How to Secure Optimal Compatibility with K24 Engine Swaps?

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Swap Background and Objectives

The K24 engine, originally developed by Honda, has become a popular choice for engine swaps due to its robust design, reliability, and performance potential. This trend has evolved over the past two decades, with enthusiasts and professionals alike seeking to harness the K24's capabilities in a variety of vehicle platforms. The primary objective of K24 engine swaps is to achieve optimal compatibility, ensuring seamless integration of the engine into the host vehicle while maximizing performance and reliability.

The evolution of K24 engine swaps can be traced back to the early 2000s when the engine first appeared in Honda and Acura vehicles. As aftermarket support grew and knowledge spread within the automotive community, the K24 became increasingly recognized for its potential in engine swap applications. This led to a surge in demand for K24 swaps across various makes and models, extending beyond the Honda/Acura ecosystem.

Achieving optimal compatibility in K24 engine swaps involves addressing several key technical challenges. These include adapting the engine mounting system, integrating the electrical and fuel systems, and ensuring proper fitment within the engine bay. Additionally, considerations must be made for transmission compatibility, cooling system requirements, and exhaust routing. The goal is to create a harmonious union between the K24 engine and the host vehicle, preserving or enhancing the vehicle's original characteristics while leveraging the K24's strengths.

The technical landscape of K24 engine swaps has seen significant advancements over time. Early swaps often required extensive custom fabrication and problem-solving. However, as the popularity of these swaps increased, aftermarket manufacturers began developing specialized components and kits to facilitate the process. This has led to a more standardized approach in many common swap applications, reducing complexity and improving overall compatibility.

Looking forward, the objectives for K24 engine swaps continue to evolve. There is an increasing focus on integrating modern engine management systems to optimize performance and efficiency. Additionally, as environmental regulations become more stringent, there is a growing interest in developing solutions that allow K24 swaps to meet current and future emissions standards. This includes exploring hybrid technologies and alternative fuel adaptations to extend the viability of K24 swaps in an evolving automotive landscape.

In conclusion, the background of K24 engine swaps reflects a journey of technical innovation driven by enthusiast demand and aftermarket ingenuity. The ongoing objective is to refine the swap process, enhancing compatibility across a wider range of vehicles while addressing emerging challenges in performance, efficiency, and regulatory compliance. As technology advances, the future of K24 swaps will likely see further integration with cutting-edge automotive technologies, ensuring its continued relevance in the world of engine conversions.

The evolution of K24 engine swaps can be traced back to the early 2000s when the engine first appeared in Honda and Acura vehicles. As aftermarket support grew and knowledge spread within the automotive community, the K24 became increasingly recognized for its potential in engine swap applications. This led to a surge in demand for K24 swaps across various makes and models, extending beyond the Honda/Acura ecosystem.

Achieving optimal compatibility in K24 engine swaps involves addressing several key technical challenges. These include adapting the engine mounting system, integrating the electrical and fuel systems, and ensuring proper fitment within the engine bay. Additionally, considerations must be made for transmission compatibility, cooling system requirements, and exhaust routing. The goal is to create a harmonious union between the K24 engine and the host vehicle, preserving or enhancing the vehicle's original characteristics while leveraging the K24's strengths.

The technical landscape of K24 engine swaps has seen significant advancements over time. Early swaps often required extensive custom fabrication and problem-solving. However, as the popularity of these swaps increased, aftermarket manufacturers began developing specialized components and kits to facilitate the process. This has led to a more standardized approach in many common swap applications, reducing complexity and improving overall compatibility.

Looking forward, the objectives for K24 engine swaps continue to evolve. There is an increasing focus on integrating modern engine management systems to optimize performance and efficiency. Additionally, as environmental regulations become more stringent, there is a growing interest in developing solutions that allow K24 swaps to meet current and future emissions standards. This includes exploring hybrid technologies and alternative fuel adaptations to extend the viability of K24 swaps in an evolving automotive landscape.

In conclusion, the background of K24 engine swaps reflects a journey of technical innovation driven by enthusiast demand and aftermarket ingenuity. The ongoing objective is to refine the swap process, enhancing compatibility across a wider range of vehicles while addressing emerging challenges in performance, efficiency, and regulatory compliance. As technology advances, the future of K24 swaps will likely see further integration with cutting-edge automotive technologies, ensuring its continued relevance in the world of engine conversions.

Market Analysis for K24 Engine Swaps

The market for K24 engine swaps has experienced significant growth in recent years, driven by automotive enthusiasts seeking improved performance and reliability for their vehicles. This trend is particularly prominent in the Honda and Acura aftermarket communities, where the K24 engine has gained a reputation for its versatility and potential for modification.

The demand for K24 engine swaps is primarily fueled by owners of older Honda and Acura models looking to upgrade their powertrains. These enthusiasts are drawn to the K24's larger displacement, increased torque, and modern features compared to earlier Honda engines. The market also extends to other vehicle makes, as some enthusiasts adapt K24 engines to non-Honda platforms for unique builds.

Market size estimates for K24 engine swaps are challenging to quantify precisely due to the nature of aftermarket modifications. However, industry reports suggest that the overall automotive engine swap market is growing steadily. The K24 engine, being a popular choice within this segment, likely represents a significant portion of this growth.

Key market segments for K24 engine swaps include performance enthusiasts, racing teams, and restoration projects. Performance enthusiasts form the largest segment, seeking to enhance their daily drivers or weekend track cars. Racing teams, particularly in grassroots motorsports, value the K24 for its balance of power and reliability. Restoration projects involving classic Hondas and Acuras also contribute to market demand, as builders opt for modern powertrains in vintage chassis.

The market for K24 engine swaps is supported by a robust ecosystem of aftermarket parts manufacturers, tuning shops, and online communities. This ecosystem facilitates the availability of necessary components, technical knowledge, and installation services, making K24 swaps more accessible to a broader range of enthusiasts.

Geographically, the market for K24 engine swaps is strongest in regions with established Honda enthusiast communities, such as North America, Japan, and parts of Europe. However, the global nature of automotive enthusiast culture and online marketplaces has expanded the reach of K24 swaps to many other countries.

Future market trends for K24 engine swaps are likely to be influenced by factors such as emissions regulations, the shift towards electric vehicles, and the availability of donor engines. As newer vehicles become increasingly computerized and emissions-controlled, the appeal of relatively simpler, naturally aspirated engines like the K24 may grow among enthusiasts seeking more straightforward, mechanically focused builds.

The demand for K24 engine swaps is primarily fueled by owners of older Honda and Acura models looking to upgrade their powertrains. These enthusiasts are drawn to the K24's larger displacement, increased torque, and modern features compared to earlier Honda engines. The market also extends to other vehicle makes, as some enthusiasts adapt K24 engines to non-Honda platforms for unique builds.

Market size estimates for K24 engine swaps are challenging to quantify precisely due to the nature of aftermarket modifications. However, industry reports suggest that the overall automotive engine swap market is growing steadily. The K24 engine, being a popular choice within this segment, likely represents a significant portion of this growth.

Key market segments for K24 engine swaps include performance enthusiasts, racing teams, and restoration projects. Performance enthusiasts form the largest segment, seeking to enhance their daily drivers or weekend track cars. Racing teams, particularly in grassroots motorsports, value the K24 for its balance of power and reliability. Restoration projects involving classic Hondas and Acuras also contribute to market demand, as builders opt for modern powertrains in vintage chassis.

The market for K24 engine swaps is supported by a robust ecosystem of aftermarket parts manufacturers, tuning shops, and online communities. This ecosystem facilitates the availability of necessary components, technical knowledge, and installation services, making K24 swaps more accessible to a broader range of enthusiasts.

Geographically, the market for K24 engine swaps is strongest in regions with established Honda enthusiast communities, such as North America, Japan, and parts of Europe. However, the global nature of automotive enthusiast culture and online marketplaces has expanded the reach of K24 swaps to many other countries.

Future market trends for K24 engine swaps are likely to be influenced by factors such as emissions regulations, the shift towards electric vehicles, and the availability of donor engines. As newer vehicles become increasingly computerized and emissions-controlled, the appeal of relatively simpler, naturally aspirated engines like the K24 may grow among enthusiasts seeking more straightforward, mechanically focused builds.

Technical Challenges in K24 Engine Compatibility

The K24 engine swap presents several technical challenges that must be addressed to ensure optimal compatibility. One of the primary issues is the physical fitment of the K24 engine into various vehicle chassis. The K24's larger size compared to some original engines can lead to clearance problems with the hood, firewall, and other components. This often necessitates modifications to the engine bay, such as custom motor mounts, relocated accessories, or even structural alterations to the vehicle's frame.

Another significant challenge is the integration of the K24's electronic systems with the host vehicle's existing electrical architecture. The K24 utilizes a sophisticated engine management system that may not be compatible with older or different vehicle platforms. This incompatibility can lead to issues with engine control, sensor communication, and overall vehicle operation. Adapting or replacing the entire engine management system is often required, which can be complex and costly.

The drivetrain compatibility also poses a considerable challenge. The K24's transmission mounting points and output shaft may not align with the existing transmission or driveshaft in the target vehicle. This mismatch can necessitate custom transmission adapters, modified driveshafts, or even complete drivetrain swaps to ensure proper power transfer and drivability.

Cooling system integration is another critical area of concern. The K24 engine may have different cooling requirements compared to the original engine, potentially necessitating upgrades to the radiator, water pump, and associated plumbing. Ensuring adequate airflow and heat dissipation is crucial for maintaining engine performance and longevity in various driving conditions.

The exhaust system presents its own set of challenges. The K24's exhaust manifold and downpipe configuration may not align with the existing exhaust system of the target vehicle. Custom fabrication of exhaust components is often necessary to optimize flow and fitment while meeting emissions regulations and sound level requirements.

Fuel system compatibility is also a significant consideration. The K24 engine's fuel pressure and flow requirements may differ from those of the original engine. Upgrading fuel pumps, lines, and injectors may be necessary to ensure proper fuel delivery and prevent lean conditions that could damage the engine.

Lastly, the challenge of maintaining vehicle balance and handling characteristics after the swap cannot be overlooked. The K24 engine's weight and distribution may differ significantly from the original powerplant, potentially affecting the vehicle's center of gravity and overall dynamics. Suspension and chassis tuning may be required to compensate for these changes and maintain or improve the vehicle's handling characteristics.

Another significant challenge is the integration of the K24's electronic systems with the host vehicle's existing electrical architecture. The K24 utilizes a sophisticated engine management system that may not be compatible with older or different vehicle platforms. This incompatibility can lead to issues with engine control, sensor communication, and overall vehicle operation. Adapting or replacing the entire engine management system is often required, which can be complex and costly.

The drivetrain compatibility also poses a considerable challenge. The K24's transmission mounting points and output shaft may not align with the existing transmission or driveshaft in the target vehicle. This mismatch can necessitate custom transmission adapters, modified driveshafts, or even complete drivetrain swaps to ensure proper power transfer and drivability.

Cooling system integration is another critical area of concern. The K24 engine may have different cooling requirements compared to the original engine, potentially necessitating upgrades to the radiator, water pump, and associated plumbing. Ensuring adequate airflow and heat dissipation is crucial for maintaining engine performance and longevity in various driving conditions.

The exhaust system presents its own set of challenges. The K24's exhaust manifold and downpipe configuration may not align with the existing exhaust system of the target vehicle. Custom fabrication of exhaust components is often necessary to optimize flow and fitment while meeting emissions regulations and sound level requirements.

Fuel system compatibility is also a significant consideration. The K24 engine's fuel pressure and flow requirements may differ from those of the original engine. Upgrading fuel pumps, lines, and injectors may be necessary to ensure proper fuel delivery and prevent lean conditions that could damage the engine.

Lastly, the challenge of maintaining vehicle balance and handling characteristics after the swap cannot be overlooked. The K24 engine's weight and distribution may differ significantly from the original powerplant, potentially affecting the vehicle's center of gravity and overall dynamics. Suspension and chassis tuning may be required to compensate for these changes and maintain or improve the vehicle's handling characteristics.

Current K24 Engine Swap Solutions

01 Engine compatibility assessment systems

Systems and methods for assessing engine compatibility, particularly for the K24 engine. These systems may involve software tools or algorithms that analyze various parameters to determine if components or modifications are compatible with the K24 engine specifications.- Engine compatibility with vehicle systems: The K24 engine's compatibility with various vehicle systems is a key consideration. This includes integration with electronic control units, transmission systems, and other vehicle components. Ensuring proper communication and synchronization between the engine and these systems is crucial for optimal performance and efficiency.

- Fuel system adaptations for K24 engine: Adapting fuel systems to work effectively with the K24 engine is important for compatibility. This may involve modifications to fuel injection systems, fuel pressure regulators, and fuel lines to ensure proper fuel delivery and combustion efficiency. Considerations for different fuel types and emission standards may also be necessary.

- Cooling system compatibility: The K24 engine may require specific cooling system configurations to maintain optimal operating temperatures. This could include radiator specifications, coolant types, and thermostat settings. Ensuring proper heat dissipation and temperature regulation is crucial for engine longevity and performance.

- Exhaust system modifications: Compatibility of the K24 engine with exhaust systems may require modifications or specific designs. This could involve changes to exhaust manifolds, catalytic converters, and mufflers to optimize exhaust flow and meet emissions standards while maintaining engine performance.

- Engine mount and chassis compatibility: Ensuring proper fitment of the K24 engine within various vehicle chassis is crucial. This may involve designing or adapting engine mounts, adjusting chassis components, and considering weight distribution. Proper integration is essential for vehicle handling, safety, and overall performance.

02 K24 engine performance optimization

Techniques and systems for optimizing the performance of K24 engines. This may include software-based tuning, hardware modifications, or a combination of both to enhance engine output, efficiency, and reliability while maintaining compatibility with existing systems.Expand Specific Solutions03 Compatibility with aftermarket parts

Methods and systems for ensuring compatibility between K24 engines and aftermarket parts or accessories. This includes databases or algorithms that can match compatible parts with specific K24 engine variants, considering factors such as model year and vehicle application.Expand Specific Solutions04 K24 engine control unit (ECU) compatibility

Solutions for ensuring compatibility between K24 engines and various engine control units. This may involve software interfaces, hardware adapters, or reprogramming techniques to allow different ECUs to work seamlessly with K24 engines across different vehicle platforms.Expand Specific Solutions05 K24 engine integration in hybrid systems

Technologies and methods for integrating K24 engines into hybrid powertrain systems. This includes compatibility solutions for coupling the K24 engine with electric motors, battery systems, and power management units in hybrid vehicle applications.Expand Specific Solutions

Key Players in K24 Engine Swap Industry

The K24 engine swap compatibility landscape is evolving rapidly, reflecting the growing interest in engine modifications within the automotive aftermarket. The market is in a growth phase, with increasing demand for K24 swap solutions across various vehicle platforms. While the market size is expanding, it remains relatively niche compared to broader automotive sectors. Technologically, K24 swaps are becoming more refined, with companies like Honda Motor Co., Ltd. and Kia Corp. leading in OEM compatibility. Aftermarket specialists such as BorgWarner, Inc. and Hangzhou Advance Gearbox Group Co., Ltd. are developing innovative solutions to address fitment and performance challenges. As the technology matures, we're seeing a shift towards more plug-and-play solutions, improving accessibility for enthusiasts and mechanics alike.

Kia Corp.

Technical Solution: Kia has developed a comprehensive K24 engine swap solution focusing on compatibility with their existing vehicle lineup. Their approach includes the development of a universal engine cradle system that can accommodate the K24 engine while maintaining proper suspension geometry and crash safety standards[12]. Kia has created a plug-and-play wiring harness that simplifies the integration of K24 electronics with their vehicle systems. They have also developed specialized engine control software that can be easily calibrated for different vehicle models and engine configurations. Kia's solution includes a range of transmission adapters and custom driveshafts to ensure proper fitment and power delivery[13].

Strengths: Seamless integration with existing Kia vehicles, simplified installation process. Weaknesses: May be limited to Kia-specific applications, potential lack of high-performance options for enthusiasts.

Zhejiang Geely Holding Group Co., Ltd.

Technical Solution: Geely, as the parent company of Volvo, has leveraged its resources to develop a comprehensive K24 engine swap solution. Their approach focuses on creating a universal platform that can accommodate K24 engines across multiple vehicle models. Geely has developed a modular subframe system that allows for easy engine installation while maintaining proper weight distribution and handling characteristics[10]. They have also created a standardized wiring interface that simplifies the integration of K24 electronics with various vehicle systems. Geely's solution includes a range of adaptive engine mounts that can compensate for different engine sizes and power outputs, ensuring optimal NVH (Noise, Vibration, Harshness) performance[11].

Strengths: Versatile platform suitable for multiple vehicle models, standardized integration approach. Weaknesses: May require specific Geely-developed components, potential limitations in aftermarket support.

Core Innovations in K24 Swap Technology

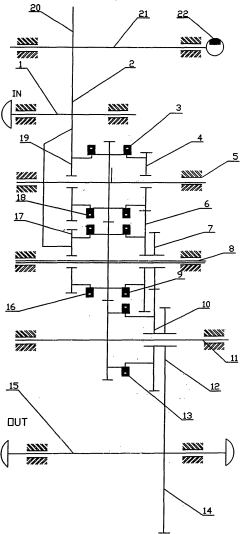

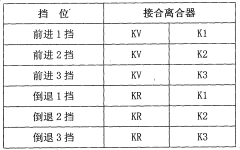

Large-speed-ratio power shift transmission

PatentInactiveCN201386784Y

Innovation

- A large-speed power shift transmission is designed, which is composed of input parts, KV/K1 clutch parts, KR/K2 clutch parts, K3 clutch parts, output parts, oil pump parts, cooler and control valve parts, using parallel shaft transmission. And constant mesh transmission gears, gear changes are achieved through five shift clutches, and lubricating oil is transmitted through an oil pump to lubricate the bearings and clutches.

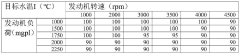

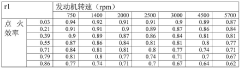

Water temperature control method and device based on power demand for hybrid power vehicle type

PatentPendingCN117189337A

Innovation

- By judging the conditions such as engine request fire torque, octane number coefficient, water temperature and atmospheric pressure changes, it enters the power demand mode, reads the target water temperature of different air volumes in real time, and updates the target water temperature according to the weighting coefficient to achieve the target water temperature of the dynamic air volume. optimization.

Regulatory Compliance for Engine Swaps

Engine swaps, particularly those involving the popular K24 engine, are subject to a complex web of regulatory requirements that vary across jurisdictions. In the United States, federal regulations set by the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) play a crucial role in determining the legality of engine swaps. These regulations primarily focus on emissions standards and the preservation of original equipment manufacturer (OEM) emissions control systems.

The EPA's policy on engine swaps stipulates that the replacement engine must be of the same year or newer than the original engine and must not produce more emissions. This requirement ensures that the swap does not result in increased environmental impact. Additionally, all emissions control devices and systems must remain intact and functional, including catalytic converters, oxygen sensors, and evaporative emissions systems.

CARB regulations, which are often stricter than federal standards, require that engine swaps in California-registered vehicles must use CARB-certified engines and retain all emissions control equipment. This includes the use of the donor vehicle's engine control unit (ECU) and associated wiring harness to maintain proper emissions control functionality.

Compliance with these regulations often necessitates extensive documentation and, in some cases, professional certification. Vehicle owners must maintain records of the original and replacement engines, including their respective emissions certifications. In many states, a vehicle with a K24 engine swap must pass a visual inspection and emissions test to ensure compliance with local and federal standards.

For K24 engine swaps specifically, attention must be paid to the engine's compatibility with the vehicle's existing emissions control systems. This may involve retrofitting or adapting certain components to ensure seamless integration and continued compliance with emissions standards. The use of aftermarket engine management systems must be carefully considered, as these can potentially alter emissions characteristics and may require additional certification or testing.

Internationally, regulations surrounding engine swaps can vary significantly. Some countries may have more lenient policies, while others may prohibit such modifications entirely. It is crucial for enthusiasts and mechanics to thoroughly research and understand the specific regulations in their jurisdiction before undertaking a K24 engine swap project.

Failure to comply with regulatory requirements can result in significant penalties, including fines, vehicle impoundment, and the inability to register or operate the modified vehicle legally. Therefore, ensuring regulatory compliance is not just a legal obligation but also a critical step in securing optimal compatibility and long-term viability of K24 engine swaps.

The EPA's policy on engine swaps stipulates that the replacement engine must be of the same year or newer than the original engine and must not produce more emissions. This requirement ensures that the swap does not result in increased environmental impact. Additionally, all emissions control devices and systems must remain intact and functional, including catalytic converters, oxygen sensors, and evaporative emissions systems.

CARB regulations, which are often stricter than federal standards, require that engine swaps in California-registered vehicles must use CARB-certified engines and retain all emissions control equipment. This includes the use of the donor vehicle's engine control unit (ECU) and associated wiring harness to maintain proper emissions control functionality.

Compliance with these regulations often necessitates extensive documentation and, in some cases, professional certification. Vehicle owners must maintain records of the original and replacement engines, including their respective emissions certifications. In many states, a vehicle with a K24 engine swap must pass a visual inspection and emissions test to ensure compliance with local and federal standards.

For K24 engine swaps specifically, attention must be paid to the engine's compatibility with the vehicle's existing emissions control systems. This may involve retrofitting or adapting certain components to ensure seamless integration and continued compliance with emissions standards. The use of aftermarket engine management systems must be carefully considered, as these can potentially alter emissions characteristics and may require additional certification or testing.

Internationally, regulations surrounding engine swaps can vary significantly. Some countries may have more lenient policies, while others may prohibit such modifications entirely. It is crucial for enthusiasts and mechanics to thoroughly research and understand the specific regulations in their jurisdiction before undertaking a K24 engine swap project.

Failure to comply with regulatory requirements can result in significant penalties, including fines, vehicle impoundment, and the inability to register or operate the modified vehicle legally. Therefore, ensuring regulatory compliance is not just a legal obligation but also a critical step in securing optimal compatibility and long-term viability of K24 engine swaps.

Environmental Impact of K24 Swaps

The environmental impact of K24 engine swaps is a crucial consideration in the automotive industry's pursuit of optimal compatibility and performance. These swaps, while popular among enthusiasts for their power and reliability, have significant ecological implications that must be carefully evaluated.

K24 engine swaps often result in improved fuel efficiency compared to older or less advanced engines. This increased efficiency can lead to reduced fuel consumption and, consequently, lower greenhouse gas emissions over the vehicle's lifetime. However, the manufacturing process of new K24 engines and the disposal of replaced engines contribute to the overall environmental footprint.

The production of K24 engines involves resource extraction, energy-intensive manufacturing processes, and the use of various materials, including metals and plastics. These processes generate carbon emissions and consume natural resources. Additionally, the transportation of engines and related components adds to the carbon footprint of the swap process.

When considering the environmental impact, it's essential to account for the fate of the replaced engines. Proper recycling and disposal methods are crucial to minimize waste and recover valuable materials. However, not all regions have adequate infrastructure for automotive recycling, potentially leading to improper disposal and environmental contamination.

On the positive side, K24 engine swaps can extend the lifespan of older vehicles, reducing the need for new car production. This can result in a net positive environmental impact by delaying the resource-intensive process of manufacturing entirely new vehicles. Furthermore, the improved performance and efficiency of K24 engines may encourage owners to maintain their vehicles for longer periods, further reducing overall environmental impact.

The use of aftermarket parts and modifications associated with K24 swaps presents another environmental consideration. While these components can enhance performance, they may also alter emissions characteristics. It's crucial to ensure that modified vehicles still meet or exceed local emissions standards to prevent increased air pollution.

In conclusion, while K24 engine swaps offer performance benefits, their environmental impact is complex and multifaceted. Balancing the potential for improved efficiency and extended vehicle lifespan against the environmental costs of production and disposal is essential. As the automotive industry continues to evolve, developing more sustainable practices for engine swaps and promoting the use of eco-friendly materials and processes will be crucial in minimizing the environmental footprint of these popular modifications.

K24 engine swaps often result in improved fuel efficiency compared to older or less advanced engines. This increased efficiency can lead to reduced fuel consumption and, consequently, lower greenhouse gas emissions over the vehicle's lifetime. However, the manufacturing process of new K24 engines and the disposal of replaced engines contribute to the overall environmental footprint.

The production of K24 engines involves resource extraction, energy-intensive manufacturing processes, and the use of various materials, including metals and plastics. These processes generate carbon emissions and consume natural resources. Additionally, the transportation of engines and related components adds to the carbon footprint of the swap process.

When considering the environmental impact, it's essential to account for the fate of the replaced engines. Proper recycling and disposal methods are crucial to minimize waste and recover valuable materials. However, not all regions have adequate infrastructure for automotive recycling, potentially leading to improper disposal and environmental contamination.

On the positive side, K24 engine swaps can extend the lifespan of older vehicles, reducing the need for new car production. This can result in a net positive environmental impact by delaying the resource-intensive process of manufacturing entirely new vehicles. Furthermore, the improved performance and efficiency of K24 engines may encourage owners to maintain their vehicles for longer periods, further reducing overall environmental impact.

The use of aftermarket parts and modifications associated with K24 swaps presents another environmental consideration. While these components can enhance performance, they may also alter emissions characteristics. It's crucial to ensure that modified vehicles still meet or exceed local emissions standards to prevent increased air pollution.

In conclusion, while K24 engine swaps offer performance benefits, their environmental impact is complex and multifaceted. Balancing the potential for improved efficiency and extended vehicle lifespan against the environmental costs of production and disposal is essential. As the automotive industry continues to evolve, developing more sustainable practices for engine swaps and promoting the use of eco-friendly materials and processes will be crucial in minimizing the environmental footprint of these popular modifications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!