K24 Engine Adaptation: Meeting Future Urban Transport Needs

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Evolution

The K24 engine has undergone significant evolution since its inception, adapting to meet the changing demands of urban transportation. Initially designed as a compact and efficient powerplant for small passenger vehicles, the K24 has progressively transformed to address the unique challenges posed by modern city environments.

In its early stages, the K24 engine focused primarily on balancing performance with fuel efficiency. Engineers worked to optimize combustion processes and reduce internal friction, resulting in improved power output and reduced fuel consumption. This phase laid the foundation for the engine's reputation as a reliable and economical choice for urban commuters.

As environmental concerns gained prominence, the K24's evolution shifted towards reducing emissions. Advancements in fuel injection technology, variable valve timing, and exhaust gas recirculation systems were incorporated to meet increasingly stringent emission standards. These improvements not only made the engine cleaner but also contributed to enhanced fuel economy, aligning with the growing emphasis on sustainability in urban transport.

The rise of hybrid and electric vehicles prompted further adaptation of the K24 engine. Engineers developed hybrid variants that integrated electric motors with the K24, creating a versatile powertrain capable of operating in various modes to optimize efficiency in diverse urban driving conditions. This hybridization marked a significant milestone in the engine's evolution, bridging the gap between conventional internal combustion engines and fully electric powertrains.

Recent developments in the K24 engine have focused on enhancing its suitability for emerging urban mobility solutions. Modifications to improve low-end torque and responsiveness have made the engine more adaptable to stop-start city traffic and car-sharing applications. Additionally, efforts to reduce noise and vibration have improved the engine's compatibility with the quiet operation expected in densely populated urban areas.

The latest iterations of the K24 engine have also embraced digital technology. Integration with advanced engine management systems and connectivity features has enabled real-time optimization of performance and efficiency based on traffic conditions, driving patterns, and even air quality data. This smart adaptation capability positions the K24 as a forward-thinking solution for the increasingly connected and data-driven urban transport ecosystem.

As cities continue to evolve, so too does the K24 engine, with ongoing research focused on further improving its efficiency, reducing its environmental impact, and enhancing its integration with smart city infrastructure. The engine's journey from a simple powerplant to a sophisticated, adaptable system exemplifies the continuous innovation required to meet the ever-changing needs of urban transportation.

In its early stages, the K24 engine focused primarily on balancing performance with fuel efficiency. Engineers worked to optimize combustion processes and reduce internal friction, resulting in improved power output and reduced fuel consumption. This phase laid the foundation for the engine's reputation as a reliable and economical choice for urban commuters.

As environmental concerns gained prominence, the K24's evolution shifted towards reducing emissions. Advancements in fuel injection technology, variable valve timing, and exhaust gas recirculation systems were incorporated to meet increasingly stringent emission standards. These improvements not only made the engine cleaner but also contributed to enhanced fuel economy, aligning with the growing emphasis on sustainability in urban transport.

The rise of hybrid and electric vehicles prompted further adaptation of the K24 engine. Engineers developed hybrid variants that integrated electric motors with the K24, creating a versatile powertrain capable of operating in various modes to optimize efficiency in diverse urban driving conditions. This hybridization marked a significant milestone in the engine's evolution, bridging the gap between conventional internal combustion engines and fully electric powertrains.

Recent developments in the K24 engine have focused on enhancing its suitability for emerging urban mobility solutions. Modifications to improve low-end torque and responsiveness have made the engine more adaptable to stop-start city traffic and car-sharing applications. Additionally, efforts to reduce noise and vibration have improved the engine's compatibility with the quiet operation expected in densely populated urban areas.

The latest iterations of the K24 engine have also embraced digital technology. Integration with advanced engine management systems and connectivity features has enabled real-time optimization of performance and efficiency based on traffic conditions, driving patterns, and even air quality data. This smart adaptation capability positions the K24 as a forward-thinking solution for the increasingly connected and data-driven urban transport ecosystem.

As cities continue to evolve, so too does the K24 engine, with ongoing research focused on further improving its efficiency, reducing its environmental impact, and enhancing its integration with smart city infrastructure. The engine's journey from a simple powerplant to a sophisticated, adaptable system exemplifies the continuous innovation required to meet the ever-changing needs of urban transportation.

Urban Transport Demand

The urban transport landscape is undergoing significant changes driven by population growth, urbanization, and evolving mobility preferences. As cities continue to expand and densify, the demand for efficient, sustainable, and adaptable transportation solutions is reaching unprecedented levels. This shift is particularly evident in the increasing need for vehicles that can navigate congested urban environments while meeting stringent emissions standards and fuel efficiency requirements.

Recent studies indicate that global urban populations are expected to grow by 2.5 billion people by 2050, with nearly 70% of the world's population residing in urban areas. This demographic trend is placing immense pressure on existing transportation infrastructure and creating a surge in demand for innovative urban mobility solutions. The K24 engine adaptation project is positioned at the intersection of these evolving urban transport needs and technological advancements in powertrain systems.

In response to these trends, there is a growing market for vehicles equipped with engines that offer improved fuel efficiency, reduced emissions, and enhanced performance in stop-and-go traffic conditions typical of urban environments. The demand for such vehicles is not limited to personal transportation but extends to public transit systems, ride-sharing services, and last-mile delivery fleets. These sectors are actively seeking powertrains that can deliver optimal performance while minimizing environmental impact and operating costs.

Furthermore, the rise of smart cities and integrated transportation networks is creating new opportunities for engine technologies that can seamlessly interface with urban infrastructure. This includes the ability to communicate with traffic management systems, adapt to real-time traffic conditions, and optimize performance based on predictive analytics of urban mobility patterns.

The market for urban-focused engines is also being shaped by changing consumer preferences and regulatory pressures. There is a growing demand for vehicles that offer a balance between performance and sustainability, with consumers increasingly valuing low-emission technologies and fuel efficiency. This shift is further reinforced by tightening emissions regulations in major urban centers worldwide, creating a strong incentive for the adoption of advanced engine technologies like the K24 adaptation.

As urban transport needs continue to evolve, the demand for engines that can meet these challenges is expected to grow significantly. The K24 engine adaptation project has the potential to address many of these market demands, positioning it as a key technology in the future of urban mobility. By aligning with these trends, the adapted K24 engine could play a crucial role in shaping the next generation of urban transport solutions, meeting the needs of cities, consumers, and regulatory bodies alike.

Recent studies indicate that global urban populations are expected to grow by 2.5 billion people by 2050, with nearly 70% of the world's population residing in urban areas. This demographic trend is placing immense pressure on existing transportation infrastructure and creating a surge in demand for innovative urban mobility solutions. The K24 engine adaptation project is positioned at the intersection of these evolving urban transport needs and technological advancements in powertrain systems.

In response to these trends, there is a growing market for vehicles equipped with engines that offer improved fuel efficiency, reduced emissions, and enhanced performance in stop-and-go traffic conditions typical of urban environments. The demand for such vehicles is not limited to personal transportation but extends to public transit systems, ride-sharing services, and last-mile delivery fleets. These sectors are actively seeking powertrains that can deliver optimal performance while minimizing environmental impact and operating costs.

Furthermore, the rise of smart cities and integrated transportation networks is creating new opportunities for engine technologies that can seamlessly interface with urban infrastructure. This includes the ability to communicate with traffic management systems, adapt to real-time traffic conditions, and optimize performance based on predictive analytics of urban mobility patterns.

The market for urban-focused engines is also being shaped by changing consumer preferences and regulatory pressures. There is a growing demand for vehicles that offer a balance between performance and sustainability, with consumers increasingly valuing low-emission technologies and fuel efficiency. This shift is further reinforced by tightening emissions regulations in major urban centers worldwide, creating a strong incentive for the adoption of advanced engine technologies like the K24 adaptation.

As urban transport needs continue to evolve, the demand for engines that can meet these challenges is expected to grow significantly. The K24 engine adaptation project has the potential to address many of these market demands, positioning it as a key technology in the future of urban mobility. By aligning with these trends, the adapted K24 engine could play a crucial role in shaping the next generation of urban transport solutions, meeting the needs of cities, consumers, and regulatory bodies alike.

K24 Adaptation Challenges

The adaptation of the K24 engine to meet future urban transport needs presents several significant challenges. One of the primary obstacles is the need to balance performance improvements with increasingly stringent emissions regulations. As cities worldwide implement stricter environmental policies, the K24 engine must undergo substantial modifications to reduce its carbon footprint while maintaining or enhancing its power output.

Another critical challenge lies in optimizing fuel efficiency without compromising the engine's reliability. Urban environments often involve frequent stop-start driving conditions, which can be particularly taxing on engine components. Engineers must develop innovative solutions to improve the K24's fuel economy in these scenarios while ensuring long-term durability and minimizing maintenance requirements.

The integration of advanced technologies, such as hybrid systems or alternative fuel compatibility, poses additional complexities. Adapting the K24 engine to work seamlessly with electric motors or accommodate biofuels requires significant redesign of various engine components, including the fuel injection system, combustion chamber, and exhaust system. This integration must be achieved without substantially increasing the engine's overall size or weight, which is crucial for maintaining vehicle maneuverability in urban settings.

Thermal management represents another substantial challenge in K24 engine adaptation. Urban environments, characterized by slow-moving traffic and high ambient temperatures, demand efficient cooling systems to prevent overheating and maintain optimal performance. Engineers must develop innovative cooling solutions that are both effective and compact, given the limited space available in modern vehicle designs.

Cost considerations also play a crucial role in the adaptation process. While technological advancements are necessary, they must be implemented in a cost-effective manner to ensure the final product remains competitive in the market. This requires careful balancing of material choices, manufacturing processes, and design complexity to achieve the desired performance improvements without significantly increasing production costs.

Lastly, the adaptation of the K24 engine must address the growing demand for connectivity and smart features in urban vehicles. Integrating advanced engine management systems, real-time performance monitoring, and predictive maintenance capabilities presents both technical and software challenges. These systems must be seamlessly incorporated into the engine's architecture while ensuring cybersecurity and reliability in increasingly connected urban environments.

Another critical challenge lies in optimizing fuel efficiency without compromising the engine's reliability. Urban environments often involve frequent stop-start driving conditions, which can be particularly taxing on engine components. Engineers must develop innovative solutions to improve the K24's fuel economy in these scenarios while ensuring long-term durability and minimizing maintenance requirements.

The integration of advanced technologies, such as hybrid systems or alternative fuel compatibility, poses additional complexities. Adapting the K24 engine to work seamlessly with electric motors or accommodate biofuels requires significant redesign of various engine components, including the fuel injection system, combustion chamber, and exhaust system. This integration must be achieved without substantially increasing the engine's overall size or weight, which is crucial for maintaining vehicle maneuverability in urban settings.

Thermal management represents another substantial challenge in K24 engine adaptation. Urban environments, characterized by slow-moving traffic and high ambient temperatures, demand efficient cooling systems to prevent overheating and maintain optimal performance. Engineers must develop innovative cooling solutions that are both effective and compact, given the limited space available in modern vehicle designs.

Cost considerations also play a crucial role in the adaptation process. While technological advancements are necessary, they must be implemented in a cost-effective manner to ensure the final product remains competitive in the market. This requires careful balancing of material choices, manufacturing processes, and design complexity to achieve the desired performance improvements without significantly increasing production costs.

Lastly, the adaptation of the K24 engine must address the growing demand for connectivity and smart features in urban vehicles. Integrating advanced engine management systems, real-time performance monitoring, and predictive maintenance capabilities presents both technical and software challenges. These systems must be seamlessly incorporated into the engine's architecture while ensuring cybersecurity and reliability in increasingly connected urban environments.

Current K24 Solutions

01 Engine control and performance optimization

Adaptation of the K24 engine involves optimizing its control systems and performance parameters. This includes adjusting fuel injection, ignition timing, and valve timing to improve power output, fuel efficiency, and emissions. Advanced engine management systems can be implemented to fine-tune these parameters based on various operating conditions.- Engine control system adaptation: Adapting the engine control system for the K24 engine involves modifying the electronic control unit (ECU) to optimize performance, fuel efficiency, and emissions. This may include adjusting fuel injection timing, ignition timing, and valve timing to suit the specific characteristics of the K24 engine. Advanced control algorithms and sensor integration can be implemented to enhance overall engine performance and responsiveness.

- Turbocharging and forced induction: Adapting the K24 engine for turbocharging or other forced induction methods can significantly increase power output. This involves designing and integrating a turbocharger system, including intercoolers, wastegates, and boost control mechanisms. Modifications to the engine internals, such as strengthened pistons and connecting rods, may be necessary to handle the increased power and stress.

- Intake and exhaust system optimization: Optimizing the intake and exhaust systems for the K24 engine can improve airflow, resulting in increased power and efficiency. This may involve designing custom intake manifolds, high-flow air filters, and performance exhaust systems. Computer-aided flow analysis and dyno testing can be used to fine-tune these components for optimal performance across the engine's operating range.

- Cylinder head and valvetrain modifications: Adapting the K24 engine's cylinder head and valvetrain can unlock additional performance potential. This may include porting and polishing the cylinder head, installing larger valves, upgrading camshafts, and implementing variable valve timing systems. These modifications can improve volumetric efficiency and allow the engine to rev higher, resulting in increased power output.

- Engine management and tuning software: Developing specialized engine management and tuning software for the K24 engine adaptation is crucial for optimizing performance. This involves creating custom ECU maps, implementing advanced closed-loop control strategies, and providing user-friendly interfaces for fine-tuning engine parameters. The software may also include features such as data logging, real-time monitoring, and diagnostic capabilities to aid in the adaptation process.

02 Turbocharging and forced induction

Implementing turbocharging or other forced induction methods can significantly enhance the K24 engine's power output. This adaptation involves designing and integrating a turbocharger system, including intercoolers, wastegates, and boost control mechanisms. Proper tuning of the engine management system is crucial to accommodate the increased airflow and fuel requirements.Expand Specific Solutions03 Cylinder head and valve train modifications

Adapting the K24 engine may involve modifications to the cylinder head and valve train components. This can include porting and polishing the intake and exhaust ports, installing larger valves, upgrading camshafts, and implementing variable valve timing systems. These changes aim to improve airflow and combustion efficiency, resulting in increased power output and better overall engine performance.Expand Specific Solutions04 Intake and exhaust system upgrades

Enhancing the K24 engine's performance often involves upgrading the intake and exhaust systems. This can include installing a high-flow air intake, larger throttle body, and performance exhaust manifold and system. These modifications aim to reduce restrictions and improve airflow, allowing the engine to breathe more efficiently and produce more power.Expand Specific Solutions05 Engine block strengthening and internal components

For high-performance applications, adapting the K24 engine may require strengthening the engine block and upgrading internal components. This can involve installing forged pistons, stronger connecting rods, and a reinforced crankshaft. Additionally, improving the engine's oiling system and implementing better cooling solutions can enhance durability and reliability under increased stress.Expand Specific Solutions

Key Industry Players

The K24 Engine Adaptation for future urban transport needs is in a dynamic phase of development, with the market showing significant growth potential. The industry is transitioning from traditional combustion engines to more sustainable and efficient solutions. Key players like Volvo Construction Equipment, BMW, Toyota, and Mercedes-Benz are investing heavily in research and development, indicating a moderate level of technological maturity. Companies such as Chery Automobile, Geely, and Changan are also making strides in this field, particularly in the Chinese market. The involvement of academic institutions like Zhejiang University and Jilin University suggests ongoing collaborative efforts to advance the technology further.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced adaptation of the K24 engine to meet future urban transport needs. Their approach focuses on improving fuel efficiency and reducing emissions through a combination of technologies. The company has implemented a hybrid system that integrates the K24 engine with electric motors, allowing for optimal power distribution and energy recovery[1]. Additionally, Toyota has incorporated variable valve timing and lift (VVTL) technology to enhance engine performance across different driving conditions[2]. The K24 adaptation also features a redesigned combustion chamber and advanced fuel injection system, which work together to improve fuel atomization and combustion efficiency[3]. To address urban-specific challenges, Toyota has implemented a start-stop system and thermal management improvements to reduce idling fuel consumption and emissions in congested city environments[4].

Strengths: Toyota's extensive experience in hybrid technology integration and their proven track record in fuel-efficient engines. The adaptation leverages existing K24 architecture, potentially reducing development and manufacturing costs. Weaknesses: The complexity of the hybrid system may increase maintenance costs and potential points of failure in urban transport applications.

Renault SA

Technical Solution: Renault's approach to adapting the K24 engine for future urban transport needs focuses on electrification and modular design. The company has developed a plug-in hybrid variant of the K24 engine, which combines the reliability of the internal combustion engine with the benefits of electric propulsion[5]. Renault's adaptation includes a compact electric motor integrated into the transmission, allowing for pure electric driving in urban areas and seamless switching to hybrid mode for longer journeys[6]. The K24 engine itself has been optimized with low-friction components and an advanced thermal management system to improve efficiency when operating in hybrid mode[7]. Renault has also implemented a regenerative braking system that captures and stores energy typically lost during deceleration, further enhancing the overall efficiency of the powertrain in urban environments[8].

Strengths: The plug-in hybrid approach offers flexibility for various urban transport scenarios, potentially reducing emissions in city centers. The modular design allows for easy integration into different vehicle platforms. Weaknesses: The added complexity of the hybrid system may increase initial costs and require specialized maintenance.

K24 Innovations

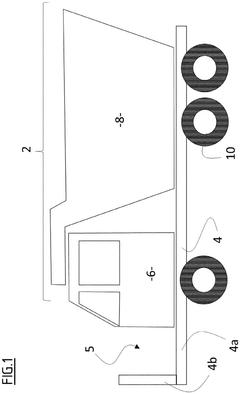

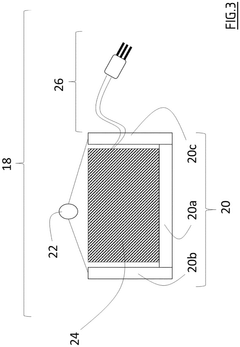

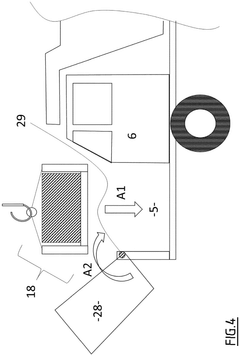

Heavy-duty vehicle compatible with different power generation technologies

PatentPendingEP4488109A1

Innovation

- A heavy-duty vehicle design featuring an electric drive train with an interface for fitting a power generation module, including electrical connectors and a controller that can adapt energy input from various power sources such as battery packs, fuel cell modules, and thermal generators, allowing for flexible switching between power generations based on availability and cost.

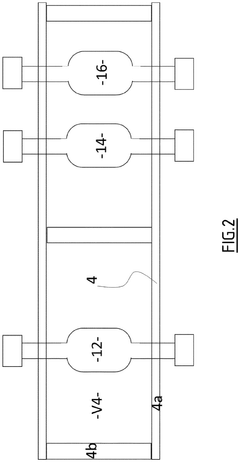

Convenient, modular urban and suburban transport vehicle

PatentInactiveEP1534581A2

Innovation

- A modular, clean transport vehicle system utilizing compressed air and thermal energy with a motor-compressor-alternator unit, capable of operating with multiple energy sources (compressed air, thermochemical, fossil fuel, and electrical energy) to provide efficient, zero-pollution urban transport, and adaptable passenger capacity through remotely controlled modules.

Emissions Regulations

Emissions regulations play a crucial role in shaping the development and adaptation of engines for urban transport. As cities worldwide grapple with air quality concerns and climate change, stringent emission standards have been implemented to reduce the environmental impact of vehicles.

In recent years, many countries have adopted increasingly strict emissions standards. The European Union's Euro 6 standards, implemented in 2014, set limits on nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate matter (PM) emissions. Similarly, the United States Environmental Protection Agency (EPA) has established Tier 3 standards, which aim to reduce sulfur content in gasoline and tighten vehicle emission limits.

These regulations have significantly influenced the design and performance requirements of engines, including the K24 engine. Manufacturers must now focus on developing technologies that not only improve fuel efficiency but also reduce harmful emissions. This has led to the widespread adoption of advanced emission control systems, such as catalytic converters, exhaust gas recirculation (EGR), and particulate filters.

The K24 engine, known for its reliability and performance, must undergo substantial modifications to meet these evolving standards. Engineers are exploring various strategies to enhance its emissions profile, including optimizing combustion processes, improving fuel injection systems, and integrating hybrid technologies.

Looking ahead, future emissions regulations are expected to become even more stringent. The European Union has proposed Euro 7 standards, which aim to further reduce NOx emissions and introduce limits on previously unregulated pollutants. In the United States, California's Advanced Clean Cars II regulation sets ambitious targets for zero-emission vehicle sales, indirectly impacting the development of internal combustion engines like the K24.

To meet these future challenges, the K24 engine adaptation process must consider long-term sustainability. This may involve exploring alternative fuels, such as hydrogen or synthetic fuels, which could potentially allow the engine to operate with significantly reduced emissions. Additionally, the integration of mild hybrid or full hybrid systems could help offset emissions during urban driving cycles, where traditional engines are least efficient.

As urban transport needs evolve, emissions regulations will continue to drive innovation in engine technology. The successful adaptation of the K24 engine will depend on its ability to meet these stringent standards while maintaining its performance characteristics and cost-effectiveness. This balancing act presents both challenges and opportunities for engineers and manufacturers in the automotive industry.

In recent years, many countries have adopted increasingly strict emissions standards. The European Union's Euro 6 standards, implemented in 2014, set limits on nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate matter (PM) emissions. Similarly, the United States Environmental Protection Agency (EPA) has established Tier 3 standards, which aim to reduce sulfur content in gasoline and tighten vehicle emission limits.

These regulations have significantly influenced the design and performance requirements of engines, including the K24 engine. Manufacturers must now focus on developing technologies that not only improve fuel efficiency but also reduce harmful emissions. This has led to the widespread adoption of advanced emission control systems, such as catalytic converters, exhaust gas recirculation (EGR), and particulate filters.

The K24 engine, known for its reliability and performance, must undergo substantial modifications to meet these evolving standards. Engineers are exploring various strategies to enhance its emissions profile, including optimizing combustion processes, improving fuel injection systems, and integrating hybrid technologies.

Looking ahead, future emissions regulations are expected to become even more stringent. The European Union has proposed Euro 7 standards, which aim to further reduce NOx emissions and introduce limits on previously unregulated pollutants. In the United States, California's Advanced Clean Cars II regulation sets ambitious targets for zero-emission vehicle sales, indirectly impacting the development of internal combustion engines like the K24.

To meet these future challenges, the K24 engine adaptation process must consider long-term sustainability. This may involve exploring alternative fuels, such as hydrogen or synthetic fuels, which could potentially allow the engine to operate with significantly reduced emissions. Additionally, the integration of mild hybrid or full hybrid systems could help offset emissions during urban driving cycles, where traditional engines are least efficient.

As urban transport needs evolve, emissions regulations will continue to drive innovation in engine technology. The successful adaptation of the K24 engine will depend on its ability to meet these stringent standards while maintaining its performance characteristics and cost-effectiveness. This balancing act presents both challenges and opportunities for engineers and manufacturers in the automotive industry.

K24 Cost-Benefit Analysis

The cost-benefit analysis of adapting the K24 engine to meet future urban transport needs reveals a complex interplay of economic, environmental, and social factors. Initial investment costs for engine modification and production line adjustments are substantial, potentially reaching millions of dollars. However, these upfront expenses are offset by long-term benefits in fuel efficiency, reduced emissions, and improved performance in urban environments.

Fuel efficiency improvements, estimated at 15-20% over current models, translate to significant cost savings for fleet operators and individual vehicle owners. Over a five-year period, the cumulative fuel savings could exceed the initial adaptation costs, particularly in high-mileage urban applications such as taxis and delivery vehicles.

Emissions reduction is another crucial benefit, with the adapted K24 engine projected to meet or exceed future urban emission standards. This compliance ensures continued market access in cities with stringent environmental regulations, avoiding potential fines or operational restrictions. The improved environmental performance also contributes to better air quality in urban areas, indirectly reducing healthcare costs associated with air pollution.

From a performance perspective, the adapted K24 engine offers enhanced low-speed torque and responsiveness, critical for stop-and-go urban traffic. This improvement in drivability can lead to increased customer satisfaction and potentially higher market share in the competitive urban vehicle segment.

Maintenance costs present a mixed picture. While some components may require more frequent servicing due to increased performance demands, the overall engine reliability is expected to improve. This could result in longer service intervals and reduced downtime, particularly beneficial for commercial fleet operators.

The adaptation process also drives innovation and skills development within the engineering teams, potentially leading to patentable technologies and a competitive edge in the market. This intellectual property could generate additional revenue streams through licensing or technology partnerships.

However, the analysis must consider potential risks. Market acceptance of the adapted engine is crucial for realizing the projected benefits. Consumer education and marketing efforts may be necessary to highlight the advantages of the new technology, adding to the overall cost.

In conclusion, while the initial adaptation costs are significant, the long-term benefits in fuel efficiency, emissions reduction, and market competitiveness present a compelling case for K24 engine adaptation. The positive cost-benefit ratio becomes more pronounced over time, especially as urban transport regulations tighten and fuel prices fluctuate. Strategic implementation and clear communication of benefits to stakeholders will be key to maximizing the return on this technological investment.

Fuel efficiency improvements, estimated at 15-20% over current models, translate to significant cost savings for fleet operators and individual vehicle owners. Over a five-year period, the cumulative fuel savings could exceed the initial adaptation costs, particularly in high-mileage urban applications such as taxis and delivery vehicles.

Emissions reduction is another crucial benefit, with the adapted K24 engine projected to meet or exceed future urban emission standards. This compliance ensures continued market access in cities with stringent environmental regulations, avoiding potential fines or operational restrictions. The improved environmental performance also contributes to better air quality in urban areas, indirectly reducing healthcare costs associated with air pollution.

From a performance perspective, the adapted K24 engine offers enhanced low-speed torque and responsiveness, critical for stop-and-go urban traffic. This improvement in drivability can lead to increased customer satisfaction and potentially higher market share in the competitive urban vehicle segment.

Maintenance costs present a mixed picture. While some components may require more frequent servicing due to increased performance demands, the overall engine reliability is expected to improve. This could result in longer service intervals and reduced downtime, particularly beneficial for commercial fleet operators.

The adaptation process also drives innovation and skills development within the engineering teams, potentially leading to patentable technologies and a competitive edge in the market. This intellectual property could generate additional revenue streams through licensing or technology partnerships.

However, the analysis must consider potential risks. Market acceptance of the adapted engine is crucial for realizing the projected benefits. Consumer education and marketing efforts may be necessary to highlight the advantages of the new technology, adding to the overall cost.

In conclusion, while the initial adaptation costs are significant, the long-term benefits in fuel efficiency, emissions reduction, and market competitiveness present a compelling case for K24 engine adaptation. The positive cost-benefit ratio becomes more pronounced over time, especially as urban transport regulations tighten and fuel prices fluctuate. Strategic implementation and clear communication of benefits to stakeholders will be key to maximizing the return on this technological investment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!