K24 Engine and Smart Diagnostics: A New Era in Monitoring

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Overview

The K24 engine represents a significant leap forward in automotive engineering, combining advanced combustion technology with state-of-the-art monitoring capabilities. Developed as a response to increasing demands for fuel efficiency and reduced emissions, the K24 engine incorporates a range of innovative features that set it apart from its predecessors.

At its core, the K24 is a 2.4-liter inline-four cylinder engine, designed to deliver optimal performance while maintaining excellent fuel economy. The engine utilizes a high-compression ratio and direct fuel injection system, allowing for precise control over the combustion process. This results in improved power output and reduced fuel consumption across a wide range of operating conditions.

One of the key innovations in the K24 engine is its variable valve timing and lift system. This technology allows for dynamic adjustment of valve operation based on engine speed and load, optimizing performance and efficiency throughout the entire power band. The system contributes significantly to the engine's ability to deliver strong low-end torque while maintaining high-rev capabilities.

The K24 engine also features an advanced thermal management system, which helps to reduce friction and improve overall efficiency. This system includes a variable-flow oil pump and an electric water pump, both of which can be precisely controlled to maintain optimal operating temperatures under various conditions.

Perhaps the most groundbreaking aspect of the K24 engine is its integration with smart diagnostics technology. This system employs a network of sensors throughout the engine, continuously monitoring various parameters such as temperature, pressure, and vibration. The data collected is processed in real-time by sophisticated algorithms, enabling predictive maintenance and early detection of potential issues.

The smart diagnostics system goes beyond traditional engine monitoring by utilizing machine learning algorithms to analyze patterns and predict potential failures before they occur. This proactive approach to maintenance can significantly reduce downtime and extend the overall lifespan of the engine.

Furthermore, the K24 engine's smart diagnostics capabilities extend to performance optimization. The system can adapt engine parameters in real-time based on driving conditions and user preferences, ensuring optimal performance and efficiency in various scenarios. This level of adaptability makes the K24 engine particularly well-suited for a wide range of applications, from everyday commuters to high-performance vehicles.

In summary, the K24 engine represents a new paradigm in engine design and monitoring. Its combination of advanced combustion technology and smart diagnostics capabilities positions it at the forefront of automotive innovation, promising improved performance, efficiency, and reliability for the next generation of vehicles.

At its core, the K24 is a 2.4-liter inline-four cylinder engine, designed to deliver optimal performance while maintaining excellent fuel economy. The engine utilizes a high-compression ratio and direct fuel injection system, allowing for precise control over the combustion process. This results in improved power output and reduced fuel consumption across a wide range of operating conditions.

One of the key innovations in the K24 engine is its variable valve timing and lift system. This technology allows for dynamic adjustment of valve operation based on engine speed and load, optimizing performance and efficiency throughout the entire power band. The system contributes significantly to the engine's ability to deliver strong low-end torque while maintaining high-rev capabilities.

The K24 engine also features an advanced thermal management system, which helps to reduce friction and improve overall efficiency. This system includes a variable-flow oil pump and an electric water pump, both of which can be precisely controlled to maintain optimal operating temperatures under various conditions.

Perhaps the most groundbreaking aspect of the K24 engine is its integration with smart diagnostics technology. This system employs a network of sensors throughout the engine, continuously monitoring various parameters such as temperature, pressure, and vibration. The data collected is processed in real-time by sophisticated algorithms, enabling predictive maintenance and early detection of potential issues.

The smart diagnostics system goes beyond traditional engine monitoring by utilizing machine learning algorithms to analyze patterns and predict potential failures before they occur. This proactive approach to maintenance can significantly reduce downtime and extend the overall lifespan of the engine.

Furthermore, the K24 engine's smart diagnostics capabilities extend to performance optimization. The system can adapt engine parameters in real-time based on driving conditions and user preferences, ensuring optimal performance and efficiency in various scenarios. This level of adaptability makes the K24 engine particularly well-suited for a wide range of applications, from everyday commuters to high-performance vehicles.

In summary, the K24 engine represents a new paradigm in engine design and monitoring. Its combination of advanced combustion technology and smart diagnostics capabilities positions it at the forefront of automotive innovation, promising improved performance, efficiency, and reliability for the next generation of vehicles.

Smart Diagnostics Market

The smart diagnostics market is experiencing rapid growth, driven by the increasing demand for advanced monitoring and predictive maintenance solutions across various industries. This market segment encompasses a wide range of technologies and applications, including real-time data analytics, machine learning algorithms, and Internet of Things (IoT) connectivity, all aimed at enhancing equipment performance, reducing downtime, and optimizing operational efficiency.

In the automotive sector, smart diagnostics systems like those integrated into the K24 Engine are revolutionizing vehicle maintenance and performance monitoring. These systems provide real-time insights into engine health, fuel efficiency, and potential issues, allowing for proactive maintenance and improved vehicle longevity. The adoption of such technologies is not limited to high-end vehicles but is increasingly becoming standard in mid-range and economy models as well.

Beyond automotive applications, smart diagnostics are gaining traction in industrial manufacturing, healthcare, aerospace, and energy sectors. In manufacturing, these systems are crucial for predictive maintenance of machinery, helping to prevent unexpected breakdowns and optimize production schedules. The healthcare industry is leveraging smart diagnostics for medical equipment monitoring, ensuring critical devices are always operational and reducing the risk of failures during patient care.

The market for smart diagnostics is characterized by a mix of established technology giants and innovative startups. Major players are investing heavily in research and development to enhance their offerings and maintain competitive edge. Collaborations between technology providers and industry-specific experts are becoming more common, leading to more tailored and effective diagnostic solutions.

One of the key drivers of market growth is the increasing awareness of the cost-saving potential of predictive maintenance. Companies across sectors are recognizing that smart diagnostics can significantly reduce maintenance costs, extend equipment lifespan, and minimize unplanned downtime. This realization is fueling investment in smart diagnostic technologies and driving market expansion.

The integration of artificial intelligence and machine learning algorithms is a notable trend in the smart diagnostics market. These technologies enable more accurate predictions, pattern recognition, and anomaly detection, enhancing the overall effectiveness of diagnostic systems. As AI capabilities continue to advance, the potential applications and sophistication of smart diagnostics are expected to grow exponentially.

In the automotive sector, smart diagnostics systems like those integrated into the K24 Engine are revolutionizing vehicle maintenance and performance monitoring. These systems provide real-time insights into engine health, fuel efficiency, and potential issues, allowing for proactive maintenance and improved vehicle longevity. The adoption of such technologies is not limited to high-end vehicles but is increasingly becoming standard in mid-range and economy models as well.

Beyond automotive applications, smart diagnostics are gaining traction in industrial manufacturing, healthcare, aerospace, and energy sectors. In manufacturing, these systems are crucial for predictive maintenance of machinery, helping to prevent unexpected breakdowns and optimize production schedules. The healthcare industry is leveraging smart diagnostics for medical equipment monitoring, ensuring critical devices are always operational and reducing the risk of failures during patient care.

The market for smart diagnostics is characterized by a mix of established technology giants and innovative startups. Major players are investing heavily in research and development to enhance their offerings and maintain competitive edge. Collaborations between technology providers and industry-specific experts are becoming more common, leading to more tailored and effective diagnostic solutions.

One of the key drivers of market growth is the increasing awareness of the cost-saving potential of predictive maintenance. Companies across sectors are recognizing that smart diagnostics can significantly reduce maintenance costs, extend equipment lifespan, and minimize unplanned downtime. This realization is fueling investment in smart diagnostic technologies and driving market expansion.

The integration of artificial intelligence and machine learning algorithms is a notable trend in the smart diagnostics market. These technologies enable more accurate predictions, pattern recognition, and anomaly detection, enhancing the overall effectiveness of diagnostic systems. As AI capabilities continue to advance, the potential applications and sophistication of smart diagnostics are expected to grow exponentially.

K24 Tech Challenges

The K24 engine, coupled with smart diagnostics, represents a significant leap in engine monitoring technology. However, this advanced system faces several technical challenges that need to be addressed for optimal performance and widespread adoption.

One of the primary challenges is the integration of multiple sensor systems within the engine environment. The K24 engine operates under extreme conditions, including high temperatures, vibrations, and varying pressures. Developing sensors that can withstand these harsh conditions while maintaining accuracy and reliability is a complex task. Moreover, ensuring seamless communication between these sensors and the central diagnostic system poses additional difficulties.

Data processing and analysis present another set of challenges. The smart diagnostics system generates vast amounts of real-time data from various engine components. Processing this data efficiently and extracting meaningful insights requires sophisticated algorithms and computing power. Balancing the need for comprehensive analysis with the constraints of onboard processing capabilities is a delicate task that engineers must navigate.

The implementation of predictive maintenance features, while promising, introduces its own set of challenges. Accurately predicting potential failures or maintenance needs requires not only extensive historical data but also complex machine learning models. These models must be continuously refined and updated to improve their accuracy, which demands significant computational resources and expertise.

Cybersecurity is an increasingly critical concern for smart diagnostic systems. As these systems become more connected and rely on data transmission, they become potential targets for cyber attacks. Ensuring the integrity and security of the diagnostic data, as well as protecting the system from unauthorized access or manipulation, is paramount.

Standardization and compatibility issues also pose challenges. As different manufacturers develop their own smart diagnostic systems, ensuring interoperability and establishing industry-wide standards becomes crucial. This is particularly important for maintenance and repair operations, where technicians may need to work with various systems across different vehicle models.

Power management is another technical hurdle. The smart diagnostic system requires a constant power supply to function effectively, which can put additional strain on the vehicle's electrical system. Optimizing power consumption while maintaining system performance is a delicate balance that engineers must strike.

Lastly, the challenge of user interface and data presentation cannot be overlooked. While the system collects and analyzes complex data, presenting this information in a clear, actionable format to drivers, mechanics, and fleet managers is crucial for the technology's practical application and acceptance.

One of the primary challenges is the integration of multiple sensor systems within the engine environment. The K24 engine operates under extreme conditions, including high temperatures, vibrations, and varying pressures. Developing sensors that can withstand these harsh conditions while maintaining accuracy and reliability is a complex task. Moreover, ensuring seamless communication between these sensors and the central diagnostic system poses additional difficulties.

Data processing and analysis present another set of challenges. The smart diagnostics system generates vast amounts of real-time data from various engine components. Processing this data efficiently and extracting meaningful insights requires sophisticated algorithms and computing power. Balancing the need for comprehensive analysis with the constraints of onboard processing capabilities is a delicate task that engineers must navigate.

The implementation of predictive maintenance features, while promising, introduces its own set of challenges. Accurately predicting potential failures or maintenance needs requires not only extensive historical data but also complex machine learning models. These models must be continuously refined and updated to improve their accuracy, which demands significant computational resources and expertise.

Cybersecurity is an increasingly critical concern for smart diagnostic systems. As these systems become more connected and rely on data transmission, they become potential targets for cyber attacks. Ensuring the integrity and security of the diagnostic data, as well as protecting the system from unauthorized access or manipulation, is paramount.

Standardization and compatibility issues also pose challenges. As different manufacturers develop their own smart diagnostic systems, ensuring interoperability and establishing industry-wide standards becomes crucial. This is particularly important for maintenance and repair operations, where technicians may need to work with various systems across different vehicle models.

Power management is another technical hurdle. The smart diagnostic system requires a constant power supply to function effectively, which can put additional strain on the vehicle's electrical system. Optimizing power consumption while maintaining system performance is a delicate balance that engineers must strike.

Lastly, the challenge of user interface and data presentation cannot be overlooked. While the system collects and analyzes complex data, presenting this information in a clear, actionable format to drivers, mechanics, and fleet managers is crucial for the technology's practical application and acceptance.

K24 Diagnostic Solutions

01 Smart diagnostics monitoring for K24 engine

Advanced diagnostic systems are implemented to monitor the performance and health of K24 engines in real-time. These systems utilize various sensors and data analysis techniques to detect potential issues, optimize engine performance, and predict maintenance needs. The smart diagnostics can provide early warnings for engine problems, reducing downtime and improving overall efficiency.- Smart diagnostics monitoring for K24 engine: Advanced diagnostic systems are implemented to monitor the performance and health of K24 engines in real-time. These systems utilize various sensors and data analysis techniques to detect potential issues, optimize engine performance, and predict maintenance needs. The smart diagnostics can provide early warnings for engine problems, reducing downtime and improving overall efficiency.

- Engine control unit (ECU) integration for K24: The K24 engine is integrated with a sophisticated Engine Control Unit (ECU) that manages various engine functions and communicates with the smart diagnostics system. This integration allows for precise control of engine parameters, fuel injection, and ignition timing based on real-time data. The ECU also plays a crucial role in interpreting diagnostic information and adjusting engine performance accordingly.

- Wireless connectivity and remote monitoring: K24 engines equipped with smart diagnostics systems feature wireless connectivity capabilities, enabling remote monitoring and data transmission. This allows for real-time tracking of engine performance, remote diagnostics, and over-the-air updates. The wireless connectivity also facilitates integration with mobile devices and cloud-based platforms for enhanced monitoring and analysis.

- Predictive maintenance algorithms for K24: Advanced algorithms are developed to analyze data from the K24 engine's smart diagnostics system, enabling predictive maintenance capabilities. These algorithms use machine learning and historical data to forecast potential failures, recommend maintenance schedules, and optimize engine performance. This proactive approach helps reduce unexpected breakdowns and extends the engine's lifespan.

- User interface and reporting for K24 diagnostics: Smart diagnostics systems for K24 engines incorporate user-friendly interfaces and comprehensive reporting features. These interfaces provide easy access to real-time engine data, diagnostic results, and maintenance recommendations. The reporting system generates detailed analytics, performance trends, and alerts, enabling operators and technicians to make informed decisions about engine management and maintenance.

02 Integration of K24 engine with vehicle control systems

The K24 engine is integrated with advanced vehicle control systems to enhance overall performance and efficiency. This integration allows for better coordination between engine management, transmission control, and other vehicle systems. The combined approach enables improved fuel economy, reduced emissions, and enhanced driving experience through intelligent power distribution and adaptive control strategies.Expand Specific Solutions03 Remote monitoring and diagnostics for K24 engines

Remote monitoring capabilities are implemented for K24 engines, allowing for off-site diagnostics and performance analysis. This feature enables real-time data transmission to service centers or fleet management systems, facilitating proactive maintenance, remote troubleshooting, and over-the-air updates. The remote monitoring system can also provide valuable insights for engine optimization and performance tracking.Expand Specific Solutions04 Machine learning algorithms for K24 engine diagnostics

Advanced machine learning algorithms are employed to enhance the diagnostic capabilities of K24 engines. These algorithms analyze vast amounts of sensor data to identify patterns, predict potential failures, and optimize engine performance. The use of artificial intelligence in engine diagnostics allows for more accurate fault detection, personalized maintenance schedules, and continuous improvement of engine efficiency.Expand Specific Solutions05 User interface for K24 engine diagnostics and monitoring

Intuitive user interfaces are developed to present K24 engine diagnostic information and monitoring data to drivers, mechanics, and fleet managers. These interfaces provide easy-to-understand visualizations of engine performance, maintenance alerts, and diagnostic reports. The user-friendly design allows for quick interpretation of complex engine data, enabling timely decision-making and efficient maintenance planning.Expand Specific Solutions

Key Industry Players

The K24 Engine and Smart Diagnostics market is in a growth phase, driven by increasing demand for advanced monitoring solutions in various industries. The market size is expanding rapidly, with significant potential for further growth. Technologically, the field is evolving quickly, with companies like Robert Bosch GmbH, Siemens Corp., and Honeywell International Technologies Ltd. leading innovation. These industry giants, along with specialized firms such as Rockwell Automation Technologies, Inc. and Nidec Motor Corp., are pushing the boundaries of smart diagnostics capabilities. The technology's maturity varies across applications, with some sectors seeing more advanced implementations than others. Academic institutions like South China University of Technology and Zhejiang University are contributing to research and development, further accelerating technological progress in this domain.

Robert Bosch GmbH

Technical Solution: Bosch's K24 Engine and Smart Diagnostics solution integrates advanced sensors and AI-driven analytics for real-time engine monitoring. The system utilizes a network of high-precision sensors to collect data on various engine parameters, including temperature, pressure, and vibration. This data is then processed using machine learning algorithms to detect anomalies and predict potential failures before they occur[1]. The solution also incorporates edge computing capabilities, allowing for rapid on-site data processing and reducing latency in diagnostic feedback[3]. Bosch's system is designed to be scalable and adaptable to different engine types, making it suitable for a wide range of applications from automotive to industrial machinery[5].

Strengths: Comprehensive sensor integration, advanced AI analytics, and edge computing capabilities. Weaknesses: May require significant initial investment and potential complexity in implementation for older engine systems.

Perkins Engines Co. Ltd.

Technical Solution: Perkins' approach to K24 Engine and Smart Diagnostics focuses on a holistic engine health management system. Their solution combines traditional engine sensors with IoT connectivity and cloud-based analytics. The system continuously monitors engine performance metrics, fuel efficiency, and emissions data. Perkins utilizes proprietary algorithms to analyze this data, providing predictive maintenance recommendations and optimizing engine performance in real-time[2]. A key feature of their system is the ability to perform remote diagnostics, allowing technicians to troubleshoot issues without physical access to the engine[4]. Perkins also emphasizes user-friendly interfaces, offering mobile apps and web portals for easy access to diagnostic information and maintenance schedules[6].

Strengths: Comprehensive engine health management, remote diagnostic capabilities, and user-friendly interfaces. Weaknesses: Potential dependency on cloud connectivity for full functionality and data security concerns.

Core K24 Innovations

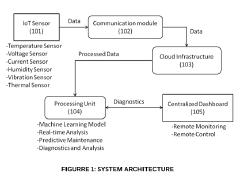

Smart diagnostics for intelligent electrical equipment monitoring

PatentPendingIN202411023672A

Innovation

- A smart diagnostics system integrating IoT sensors, a communication module, cloud infrastructure, and machine learning models for real-time data capture, analysis, and predictive maintenance, enabling remote monitoring and management through a centralized dashboard.

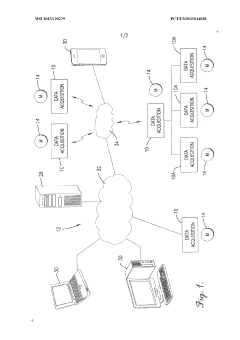

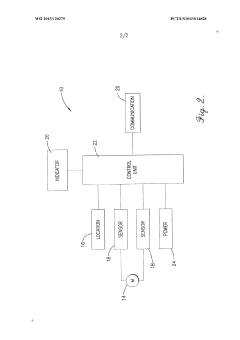

Systems, devices, and methods for motor monitoring

PatentWO2015120279A1

Innovation

- A data acquisition device that can be coupled with electric motors to automatically monitor their operation, transmit sensor data and location information to a remote monitoring device, providing alerts for necessary repairs or replacements without the need for integral motor controllers or dedicated central control stations.

Regulatory Compliance

The regulatory landscape surrounding engine monitoring and diagnostics systems is rapidly evolving to keep pace with technological advancements. For the K24 Engine and Smart Diagnostics system, compliance with various regulations is crucial for market acceptance and legal operation. Key regulatory bodies, such as the Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA) in the United States, play significant roles in shaping the compliance requirements.

Emissions regulations are a primary concern for engine monitoring systems. The K24 Engine and Smart Diagnostics must adhere to stringent emission standards, including those set by the EPA's Tier 4 regulations for off-road diesel engines and the Euro VI standards in Europe. These regulations mandate specific limits on pollutants such as nitrogen oxides (NOx), particulate matter (PM), and carbon monoxide (CO). The smart diagnostics system must accurately monitor and report these emissions in real-time to ensure ongoing compliance.

Safety regulations also impact the development and implementation of smart diagnostics systems. The NHTSA's Federal Motor Vehicle Safety Standards (FMVSS) include requirements for engine control systems and diagnostic capabilities. The K24 Engine and Smart Diagnostics system must comply with these standards to ensure safe operation and timely detection of potential safety issues.

Data privacy and cybersecurity regulations are increasingly relevant to smart diagnostics systems. As these systems collect and transmit sensitive data about engine performance and vehicle operation, they must comply with data protection laws such as the General Data Protection Regulation (GDPR) in Europe and the California Consumer Privacy Act (CCPA) in the United States. Ensuring secure data transmission, storage, and access control is essential for regulatory compliance.

The automotive industry's shift towards connected and autonomous vehicles has led to new regulations addressing vehicle-to-vehicle (V2V) and vehicle-to-infrastructure (V2I) communications. The K24 Engine and Smart Diagnostics system may need to comply with standards such as the IEEE 802.11p for wireless access in vehicular environments (WAVE) to ensure interoperability and safety in connected vehicle ecosystems.

Regulatory compliance also extends to the manufacturing and quality control processes. Standards such as ISO 9001 for quality management systems and ISO 26262 for functional safety of automotive electronic systems are crucial for ensuring the reliability and safety of the K24 Engine and Smart Diagnostics system throughout its lifecycle.

As regulations continue to evolve, manufacturers must maintain flexibility in their smart diagnostics systems to accommodate future changes. This may involve designing systems with updateable firmware and software to adapt to new regulatory requirements without necessitating complete hardware overhauls. Staying abreast of regulatory developments and actively participating in industry standards committees can help manufacturers anticipate and prepare for upcoming compliance challenges in the rapidly advancing field of engine monitoring and smart diagnostics.

Emissions regulations are a primary concern for engine monitoring systems. The K24 Engine and Smart Diagnostics must adhere to stringent emission standards, including those set by the EPA's Tier 4 regulations for off-road diesel engines and the Euro VI standards in Europe. These regulations mandate specific limits on pollutants such as nitrogen oxides (NOx), particulate matter (PM), and carbon monoxide (CO). The smart diagnostics system must accurately monitor and report these emissions in real-time to ensure ongoing compliance.

Safety regulations also impact the development and implementation of smart diagnostics systems. The NHTSA's Federal Motor Vehicle Safety Standards (FMVSS) include requirements for engine control systems and diagnostic capabilities. The K24 Engine and Smart Diagnostics system must comply with these standards to ensure safe operation and timely detection of potential safety issues.

Data privacy and cybersecurity regulations are increasingly relevant to smart diagnostics systems. As these systems collect and transmit sensitive data about engine performance and vehicle operation, they must comply with data protection laws such as the General Data Protection Regulation (GDPR) in Europe and the California Consumer Privacy Act (CCPA) in the United States. Ensuring secure data transmission, storage, and access control is essential for regulatory compliance.

The automotive industry's shift towards connected and autonomous vehicles has led to new regulations addressing vehicle-to-vehicle (V2V) and vehicle-to-infrastructure (V2I) communications. The K24 Engine and Smart Diagnostics system may need to comply with standards such as the IEEE 802.11p for wireless access in vehicular environments (WAVE) to ensure interoperability and safety in connected vehicle ecosystems.

Regulatory compliance also extends to the manufacturing and quality control processes. Standards such as ISO 9001 for quality management systems and ISO 26262 for functional safety of automotive electronic systems are crucial for ensuring the reliability and safety of the K24 Engine and Smart Diagnostics system throughout its lifecycle.

As regulations continue to evolve, manufacturers must maintain flexibility in their smart diagnostics systems to accommodate future changes. This may involve designing systems with updateable firmware and software to adapt to new regulatory requirements without necessitating complete hardware overhauls. Staying abreast of regulatory developments and actively participating in industry standards committees can help manufacturers anticipate and prepare for upcoming compliance challenges in the rapidly advancing field of engine monitoring and smart diagnostics.

Environmental Impact

The K24 Engine and Smart Diagnostics system represents a significant leap forward in engine monitoring technology, with potential for substantial environmental benefits. This advanced system enables real-time monitoring and analysis of engine performance, allowing for more efficient operation and reduced emissions. By providing continuous data on engine parameters, it facilitates proactive maintenance and optimization, leading to improved fuel efficiency and reduced waste.

One of the primary environmental impacts of this technology is the potential for significant reductions in greenhouse gas emissions. Through precise monitoring and adjustment of engine performance, the K24 system can help optimize fuel consumption, resulting in lower carbon dioxide emissions. This is particularly important in industries such as transportation and manufacturing, where even small improvements in efficiency can lead to substantial reductions in overall emissions.

The smart diagnostics component of the K24 system also contributes to environmental sustainability by extending engine life and reducing the need for premature replacements. By identifying potential issues before they become critical, the system allows for timely maintenance and repairs, preventing catastrophic failures that could result in environmental damage. This proactive approach not only reduces the environmental impact associated with manufacturing new engines but also minimizes the waste generated from discarded engine components.

Furthermore, the K24 Engine and Smart Diagnostics system can play a crucial role in reducing other harmful emissions, such as nitrogen oxides and particulate matter. By continuously monitoring and adjusting engine parameters, the system can ensure that engines operate within optimal ranges, minimizing the production of these pollutants. This is particularly beneficial in urban areas, where air quality is a significant concern and stricter emissions regulations are being implemented.

The technology also has the potential to contribute to the development of more environmentally friendly engine designs. The wealth of data collected by the K24 system can inform future engine development, leading to innovations that further reduce environmental impact. This could include advancements in combustion efficiency, materials science, and alternative fuel technologies.

In the context of the circular economy, the K24 Engine and Smart Diagnostics system aligns well with principles of resource efficiency and waste reduction. By extending engine life and optimizing performance, it reduces the demand for raw materials and energy associated with new engine production. Additionally, the system's ability to predict maintenance needs can lead to more efficient use of spare parts and reduce overall waste in the engine lifecycle.

One of the primary environmental impacts of this technology is the potential for significant reductions in greenhouse gas emissions. Through precise monitoring and adjustment of engine performance, the K24 system can help optimize fuel consumption, resulting in lower carbon dioxide emissions. This is particularly important in industries such as transportation and manufacturing, where even small improvements in efficiency can lead to substantial reductions in overall emissions.

The smart diagnostics component of the K24 system also contributes to environmental sustainability by extending engine life and reducing the need for premature replacements. By identifying potential issues before they become critical, the system allows for timely maintenance and repairs, preventing catastrophic failures that could result in environmental damage. This proactive approach not only reduces the environmental impact associated with manufacturing new engines but also minimizes the waste generated from discarded engine components.

Furthermore, the K24 Engine and Smart Diagnostics system can play a crucial role in reducing other harmful emissions, such as nitrogen oxides and particulate matter. By continuously monitoring and adjusting engine parameters, the system can ensure that engines operate within optimal ranges, minimizing the production of these pollutants. This is particularly beneficial in urban areas, where air quality is a significant concern and stricter emissions regulations are being implemented.

The technology also has the potential to contribute to the development of more environmentally friendly engine designs. The wealth of data collected by the K24 system can inform future engine development, leading to innovations that further reduce environmental impact. This could include advancements in combustion efficiency, materials science, and alternative fuel technologies.

In the context of the circular economy, the K24 Engine and Smart Diagnostics system aligns well with principles of resource efficiency and waste reduction. By extending engine life and optimizing performance, it reduces the demand for raw materials and energy associated with new engine production. Additionally, the system's ability to predict maintenance needs can lead to more efficient use of spare parts and reduce overall waste in the engine lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!