasing due to their potential to significantly enhance energy density and overall battery performance. This demand is primarily driven by the growing electric vehicle (EV) market, consumer electronics, and renewable energy storage systems. The automotive sector, in particular, is pushing for higher energy density batteries to extend the range of EVs and reduce charging times, making silicon anodes an attractive option.

Silicon anodes offer theoretical capacities up to ten times higher than traditional graphite anodes, which could potentially lead to a 20-40% increase in overall battery energy density. This improvement aligns with the industry's goal of achieving longer-lasting and more efficient energy storage solutions. As a result, major battery manufacturers and automotive companies are investing heavily in silicon anode technology research and development.

The consumer electronics market also contributes to the demand for silicon anodes. Smartphone manufacturers are constantly seeking ways to increase battery life without increasing device size, making silicon anodes an appealing option. Additionally, the growing popularity of wearable devices and IoT applications further fuels the need for compact, high-capacity energy storage solutions.

In the renewable energy sector, the push for more efficient and cost-effective energy storage systems is driving interest in silicon anode technology. As countries worldwide aim to increase their renewable energy capacity, the demand for advanced battery technologies that can store and distribute energy more effectively is on the rise.

However, the market demand for silicon anodes is tempered by the challenges associated with volume-change degradation. This issue has been a significant barrier to widespread commercial adoption, as it affects the long-term stability and cycle life of batteries. Consequently, there is a strong market pull for innovative design and modeling approaches that can effectively mitigate this problem.

The potential market size for silicon anode batteries is substantial, with some industry analysts projecting it to reach several billion dollars within the next decade. This growth is expected to be driven by advancements in addressing the volume-change issue and the increasing adoption of EVs and renewable energy systems globally.

In conclusion, the market demand for solutions to reduce volume-change degradation in silicon anodes is robust and growing. Success in this area could unlock significant market opportunities across multiple industries, making it a critical focus for battery technology research and development efforts.

Silicon anodes offer theoretical capacities up to ten times higher than traditional graphite anodes, which could potentially lead to a 20-40% increase in overall battery energy density. This improvement aligns with the industry's goal of achieving longer-lasting and more efficient energy storage solutions. As a result, major battery manufacturers and automotive companies are investing heavily in silicon anode technology research and development.

The consumer electronics market also contributes to the demand for silicon anodes. Smartphone manufacturers are constantly seeking ways to increase battery life without increasing device size, making silicon anodes an appealing option. Additionally, the growing popularity of wearable devices and IoT applications further fuels the need for compact, high-capacity energy storage solutions.

In the renewable energy sector, the push for more efficient and cost-effective energy storage systems is driving interest in silicon anode technology. As countries worldwide aim to increase their renewable energy capacity, the demand for advanced battery technologies that can store and distribute energy more effectively is on the rise.

However, the market demand for silicon anodes is tempered by the challenges associated with volume-change degradation. This issue has been a significant barrier to widespread commercial adoption, as it affects the long-term stability and cycle life of batteries. Consequently, there is a strong market pull for innovative design and modeling approaches that can effectively mitigate this problem.

The potential market size for silicon anode batteries is substantial, with some industry analysts projecting it to reach several billion dollars within the next decade. This growth is expected to be driven by advancements in addressing the volume-change issue and the increasing adoption of EVs and renewable energy systems globally.

In conclusion, the market demand for solutions to reduce volume-change degradation in silicon anodes is robust and growing. Success in this area could unlock significant market opportunities across multiple industries, making it a critical focus for battery technology research and development efforts.

Current Challenges

Silicon anodes in lithium-ion batteries have garnered significant attention due to their high theoretical capacity. However, the widespread adoption of silicon anodes faces a major challenge: volume-change degradation. This issue stems from the substantial volume expansion and contraction that silicon undergoes during lithiation and delithiation cycles, leading to mechanical stress, cracking, and ultimately, capacity fade.

One of the primary challenges in addressing volume-change degradation is the development of robust structural designs that can accommodate the large volume changes without compromising the electrode integrity. Current approaches, such as nanostructured silicon and silicon-carbon composites, have shown promise but still face limitations in terms of scalability and long-term stability.

Another significant challenge lies in the formation and evolution of the solid-electrolyte interphase (SEI) layer on silicon anodes. The repeated volume changes cause continuous breaking and reforming of the SEI, leading to increased electrolyte consumption and loss of active material. Developing strategies to stabilize the SEI layer while maintaining efficient lithium-ion transport remains a critical area of research.

The mechanical degradation of silicon particles during cycling poses another hurdle. As silicon expands and contracts, it can pulverize into smaller particles, leading to loss of electrical contact and reduced capacity. Addressing this issue requires innovative approaches in particle design and the development of mechanically robust binder materials.

Furthermore, the high volume expansion of silicon anodes presents challenges in electrode design and cell engineering. Accommodating the volume changes while maintaining good electrical conductivity and electrolyte accessibility throughout the electrode structure is crucial for achieving high-performance batteries.

Modeling and simulation of silicon anode behavior present their own set of challenges. Accurately predicting the complex interplay between mechanical stress, electrochemical reactions, and transport phenomena in silicon anodes requires sophisticated multi-physics models. Developing and validating such models, particularly at different length and time scales, remains an active area of research.

Lastly, bridging the gap between laboratory-scale research and industrial-scale production of silicon anodes presents significant challenges. Scaling up the production of nanostructured silicon materials, ensuring uniform performance across large-format cells, and developing cost-effective manufacturing processes are critical for the commercial viability of silicon anodes.

One of the primary challenges in addressing volume-change degradation is the development of robust structural designs that can accommodate the large volume changes without compromising the electrode integrity. Current approaches, such as nanostructured silicon and silicon-carbon composites, have shown promise but still face limitations in terms of scalability and long-term stability.

Another significant challenge lies in the formation and evolution of the solid-electrolyte interphase (SEI) layer on silicon anodes. The repeated volume changes cause continuous breaking and reforming of the SEI, leading to increased electrolyte consumption and loss of active material. Developing strategies to stabilize the SEI layer while maintaining efficient lithium-ion transport remains a critical area of research.

The mechanical degradation of silicon particles during cycling poses another hurdle. As silicon expands and contracts, it can pulverize into smaller particles, leading to loss of electrical contact and reduced capacity. Addressing this issue requires innovative approaches in particle design and the development of mechanically robust binder materials.

Furthermore, the high volume expansion of silicon anodes presents challenges in electrode design and cell engineering. Accommodating the volume changes while maintaining good electrical conductivity and electrolyte accessibility throughout the electrode structure is crucial for achieving high-performance batteries.

Modeling and simulation of silicon anode behavior present their own set of challenges. Accurately predicting the complex interplay between mechanical stress, electrochemical reactions, and transport phenomena in silicon anodes requires sophisticated multi-physics models. Developing and validating such models, particularly at different length and time scales, remains an active area of research.

Lastly, bridging the gap between laboratory-scale research and industrial-scale production of silicon anodes presents significant challenges. Scaling up the production of nanostructured silicon materials, ensuring uniform performance across large-format cells, and developing cost-effective manufacturing processes are critical for the commercial viability of silicon anodes.

Design Solutions

01 Nanostructured silicon anodes

Utilizing nanostructured silicon anodes, such as silicon nanowires or nanoparticles, can help mitigate volume expansion issues during charging and discharging cycles. These nanostructures provide more space for expansion and contraction, reducing mechanical stress and improving cycle life.- Nanostructured silicon anodes: Utilizing nanostructured silicon anodes, such as silicon nanowires or nanoparticles, can help accommodate volume changes during charging and discharging. These structures provide more space for expansion and contraction, reducing mechanical stress and improving cycle life.

- Composite materials with silicon: Developing composite materials that combine silicon with other elements or compounds can help mitigate volume changes. These composites often include carbon-based materials or other metals to provide structural support and improve conductivity while allowing for silicon expansion.

- Electrolyte additives: Incorporating specific additives into the electrolyte can help form a stable solid electrolyte interphase (SEI) layer on the silicon anode surface. This layer can help prevent excessive electrolyte decomposition and reduce volume change-induced degradation.

- Binder optimization: Developing and optimizing binder materials that can accommodate the volume changes of silicon anodes is crucial. Elastic binders or those with self-healing properties can help maintain the structural integrity of the electrode during cycling.

- Porous silicon structures: Creating porous silicon structures or using silicon with engineered void spaces can provide room for volume expansion without causing significant structural damage to the electrode. These designs allow for better accommodation of the volume changes during lithiation and delithiation.

02 Composite materials with silicon

Developing composite materials that combine silicon with other elements or compounds can help address volume change degradation. These composites often include carbon-based materials or other metals to provide structural stability and improve conductivity while allowing for silicon's volume changes.Expand Specific Solutions03 Electrolyte additives and coatings

Incorporating specific electrolyte additives or applying protective coatings to silicon anodes can help form stable solid electrolyte interphase (SEI) layers. These layers can accommodate volume changes and prevent continuous electrolyte decomposition, thereby improving the anode's stability and longevity.Expand Specific Solutions04 Porous silicon structures

Creating porous silicon structures or using silicon with engineered void spaces can accommodate volume expansion during lithiation. These designs allow for internal expansion, reducing overall volume changes and mechanical stress on the anode structure.Expand Specific Solutions05 Binder and conductive additive optimization

Optimizing binder materials and conductive additives in silicon anode formulations can improve the mechanical integrity and electrical connectivity of the electrode. This approach helps maintain structural stability during volume changes and enhances overall battery performance.Expand Specific Solutions

Key Industry Players

The competition landscape for reducing volume-change degradation in silicon anodes is characterized by a mature market with significant research and development efforts. The global lithium-ion battery market, which this technology supports, is projected to reach $129.3 billion by 2027, with a CAGR of 18.0%. Major players like BTR New Material Group, Shin-Etsu Chemical, and Enovix Operations are at the forefront of silicon anode technology development. These companies, along with research institutions such as the University of California and Shanghai Jiao Tong University, are focusing on innovative design and modeling approaches to enhance silicon anode performance. The technology's maturity varies, with some companies offering commercial products while others are still in the research phase, indicating a dynamic and competitive environment.

The Regents of the University of California

Technical Solution: The University of California has developed a novel approach to address volume-change degradation in silicon anodes. Their method involves creating a nanostructured silicon anode with a hierarchical porous structure[1]. This design allows for the accommodation of volume expansion during lithiation while maintaining structural integrity. The researchers have also implemented a conductive coating on the silicon particles to enhance electron transport and stability[2]. Additionally, they have explored the use of artificial solid electrolyte interphase (SEI) layers to protect the silicon surface and mitigate continuous SEI formation[3]. Their modeling approaches include finite element analysis to predict stress distribution and crack propagation in silicon particles during cycling[4].

Strengths: Advanced nanostructuring techniques, innovative coating strategies, and comprehensive modeling capabilities. Weaknesses: Potential scalability issues for mass production and higher manufacturing costs compared to traditional graphite anodes.

Enovix Operations, Inc.

Technical Solution: Enovix has developed a proprietary 3D silicon lithium-ion battery architecture to address volume-change degradation. Their approach involves using silicon-dominant anodes with a unique structural design that constrains silicon expansion within the cell[5]. The company employs precision laser cutting and stacking techniques to create their 3D electrode structure, which allows for better control of silicon swelling[6]. Enovix has also implemented advanced electrolyte formulations and coatings to stabilize the silicon-electrolyte interface[7]. Their modeling efforts focus on multi-physics simulations to optimize the 3D structure and predict long-term cycling performance[8].

Strengths: Innovative 3D battery architecture, advanced manufacturing techniques, and integrated cell design approach. Weaknesses: Limited production capacity and higher initial costs compared to conventional lithium-ion batteries.

Modeling Innovations

Silicon composite electrodes with dynamic ionic bonding

PatentWO2018081708A1

Innovation

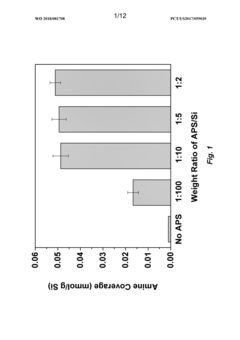

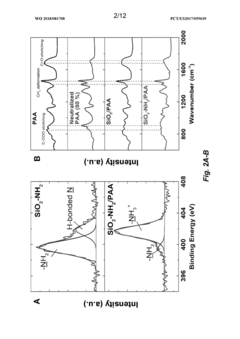

- Incorporation of dynamic ionic bonds between amine-functionalized silicon nanoparticles and a poly(acrylic acid) binder, forming a self-healing composite anode with a network of conductive electrical contacts that can restore interfaces upon damage, as confirmed by X-ray photoelectron spectroscopy and Raman spectroscopy.

Energy storage material and method of producing the same

PatentActiveUS20190355980A1

Innovation

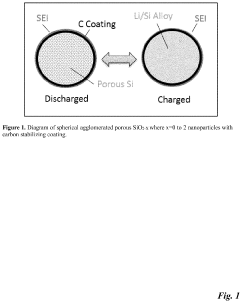

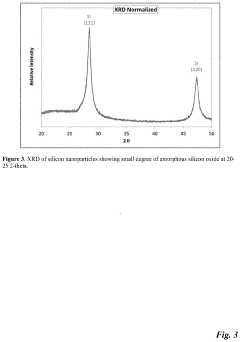

- The development of spherical porous secondary silicon-based particles formed by agglomerating primary silicon nanoparticles with a carbon coating, which reduces the exposed surface area and allows for volume expansion, using low-cost earth-abundant elements and scalable spray-drying processes to enhance energy density and cyclability.

Material Science Impact

The impact of silicon anode technology on material science is profound and far-reaching. Silicon anodes have emerged as a promising alternative to traditional graphite anodes in lithium-ion batteries due to their significantly higher theoretical capacity. This advancement has spurred extensive research and development in materials engineering, particularly in the field of nanostructured materials and composite design.

The challenge of volume-change degradation in silicon anodes has driven innovation in material synthesis and characterization techniques. Researchers have developed novel methods for creating nanostructured silicon, such as silicon nanowires, nanotubes, and porous silicon structures. These approaches have necessitated advancements in nanofabrication techniques, including chemical vapor deposition, electrospinning, and template-assisted synthesis.

The quest for stable silicon anodes has also led to breakthroughs in composite material design. Scientists have explored various carbon-silicon composites, silicon-metal alloys, and silicon-polymer hybrids. This has expanded our understanding of interfacial interactions between different materials and their role in maintaining structural integrity during cycling.

Advanced characterization techniques have been developed and refined to study the complex mechanisms of volume change and degradation in silicon anodes. In-situ transmission electron microscopy, synchrotron-based X-ray techniques, and advanced spectroscopic methods have been employed to observe real-time structural changes during battery operation. These tools have provided unprecedented insights into the behavior of materials at the nanoscale.

The challenges posed by silicon anodes have also stimulated progress in computational materials science. Advanced modeling techniques, including density functional theory calculations and molecular dynamics simulations, have been employed to predict and understand the behavior of silicon-based materials under various conditions. These computational approaches have become invaluable in guiding experimental design and accelerating the discovery of new materials.

Furthermore, the research into silicon anodes has catalyzed advancements in surface modification techniques and the development of novel electrolyte formulations. This has led to a deeper understanding of solid-electrolyte interphase (SEI) formation and stability, which is crucial for the long-term performance of battery materials.

The pursuit of improved silicon anodes has also fostered interdisciplinary collaboration between materials scientists, chemists, physicists, and engineers. This cross-pollination of ideas has accelerated innovation and led to novel approaches in addressing the volume-change issue, benefiting not only battery technology but also other areas of materials science where structural stability is critical.

The challenge of volume-change degradation in silicon anodes has driven innovation in material synthesis and characterization techniques. Researchers have developed novel methods for creating nanostructured silicon, such as silicon nanowires, nanotubes, and porous silicon structures. These approaches have necessitated advancements in nanofabrication techniques, including chemical vapor deposition, electrospinning, and template-assisted synthesis.

The quest for stable silicon anodes has also led to breakthroughs in composite material design. Scientists have explored various carbon-silicon composites, silicon-metal alloys, and silicon-polymer hybrids. This has expanded our understanding of interfacial interactions between different materials and their role in maintaining structural integrity during cycling.

Advanced characterization techniques have been developed and refined to study the complex mechanisms of volume change and degradation in silicon anodes. In-situ transmission electron microscopy, synchrotron-based X-ray techniques, and advanced spectroscopic methods have been employed to observe real-time structural changes during battery operation. These tools have provided unprecedented insights into the behavior of materials at the nanoscale.

The challenges posed by silicon anodes have also stimulated progress in computational materials science. Advanced modeling techniques, including density functional theory calculations and molecular dynamics simulations, have been employed to predict and understand the behavior of silicon-based materials under various conditions. These computational approaches have become invaluable in guiding experimental design and accelerating the discovery of new materials.

Furthermore, the research into silicon anodes has catalyzed advancements in surface modification techniques and the development of novel electrolyte formulations. This has led to a deeper understanding of solid-electrolyte interphase (SEI) formation and stability, which is crucial for the long-term performance of battery materials.

The pursuit of improved silicon anodes has also fostered interdisciplinary collaboration between materials scientists, chemists, physicists, and engineers. This cross-pollination of ideas has accelerated innovation and led to novel approaches in addressing the volume-change issue, benefiting not only battery technology but also other areas of materials science where structural stability is critical.

Sustainability Aspects

The sustainability aspects of silicon anode development for lithium-ion batteries are crucial considerations in the quest to reduce volume-change degradation. As the demand for high-capacity energy storage solutions continues to grow, the environmental impact of battery production and disposal becomes increasingly significant.

Silicon anodes offer promising potential for increased energy density, but their volume expansion during cycling poses challenges for long-term sustainability. Addressing this issue requires a holistic approach that considers the entire lifecycle of the battery, from raw material extraction to end-of-life management.

One key sustainability aspect is the sourcing of silicon. While silicon is abundant in the Earth's crust, its extraction and processing can be energy-intensive. Developing more efficient and environmentally friendly methods for silicon production is essential. This includes exploring alternative sources, such as recycled silicon from the semiconductor industry or biogenic silica from agricultural waste.

The manufacturing process of silicon anodes also presents opportunities for sustainability improvements. Techniques that reduce energy consumption and minimize the use of harmful chemicals can significantly decrease the environmental footprint of battery production. For instance, water-based processing methods and low-temperature synthesis techniques show promise in this regard.

Extending the cycle life of silicon anodes is paramount for sustainability. By mitigating volume-change degradation, batteries can last longer, reducing the need for frequent replacements and minimizing electronic waste. This aligns with circular economy principles and helps conserve valuable resources.

Furthermore, the design of silicon anodes should consider end-of-life scenarios. Developing anodes that are easier to disassemble and recycle can facilitate more efficient material recovery. This is particularly important given the increasing focus on battery recycling as a means to secure a sustainable supply of critical materials.

The environmental impact of potential solutions to volume-change degradation must also be evaluated. For example, while certain additives or coatings may improve performance, their long-term effects on the environment and human health should be carefully assessed. Sustainable design approaches should prioritize non-toxic, biodegradable, or easily recyclable materials wherever possible.

Lastly, the energy efficiency of silicon anodes throughout their operational life is a crucial sustainability factor. Improvements in charge-discharge efficiency can lead to reduced energy consumption during battery use, contributing to overall energy conservation and lower carbon emissions in various applications, from electric vehicles to grid storage systems.

Silicon anodes offer promising potential for increased energy density, but their volume expansion during cycling poses challenges for long-term sustainability. Addressing this issue requires a holistic approach that considers the entire lifecycle of the battery, from raw material extraction to end-of-life management.

One key sustainability aspect is the sourcing of silicon. While silicon is abundant in the Earth's crust, its extraction and processing can be energy-intensive. Developing more efficient and environmentally friendly methods for silicon production is essential. This includes exploring alternative sources, such as recycled silicon from the semiconductor industry or biogenic silica from agricultural waste.

The manufacturing process of silicon anodes also presents opportunities for sustainability improvements. Techniques that reduce energy consumption and minimize the use of harmful chemicals can significantly decrease the environmental footprint of battery production. For instance, water-based processing methods and low-temperature synthesis techniques show promise in this regard.

Extending the cycle life of silicon anodes is paramount for sustainability. By mitigating volume-change degradation, batteries can last longer, reducing the need for frequent replacements and minimizing electronic waste. This aligns with circular economy principles and helps conserve valuable resources.

Furthermore, the design of silicon anodes should consider end-of-life scenarios. Developing anodes that are easier to disassemble and recycle can facilitate more efficient material recovery. This is particularly important given the increasing focus on battery recycling as a means to secure a sustainable supply of critical materials.

The environmental impact of potential solutions to volume-change degradation must also be evaluated. For example, while certain additives or coatings may improve performance, their long-term effects on the environment and human health should be carefully assessed. Sustainable design approaches should prioritize non-toxic, biodegradable, or easily recyclable materials wherever possible.

Lastly, the energy efficiency of silicon anodes throughout their operational life is a crucial sustainability factor. Improvements in charge-discharge efficiency can lead to reduced energy consumption during battery use, contributing to overall energy conservation and lower carbon emissions in various applications, from electric vehicles to grid storage systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!