Silicon Anode Electrode Calendering: Effects on Porosity, Conductivity and Cycle Stability

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicon Anode Evolution

The evolution of silicon anodes in lithium-ion batteries represents a significant advancement in energy storage technology. Initially, graphite anodes dominated the market due to their stability and relatively high capacity. However, the theoretical capacity of graphite (372 mAh/g) limited further improvements in battery energy density.

Silicon emerged as a promising alternative due to its exceptionally high theoretical capacity of 4200 mAh/g, nearly ten times that of graphite. Early research in the 1990s focused on understanding silicon's lithiation mechanisms and addressing its primary challenge: volume expansion. During charge-discharge cycles, silicon particles can expand up to 300%, leading to mechanical stress, electrode pulverization, and rapid capacity fade.

The 2000s saw significant progress in mitigating these issues. Researchers explored various nanostructured silicon materials, including nanoparticles, nanowires, and porous structures. These designs aimed to accommodate volume changes and improve cycling stability. Concurrently, the development of silicon-carbon composites gained traction, combining silicon's high capacity with carbon's structural stability and conductivity.

By the early 2010s, silicon-graphite composite anodes began entering commercial applications, typically incorporating small amounts of silicon (5-10%) to boost capacity while maintaining acceptable cycle life. This marked the beginning of silicon's practical implementation in consumer electronics batteries.

Recent years have witnessed advancements in silicon anode engineering, including the development of silicon-dominant anodes with over 50% silicon content. Innovations in binder technologies, electrolyte additives, and electrode architectures have played crucial roles in enhancing the performance and longevity of silicon anodes.

The focus on electrode calendering emerged as researchers recognized its potential to optimize silicon anode properties. Calendering, a process of compressing electrode materials, influences crucial parameters such as porosity, conductivity, and mechanical stability. By fine-tuning the calendering process, researchers aim to strike a balance between high energy density and long-term cycling stability in silicon anodes.

Current research efforts are directed towards understanding the complex interplay between calendering parameters, electrode microstructure, and electrochemical performance. This includes investigating how different degrees of calendering affect the porosity of silicon-based electrodes, which in turn impacts electrolyte penetration, ion transport, and the electrode's ability to accommodate volume changes during cycling.

Silicon emerged as a promising alternative due to its exceptionally high theoretical capacity of 4200 mAh/g, nearly ten times that of graphite. Early research in the 1990s focused on understanding silicon's lithiation mechanisms and addressing its primary challenge: volume expansion. During charge-discharge cycles, silicon particles can expand up to 300%, leading to mechanical stress, electrode pulverization, and rapid capacity fade.

The 2000s saw significant progress in mitigating these issues. Researchers explored various nanostructured silicon materials, including nanoparticles, nanowires, and porous structures. These designs aimed to accommodate volume changes and improve cycling stability. Concurrently, the development of silicon-carbon composites gained traction, combining silicon's high capacity with carbon's structural stability and conductivity.

By the early 2010s, silicon-graphite composite anodes began entering commercial applications, typically incorporating small amounts of silicon (5-10%) to boost capacity while maintaining acceptable cycle life. This marked the beginning of silicon's practical implementation in consumer electronics batteries.

Recent years have witnessed advancements in silicon anode engineering, including the development of silicon-dominant anodes with over 50% silicon content. Innovations in binder technologies, electrolyte additives, and electrode architectures have played crucial roles in enhancing the performance and longevity of silicon anodes.

The focus on electrode calendering emerged as researchers recognized its potential to optimize silicon anode properties. Calendering, a process of compressing electrode materials, influences crucial parameters such as porosity, conductivity, and mechanical stability. By fine-tuning the calendering process, researchers aim to strike a balance between high energy density and long-term cycling stability in silicon anodes.

Current research efforts are directed towards understanding the complex interplay between calendering parameters, electrode microstructure, and electrochemical performance. This includes investigating how different degrees of calendering affect the porosity of silicon-based electrodes, which in turn impacts electrolyte penetration, ion transport, and the electrode's ability to accommodate volume changes during cycling.

Market Demand Analysis

The market demand for silicon anode electrode calendering technology is driven by the rapidly growing electric vehicle (EV) and energy storage sectors. As the world shifts towards sustainable energy solutions, the need for high-performance batteries with improved energy density, longer cycle life, and faster charging capabilities has become paramount. Silicon anodes offer significant advantages over traditional graphite anodes, including a theoretical capacity nearly ten times higher.

The global lithium-ion battery market, which directly impacts the demand for silicon anode technologies, is experiencing robust growth. This expansion is fueled by increasing EV adoption, renewable energy integration, and the proliferation of portable electronic devices. The automotive industry, in particular, is a key driver of this demand, as manufacturers seek to extend the range and reduce the charging time of electric vehicles.

Silicon anode electrode calendering plays a crucial role in addressing the challenges associated with silicon-based anodes, such as volume expansion and capacity fading. By optimizing porosity and conductivity through the calendering process, manufacturers can enhance the overall performance and stability of silicon anodes. This technology is essential for realizing the full potential of silicon in battery applications and meeting the market's demand for higher energy density and longer-lasting batteries.

The demand for advanced battery technologies is not limited to the automotive sector. Stationary energy storage systems for grid stabilization and renewable energy integration also require high-performance batteries. Silicon anode technologies, including optimized calendering processes, are well-positioned to address these needs, further expanding the market potential.

As environmental regulations become more stringent and consumers increasingly prioritize sustainability, the demand for silicon anode technologies is expected to grow. Governments worldwide are implementing policies to promote electric vehicle adoption and renewable energy integration, which in turn drives the need for advanced battery technologies. This regulatory landscape creates a favorable environment for the development and commercialization of silicon anode electrode calendering technologies.

The market also shows a strong interest in fast-charging capabilities, an area where silicon anodes excel. By optimizing the electrode structure through calendering, manufacturers can potentially reduce charging times while maintaining battery longevity. This aligns with consumer expectations for more convenient and efficient electric vehicles, further driving demand for silicon anode technologies.

The global lithium-ion battery market, which directly impacts the demand for silicon anode technologies, is experiencing robust growth. This expansion is fueled by increasing EV adoption, renewable energy integration, and the proliferation of portable electronic devices. The automotive industry, in particular, is a key driver of this demand, as manufacturers seek to extend the range and reduce the charging time of electric vehicles.

Silicon anode electrode calendering plays a crucial role in addressing the challenges associated with silicon-based anodes, such as volume expansion and capacity fading. By optimizing porosity and conductivity through the calendering process, manufacturers can enhance the overall performance and stability of silicon anodes. This technology is essential for realizing the full potential of silicon in battery applications and meeting the market's demand for higher energy density and longer-lasting batteries.

The demand for advanced battery technologies is not limited to the automotive sector. Stationary energy storage systems for grid stabilization and renewable energy integration also require high-performance batteries. Silicon anode technologies, including optimized calendering processes, are well-positioned to address these needs, further expanding the market potential.

As environmental regulations become more stringent and consumers increasingly prioritize sustainability, the demand for silicon anode technologies is expected to grow. Governments worldwide are implementing policies to promote electric vehicle adoption and renewable energy integration, which in turn drives the need for advanced battery technologies. This regulatory landscape creates a favorable environment for the development and commercialization of silicon anode electrode calendering technologies.

The market also shows a strong interest in fast-charging capabilities, an area where silicon anodes excel. By optimizing the electrode structure through calendering, manufacturers can potentially reduce charging times while maintaining battery longevity. This aligns with consumer expectations for more convenient and efficient electric vehicles, further driving demand for silicon anode technologies.

Calendering Challenges

Calendering, a critical process in electrode manufacturing, presents several challenges when applied to silicon anode electrodes. The primary issue stems from silicon's unique properties, particularly its significant volume expansion during lithiation. This expansion can lead to mechanical stress and structural degradation, which are exacerbated by the high pressures applied during calendering.

One of the main challenges is maintaining an optimal porosity in the electrode structure. Silicon anodes require a certain level of porosity to accommodate volume changes and facilitate electrolyte penetration. However, the calendering process, designed to increase the volumetric energy density, can potentially over-compress the electrode, reducing porosity to detrimental levels. This reduction in porosity can impede ion transport and limit the electrode's ability to withstand cycling-induced stress.

Another significant challenge is the potential for particle fracture and pulverization during calendering. Silicon particles are inherently brittle, and the high pressures applied during calendering can cause them to break. This fragmentation can lead to the formation of electrically isolated particles, reducing the overall capacity and conductivity of the electrode. Moreover, the creation of new surfaces through particle fracture can increase the formation of solid electrolyte interphase (SEI), leading to increased irreversible capacity loss.

The conductivity of silicon anode electrodes is also affected by the calendering process. While calendering generally improves electrical contact between particles, the unique properties of silicon can complicate this effect. The volume changes during cycling can disrupt the conductive network established during calendering, potentially leading to increased internal resistance over time. Balancing the need for good inter-particle contact with the requirement for a flexible structure that can accommodate volume changes is a significant challenge.

Cycle stability is another critical aspect affected by calendering. The compressed structure resulting from calendering can limit the electrode's ability to accommodate the repeated volume changes during charge-discharge cycles. This can lead to accelerated degradation, manifesting as capacity fade and reduced cycle life. Finding the right balance between compression for high energy density and maintaining structural integrity for long-term stability is a key challenge in silicon anode electrode calendering.

Furthermore, the calendering process must be carefully optimized to account for the different components in the electrode, including silicon particles, conductive additives, and binders. Each of these components responds differently to the applied pressure, and their relative proportions can significantly impact the effectiveness of calendering. Achieving a uniform distribution of these components throughout the compressed electrode structure is crucial for optimal performance but remains a significant challenge.

One of the main challenges is maintaining an optimal porosity in the electrode structure. Silicon anodes require a certain level of porosity to accommodate volume changes and facilitate electrolyte penetration. However, the calendering process, designed to increase the volumetric energy density, can potentially over-compress the electrode, reducing porosity to detrimental levels. This reduction in porosity can impede ion transport and limit the electrode's ability to withstand cycling-induced stress.

Another significant challenge is the potential for particle fracture and pulverization during calendering. Silicon particles are inherently brittle, and the high pressures applied during calendering can cause them to break. This fragmentation can lead to the formation of electrically isolated particles, reducing the overall capacity and conductivity of the electrode. Moreover, the creation of new surfaces through particle fracture can increase the formation of solid electrolyte interphase (SEI), leading to increased irreversible capacity loss.

The conductivity of silicon anode electrodes is also affected by the calendering process. While calendering generally improves electrical contact between particles, the unique properties of silicon can complicate this effect. The volume changes during cycling can disrupt the conductive network established during calendering, potentially leading to increased internal resistance over time. Balancing the need for good inter-particle contact with the requirement for a flexible structure that can accommodate volume changes is a significant challenge.

Cycle stability is another critical aspect affected by calendering. The compressed structure resulting from calendering can limit the electrode's ability to accommodate the repeated volume changes during charge-discharge cycles. This can lead to accelerated degradation, manifesting as capacity fade and reduced cycle life. Finding the right balance between compression for high energy density and maintaining structural integrity for long-term stability is a key challenge in silicon anode electrode calendering.

Furthermore, the calendering process must be carefully optimized to account for the different components in the electrode, including silicon particles, conductive additives, and binders. Each of these components responds differently to the applied pressure, and their relative proportions can significantly impact the effectiveness of calendering. Achieving a uniform distribution of these components throughout the compressed electrode structure is crucial for optimal performance but remains a significant challenge.

Current Calendering

01 Porous silicon anode structure

Developing porous silicon anode structures can enhance electrode performance by providing space for volume expansion during charging and discharging. This approach improves cycle stability and conductivity by maintaining structural integrity and facilitating electrolyte penetration. Techniques such as etching or templating can be used to create controlled porosity in silicon anodes.- Porous silicon anode structure: Developing porous silicon anode structures can enhance electrode performance by providing space for volume expansion during cycling, improving electrolyte penetration, and increasing the surface area for lithium-ion interaction. This approach can lead to better cycle stability and improved conductivity.

- Conductive additives for silicon anodes: Incorporating conductive additives such as carbon materials or conductive polymers into silicon anodes can significantly improve their electrical conductivity. These additives create conductive networks within the electrode, facilitating electron transport and enhancing overall battery performance.

- Silicon-carbon composite anodes: Developing silicon-carbon composite anodes can address multiple challenges simultaneously. The carbon component can provide structural stability, improve conductivity, and buffer volume changes, while the silicon offers high capacity. This combination can lead to improved cycle stability and overall electrode performance.

- Nanostructured silicon anodes: Utilizing nanostructured silicon, such as silicon nanowires or nanoparticles, can improve the electrode's cycle stability and conductivity. These nanostructures can better accommodate volume changes during cycling and provide shorter diffusion paths for lithium ions, enhancing overall electrode performance.

- Surface modification of silicon anodes: Modifying the surface of silicon anodes through coatings or functional groups can improve their stability and conductivity. These modifications can help form stable solid electrolyte interphases, prevent side reactions, and enhance the electrode's overall performance and cycle life.

02 Conductive additives for silicon anodes

Incorporating conductive additives into silicon anodes can significantly improve their electrical conductivity. Common additives include carbon-based materials like graphene, carbon nanotubes, or conductive polymers. These additives form a conductive network within the electrode, enhancing electron transport and overall battery performance.Expand Specific Solutions03 Silicon-carbon composite anodes

Developing silicon-carbon composite anodes can address multiple challenges simultaneously. The carbon component provides structural support, improves conductivity, and helps accommodate volume changes. This composite structure enhances cycle stability and maintains high capacity. Various methods of combining silicon and carbon, such as coating or encapsulation, can be employed.Expand Specific Solutions04 Nanostructured silicon anodes

Utilizing nanostructured silicon, such as silicon nanowires or nanoparticles, can improve electrode performance. These nanostructures provide shorter diffusion paths for lithium ions, better accommodate volume changes, and enhance overall conductivity. Various synthesis methods and surface modifications can be applied to optimize nanostructured silicon anodes.Expand Specific Solutions05 Electrolyte additives for silicon anodes

Incorporating specific electrolyte additives can improve the performance of silicon anodes. These additives can help form a stable solid electrolyte interphase (SEI) layer, reduce irreversible capacity loss, and enhance cycle stability. Fluoroethylene carbonate (FEC) and vinylene carbonate (VC) are examples of additives that have shown promising results in silicon anode systems.Expand Specific Solutions

Key Industry Players

The silicon anode electrode calendering technology is in a transitional phase, moving from research to early commercialization. The market for this technology is expanding rapidly, driven by the growing demand for high-performance lithium-ion batteries in electric vehicles and energy storage systems. While the market size is still relatively small, it is expected to grow significantly in the coming years. Technologically, silicon anode electrodes are advancing, with companies like NanoGraf, Enovix, and Enevate making notable progress. However, challenges related to cycle stability and manufacturing scalability persist. Established players such as GM, Bosch, and BYD are also investing in this technology, indicating its potential to revolutionize battery performance in the near future.

NanoGraf Corp.

Technical Solution: NanoGraf has developed a silicon-graphene composite anode material that addresses the challenges of silicon anode calendering. Their technology utilizes a proprietary silicon-graphene architecture that allows for improved porosity control during the calendering process. This structure helps maintain electrical conductivity while accommodating the volume expansion of silicon during cycling. NanoGraf's approach involves a careful balance of silicon nanoparticles embedded in a graphene matrix, which provides mechanical stability and electron pathways[1]. The company has reported achieving energy densities up to 1400 Wh/L, significantly higher than traditional graphite anodes[2]. Their calendering process is optimized to create a porous network that allows for electrolyte penetration while maintaining structural integrity, crucial for long-term cycle stability.

Strengths: High energy density, improved cycle stability, and better control over porosity during calendering. Weaknesses: Potential higher production costs and complexity in scaling up manufacturing processes.

Enevate Corp.

Technical Solution: Enevate has pioneered a silicon-dominant anode technology that addresses the challenges of electrode calendering. Their approach uses a unique silicon film deposition method that creates a porous silicon structure directly on the current collector[3]. This pre-formed porous structure is designed to withstand the pressures of calendering while maintaining critical void spaces for electrolyte access and silicon expansion. Enevate's technology reportedly allows for silicon content of over 70% in the anode, leading to energy densities exceeding 1000 Wh/L[4]. The company's calendering process is tailored to compress the electrode to an optimal density without compromising the engineered porosity, resulting in improved conductivity and cycle stability. Enevate claims their anodes can achieve over 1000 cycles with minimal capacity loss[5].

Strengths: High silicon content, pre-engineered porosity, and excellent cycle life. Weaknesses: Potentially higher initial costs and specialized manufacturing equipment requirements.

Porosity Innovations

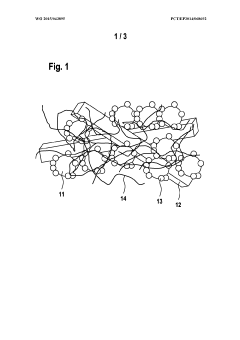

Electrode composition, electrode, and lithium-ion battery

PatentWO2015043895A1

Innovation

- An electrode composition combining silicon with specific ratios of crystalline graphite, carbon black, and a binder like carboxymethyl cellulose (CMC) to enhance mechanical stability and electrical conductivity, ensuring good contact and improved lithium-ion diffusion and cycle stability.

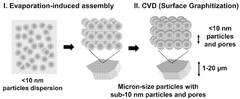

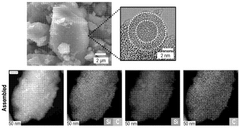

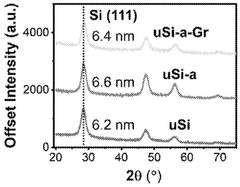

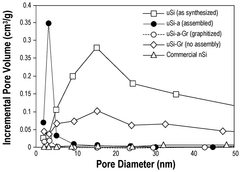

Super-assembled micron-sized silicon particles

PatentWO2025129140A1

Innovation

- The development of ultrasmall silicon particle-pore assemblies, where silicon nanoparticles with an average size of less than 12 nm are dispersed with nanopores of less than 10 nm, forming micron-sized assemblies through evaporation-induced assembly and subsequent carbon coating, stabilizes the SEI formation and enhances charge-discharge stability.

Performance Metrics

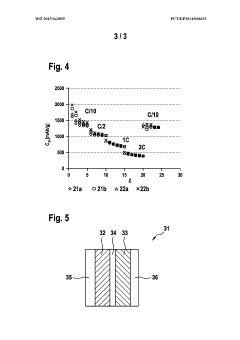

Performance metrics play a crucial role in evaluating the effectiveness of silicon anode electrode calendering and its impact on battery performance. These metrics provide quantitative measures to assess the improvements in porosity, conductivity, and cycle stability resulting from the calendering process.

Porosity is a key metric that directly influences the electrode's ability to accommodate silicon expansion during cycling. The calendering process typically reduces porosity, which can be measured using techniques such as mercury intrusion porosimetry or gas adsorption methods. Optimal porosity levels are essential for maintaining mechanical stability while allowing sufficient electrolyte penetration. Researchers often report porosity values before and after calendering to demonstrate the process's impact on electrode structure.

Conductivity is another critical performance metric affected by calendering. As the electrode is compressed, the contact between conductive additives and active materials improves, potentially enhancing overall conductivity. Measurements of electronic conductivity can be performed using four-point probe techniques or electrochemical impedance spectroscopy (EIS). Improved conductivity translates to better rate capability and reduced internal resistance, which are vital for high-performance batteries.

Cycle stability is perhaps the most important metric for assessing the long-term viability of silicon anode electrodes. It is typically evaluated through extended charge-discharge cycling tests, often involving hundreds or thousands of cycles. Key parameters include capacity retention, coulombic efficiency, and the rate of capacity fade over time. Calendered electrodes may exhibit improved cycle stability due to enhanced particle-to-particle contact and reduced electrode degradation.

Specific capacity is another crucial metric, measured in mAh/g or mAh/cm³. While silicon offers high theoretical capacity, the calendering process may affect the practical achievable capacity. Researchers often compare the specific capacities of calendered and uncalendered electrodes to optimize the trade-off between high capacity and structural stability.

Rate capability is an additional performance metric that reflects the electrode's ability to maintain capacity at various charge-discharge rates. This is particularly important for applications requiring fast charging or high power output. Calendering can impact rate capability by altering the electrode's porosity and tortuosity, which affect lithium-ion transport kinetics.

Mechanical properties such as adhesion strength and flexibility are also relevant metrics, as they influence the electrode's durability during cycling. Calendering can improve adhesion between the active material and current collector, potentially enhancing the electrode's mechanical integrity. These properties can be assessed through peel tests, bending tests, or nanoindentation techniques.

Porosity is a key metric that directly influences the electrode's ability to accommodate silicon expansion during cycling. The calendering process typically reduces porosity, which can be measured using techniques such as mercury intrusion porosimetry or gas adsorption methods. Optimal porosity levels are essential for maintaining mechanical stability while allowing sufficient electrolyte penetration. Researchers often report porosity values before and after calendering to demonstrate the process's impact on electrode structure.

Conductivity is another critical performance metric affected by calendering. As the electrode is compressed, the contact between conductive additives and active materials improves, potentially enhancing overall conductivity. Measurements of electronic conductivity can be performed using four-point probe techniques or electrochemical impedance spectroscopy (EIS). Improved conductivity translates to better rate capability and reduced internal resistance, which are vital for high-performance batteries.

Cycle stability is perhaps the most important metric for assessing the long-term viability of silicon anode electrodes. It is typically evaluated through extended charge-discharge cycling tests, often involving hundreds or thousands of cycles. Key parameters include capacity retention, coulombic efficiency, and the rate of capacity fade over time. Calendered electrodes may exhibit improved cycle stability due to enhanced particle-to-particle contact and reduced electrode degradation.

Specific capacity is another crucial metric, measured in mAh/g or mAh/cm³. While silicon offers high theoretical capacity, the calendering process may affect the practical achievable capacity. Researchers often compare the specific capacities of calendered and uncalendered electrodes to optimize the trade-off between high capacity and structural stability.

Rate capability is an additional performance metric that reflects the electrode's ability to maintain capacity at various charge-discharge rates. This is particularly important for applications requiring fast charging or high power output. Calendering can impact rate capability by altering the electrode's porosity and tortuosity, which affect lithium-ion transport kinetics.

Mechanical properties such as adhesion strength and flexibility are also relevant metrics, as they influence the electrode's durability during cycling. Calendering can improve adhesion between the active material and current collector, potentially enhancing the electrode's mechanical integrity. These properties can be assessed through peel tests, bending tests, or nanoindentation techniques.

Scalability Assessment

The scalability assessment of silicon anode electrode calendering is crucial for determining its potential for large-scale implementation in battery production. The process of calendering silicon anodes presents unique challenges due to the material's properties and its effects on porosity, conductivity, and cycle stability.

One of the primary considerations for scalability is the equipment required for calendering silicon anodes. Current calendering machinery used for graphite anodes may need significant modifications or complete redesign to accommodate the specific requirements of silicon-based electrodes. The pressure and temperature control systems must be more precise and adaptable to prevent damage to the silicon particles while achieving the desired porosity and conductivity.

The consistency of calendering across large electrode sheets is another critical factor. Ensuring uniform compression and porosity distribution over sizeable areas is essential for maintaining consistent battery performance. This may require advanced sensing and control systems to adjust calendering parameters in real-time, compensating for any variations in electrode thickness or composition.

Material handling and throughput rates also play a significant role in scalability. Silicon anodes are more sensitive to mechanical stress than traditional graphite anodes, which may necessitate slower processing speeds or multiple passes through the calendering rollers. This could potentially reduce production rates and increase manufacturing costs, impacting the overall scalability of the process.

The integration of silicon anode calendering into existing battery production lines is another aspect to consider. Retrofitting current facilities or designing new production lines that can accommodate the specific requirements of silicon anode calendering will be necessary for large-scale adoption. This may involve significant capital investment and production line redesigns.

Quality control and in-line monitoring systems are crucial for scalable production. Developing rapid, non-destructive testing methods to assess porosity, conductivity, and potential cycle stability immediately after calendering would be essential for maintaining consistent quality in high-volume production scenarios.

Lastly, the environmental impact and sustainability of scaled-up silicon anode calendering processes must be evaluated. This includes assessing energy consumption, potential material waste, and the recyclability of calendered silicon anodes at the end of their life cycle. Addressing these factors is crucial for ensuring the long-term viability and acceptance of silicon anode technology in large-scale battery production.

One of the primary considerations for scalability is the equipment required for calendering silicon anodes. Current calendering machinery used for graphite anodes may need significant modifications or complete redesign to accommodate the specific requirements of silicon-based electrodes. The pressure and temperature control systems must be more precise and adaptable to prevent damage to the silicon particles while achieving the desired porosity and conductivity.

The consistency of calendering across large electrode sheets is another critical factor. Ensuring uniform compression and porosity distribution over sizeable areas is essential for maintaining consistent battery performance. This may require advanced sensing and control systems to adjust calendering parameters in real-time, compensating for any variations in electrode thickness or composition.

Material handling and throughput rates also play a significant role in scalability. Silicon anodes are more sensitive to mechanical stress than traditional graphite anodes, which may necessitate slower processing speeds or multiple passes through the calendering rollers. This could potentially reduce production rates and increase manufacturing costs, impacting the overall scalability of the process.

The integration of silicon anode calendering into existing battery production lines is another aspect to consider. Retrofitting current facilities or designing new production lines that can accommodate the specific requirements of silicon anode calendering will be necessary for large-scale adoption. This may involve significant capital investment and production line redesigns.

Quality control and in-line monitoring systems are crucial for scalable production. Developing rapid, non-destructive testing methods to assess porosity, conductivity, and potential cycle stability immediately after calendering would be essential for maintaining consistent quality in high-volume production scenarios.

Lastly, the environmental impact and sustainability of scaled-up silicon anode calendering processes must be evaluated. This includes assessing energy consumption, potential material waste, and the recyclability of calendered silicon anodes at the end of their life cycle. Addressing these factors is crucial for ensuring the long-term viability and acceptance of silicon anode technology in large-scale battery production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!