How to Achieve Maximum Efficiency with K24 Engine Mods?

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Mod Background and Objectives

The K24 engine, developed by Honda, has been a popular choice for performance enthusiasts since its introduction in the early 2000s. This 2.4-liter inline-four engine has gained a reputation for its reliability, versatility, and potential for modification. The background of K24 engine modifications stems from the desire to extract maximum performance from this already capable powerplant.

Initially designed for various Honda and Acura models, the K24 engine has become a favorite among tuners due to its robust construction and responsive nature. The evolution of K24 engine modifications has been driven by advancements in automotive technology, increased understanding of engine dynamics, and the growing demand for higher performance in both street and racing applications.

The primary objective of K24 engine modifications is to achieve maximum efficiency, which translates to increased power output, improved throttle response, and enhanced overall engine performance. This goal encompasses various aspects of engine tuning, including optimizing air intake, fuel delivery, exhaust flow, and internal engine components.

One of the key areas of focus in K24 engine modifications is increasing volumetric efficiency. This involves improving the engine's ability to breathe more effectively, allowing for a greater volume of air-fuel mixture to enter the combustion chambers. Techniques such as porting and polishing cylinder heads, installing larger valves, and optimizing camshaft profiles are commonly employed to achieve this objective.

Another critical aspect of K24 engine modifications is enhancing the combustion process. This includes optimizing the compression ratio, fine-tuning ignition timing, and improving fuel atomization. By achieving a more complete and efficient burn of the air-fuel mixture, modifiers aim to extract maximum energy from each combustion cycle.

Reducing internal friction and mechanical losses is also a significant objective in K24 engine modifications. This can be achieved through the use of lightweight components, such as forged pistons and connecting rods, as well as implementing advanced coatings and surface treatments to minimize friction between moving parts.

The pursuit of maximum efficiency in K24 engine modifications also extends to the engine management system. Advanced engine control units (ECUs) and tuning software allow for precise control over fuel injection, ignition timing, and other critical parameters. This level of control enables tuners to optimize the engine's performance across its entire operating range, ensuring maximum efficiency under various conditions.

As technology continues to advance, the objectives of K24 engine modifications evolve to incorporate new techniques and materials. The integration of forced induction systems, such as turbochargers or superchargers, has become increasingly popular, presenting new challenges and opportunities for achieving maximum efficiency in K24 engines.

Initially designed for various Honda and Acura models, the K24 engine has become a favorite among tuners due to its robust construction and responsive nature. The evolution of K24 engine modifications has been driven by advancements in automotive technology, increased understanding of engine dynamics, and the growing demand for higher performance in both street and racing applications.

The primary objective of K24 engine modifications is to achieve maximum efficiency, which translates to increased power output, improved throttle response, and enhanced overall engine performance. This goal encompasses various aspects of engine tuning, including optimizing air intake, fuel delivery, exhaust flow, and internal engine components.

One of the key areas of focus in K24 engine modifications is increasing volumetric efficiency. This involves improving the engine's ability to breathe more effectively, allowing for a greater volume of air-fuel mixture to enter the combustion chambers. Techniques such as porting and polishing cylinder heads, installing larger valves, and optimizing camshaft profiles are commonly employed to achieve this objective.

Another critical aspect of K24 engine modifications is enhancing the combustion process. This includes optimizing the compression ratio, fine-tuning ignition timing, and improving fuel atomization. By achieving a more complete and efficient burn of the air-fuel mixture, modifiers aim to extract maximum energy from each combustion cycle.

Reducing internal friction and mechanical losses is also a significant objective in K24 engine modifications. This can be achieved through the use of lightweight components, such as forged pistons and connecting rods, as well as implementing advanced coatings and surface treatments to minimize friction between moving parts.

The pursuit of maximum efficiency in K24 engine modifications also extends to the engine management system. Advanced engine control units (ECUs) and tuning software allow for precise control over fuel injection, ignition timing, and other critical parameters. This level of control enables tuners to optimize the engine's performance across its entire operating range, ensuring maximum efficiency under various conditions.

As technology continues to advance, the objectives of K24 engine modifications evolve to incorporate new techniques and materials. The integration of forced induction systems, such as turbochargers or superchargers, has become increasingly popular, presenting new challenges and opportunities for achieving maximum efficiency in K24 engines.

Market Analysis for K24 Engine Modifications

The market for K24 engine modifications has experienced significant growth in recent years, driven by enthusiasts seeking to maximize the performance of their Honda and Acura vehicles. The K24 engine, known for its reliability and potential for tuning, has become a popular choice among automotive enthusiasts and racers alike.

The demand for K24 engine modifications is primarily fueled by owners of Honda Accord, Civic Si, CR-V, and Acura TSX models. These vehicles, equipped with the K24 engine, have a large and dedicated fan base that constantly seeks ways to improve performance. The aftermarket industry has responded to this demand by developing a wide range of products and services tailored specifically for K24 engine upgrades.

Market research indicates that the global automotive aftermarket parts industry is valued at over $400 billion, with engine modifications representing a substantial portion of this market. The K24 engine modification segment, while smaller, has shown steady growth, with annual sales estimated in the tens of millions of dollars.

Key drivers of market growth include the increasing popularity of track days and amateur racing events, where enthusiasts can showcase their modified vehicles. Additionally, the rise of social media platforms and online communities has facilitated knowledge sharing and inspiration among K24 engine owners, further stimulating demand for performance upgrades.

The market for K24 engine modifications can be segmented into several categories, including intake systems, exhaust systems, turbocharger kits, engine management systems, and internal engine components. Each segment caters to different levels of modification, from simple bolt-on upgrades to complete engine rebuilds.

Geographically, the market is strongest in North America and Japan, where Honda and Acura vehicles are most prevalent. However, there is growing interest in European and Asian markets, particularly in countries with a strong car modification culture.

Consumer trends indicate a preference for modular upgrades that allow for incremental performance gains. This approach enables enthusiasts to spread their investments over time while gradually improving their vehicle's performance. There is also an increasing demand for eco-friendly modifications that balance performance gains with fuel efficiency and emissions reduction.

The competitive landscape of the K24 engine modification market is diverse, featuring both established aftermarket manufacturers and smaller, specialized tuning shops. Major players in this space include companies like Hondata, K-Tuned, and Skunk2 Racing, which offer comprehensive product lines for K24 engine upgrades.

Looking ahead, the market for K24 engine modifications is expected to continue its growth trajectory, albeit with some challenges. The shift towards electric vehicles may impact long-term demand, but the large existing base of K24-equipped vehicles ensures a stable market for the foreseeable future. Opportunities for innovation lie in developing hybrid solutions and adapting K24 engines for alternative fuels, potentially extending the lifespan of this popular engine platform in an evolving automotive landscape.

The demand for K24 engine modifications is primarily fueled by owners of Honda Accord, Civic Si, CR-V, and Acura TSX models. These vehicles, equipped with the K24 engine, have a large and dedicated fan base that constantly seeks ways to improve performance. The aftermarket industry has responded to this demand by developing a wide range of products and services tailored specifically for K24 engine upgrades.

Market research indicates that the global automotive aftermarket parts industry is valued at over $400 billion, with engine modifications representing a substantial portion of this market. The K24 engine modification segment, while smaller, has shown steady growth, with annual sales estimated in the tens of millions of dollars.

Key drivers of market growth include the increasing popularity of track days and amateur racing events, where enthusiasts can showcase their modified vehicles. Additionally, the rise of social media platforms and online communities has facilitated knowledge sharing and inspiration among K24 engine owners, further stimulating demand for performance upgrades.

The market for K24 engine modifications can be segmented into several categories, including intake systems, exhaust systems, turbocharger kits, engine management systems, and internal engine components. Each segment caters to different levels of modification, from simple bolt-on upgrades to complete engine rebuilds.

Geographically, the market is strongest in North America and Japan, where Honda and Acura vehicles are most prevalent. However, there is growing interest in European and Asian markets, particularly in countries with a strong car modification culture.

Consumer trends indicate a preference for modular upgrades that allow for incremental performance gains. This approach enables enthusiasts to spread their investments over time while gradually improving their vehicle's performance. There is also an increasing demand for eco-friendly modifications that balance performance gains with fuel efficiency and emissions reduction.

The competitive landscape of the K24 engine modification market is diverse, featuring both established aftermarket manufacturers and smaller, specialized tuning shops. Major players in this space include companies like Hondata, K-Tuned, and Skunk2 Racing, which offer comprehensive product lines for K24 engine upgrades.

Looking ahead, the market for K24 engine modifications is expected to continue its growth trajectory, albeit with some challenges. The shift towards electric vehicles may impact long-term demand, but the large existing base of K24-equipped vehicles ensures a stable market for the foreseeable future. Opportunities for innovation lie in developing hybrid solutions and adapting K24 engines for alternative fuels, potentially extending the lifespan of this popular engine platform in an evolving automotive landscape.

Current K24 Engine Mod Challenges

The K24 engine, renowned for its versatility and potential, faces several challenges when it comes to achieving maximum efficiency through modifications. One of the primary obstacles is the stock engine management system, which is not designed to accommodate significant alterations in fuel delivery, ignition timing, and boost pressure. This limitation often requires aftermarket engine control units (ECUs) or piggyback systems, adding complexity and cost to the modification process.

Another challenge lies in the stock intake and exhaust systems, which become restrictive when pursuing higher power outputs. The factory intake manifold and throttle body are not optimized for increased airflow, while the exhaust system, including headers and catalytic converters, can create bottlenecks that hinder performance gains. Upgrading these components is essential but requires careful selection to maintain proper engine balance and emissions compliance.

The K24's valve train also presents challenges when pushing for maximum efficiency. While the i-VTEC system is impressive, it may not provide optimal valve timing and lift for high-performance applications. Aftermarket camshafts and valve springs are often necessary to fully exploit the engine's potential, but these modifications can affect reliability and require precise tuning to avoid valve float or interference.

Fuel system limitations become apparent when significantly increasing the engine's output. The stock fuel injectors and fuel pump may struggle to provide adequate fuel delivery at higher power levels, necessitating upgrades that must be carefully matched to the engine's requirements. Balancing fuel delivery with air intake is crucial for achieving optimal air-fuel ratios across the entire RPM range.

Heat management is another critical challenge, particularly when adding forced induction or increasing compression ratios. The K24's cooling system may be inadequate for sustained high-performance operation, leading to potential overheating issues. This often necessitates upgrades to the radiator, oil cooler, and sometimes even the addition of an intercooler for turbocharged applications.

Durability concerns arise when pushing the K24 beyond its stock capabilities. Internal components such as pistons, connecting rods, and bearings may require reinforcement or replacement to withstand increased stresses. Balancing performance gains with longevity is a delicate act that often involves compromises between maximum output and engine lifespan.

Lastly, emissions compliance remains a significant challenge, especially in regions with strict regulations. Many high-performance modifications can potentially alter the engine's emissions profile, making it difficult to pass inspections or maintain street legality. Developing solutions that enhance performance while meeting emissions standards requires innovative approaches and often involves the use of advanced catalytic converters or exhaust gas recirculation systems.

Another challenge lies in the stock intake and exhaust systems, which become restrictive when pursuing higher power outputs. The factory intake manifold and throttle body are not optimized for increased airflow, while the exhaust system, including headers and catalytic converters, can create bottlenecks that hinder performance gains. Upgrading these components is essential but requires careful selection to maintain proper engine balance and emissions compliance.

The K24's valve train also presents challenges when pushing for maximum efficiency. While the i-VTEC system is impressive, it may not provide optimal valve timing and lift for high-performance applications. Aftermarket camshafts and valve springs are often necessary to fully exploit the engine's potential, but these modifications can affect reliability and require precise tuning to avoid valve float or interference.

Fuel system limitations become apparent when significantly increasing the engine's output. The stock fuel injectors and fuel pump may struggle to provide adequate fuel delivery at higher power levels, necessitating upgrades that must be carefully matched to the engine's requirements. Balancing fuel delivery with air intake is crucial for achieving optimal air-fuel ratios across the entire RPM range.

Heat management is another critical challenge, particularly when adding forced induction or increasing compression ratios. The K24's cooling system may be inadequate for sustained high-performance operation, leading to potential overheating issues. This often necessitates upgrades to the radiator, oil cooler, and sometimes even the addition of an intercooler for turbocharged applications.

Durability concerns arise when pushing the K24 beyond its stock capabilities. Internal components such as pistons, connecting rods, and bearings may require reinforcement or replacement to withstand increased stresses. Balancing performance gains with longevity is a delicate act that often involves compromises between maximum output and engine lifespan.

Lastly, emissions compliance remains a significant challenge, especially in regions with strict regulations. Many high-performance modifications can potentially alter the engine's emissions profile, making it difficult to pass inspections or maintain street legality. Developing solutions that enhance performance while meeting emissions standards requires innovative approaches and often involves the use of advanced catalytic converters or exhaust gas recirculation systems.

Existing K24 Engine Mod Solutions

01 Improved combustion efficiency

The K24 engine's efficiency can be enhanced through optimized combustion processes. This includes improvements in fuel injection systems, air-fuel mixture control, and ignition timing. These advancements lead to more complete combustion, reduced fuel consumption, and lower emissions.- Improved combustion efficiency: Enhancements to the K24 engine's combustion process, including optimized fuel injection systems, advanced ignition timing, and improved air-fuel mixture control, contribute to increased engine efficiency. These modifications result in more complete fuel burning and reduced emissions.

- Advanced thermal management: Implementation of sophisticated thermal management systems in the K24 engine, such as improved cooling circuits, heat recovery systems, and thermal barrier coatings, helps maintain optimal operating temperatures. This leads to reduced friction, decreased heat loss, and overall improved engine efficiency.

- Friction reduction technologies: Incorporation of low-friction materials, surface treatments, and advanced lubricants in the K24 engine's components reduces internal friction. This minimizes energy losses and improves overall engine efficiency, particularly in high-stress areas such as piston rings and bearings.

- Variable valve timing and lift: Implementation of advanced variable valve timing and lift systems in the K24 engine allows for optimized air intake and exhaust flow across different engine speeds and loads. This results in improved volumetric efficiency, better fuel economy, and increased power output.

- Engine control unit optimization: Refinement of the K24 engine's control unit software and algorithms enables more precise management of fuel injection, ignition timing, and other engine parameters. This optimization leads to improved engine performance, fuel efficiency, and reduced emissions across various operating conditions.

02 Advanced thermal management

Efficient thermal management systems are crucial for K24 engine performance. This involves innovative cooling techniques, heat dissipation methods, and temperature control mechanisms. Proper thermal management helps maintain optimal operating temperatures, reducing energy losses and improving overall engine efficiency.Expand Specific Solutions03 Friction reduction technologies

Minimizing friction within the K24 engine components is essential for improving efficiency. This includes the use of advanced lubricants, low-friction coatings, and optimized surface finishes on engine parts. Reduced friction leads to less energy loss and improved fuel economy.Expand Specific Solutions04 Variable valve timing and lift

Implementing advanced variable valve timing and lift systems in the K24 engine can significantly enhance its efficiency. These systems allow for optimized air intake and exhaust flow across different engine speeds and loads, resulting in improved power output and fuel efficiency.Expand Specific Solutions05 Engine control and monitoring systems

Sophisticated engine control units (ECUs) and monitoring systems play a crucial role in optimizing K24 engine efficiency. These systems use advanced algorithms and sensors to continuously adjust engine parameters, ensuring optimal performance under various operating conditions. Real-time monitoring and adaptive control contribute to improved fuel economy and reduced emissions.Expand Specific Solutions

Key Players in K24 Engine Tuning Industry

The K24 engine modification market is in a mature stage, with a well-established ecosystem of manufacturers and aftermarket suppliers. The global market for performance engine modifications is substantial, estimated to be worth billions of dollars annually. Technologically, K24 engine mods are well-developed, with a range of proven solutions available. Key players in this space include major automotive manufacturers like Honda (original K24 developer), Toyota, and GM, as well as aftermarket specialists. Companies such as SAIC Volkswagen, BYD, and Dongfeng Motor Group are also investing in engine optimization technologies, potentially applicable to K24 mods. Additionally, research institutions like Chongqing University and Jilin University contribute to advancing engine efficiency technologies.

BYD Co., Ltd.

Technical Solution: BYD's strategy for K24 engine efficiency improvements revolves around their Dual Mode (DM) hybrid system. While not specifically designed for the K24 engine, their approach can be adapted to enhance its efficiency. The DM system integrates an electric motor with the internal combustion engine, allowing for various operating modes to optimize efficiency [1]. BYD has developed advanced power electronics and control algorithms that seamlessly switch between pure electric, series hybrid, and parallel hybrid modes based on driving conditions [2]. Their system also incorporates regenerative braking to recover energy typically lost during deceleration [3]. Additionally, BYD has focused on weight reduction through the use of advanced materials in engine components, which indirectly improves overall vehicle efficiency [4].

Strengths: Holistic approach that combines hybrid technology with traditional engine optimization. Weaknesses: May require significant modifications to the base K24 engine design to fully implement the hybrid system.

GM Global Technology Operations LLC

Technical Solution: GM's approach to maximizing K24 engine efficiency involves advanced variable valve timing (VVT) and lift control systems. They have implemented a dual-stage VVT system that independently adjusts intake and exhaust valve timing, optimizing combustion across a wide range of engine speeds and loads [1]. Additionally, GM has developed a variable displacement oil pump that reduces parasitic losses by adjusting oil pressure based on engine demand [2]. The company has also focused on reducing friction through the use of low-friction coatings on piston skirts and advanced bearing materials [3]. To further enhance efficiency, GM has integrated direct fuel injection technology, allowing for precise fuel delivery and improved combustion efficiency [4].

Strengths: Comprehensive approach addressing multiple aspects of engine efficiency. Weaknesses: Complexity of systems may increase manufacturing costs and potential for reliability issues in the long term.

Core K24 Engine Mod Innovations

A method to improve efficiency of an engine in a vehicle

PatentInactiveIN201841024311A

Innovation

- An electronic control unit in vehicles communicates with a fuel station's IoT server to receive knock adaptation values based on detected fuel parameters, adjusting ignition timing accordingly to optimize engine efficiency.

Upshift control method and device for hybrid vehicle and vehicle

PatentPendingCN118850037A

Innovation

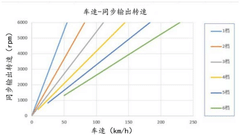

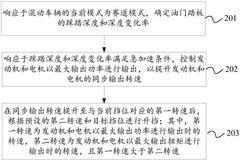

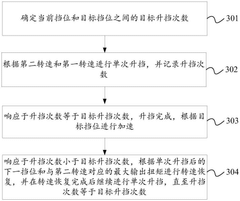

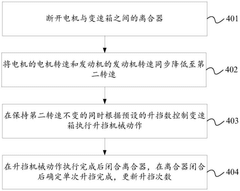

- By determining the stepping depth and depth change rate of the accelerator pedal in track mode, if the rapid acceleration conditions are met, the engine and motor are controlled to output at maximum output power, the synchronous output speed is increased, and the speed is adjusted according to the preset second speed and target gear. to ensure maximum performance output in each gear, shorten the upshift time, and provide maximum acceleration.

Emissions Regulations Impact on K24 Mods

Emissions regulations have significantly impacted the landscape of K24 engine modifications, creating both challenges and opportunities for enthusiasts and manufacturers alike. As environmental concerns continue to drive stricter emissions standards worldwide, the pursuit of maximum efficiency in K24 engine mods must now balance performance gains with compliance to these regulations.

The introduction of more stringent emissions standards, such as Euro 6 in Europe and Tier 3 in the United States, has necessitated a shift in approach to K24 engine modifications. These regulations have placed increased emphasis on reducing harmful exhaust emissions, particularly nitrogen oxides (NOx) and particulate matter. As a result, traditional performance-enhancing mods that may have increased emissions are now subject to greater scrutiny and potential legal restrictions.

One of the primary challenges faced by K24 engine modders is the need to maintain or improve the effectiveness of the engine's catalytic converter. Many high-performance modifications can lead to increased exhaust temperatures and altered air-fuel ratios, potentially compromising the catalyst's ability to reduce emissions. This has led to the development of more sophisticated engine management systems and tuning techniques that can optimize performance while still meeting emissions requirements.

The regulations have also spurred innovation in the aftermarket industry. Manufacturers are now focusing on developing "emissions-friendly" performance parts, such as high-flow catalytic converters and advanced fuel injection systems. These components are designed to enhance engine efficiency and power output while simultaneously reducing harmful emissions, allowing enthusiasts to modify their K24 engines without running afoul of environmental regulations.

Another significant impact of emissions regulations on K24 mods is the increased emphasis on forced induction systems. Turbocharging and supercharging have become more prevalent as they offer a way to boost performance while potentially improving fuel efficiency and emissions control. When properly implemented, these forced induction systems can help K24 engines meet stricter emissions standards while still delivering impressive power gains.

The regulatory landscape has also led to a growing interest in alternative fuels and hybrid technologies for K24-powered vehicles. Some enthusiasts are exploring the use of E85 ethanol or even full electric conversions to achieve high performance while adhering to emissions standards. This trend reflects a broader shift in the automotive industry towards more sustainable and environmentally friendly performance solutions.

In conclusion, emissions regulations have fundamentally altered the approach to K24 engine modifications. While they present challenges, they have also driven innovation and a more holistic approach to engine tuning that considers both performance and environmental impact. As regulations continue to evolve, the future of K24 mods will likely see further advancements in clean performance technologies, ensuring that enthusiasts can continue to pursue maximum efficiency within the bounds of environmental responsibility.

The introduction of more stringent emissions standards, such as Euro 6 in Europe and Tier 3 in the United States, has necessitated a shift in approach to K24 engine modifications. These regulations have placed increased emphasis on reducing harmful exhaust emissions, particularly nitrogen oxides (NOx) and particulate matter. As a result, traditional performance-enhancing mods that may have increased emissions are now subject to greater scrutiny and potential legal restrictions.

One of the primary challenges faced by K24 engine modders is the need to maintain or improve the effectiveness of the engine's catalytic converter. Many high-performance modifications can lead to increased exhaust temperatures and altered air-fuel ratios, potentially compromising the catalyst's ability to reduce emissions. This has led to the development of more sophisticated engine management systems and tuning techniques that can optimize performance while still meeting emissions requirements.

The regulations have also spurred innovation in the aftermarket industry. Manufacturers are now focusing on developing "emissions-friendly" performance parts, such as high-flow catalytic converters and advanced fuel injection systems. These components are designed to enhance engine efficiency and power output while simultaneously reducing harmful emissions, allowing enthusiasts to modify their K24 engines without running afoul of environmental regulations.

Another significant impact of emissions regulations on K24 mods is the increased emphasis on forced induction systems. Turbocharging and supercharging have become more prevalent as they offer a way to boost performance while potentially improving fuel efficiency and emissions control. When properly implemented, these forced induction systems can help K24 engines meet stricter emissions standards while still delivering impressive power gains.

The regulatory landscape has also led to a growing interest in alternative fuels and hybrid technologies for K24-powered vehicles. Some enthusiasts are exploring the use of E85 ethanol or even full electric conversions to achieve high performance while adhering to emissions standards. This trend reflects a broader shift in the automotive industry towards more sustainable and environmentally friendly performance solutions.

In conclusion, emissions regulations have fundamentally altered the approach to K24 engine modifications. While they present challenges, they have also driven innovation and a more holistic approach to engine tuning that considers both performance and environmental impact. As regulations continue to evolve, the future of K24 mods will likely see further advancements in clean performance technologies, ensuring that enthusiasts can continue to pursue maximum efficiency within the bounds of environmental responsibility.

K24 Engine Mod Performance Testing

Performance testing is a critical aspect of K24 engine modifications to achieve maximum efficiency. This process involves rigorous evaluation of various engine components and their impact on overall performance. The testing typically begins with establishing a baseline for the stock engine, measuring key parameters such as horsepower, torque, fuel efficiency, and emissions.

Once the baseline is established, modifications are systematically implemented and tested. Common modifications include upgrading the intake system, exhaust system, camshafts, and engine management software. Each modification is tested individually to assess its impact on performance metrics. This approach allows for precise identification of which modifications yield the most significant improvements.

Dynamometer testing is a crucial tool in this process. It provides accurate measurements of power output across the engine's RPM range. This data is essential for fine-tuning modifications and ensuring optimal performance gains. In addition to power output, fuel consumption is closely monitored to evaluate the efficiency of each modification.

Temperature and pressure sensors are strategically placed throughout the engine to monitor critical parameters during testing. This data helps identify potential issues such as excessive heat generation or inadequate oil pressure, which could compromise engine longevity or reliability.

Emissions testing is another vital component of the performance evaluation process. As modifications often impact the engine's combustion characteristics, it's crucial to ensure that the modified engine still meets applicable emissions standards. This may involve using specialized equipment to measure exhaust gases and particulate matter.

Long-term durability testing is also conducted to assess the reliability of the modified engine under sustained high-performance conditions. This typically involves extended periods of operation at high loads, simulating real-world driving scenarios. The engine is periodically inspected for wear and tear, and any components showing signs of premature failure are identified and addressed.

Data logging and analysis play a significant role in the testing process. Advanced software is used to collect and interpret vast amounts of data from various sensors. This allows engineers to identify trends, optimize performance, and make data-driven decisions about further modifications.

Finally, real-world testing complements the laboratory and dynamometer results. This involves road testing the modified engine in various conditions to evaluate its performance, drivability, and reliability in practical scenarios. The feedback from these tests often leads to further refinements in the modification strategy.

Once the baseline is established, modifications are systematically implemented and tested. Common modifications include upgrading the intake system, exhaust system, camshafts, and engine management software. Each modification is tested individually to assess its impact on performance metrics. This approach allows for precise identification of which modifications yield the most significant improvements.

Dynamometer testing is a crucial tool in this process. It provides accurate measurements of power output across the engine's RPM range. This data is essential for fine-tuning modifications and ensuring optimal performance gains. In addition to power output, fuel consumption is closely monitored to evaluate the efficiency of each modification.

Temperature and pressure sensors are strategically placed throughout the engine to monitor critical parameters during testing. This data helps identify potential issues such as excessive heat generation or inadequate oil pressure, which could compromise engine longevity or reliability.

Emissions testing is another vital component of the performance evaluation process. As modifications often impact the engine's combustion characteristics, it's crucial to ensure that the modified engine still meets applicable emissions standards. This may involve using specialized equipment to measure exhaust gases and particulate matter.

Long-term durability testing is also conducted to assess the reliability of the modified engine under sustained high-performance conditions. This typically involves extended periods of operation at high loads, simulating real-world driving scenarios. The engine is periodically inspected for wear and tear, and any components showing signs of premature failure are identified and addressed.

Data logging and analysis play a significant role in the testing process. Advanced software is used to collect and interpret vast amounts of data from various sensors. This allows engineers to identify trends, optimize performance, and make data-driven decisions about further modifications.

Finally, real-world testing complements the laboratory and dynamometer results. This involves road testing the modified engine in various conditions to evaluate its performance, drivability, and reliability in practical scenarios. The feedback from these tests often leads to further refinements in the modification strategy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!