How to Innovate K24 Engine Control for Ultimate Driving Experience?

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Control Evolution and Objectives

The K24 engine, a marvel of Honda's engineering prowess, has undergone significant evolution since its inception in 2001. Initially designed for the Honda Accord, this 2.4-liter inline-four engine has become a cornerstone of Honda's powertrain lineup, finding its way into various models across the Honda and Acura brands. The engine's development has been driven by the continuous pursuit of improved performance, fuel efficiency, and reduced emissions.

Over the years, the K24 engine has seen several iterations, each bringing notable advancements in engine control technology. The early versions featured relatively simple engine management systems, focusing primarily on basic fuel injection and ignition timing control. As emissions regulations tightened and consumer demands for better fuel economy increased, Honda engineers implemented more sophisticated control strategies.

The introduction of i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) marked a significant milestone in K24 engine control. This system allowed for dynamic adjustment of valve timing and lift, optimizing engine performance across a wide range of operating conditions. Subsequent iterations saw the integration of drive-by-wire throttle systems, which provided more precise control over engine output and enabled the implementation of advanced traction and stability control features.

Recent developments in K24 engine control have focused on enhancing the driving experience while meeting increasingly stringent emissions standards. This has led to the adoption of direct injection technology in some variants, allowing for more precise fuel metering and improved combustion efficiency. Additionally, the integration of advanced sensors and real-time data processing has enabled more responsive and adaptive engine management strategies.

The current objectives for K24 engine control innovation are multifaceted, aiming to deliver an ultimate driving experience while addressing contemporary challenges. Key goals include further improving fuel efficiency without compromising performance, reducing emissions to meet future regulatory requirements, and enhancing overall drivability and responsiveness.

One of the primary objectives is to develop more intelligent and predictive engine control algorithms. These systems would anticipate driver intentions and road conditions, adjusting engine parameters in real-time to optimize performance and efficiency. Another focus area is the seamless integration of hybrid technologies, allowing for smooth transitions between combustion and electric power sources in hybrid variants of vehicles equipped with K24 engines.

Furthermore, there is a push towards more personalized driving experiences. This involves developing adaptive engine control systems that can learn and adjust to individual driving styles, providing a tailored performance profile for each driver. Concurrently, efforts are being made to improve engine sound management, enhancing the auditory feedback to the driver for a more engaging driving experience.

As we look to the future, the evolution of K24 engine control will likely involve increased connectivity and integration with vehicle systems. This could include leveraging data from navigation systems, traffic information, and even other vehicles to optimize engine performance and efficiency in various driving scenarios.

Over the years, the K24 engine has seen several iterations, each bringing notable advancements in engine control technology. The early versions featured relatively simple engine management systems, focusing primarily on basic fuel injection and ignition timing control. As emissions regulations tightened and consumer demands for better fuel economy increased, Honda engineers implemented more sophisticated control strategies.

The introduction of i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) marked a significant milestone in K24 engine control. This system allowed for dynamic adjustment of valve timing and lift, optimizing engine performance across a wide range of operating conditions. Subsequent iterations saw the integration of drive-by-wire throttle systems, which provided more precise control over engine output and enabled the implementation of advanced traction and stability control features.

Recent developments in K24 engine control have focused on enhancing the driving experience while meeting increasingly stringent emissions standards. This has led to the adoption of direct injection technology in some variants, allowing for more precise fuel metering and improved combustion efficiency. Additionally, the integration of advanced sensors and real-time data processing has enabled more responsive and adaptive engine management strategies.

The current objectives for K24 engine control innovation are multifaceted, aiming to deliver an ultimate driving experience while addressing contemporary challenges. Key goals include further improving fuel efficiency without compromising performance, reducing emissions to meet future regulatory requirements, and enhancing overall drivability and responsiveness.

One of the primary objectives is to develop more intelligent and predictive engine control algorithms. These systems would anticipate driver intentions and road conditions, adjusting engine parameters in real-time to optimize performance and efficiency. Another focus area is the seamless integration of hybrid technologies, allowing for smooth transitions between combustion and electric power sources in hybrid variants of vehicles equipped with K24 engines.

Furthermore, there is a push towards more personalized driving experiences. This involves developing adaptive engine control systems that can learn and adjust to individual driving styles, providing a tailored performance profile for each driver. Concurrently, efforts are being made to improve engine sound management, enhancing the auditory feedback to the driver for a more engaging driving experience.

As we look to the future, the evolution of K24 engine control will likely involve increased connectivity and integration with vehicle systems. This could include leveraging data from navigation systems, traffic information, and even other vehicles to optimize engine performance and efficiency in various driving scenarios.

Market Analysis for Advanced Engine Control Systems

The market for advanced engine control systems is experiencing significant growth, driven by the increasing demand for improved fuel efficiency, reduced emissions, and enhanced vehicle performance. As automotive manufacturers strive to meet stringent environmental regulations and consumer expectations for a superior driving experience, the K24 engine control innovation presents a compelling opportunity.

The global market for engine management systems is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) exceeding industry averages. This growth is primarily attributed to the rising adoption of electronic control units (ECUs) in modern vehicles, which play a crucial role in optimizing engine performance and fuel consumption.

In the context of K24 engine control innovation, there is a notable shift towards more sophisticated control algorithms and sensor technologies. These advancements enable real-time monitoring and adjustment of engine parameters, resulting in improved power delivery, responsiveness, and overall driving dynamics. The market demand for such innovations is particularly strong in the performance and luxury vehicle segments, where discerning customers prioritize an exceptional driving experience.

The automotive industry's transition towards electrification and hybridization has also created new opportunities for advanced engine control systems. As manufacturers develop hybrid powertrains that combine internal combustion engines with electric motors, the need for intelligent control systems that can seamlessly integrate these diverse power sources becomes paramount. This trend is expected to further drive the market for innovative engine control solutions.

Geographically, mature automotive markets such as North America, Europe, and Japan are at the forefront of adopting advanced engine control technologies. However, emerging markets in Asia-Pacific and Latin America are showing rapid growth potential as vehicle ownership rates increase and environmental regulations become more stringent.

Key market players in the engine control systems sector include established automotive suppliers and technology companies. These firms are investing heavily in research and development to create cutting-edge solutions that can deliver the ultimate driving experience while meeting regulatory requirements. Collaborations between automakers and technology providers are becoming increasingly common, fostering innovation and accelerating time-to-market for new engine control technologies.

Consumer preferences are evolving, with a growing emphasis on personalized driving experiences and connected vehicle features. This shift is creating demand for engine control systems that can adapt to individual driving styles and preferences, as well as integrate with broader vehicle connectivity and infotainment systems. The ability to offer customizable performance profiles and real-time feedback to drivers is becoming a key differentiator in the market.

The global market for engine management systems is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) exceeding industry averages. This growth is primarily attributed to the rising adoption of electronic control units (ECUs) in modern vehicles, which play a crucial role in optimizing engine performance and fuel consumption.

In the context of K24 engine control innovation, there is a notable shift towards more sophisticated control algorithms and sensor technologies. These advancements enable real-time monitoring and adjustment of engine parameters, resulting in improved power delivery, responsiveness, and overall driving dynamics. The market demand for such innovations is particularly strong in the performance and luxury vehicle segments, where discerning customers prioritize an exceptional driving experience.

The automotive industry's transition towards electrification and hybridization has also created new opportunities for advanced engine control systems. As manufacturers develop hybrid powertrains that combine internal combustion engines with electric motors, the need for intelligent control systems that can seamlessly integrate these diverse power sources becomes paramount. This trend is expected to further drive the market for innovative engine control solutions.

Geographically, mature automotive markets such as North America, Europe, and Japan are at the forefront of adopting advanced engine control technologies. However, emerging markets in Asia-Pacific and Latin America are showing rapid growth potential as vehicle ownership rates increase and environmental regulations become more stringent.

Key market players in the engine control systems sector include established automotive suppliers and technology companies. These firms are investing heavily in research and development to create cutting-edge solutions that can deliver the ultimate driving experience while meeting regulatory requirements. Collaborations between automakers and technology providers are becoming increasingly common, fostering innovation and accelerating time-to-market for new engine control technologies.

Consumer preferences are evolving, with a growing emphasis on personalized driving experiences and connected vehicle features. This shift is creating demand for engine control systems that can adapt to individual driving styles and preferences, as well as integrate with broader vehicle connectivity and infotainment systems. The ability to offer customizable performance profiles and real-time feedback to drivers is becoming a key differentiator in the market.

K24 Engine Control Challenges and Limitations

The K24 engine, renowned for its reliability and performance, faces several challenges and limitations in its control systems when aiming for the ultimate driving experience. One of the primary challenges is the engine's relatively high displacement, which can lead to increased fuel consumption and emissions. This necessitates more sophisticated control strategies to optimize efficiency without compromising performance.

Another significant limitation is the engine's naturally aspirated design. While this contributes to its reliability, it also limits the potential for power gains through traditional means. The absence of forced induction requires more intricate control mechanisms to extract maximum performance, particularly in terms of throttle response and power delivery across the rev range.

The K24's variable valve timing system, while advanced for its time, presents challenges in achieving seamless transitions between different operating modes. Fine-tuning the control algorithms to provide smooth power delivery while maximizing efficiency remains a complex task, especially when considering diverse driving conditions and user preferences.

Thermal management is another critical area where the K24 engine control faces limitations. As performance demands increase, managing heat becomes more challenging, requiring advanced cooling strategies and temperature-sensitive control adjustments to maintain optimal operating conditions and prevent performance degradation.

The engine's electronic throttle control system, while offering precise throttle modulation, can sometimes feel less responsive compared to mechanical systems. Overcoming this perceived lag while maintaining the benefits of electronic control is a significant challenge in enhancing the driving experience.

Emissions regulations pose an ongoing challenge for K24 engine control. As standards become more stringent, balancing performance with compliance requires increasingly sophisticated control strategies, potentially limiting the engine's output in certain conditions.

Integrating modern features such as cylinder deactivation or advanced start-stop systems presents both opportunities and challenges. While these technologies can improve efficiency, they require complex control algorithms to ensure seamless operation without compromising the driving experience.

Lastly, the K24's age means it lacks some of the more advanced sensors and actuators found in newer engines. This limitation in data acquisition and precise control can hinder the implementation of cutting-edge control strategies, necessitating innovative approaches to maximize the existing hardware's potential.

Another significant limitation is the engine's naturally aspirated design. While this contributes to its reliability, it also limits the potential for power gains through traditional means. The absence of forced induction requires more intricate control mechanisms to extract maximum performance, particularly in terms of throttle response and power delivery across the rev range.

The K24's variable valve timing system, while advanced for its time, presents challenges in achieving seamless transitions between different operating modes. Fine-tuning the control algorithms to provide smooth power delivery while maximizing efficiency remains a complex task, especially when considering diverse driving conditions and user preferences.

Thermal management is another critical area where the K24 engine control faces limitations. As performance demands increase, managing heat becomes more challenging, requiring advanced cooling strategies and temperature-sensitive control adjustments to maintain optimal operating conditions and prevent performance degradation.

The engine's electronic throttle control system, while offering precise throttle modulation, can sometimes feel less responsive compared to mechanical systems. Overcoming this perceived lag while maintaining the benefits of electronic control is a significant challenge in enhancing the driving experience.

Emissions regulations pose an ongoing challenge for K24 engine control. As standards become more stringent, balancing performance with compliance requires increasingly sophisticated control strategies, potentially limiting the engine's output in certain conditions.

Integrating modern features such as cylinder deactivation or advanced start-stop systems presents both opportunities and challenges. While these technologies can improve efficiency, they require complex control algorithms to ensure seamless operation without compromising the driving experience.

Lastly, the K24's age means it lacks some of the more advanced sensors and actuators found in newer engines. This limitation in data acquisition and precise control can hinder the implementation of cutting-edge control strategies, necessitating innovative approaches to maximize the existing hardware's potential.

Current K24 Engine Control Solutions

01 Engine control system optimization

Advanced control systems are implemented to optimize the K24 engine's performance, fuel efficiency, and emissions. These systems utilize various sensors and algorithms to adjust engine parameters in real-time, enhancing the overall driving experience. The control systems may include features such as adaptive fuel injection, variable valve timing, and electronic throttle control.- Engine control system optimization: Advanced control systems are implemented to optimize the K24 engine's performance, fuel efficiency, and emissions. These systems utilize various sensors and actuators to monitor and adjust engine parameters in real-time, enhancing the overall driving experience.

- Driving mode selection and customization: The K24 engine control system incorporates multiple driving modes, allowing drivers to select and customize their preferred driving experience. These modes may include eco, sport, and comfort settings, each adjusting engine response and performance characteristics accordingly.

- Adaptive transmission control: Integration of adaptive transmission control algorithms with the K24 engine management system enables smoother gear shifts and improved power delivery. This feature enhances the overall driving experience by optimizing gear selection based on driving conditions and driver input.

- Real-time performance monitoring and feedback: The K24 engine control system incorporates real-time performance monitoring and feedback mechanisms. This feature provides drivers with instant information on engine status, fuel consumption, and driving efficiency, allowing for adjustments to improve the overall driving experience.

- Integration with vehicle dynamics control: The K24 engine control system is integrated with vehicle dynamics control systems, such as traction control and stability control. This integration ensures a more responsive and stable driving experience, particularly during cornering, acceleration, and varying road conditions.

02 Driving mode selection and customization

The K24 engine control system incorporates multiple driving modes, allowing drivers to select their preferred performance characteristics. These modes may include eco, normal, sport, and custom settings, each adjusting various engine parameters to suit different driving conditions and preferences. The system may also learn from driver behavior to further personalize the driving experience.Expand Specific Solutions03 Integration with vehicle dynamics control

The K24 engine control system is integrated with the vehicle's dynamics control systems, such as traction control, stability control, and adaptive suspension. This integration allows for a more cohesive and responsive driving experience, as the engine's output is coordinated with other vehicle systems to enhance handling, safety, and comfort.Expand Specific Solutions04 Advanced driver assistance features

The engine control system incorporates advanced driver assistance features to enhance the driving experience. These may include adaptive cruise control, automatic emergency braking, and lane-keeping assist. The engine control system works in conjunction with these features to provide smooth and seamless operation, improving both safety and comfort for the driver.Expand Specific Solutions05 Real-time performance monitoring and feedback

The K24 engine control system includes real-time performance monitoring and feedback mechanisms. This feature provides drivers with instant information about engine performance, fuel efficiency, and driving behavior. The system may offer suggestions for improving driving techniques or alert the driver to potential issues, contributing to a more engaging and informed driving experience.Expand Specific Solutions

Key Players in Engine Control System Industry

The K24 engine control innovation landscape is characterized by intense competition among established automotive giants and emerging players. The market is in a growth phase, driven by increasing demand for enhanced driving experiences and fuel efficiency. The global automotive engine control unit market size is projected to reach $45 billion by 2025, with a CAGR of 6.5%. Technologically, major players like GM, Honda, Toyota, and Ford are at the forefront, leveraging their extensive R&D capabilities. Chinese manufacturers such as Changan, GAC, and BYD are rapidly catching up, investing heavily in advanced engine control systems. The technology maturity varies, with traditional automakers having a slight edge, but innovative startups and tech companies are disrupting the space with novel approaches to engine control optimization.

Honda Motor Co., Ltd.

Technical Solution: Honda's innovative approach to K24 engine control focuses on adaptive valve timing and direct injection technology. The company has developed an advanced i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) system specifically for the K24 engine, which optimizes valve timing and lift across a wide range of engine speeds[1]. This system is coupled with a high-precision direct injection system that enhances fuel atomization and combustion efficiency. Honda has also implemented a sophisticated engine control unit (ECU) that utilizes real-time data from multiple sensors to continuously adjust fuel injection, ignition timing, and valve operation[3]. The ECU incorporates machine learning algorithms to adapt to individual driving styles and environmental conditions, further enhancing performance and efficiency[5].

Strengths: Excellent balance of performance and fuel efficiency, smooth power delivery across the rev range, and adaptability to various driving conditions. Weaknesses: Complexity of the system may lead to higher maintenance costs and potential reliability issues in the long term.

Toyota Motor Corp.

Technical Solution: Toyota's innovation in K24 engine control centers around their D-4S (Direct injection 4-stroke gasoline engine Superior version) technology. This system combines direct and port fuel injection, allowing for precise fuel delivery optimization based on engine load and speed[2]. Toyota has enhanced the K24 engine with a variable valve timing system that operates on both intake and exhaust camshafts, providing a wider range of valve timing adjustments. The company has also integrated a new combustion chamber design that improves fuel mixture and flame propagation, resulting in more complete combustion[4]. Toyota's engine control module utilizes advanced mapping and predictive algorithms to anticipate driver inputs and adjust engine parameters proactively, enhancing responsiveness and driving experience[6].

Strengths: Exceptional fuel efficiency, reduced emissions, and improved low-end torque. Weaknesses: The dual injection system adds complexity and potential points of failure, and the technology may be more expensive to implement.

Innovative Technologies in K24 Engine Management

Smart engine management and performance optimization system for peak vehicle efficiency

PatentPendingIN202311081489A

Innovation

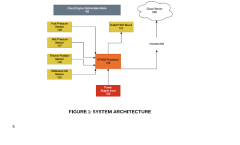

- A Smart Engine Management and Performance Optimization System that integrates sensors like Wideband O2, Fuel Pressure, and Throttle Position with an STM32 Processor for real-time data analysis and modification of critical engine parameters, coupled with cloud-based storage and remote access via a NuttyFi WiFi Board, enabling users to customize engine behavior through a mobile or web application.

A method to improve efficiency of an engine in a vehicle

PatentInactiveIN201841024311A

Innovation

- An electronic control unit in vehicles communicates with a fuel station's IoT server to receive knock adaptation values based on detected fuel parameters, adjusting ignition timing accordingly to optimize engine efficiency.

Regulatory Compliance for Engine Control Systems

Regulatory compliance is a critical aspect of engine control system development, particularly for innovative technologies aimed at enhancing driving experiences. For the K24 engine control innovation, adherence to various international and regional standards is paramount. The primary regulatory bodies governing engine control systems include the Environmental Protection Agency (EPA) in the United States, the European Union's Euro emissions standards, and Japan's Ministry of Land, Infrastructure, Transport and Tourism (MLIT).

These regulatory frameworks focus on several key areas, including emissions control, fuel efficiency, and safety. The EPA's Tier 3 standards, for instance, set stringent limits on tailpipe and evaporative emissions for light-duty vehicles, trucks, and some heavy-duty vehicles. Similarly, the Euro 6 standards in Europe define acceptable limits for exhaust emissions of new vehicles sold in EU member states.

In the context of K24 engine control innovation, compliance with On-Board Diagnostics (OBD) requirements is crucial. OBD systems monitor the performance of engine components related to emissions control, ensuring that vehicles maintain low emissions throughout their operational life. The California Air Resources Board (CARB) OBD II regulations, which have been adopted by many other states and countries, mandate specific diagnostic capabilities and fault code reporting.

Fuel efficiency regulations, such as the Corporate Average Fuel Economy (CAFE) standards in the United States, also play a significant role in engine control system design. These standards require manufacturers to achieve specific fleet-wide average fuel economy targets, influencing the development of engine control strategies that optimize fuel consumption without compromising performance.

Safety regulations, including those set by the National Highway Traffic Safety Administration (NHTSA) in the U.S., impact engine control systems through requirements for features like electronic stability control and traction control. These systems rely heavily on engine management to modulate power output in response to driving conditions.

For the K24 engine control innovation to deliver an ultimate driving experience while maintaining regulatory compliance, developers must implement advanced control algorithms that balance performance, emissions, and fuel efficiency. This may involve the use of model-based control strategies, adaptive learning algorithms, and real-time optimization techniques. Additionally, the integration of predictive control elements that anticipate driver behavior and road conditions could further enhance the driving experience while ensuring compliance with regulatory standards.

Compliance testing and certification processes are integral to the development cycle. These typically involve rigorous laboratory testing under standardized driving cycles, as well as real-world driving emissions (RDE) tests. The use of hardware-in-the-loop (HIL) simulation during development can help identify and address potential compliance issues early in the design process, reducing the risk of costly late-stage modifications.

These regulatory frameworks focus on several key areas, including emissions control, fuel efficiency, and safety. The EPA's Tier 3 standards, for instance, set stringent limits on tailpipe and evaporative emissions for light-duty vehicles, trucks, and some heavy-duty vehicles. Similarly, the Euro 6 standards in Europe define acceptable limits for exhaust emissions of new vehicles sold in EU member states.

In the context of K24 engine control innovation, compliance with On-Board Diagnostics (OBD) requirements is crucial. OBD systems monitor the performance of engine components related to emissions control, ensuring that vehicles maintain low emissions throughout their operational life. The California Air Resources Board (CARB) OBD II regulations, which have been adopted by many other states and countries, mandate specific diagnostic capabilities and fault code reporting.

Fuel efficiency regulations, such as the Corporate Average Fuel Economy (CAFE) standards in the United States, also play a significant role in engine control system design. These standards require manufacturers to achieve specific fleet-wide average fuel economy targets, influencing the development of engine control strategies that optimize fuel consumption without compromising performance.

Safety regulations, including those set by the National Highway Traffic Safety Administration (NHTSA) in the U.S., impact engine control systems through requirements for features like electronic stability control and traction control. These systems rely heavily on engine management to modulate power output in response to driving conditions.

For the K24 engine control innovation to deliver an ultimate driving experience while maintaining regulatory compliance, developers must implement advanced control algorithms that balance performance, emissions, and fuel efficiency. This may involve the use of model-based control strategies, adaptive learning algorithms, and real-time optimization techniques. Additionally, the integration of predictive control elements that anticipate driver behavior and road conditions could further enhance the driving experience while ensuring compliance with regulatory standards.

Compliance testing and certification processes are integral to the development cycle. These typically involve rigorous laboratory testing under standardized driving cycles, as well as real-world driving emissions (RDE) tests. The use of hardware-in-the-loop (HIL) simulation during development can help identify and address potential compliance issues early in the design process, reducing the risk of costly late-stage modifications.

Environmental Impact of K24 Engine Innovations

The environmental impact of K24 engine innovations is a critical consideration in the pursuit of ultimate driving experience. As automotive manufacturers strive to enhance performance and efficiency, they must also address the growing concerns surrounding emissions and sustainability. The K24 engine, known for its reliability and versatility, presents an opportunity for significant environmental improvements through innovative control systems.

One of the primary areas of focus for K24 engine control innovations is the reduction of greenhouse gas emissions. By implementing advanced fuel injection systems and optimizing combustion processes, engineers can significantly decrease carbon dioxide output. These improvements not only contribute to meeting increasingly stringent emissions regulations but also align with global efforts to combat climate change.

Innovative engine control strategies can also lead to improved fuel efficiency, which directly translates to reduced environmental impact. By fine-tuning parameters such as air-fuel mixture, ignition timing, and valve control, the K24 engine can achieve better fuel economy without sacrificing performance. This optimization results in fewer resources consumed over the engine's lifetime and a lower carbon footprint for vehicles equipped with this powerplant.

Another crucial aspect of environmental impact is the reduction of harmful pollutants such as nitrogen oxides (NOx) and particulate matter. Advanced catalytic converter systems, coupled with precise engine control, can dramatically reduce these emissions. Innovations in exhaust gas recirculation (EGR) and variable valve timing (VVT) technologies further contribute to cleaner exhaust output, minimizing the engine's impact on air quality and public health.

The development of start-stop systems and hybrid integration for the K24 engine represents a significant leap in environmental performance. These technologies allow the engine to shut off during idle periods and seamlessly restart when power is needed, reducing unnecessary fuel consumption and emissions in urban driving scenarios. Furthermore, the integration of electric motors in hybrid configurations can substantially decrease the overall environmental footprint of vehicles powered by the K24 engine.

Lastly, innovations in materials and manufacturing processes for K24 engine components can lead to more sustainable production and improved recyclability. The use of lightweight materials and advanced coatings can enhance durability and reduce friction, leading to longer engine life and decreased resource consumption over time. Additionally, designing components with end-of-life recycling in mind ensures that the environmental impact is minimized even after the engine's operational lifespan.

One of the primary areas of focus for K24 engine control innovations is the reduction of greenhouse gas emissions. By implementing advanced fuel injection systems and optimizing combustion processes, engineers can significantly decrease carbon dioxide output. These improvements not only contribute to meeting increasingly stringent emissions regulations but also align with global efforts to combat climate change.

Innovative engine control strategies can also lead to improved fuel efficiency, which directly translates to reduced environmental impact. By fine-tuning parameters such as air-fuel mixture, ignition timing, and valve control, the K24 engine can achieve better fuel economy without sacrificing performance. This optimization results in fewer resources consumed over the engine's lifetime and a lower carbon footprint for vehicles equipped with this powerplant.

Another crucial aspect of environmental impact is the reduction of harmful pollutants such as nitrogen oxides (NOx) and particulate matter. Advanced catalytic converter systems, coupled with precise engine control, can dramatically reduce these emissions. Innovations in exhaust gas recirculation (EGR) and variable valve timing (VVT) technologies further contribute to cleaner exhaust output, minimizing the engine's impact on air quality and public health.

The development of start-stop systems and hybrid integration for the K24 engine represents a significant leap in environmental performance. These technologies allow the engine to shut off during idle periods and seamlessly restart when power is needed, reducing unnecessary fuel consumption and emissions in urban driving scenarios. Furthermore, the integration of electric motors in hybrid configurations can substantially decrease the overall environmental footprint of vehicles powered by the K24 engine.

Lastly, innovations in materials and manufacturing processes for K24 engine components can lead to more sustainable production and improved recyclability. The use of lightweight materials and advanced coatings can enhance durability and reduce friction, leading to longer engine life and decreased resource consumption over time. Additionally, designing components with end-of-life recycling in mind ensures that the environmental impact is minimized even after the engine's operational lifespan.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!