K24 Engine Management: Exploring Future Software Innovations

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Evolution

The K24 engine, first introduced by Honda in 2001, has undergone significant evolution over the past two decades. Initially designed for the Honda Accord, this 2.4-liter inline-four engine quickly gained popularity for its balance of performance and efficiency. The engine's development can be traced through several key stages, each marked by technological advancements and refinements.

In its early iterations, the K24 featured a relatively simple design with a single overhead camshaft (SOHC) and Honda's VTEC (Variable Valve Timing and Lift Electronic Control) system. This initial version produced around 160 horsepower and was praised for its smooth operation and reliability. As emissions regulations tightened and consumer demands for better fuel economy increased, Honda engineers focused on improving the engine's efficiency without sacrificing performance.

The mid-2000s saw the introduction of the K24A2 variant, which incorporated a dual overhead camshaft (DOHC) design and an upgraded i-VTEC system. This evolution boosted power output to approximately 200 horsepower while maintaining fuel efficiency. The i-VTEC system allowed for more precise control over valve timing, resulting in improved low-end torque and high-end power.

Further advancements came with the integration of direct fuel injection technology in the late 2000s. This innovation, coupled with continued refinements to the VTEC system, led to the development of the Earth Dreams series of K24 engines. These engines achieved higher compression ratios, reduced friction, and improved thermal efficiency, resulting in power outputs exceeding 220 horsepower in some applications while simultaneously reducing fuel consumption and emissions.

The most recent iterations of the K24 engine have seen the incorporation of turbocharging technology. This significant leap forward has allowed Honda to extract even more power from the 2.4-liter displacement while further improving fuel efficiency. The turbocharged K24 engines can produce over 250 horsepower in certain applications, rivaling the output of larger displacement naturally aspirated engines.

Throughout its evolution, the K24 engine has consistently benefited from advancements in materials science and manufacturing processes. The use of lighter, stronger materials and more precise machining techniques has contributed to improved durability, reduced weight, and enhanced overall performance. Additionally, the integration of more sophisticated engine management systems has played a crucial role in optimizing the K24's operation across various driving conditions.

In its early iterations, the K24 featured a relatively simple design with a single overhead camshaft (SOHC) and Honda's VTEC (Variable Valve Timing and Lift Electronic Control) system. This initial version produced around 160 horsepower and was praised for its smooth operation and reliability. As emissions regulations tightened and consumer demands for better fuel economy increased, Honda engineers focused on improving the engine's efficiency without sacrificing performance.

The mid-2000s saw the introduction of the K24A2 variant, which incorporated a dual overhead camshaft (DOHC) design and an upgraded i-VTEC system. This evolution boosted power output to approximately 200 horsepower while maintaining fuel efficiency. The i-VTEC system allowed for more precise control over valve timing, resulting in improved low-end torque and high-end power.

Further advancements came with the integration of direct fuel injection technology in the late 2000s. This innovation, coupled with continued refinements to the VTEC system, led to the development of the Earth Dreams series of K24 engines. These engines achieved higher compression ratios, reduced friction, and improved thermal efficiency, resulting in power outputs exceeding 220 horsepower in some applications while simultaneously reducing fuel consumption and emissions.

The most recent iterations of the K24 engine have seen the incorporation of turbocharging technology. This significant leap forward has allowed Honda to extract even more power from the 2.4-liter displacement while further improving fuel efficiency. The turbocharged K24 engines can produce over 250 horsepower in certain applications, rivaling the output of larger displacement naturally aspirated engines.

Throughout its evolution, the K24 engine has consistently benefited from advancements in materials science and manufacturing processes. The use of lighter, stronger materials and more precise machining techniques has contributed to improved durability, reduced weight, and enhanced overall performance. Additionally, the integration of more sophisticated engine management systems has played a crucial role in optimizing the K24's operation across various driving conditions.

Market Demand Analysis

The market demand for advanced engine management software in the automotive industry has been steadily increasing, driven by several key factors. Stringent emissions regulations worldwide are pushing manufacturers to develop more efficient and cleaner engines, necessitating sophisticated software solutions. The global trend towards electrification and hybridization of vehicles also requires advanced engine management systems to optimize the interplay between traditional combustion engines and electric powertrains.

Consumer expectations for improved fuel efficiency and performance are further fueling the demand for innovative engine management software. As vehicles become more connected and autonomous, there is a growing need for engine management systems that can integrate seamlessly with other vehicle systems and adapt to various driving conditions in real-time.

The aftermarket sector presents a significant opportunity for K24 Engine Management software innovations. Performance enthusiasts and tuning shops are constantly seeking more advanced tools to fine-tune engine parameters and extract maximum performance. This segment values software that offers greater customization options, real-time data analysis, and compatibility with a wide range of vehicle makes and models.

In the commercial vehicle sector, fleet operators are increasingly looking for engine management solutions that can help reduce fuel consumption and maintenance costs. Software that can provide predictive maintenance capabilities and optimize engine performance based on specific usage patterns is in high demand.

The racing and motorsports industry continues to be a driving force for cutting-edge engine management software. Teams and manufacturers in this sector require highly specialized solutions that can push the boundaries of engine performance while adhering to strict regulations.

Emerging markets, particularly in Asia and South America, are showing rapid growth in demand for advanced automotive technologies, including sophisticated engine management systems. As these markets mature and adopt stricter emissions standards, the need for advanced software solutions is expected to surge.

The shift towards cloud-based and over-the-air update capabilities in vehicles is creating new opportunities for engine management software providers. Manufacturers and consumers alike are seeking solutions that can be easily updated and optimized throughout the vehicle's lifecycle, without the need for physical interventions.

As the automotive industry moves towards more sustainable practices, there is a growing market for engine management software that can optimize the use of alternative fuels and support the development of more environmentally friendly powertrains. This includes software solutions for hydrogen fuel cells, synthetic fuels, and other emerging technologies.

Consumer expectations for improved fuel efficiency and performance are further fueling the demand for innovative engine management software. As vehicles become more connected and autonomous, there is a growing need for engine management systems that can integrate seamlessly with other vehicle systems and adapt to various driving conditions in real-time.

The aftermarket sector presents a significant opportunity for K24 Engine Management software innovations. Performance enthusiasts and tuning shops are constantly seeking more advanced tools to fine-tune engine parameters and extract maximum performance. This segment values software that offers greater customization options, real-time data analysis, and compatibility with a wide range of vehicle makes and models.

In the commercial vehicle sector, fleet operators are increasingly looking for engine management solutions that can help reduce fuel consumption and maintenance costs. Software that can provide predictive maintenance capabilities and optimize engine performance based on specific usage patterns is in high demand.

The racing and motorsports industry continues to be a driving force for cutting-edge engine management software. Teams and manufacturers in this sector require highly specialized solutions that can push the boundaries of engine performance while adhering to strict regulations.

Emerging markets, particularly in Asia and South America, are showing rapid growth in demand for advanced automotive technologies, including sophisticated engine management systems. As these markets mature and adopt stricter emissions standards, the need for advanced software solutions is expected to surge.

The shift towards cloud-based and over-the-air update capabilities in vehicles is creating new opportunities for engine management software providers. Manufacturers and consumers alike are seeking solutions that can be easily updated and optimized throughout the vehicle's lifecycle, without the need for physical interventions.

As the automotive industry moves towards more sustainable practices, there is a growing market for engine management software that can optimize the use of alternative fuels and support the development of more environmentally friendly powertrains. This includes software solutions for hydrogen fuel cells, synthetic fuels, and other emerging technologies.

Current Challenges

The K24 Engine Management System faces several significant challenges in its current state, primarily stemming from the rapid evolution of automotive technology and changing regulatory landscapes. One of the most pressing issues is the increasing complexity of engine control algorithms required to meet stringent emissions standards while maintaining optimal performance. As regulations become more demanding, particularly in terms of reducing greenhouse gas emissions and improving fuel efficiency, the software must continuously adapt to balance these often-conflicting requirements.

Another major challenge lies in the integration of advanced driver assistance systems (ADAS) and autonomous driving features with engine management. The K24 system needs to seamlessly communicate and coordinate with a growing number of vehicle subsystems, requiring more sophisticated inter-system communication protocols and real-time data processing capabilities. This integration challenge extends to the incorporation of electrification technologies, as hybrid and electric powertrains become more prevalent, necessitating adaptive engine management strategies that can optimize performance across various driving modes.

Cybersecurity presents an increasingly critical concern for engine management systems. As vehicles become more connected and software-dependent, the K24 system must incorporate robust security measures to protect against potential cyber threats and unauthorized access. This includes implementing secure over-the-air (OTA) update mechanisms to ensure that the engine management software can be safely and efficiently updated throughout the vehicle's lifecycle.

The rapid pace of technological advancement in the automotive industry also poses a challenge for the K24 system in terms of hardware compatibility and scalability. As new sensors, actuators, and processing units become available, the engine management software must be flexible enough to leverage these advancements without requiring a complete system overhaul. This necessitates a modular software architecture that can accommodate hardware upgrades and new features with minimal disruption.

Furthermore, the increasing demand for personalized driving experiences and vehicle customization puts pressure on the K24 system to offer more adaptable and user-configurable options. This requires developing intelligent algorithms that can learn and adapt to individual driving styles and preferences while still maintaining optimal engine performance and efficiency. Balancing these personalization features with safety and regulatory compliance adds another layer of complexity to the software development process.

Lastly, the K24 Engine Management System faces the ongoing challenge of reducing development time and costs while increasing software reliability and functionality. As the automotive industry moves towards more frequent model updates and shorter development cycles, there is a growing need for advanced simulation tools, automated testing procedures, and efficient software validation methods to ensure that new features and updates can be deployed quickly and safely.

Another major challenge lies in the integration of advanced driver assistance systems (ADAS) and autonomous driving features with engine management. The K24 system needs to seamlessly communicate and coordinate with a growing number of vehicle subsystems, requiring more sophisticated inter-system communication protocols and real-time data processing capabilities. This integration challenge extends to the incorporation of electrification technologies, as hybrid and electric powertrains become more prevalent, necessitating adaptive engine management strategies that can optimize performance across various driving modes.

Cybersecurity presents an increasingly critical concern for engine management systems. As vehicles become more connected and software-dependent, the K24 system must incorporate robust security measures to protect against potential cyber threats and unauthorized access. This includes implementing secure over-the-air (OTA) update mechanisms to ensure that the engine management software can be safely and efficiently updated throughout the vehicle's lifecycle.

The rapid pace of technological advancement in the automotive industry also poses a challenge for the K24 system in terms of hardware compatibility and scalability. As new sensors, actuators, and processing units become available, the engine management software must be flexible enough to leverage these advancements without requiring a complete system overhaul. This necessitates a modular software architecture that can accommodate hardware upgrades and new features with minimal disruption.

Furthermore, the increasing demand for personalized driving experiences and vehicle customization puts pressure on the K24 system to offer more adaptable and user-configurable options. This requires developing intelligent algorithms that can learn and adapt to individual driving styles and preferences while still maintaining optimal engine performance and efficiency. Balancing these personalization features with safety and regulatory compliance adds another layer of complexity to the software development process.

Lastly, the K24 Engine Management System faces the ongoing challenge of reducing development time and costs while increasing software reliability and functionality. As the automotive industry moves towards more frequent model updates and shorter development cycles, there is a growing need for advanced simulation tools, automated testing procedures, and efficient software validation methods to ensure that new features and updates can be deployed quickly and safely.

Existing Solutions

01 Software update and management for engine control systems

This category focuses on methods and systems for updating and managing software in engine control units, particularly for K24 engines. It includes techniques for over-the-air updates, version control, and ensuring compatibility with various engine configurations.- Software development and management for engine control systems: This category focuses on the development, management, and optimization of software specifically designed for engine control systems. It includes methods for creating, updating, and maintaining software that manages various aspects of engine performance, including fuel injection, ignition timing, and emissions control.

- Engine performance optimization through software algorithms: This point covers the use of advanced algorithms and software techniques to optimize engine performance. It includes methods for real-time adjustment of engine parameters, predictive analysis for improved efficiency, and adaptive learning systems that fine-tune engine operation based on various inputs and conditions.

- Integration of engine management software with vehicle systems: This category addresses the integration of engine management software with other vehicle systems, such as transmission control, stability control, and infotainment systems. It includes methods for seamless communication between different software modules and ensuring overall vehicle performance and efficiency.

- Security and protection of engine management software: This point focuses on ensuring the security and integrity of engine management software. It includes methods for preventing unauthorized access, protecting against malware and hacking attempts, and implementing secure update procedures to maintain the reliability and safety of the engine control system.

- Diagnostic and monitoring features in engine management software: This category covers the implementation of diagnostic and monitoring features within engine management software. It includes methods for real-time error detection, performance analysis, and predictive maintenance to ensure optimal engine operation and reduce downtime.

02 Engine performance optimization through software algorithms

This point covers software algorithms designed to optimize K24 engine performance. It includes adaptive learning systems, real-time adjustments based on sensor data, and fuel efficiency improvements through advanced software control.Expand Specific Solutions03 Integration of engine management software with vehicle systems

This category addresses the integration of K24 engine management software with other vehicle systems. It includes communication protocols, data sharing between different control units, and unified software platforms for comprehensive vehicle management.Expand Specific Solutions04 Diagnostic and monitoring features in engine management software

This point focuses on diagnostic and monitoring capabilities within K24 engine management software. It includes real-time error detection, predictive maintenance algorithms, and advanced logging features for performance analysis and troubleshooting.Expand Specific Solutions05 Security measures in engine management software

This category covers security features implemented in K24 engine management software. It includes encryption methods, secure boot processes, and protection against unauthorized access or modifications to ensure the integrity of the engine control system.Expand Specific Solutions

Key Industry Players

The K24 Engine Management software innovation landscape is in a mature yet evolving phase, with significant market potential driven by the automotive industry's shift towards more sophisticated engine control systems. The market size is substantial, reflecting the global automotive sector's scale. Technologically, the field is well-established but continually advancing, with key players like Scania CV AB, GM Global Technology Operations LLC, and Toyota Motor Corp. leading innovation. These companies, along with others such as Volkswagen AG and Hyundai Motor Co., Ltd., are investing heavily in software development to enhance engine efficiency, performance, and emissions control. The competitive landscape is characterized by a mix of traditional automotive manufacturers and specialized technology firms, all vying to develop cutting-edge solutions for next-generation engine management systems.

GM Global Technology Operations LLC

Technical Solution: GM Global Technology Operations LLC is innovating in K24 engine management software with a focus on advanced control strategies and connectivity. The company is developing a next-generation Engine Control Module (ECM) that utilizes sophisticated algorithms for precise control of fuel injection, ignition timing, and valve actuation[1]. GM's system incorporates machine learning techniques to continuously optimize engine performance based on driving conditions and historical data. The company is also exploring the integration of vehicle-to-everything (V2X) communication capabilities, allowing the engine management system to adapt to traffic conditions and infrastructure information in real-time[2]. Furthermore, GM is working on advanced diagnostic features that can predict potential engine issues and suggest preventive maintenance, reducing downtime and improving overall vehicle reliability[3].

Strengths: Extensive experience in powertrain development, strong focus on connectivity and data-driven optimization. Weaknesses: Potential challenges in implementing complex software systems across a diverse range of vehicle platforms.

Hitachi Ltd.

Technical Solution: Hitachi Ltd. is advancing K24 engine management software through its expertise in both automotive and information technology sectors. The company is developing an intelligent engine control system that leverages big data analytics and artificial intelligence to optimize engine performance and efficiency[1]. Hitachi's approach includes the use of edge computing to process sensor data in real-time, allowing for faster and more precise adjustments to engine parameters. The company is also exploring the integration of predictive maintenance capabilities, using machine learning algorithms to anticipate potential engine issues before they occur[2]. Additionally, Hitachi is working on advanced cybersecurity measures to protect engine management systems from potential threats, ensuring the integrity and reliability of the software[3].

Strengths: Strong capabilities in both automotive and IT sectors, expertise in big data analytics and AI. Weaknesses: May face challenges in competing with traditional automotive manufacturers in engine-specific optimizations.

Core Innovations

Smart engine management and performance optimization system for peak vehicle efficiency

PatentPendingIN202311081489A

Innovation

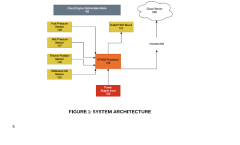

- A Smart Engine Management and Performance Optimization System that integrates sensors like Wideband O2, Fuel Pressure, and Throttle Position with an STM32 Processor for real-time data analysis and modification of critical engine parameters, coupled with cloud-based storage and remote access via a NuttyFi WiFi Board, enabling users to customize engine behavior through a mobile or web application.

Software Management Method for Future Cars on Artificial Intelligence

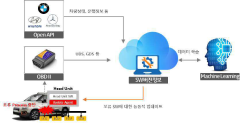

PatentPendingKR1020210146654A

Innovation

- A software management method utilizing machine learning to automatically determine software errors and update timing, employing Delta technology for efficient wireless updates, integrating AI-based services for error prediction and proactive correction, and implementing a comprehensive update service architecture including a Delta Generator, Software Management Client, and Cloud Service Delivery Platform.

Emissions Regulations

Emissions regulations play a crucial role in shaping the future of engine management systems, particularly for the K24 engine. As global environmental concerns intensify, governments worldwide are implementing increasingly stringent emissions standards to reduce the environmental impact of internal combustion engines.

The European Union's Euro 7 standards, set to take effect in 2025, will impose even tighter limits on pollutants such as nitrogen oxides (NOx) and particulate matter. These regulations will necessitate significant advancements in engine management software to ensure compliance while maintaining performance and fuel efficiency.

In the United States, the Environmental Protection Agency (EPA) continues to refine its emissions standards, with a focus on reducing greenhouse gas emissions from vehicles. The Corporate Average Fuel Economy (CAFE) standards also indirectly influence engine management systems by pushing manufacturers to improve fuel efficiency across their vehicle lineups.

China, the world's largest automotive market, has implemented its China 6 emissions standards, which are comparable to Euro 6 standards. As these regulations evolve, they will drive innovation in engine management software to meet the demands of different global markets.

To address these regulatory challenges, future K24 engine management software will need to incorporate advanced emissions control strategies. Real-time monitoring and adjustment of fuel injection, ignition timing, and exhaust gas recirculation (EGR) will become increasingly sophisticated to optimize emissions performance under various driving conditions.

Predictive emissions control algorithms, leveraging machine learning and artificial intelligence, may be integrated into future engine management systems. These algorithms could anticipate driving conditions and adjust engine parameters proactively to minimize emissions while maximizing efficiency.

On-board diagnostics (OBD) systems will also need to evolve to provide more comprehensive emissions monitoring and fault detection capabilities. This will ensure that vehicles maintain their emissions performance throughout their lifecycle and comply with in-use emissions regulations.

As emissions regulations continue to tighten, the integration of hybrid and electrification technologies with the K24 engine may become necessary. Engine management software will need to seamlessly coordinate between combustion and electric power sources to optimize emissions performance and meet regulatory requirements.

The European Union's Euro 7 standards, set to take effect in 2025, will impose even tighter limits on pollutants such as nitrogen oxides (NOx) and particulate matter. These regulations will necessitate significant advancements in engine management software to ensure compliance while maintaining performance and fuel efficiency.

In the United States, the Environmental Protection Agency (EPA) continues to refine its emissions standards, with a focus on reducing greenhouse gas emissions from vehicles. The Corporate Average Fuel Economy (CAFE) standards also indirectly influence engine management systems by pushing manufacturers to improve fuel efficiency across their vehicle lineups.

China, the world's largest automotive market, has implemented its China 6 emissions standards, which are comparable to Euro 6 standards. As these regulations evolve, they will drive innovation in engine management software to meet the demands of different global markets.

To address these regulatory challenges, future K24 engine management software will need to incorporate advanced emissions control strategies. Real-time monitoring and adjustment of fuel injection, ignition timing, and exhaust gas recirculation (EGR) will become increasingly sophisticated to optimize emissions performance under various driving conditions.

Predictive emissions control algorithms, leveraging machine learning and artificial intelligence, may be integrated into future engine management systems. These algorithms could anticipate driving conditions and adjust engine parameters proactively to minimize emissions while maximizing efficiency.

On-board diagnostics (OBD) systems will also need to evolve to provide more comprehensive emissions monitoring and fault detection capabilities. This will ensure that vehicles maintain their emissions performance throughout their lifecycle and comply with in-use emissions regulations.

As emissions regulations continue to tighten, the integration of hybrid and electrification technologies with the K24 engine may become necessary. Engine management software will need to seamlessly coordinate between combustion and electric power sources to optimize emissions performance and meet regulatory requirements.

Integration Strategies

Integration strategies for K24 Engine Management software innovations are crucial for ensuring seamless functionality and optimal performance. One key approach is the development of modular software architectures that allow for easy integration of new features and updates. This modular design enables engineers to implement and test individual components independently, reducing development time and improving overall system reliability.

Another important integration strategy involves the use of standardized communication protocols and interfaces. By adopting industry-standard protocols such as CAN (Controller Area Network) or Ethernet, K24 Engine Management systems can more easily integrate with other vehicle subsystems and third-party components. This standardization also facilitates future upgrades and compatibility with emerging technologies.

Cloud integration is becoming increasingly important in engine management software. By leveraging cloud computing capabilities, K24 systems can offload complex calculations, access real-time data, and enable over-the-air updates. This strategy not only enhances system performance but also allows for continuous improvement and adaptation to changing environmental and regulatory requirements.

Machine learning and artificial intelligence integration strategies are gaining traction in engine management systems. These technologies can be used to optimize engine performance, predict maintenance needs, and adapt to individual driving patterns. Implementing AI algorithms within the K24 software architecture requires careful consideration of processing power, data storage, and real-time execution capabilities.

Security integration is paramount in modern engine management systems. Strategies for integrating robust cybersecurity measures include encryption of communication channels, secure boot processes, and intrusion detection systems. These security features must be seamlessly integrated into the software architecture without compromising system performance or introducing latency.

Lastly, integration strategies must consider the human-machine interface. Advanced user interface technologies, such as augmented reality displays and voice control systems, need to be integrated in a way that enhances driver experience without causing distraction. This requires close collaboration between software engineers, UI/UX designers, and human factors experts to create intuitive and safe interfaces for K24 Engine Management systems.

Another important integration strategy involves the use of standardized communication protocols and interfaces. By adopting industry-standard protocols such as CAN (Controller Area Network) or Ethernet, K24 Engine Management systems can more easily integrate with other vehicle subsystems and third-party components. This standardization also facilitates future upgrades and compatibility with emerging technologies.

Cloud integration is becoming increasingly important in engine management software. By leveraging cloud computing capabilities, K24 systems can offload complex calculations, access real-time data, and enable over-the-air updates. This strategy not only enhances system performance but also allows for continuous improvement and adaptation to changing environmental and regulatory requirements.

Machine learning and artificial intelligence integration strategies are gaining traction in engine management systems. These technologies can be used to optimize engine performance, predict maintenance needs, and adapt to individual driving patterns. Implementing AI algorithms within the K24 software architecture requires careful consideration of processing power, data storage, and real-time execution capabilities.

Security integration is paramount in modern engine management systems. Strategies for integrating robust cybersecurity measures include encryption of communication channels, secure boot processes, and intrusion detection systems. These security features must be seamlessly integrated into the software architecture without compromising system performance or introducing latency.

Lastly, integration strategies must consider the human-machine interface. Advanced user interface technologies, such as augmented reality displays and voice control systems, need to be integrated in a way that enhances driver experience without causing distraction. This requires close collaboration between software engineers, UI/UX designers, and human factors experts to create intuitive and safe interfaces for K24 Engine Management systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!