K24 Engine Contributions: Pioneering the Sports Car Revolution

JUL 3, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Evolution

The K24 engine, a marvel of automotive engineering, has undergone significant evolution since its inception. Initially introduced in the early 2000s, this powerplant has been a cornerstone of Honda's performance lineup, particularly in sports cars and high-performance vehicles.

The engine's journey began with the K20A series, which laid the groundwork for the K24's development. As market demands shifted towards a balance of power and efficiency, Honda engineers refined the design, increasing displacement from 2.0 to 2.4 liters. This change marked the birth of the K24, which offered improved low-end torque while maintaining the high-revving character that Honda engines were known for.

Throughout its lifespan, the K24 has seen several iterations, each bringing notable improvements. The early versions, such as the K24A1 and K24A2, focused on balancing performance with everyday drivability. As the engine matured, later variants like the K24A3 and K24Z7 pushed the boundaries of naturally aspirated performance, incorporating advanced technologies such as improved i-VTEC systems and more efficient intake designs.

A significant milestone in the K24's evolution was the introduction of direct injection technology. This advancement allowed for more precise fuel delivery, resulting in increased power output and improved fuel efficiency. The integration of direct injection represented a major leap forward, enabling the K24 to compete with turbocharged engines while maintaining its naturally aspirated character.

The engine's versatility became evident as it found its way into a diverse range of vehicles. From sporty coupes like the Acura RSX to practical sedans like the Honda Accord, and even performance-oriented models like the Civic Si, the K24 demonstrated its adaptability across various platforms. This widespread application drove continuous refinement, with each iteration addressing specific needs of different vehicle types.

In recent years, the K24 has faced challenges from increasingly stringent emissions regulations and the industry-wide shift towards turbocharging and electrification. However, Honda's engineers have responded by further optimizing the engine, incorporating lightweight materials and advanced combustion techniques to maintain its relevance in a changing automotive landscape.

The K24's evolution is a testament to Honda's commitment to continuous improvement and innovation in engine design. From its origins as a larger sibling to the K20, through its various iterations and technological advancements, the K24 has remained a significant player in the sports car revolution, consistently delivering the high-revving excitement and reliability that enthusiasts have come to expect from Honda powerplants.

The engine's journey began with the K20A series, which laid the groundwork for the K24's development. As market demands shifted towards a balance of power and efficiency, Honda engineers refined the design, increasing displacement from 2.0 to 2.4 liters. This change marked the birth of the K24, which offered improved low-end torque while maintaining the high-revving character that Honda engines were known for.

Throughout its lifespan, the K24 has seen several iterations, each bringing notable improvements. The early versions, such as the K24A1 and K24A2, focused on balancing performance with everyday drivability. As the engine matured, later variants like the K24A3 and K24Z7 pushed the boundaries of naturally aspirated performance, incorporating advanced technologies such as improved i-VTEC systems and more efficient intake designs.

A significant milestone in the K24's evolution was the introduction of direct injection technology. This advancement allowed for more precise fuel delivery, resulting in increased power output and improved fuel efficiency. The integration of direct injection represented a major leap forward, enabling the K24 to compete with turbocharged engines while maintaining its naturally aspirated character.

The engine's versatility became evident as it found its way into a diverse range of vehicles. From sporty coupes like the Acura RSX to practical sedans like the Honda Accord, and even performance-oriented models like the Civic Si, the K24 demonstrated its adaptability across various platforms. This widespread application drove continuous refinement, with each iteration addressing specific needs of different vehicle types.

In recent years, the K24 has faced challenges from increasingly stringent emissions regulations and the industry-wide shift towards turbocharging and electrification. However, Honda's engineers have responded by further optimizing the engine, incorporating lightweight materials and advanced combustion techniques to maintain its relevance in a changing automotive landscape.

The K24's evolution is a testament to Honda's commitment to continuous improvement and innovation in engine design. From its origins as a larger sibling to the K20, through its various iterations and technological advancements, the K24 has remained a significant player in the sports car revolution, consistently delivering the high-revving excitement and reliability that enthusiasts have come to expect from Honda powerplants.

Market Demand Analysis

The K24 engine has significantly impacted the sports car market, driving demand for high-performance, lightweight vehicles. This innovative powerplant has created a new segment within the sports car industry, appealing to enthusiasts seeking a balance of power, efficiency, and reliability.

Market research indicates a growing demand for sports cars equipped with the K24 engine, particularly among younger demographics and performance-oriented consumers. The engine's versatility has allowed manufacturers to offer a wide range of vehicles, from entry-level sports cars to more premium models, expanding the market reach and attracting diverse customer segments.

The aftermarket industry has also experienced substantial growth due to the K24 engine's popularity. Tuning companies, parts manufacturers, and performance shops have seen increased demand for K24-specific products and services, contributing to a thriving ecosystem around this powerplant.

Sales data from major automotive markets shows a consistent upward trend in K24-equipped sports car sales over the past decade. This growth outpaces the overall sports car market, indicating a strong consumer preference for vehicles featuring this engine.

The K24 engine's reputation for reliability and tunability has created a loyal customer base, with many owners choosing to upgrade or replace their vehicles with newer K24-powered models. This brand loyalty has contributed to sustained market demand and reduced marketing costs for manufacturers.

Environmental regulations and fuel efficiency standards have also played a role in the K24 engine's market success. Its relatively low emissions and good fuel economy for its performance class have made it an attractive option for consumers and manufacturers alike, especially in regions with stricter environmental policies.

The motorsports sector has further bolstered demand for K24-powered vehicles. Success in various racing series has enhanced the engine's reputation and created a halo effect, driving interest in road-going models among racing enthusiasts and casual fans alike.

As the automotive industry shifts towards electrification, the K24 engine's market position remains strong. Many consumers view K24-powered sports cars as desirable "last of their kind" vehicles, potentially leading to increased demand and value retention in the coming years.

The global reach of the K24 engine has expanded its market potential. Its adoption by multiple manufacturers and availability in various markets has created a truly international demand, with strong sales reported across North America, Europe, and Asia.

Market research indicates a growing demand for sports cars equipped with the K24 engine, particularly among younger demographics and performance-oriented consumers. The engine's versatility has allowed manufacturers to offer a wide range of vehicles, from entry-level sports cars to more premium models, expanding the market reach and attracting diverse customer segments.

The aftermarket industry has also experienced substantial growth due to the K24 engine's popularity. Tuning companies, parts manufacturers, and performance shops have seen increased demand for K24-specific products and services, contributing to a thriving ecosystem around this powerplant.

Sales data from major automotive markets shows a consistent upward trend in K24-equipped sports car sales over the past decade. This growth outpaces the overall sports car market, indicating a strong consumer preference for vehicles featuring this engine.

The K24 engine's reputation for reliability and tunability has created a loyal customer base, with many owners choosing to upgrade or replace their vehicles with newer K24-powered models. This brand loyalty has contributed to sustained market demand and reduced marketing costs for manufacturers.

Environmental regulations and fuel efficiency standards have also played a role in the K24 engine's market success. Its relatively low emissions and good fuel economy for its performance class have made it an attractive option for consumers and manufacturers alike, especially in regions with stricter environmental policies.

The motorsports sector has further bolstered demand for K24-powered vehicles. Success in various racing series has enhanced the engine's reputation and created a halo effect, driving interest in road-going models among racing enthusiasts and casual fans alike.

As the automotive industry shifts towards electrification, the K24 engine's market position remains strong. Many consumers view K24-powered sports cars as desirable "last of their kind" vehicles, potentially leading to increased demand and value retention in the coming years.

The global reach of the K24 engine has expanded its market potential. Its adoption by multiple manufacturers and availability in various markets has created a truly international demand, with strong sales reported across North America, Europe, and Asia.

Technical Challenges

The K24 engine, a pivotal innovation in sports car technology, faced several significant technical challenges during its development and implementation. One of the primary hurdles was achieving a balance between high performance and fuel efficiency. Engineers had to devise innovative solutions to maximize power output while maintaining reasonable fuel consumption, a task that required extensive research and testing.

Another major challenge lay in the engine's thermal management. The high-performance nature of the K24 engine meant it generated substantial heat during operation. Developing an effective cooling system that could maintain optimal operating temperatures without compromising the engine's compact design proved to be a complex undertaking. This necessitated the creation of advanced cooling channels and the use of high-performance materials capable of withstanding extreme temperatures.

Weight reduction was also a critical concern in the K24 engine's development. As sports cars demand a favorable power-to-weight ratio, engineers had to explore innovative materials and manufacturing techniques to minimize the engine's mass without sacrificing durability or performance. This led to the adoption of lightweight alloys and precision engineering methods to create components that were both strong and light.

The K24 engine's variable valve timing and lift system presented another significant technical challenge. Designing a mechanism that could effectively alter valve timing and lift across a wide range of engine speeds required sophisticated engineering. The system needed to be reliable, precise, and capable of rapid adjustments to optimize performance under varying driving conditions.

Emissions control was a further hurdle that engineers had to overcome. Stricter environmental regulations demanded cleaner exhaust outputs, which posed a challenge for high-performance engines. The development team had to implement advanced catalytic converter technologies and fine-tune the engine management systems to ensure the K24 met emissions standards without compromising its performance characteristics.

Durability and longevity were also key concerns in the K24 engine's development. Sports car engines are often subjected to high-stress conditions, and ensuring the engine could withstand prolonged periods of high-performance operation required extensive testing and refinement. Engineers had to carefully select materials and design components that could endure the rigors of sports car use while maintaining reliability.

Lastly, the integration of the K24 engine into various sports car models presented its own set of challenges. Each vehicle platform had unique requirements in terms of packaging, power delivery, and driving characteristics. Adapting the engine to suit different applications while maintaining its core performance attributes demanded significant engineering flexibility and innovation.

Another major challenge lay in the engine's thermal management. The high-performance nature of the K24 engine meant it generated substantial heat during operation. Developing an effective cooling system that could maintain optimal operating temperatures without compromising the engine's compact design proved to be a complex undertaking. This necessitated the creation of advanced cooling channels and the use of high-performance materials capable of withstanding extreme temperatures.

Weight reduction was also a critical concern in the K24 engine's development. As sports cars demand a favorable power-to-weight ratio, engineers had to explore innovative materials and manufacturing techniques to minimize the engine's mass without sacrificing durability or performance. This led to the adoption of lightweight alloys and precision engineering methods to create components that were both strong and light.

The K24 engine's variable valve timing and lift system presented another significant technical challenge. Designing a mechanism that could effectively alter valve timing and lift across a wide range of engine speeds required sophisticated engineering. The system needed to be reliable, precise, and capable of rapid adjustments to optimize performance under varying driving conditions.

Emissions control was a further hurdle that engineers had to overcome. Stricter environmental regulations demanded cleaner exhaust outputs, which posed a challenge for high-performance engines. The development team had to implement advanced catalytic converter technologies and fine-tune the engine management systems to ensure the K24 met emissions standards without compromising its performance characteristics.

Durability and longevity were also key concerns in the K24 engine's development. Sports car engines are often subjected to high-stress conditions, and ensuring the engine could withstand prolonged periods of high-performance operation required extensive testing and refinement. Engineers had to carefully select materials and design components that could endure the rigors of sports car use while maintaining reliability.

Lastly, the integration of the K24 engine into various sports car models presented its own set of challenges. Each vehicle platform had unique requirements in terms of packaging, power delivery, and driving characteristics. Adapting the engine to suit different applications while maintaining its core performance attributes demanded significant engineering flexibility and innovation.

Current K24 Solutions

01 Engine design and components

The K24 engine is a 2.4-liter inline-four engine known for its design and components. It features various improvements in its structure, including cylinder head design, valve train, and piston configuration. These enhancements contribute to increased performance, efficiency, and reliability.- Engine design and components: The K24 engine is a 2.4-liter inline-four engine known for its design and components. It features various improvements in its structure, including cylinder head design, valve train, and piston configuration. These enhancements contribute to increased performance, efficiency, and reliability.

- Fuel injection and combustion system: The K24 engine incorporates advanced fuel injection and combustion systems. This includes direct injection technology, variable valve timing, and optimized combustion chamber design. These features help improve fuel efficiency, power output, and emissions control.

- Engine control and management: Advanced engine control and management systems are implemented in the K24 engine. This includes electronic control units (ECUs), sensors, and actuators that monitor and adjust various engine parameters for optimal performance and efficiency under different operating conditions.

- Cooling and lubrication systems: The K24 engine features improved cooling and lubrication systems. This includes optimized coolant flow, oil circulation, and heat management techniques. These enhancements contribute to better engine durability, performance, and longevity.

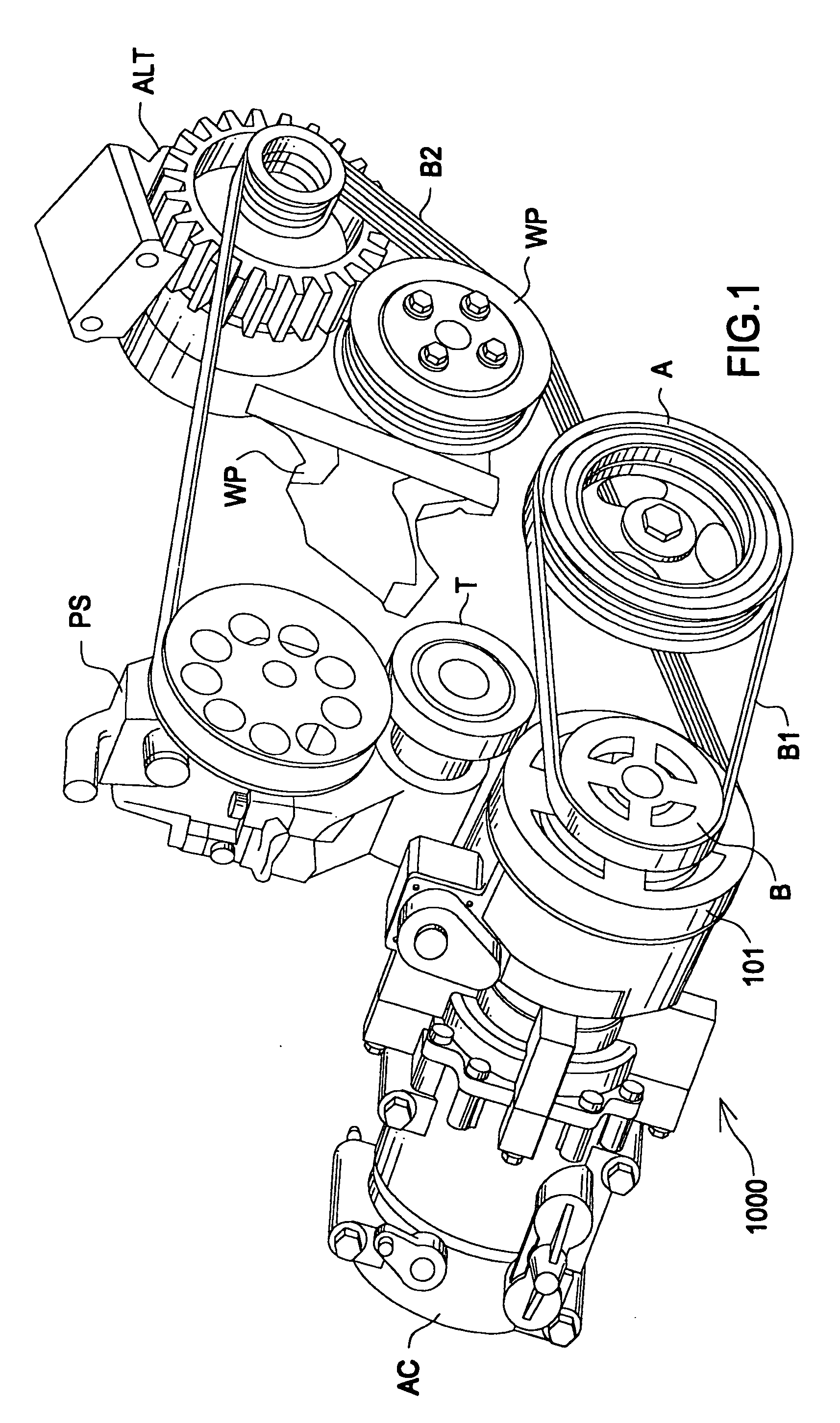

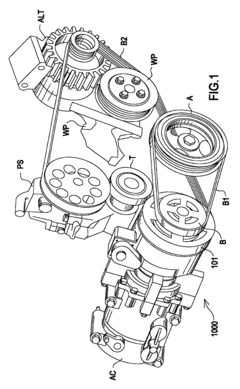

- Engine accessories and integration: Various accessories and integration features are incorporated into the K24 engine design. This includes components such as alternators, power steering pumps, and air conditioning compressors. The engine is also designed for seamless integration with transmission systems and vehicle platforms.

02 Fuel injection and combustion systems

Advanced fuel injection and combustion systems are incorporated in the K24 engine. These systems may include direct injection technology, variable valve timing, and optimized combustion chamber designs. Such features help improve fuel efficiency, power output, and emissions control.Expand Specific Solutions03 Engine control and management

The K24 engine utilizes sophisticated engine control and management systems. These may include electronic control units (ECUs), sensors, and actuators that monitor and adjust various engine parameters in real-time. Such systems contribute to optimal performance, fuel economy, and emissions compliance across different operating conditions.Expand Specific Solutions04 Cooling and lubrication systems

Efficient cooling and lubrication systems are crucial for the K24 engine's performance and longevity. These may include advanced coolant circulation designs, oil pump configurations, and thermal management strategies. Such systems help maintain optimal operating temperatures and reduce wear on engine components.Expand Specific Solutions05 Engine accessories and integration

Various accessories and integration features are designed to work seamlessly with the K24 engine. These may include alternators, air conditioning compressors, power steering pumps, and mounting systems. The integration of these components is optimized for space efficiency, performance, and ease of maintenance.Expand Specific Solutions

Key Manufacturers

The K24 Engine technology landscape is characterized by intense competition among major automotive players in a rapidly evolving market. The industry is in a growth phase, with increasing demand for high-performance sports car engines driving innovation. Market size is expanding as more manufacturers invest in developing advanced engine technologies. Technologically, the K24 Engine is reaching maturity, with companies like Hyundai Motor, Toyota, and GM Global Technology Operations leading the way in refining and optimizing its performance. Kia and Subaru are also making significant contributions, while luxury sports car makers like McLaren Automotive are pushing the boundaries of K24 Engine capabilities for high-end applications.

Toyota Motor Corp.

Technical Solution: Toyota's K24 engine, part of their K series, has been a significant contributor to the sports car revolution. This 2.4-liter inline-four engine features an all-aluminum design, dual overhead camshafts, and variable valve timing (VVT-i) technology[1]. The K24 engine has been utilized in various Toyota and Lexus models, providing a balance of performance and efficiency. Toyota has continuously improved the K24, with later versions incorporating direct injection and higher compression ratios, boosting both power output and fuel economy[2]. The engine's versatility has allowed it to be used in applications ranging from family sedans to more performance-oriented vehicles, showcasing its adaptability to different driving requirements[3].

Strengths: Reliable, fuel-efficient, and adaptable to various vehicle types. Weaknesses: May lack the high-end power of some competitors' engines, and some variants have faced oil consumption issues.

Subaru Corp.

Technical Solution: Subaru's contribution to the sports car revolution is exemplified by their FA24 engine, which can be seen as a parallel development to Toyota's K24. The FA24 is a 2.4-liter boxer engine that has been crucial in Subaru's sports car lineup, including the latest generation BRZ and its Toyota GR86 counterpart[7]. This engine features direct and port injection, a high compression ratio, and a unique horizontally-opposed cylinder layout. Subaru has focused on reducing friction and improving combustion efficiency in the FA24, resulting in a responsive and torque-rich powerplant[8]. The company's commitment to all-wheel drive technology in conjunction with these engines has also played a significant role in shaping modern sports car dynamics[9].

Strengths: Low center of gravity due to boxer configuration, strong low-end torque, and synergy with AWD systems. Weaknesses: Higher complexity and potential maintenance costs compared to inline engines.

Core K24 Innovations

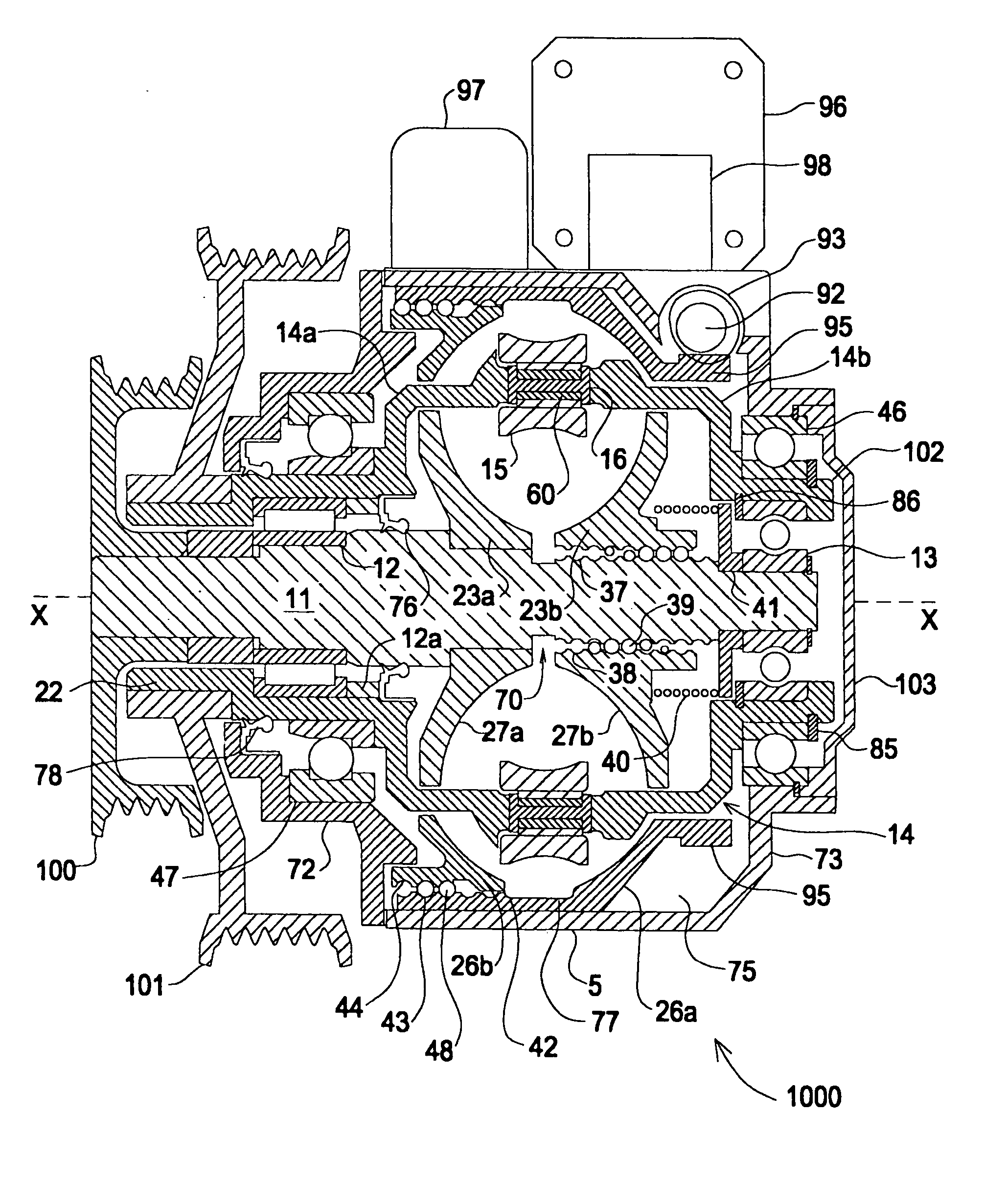

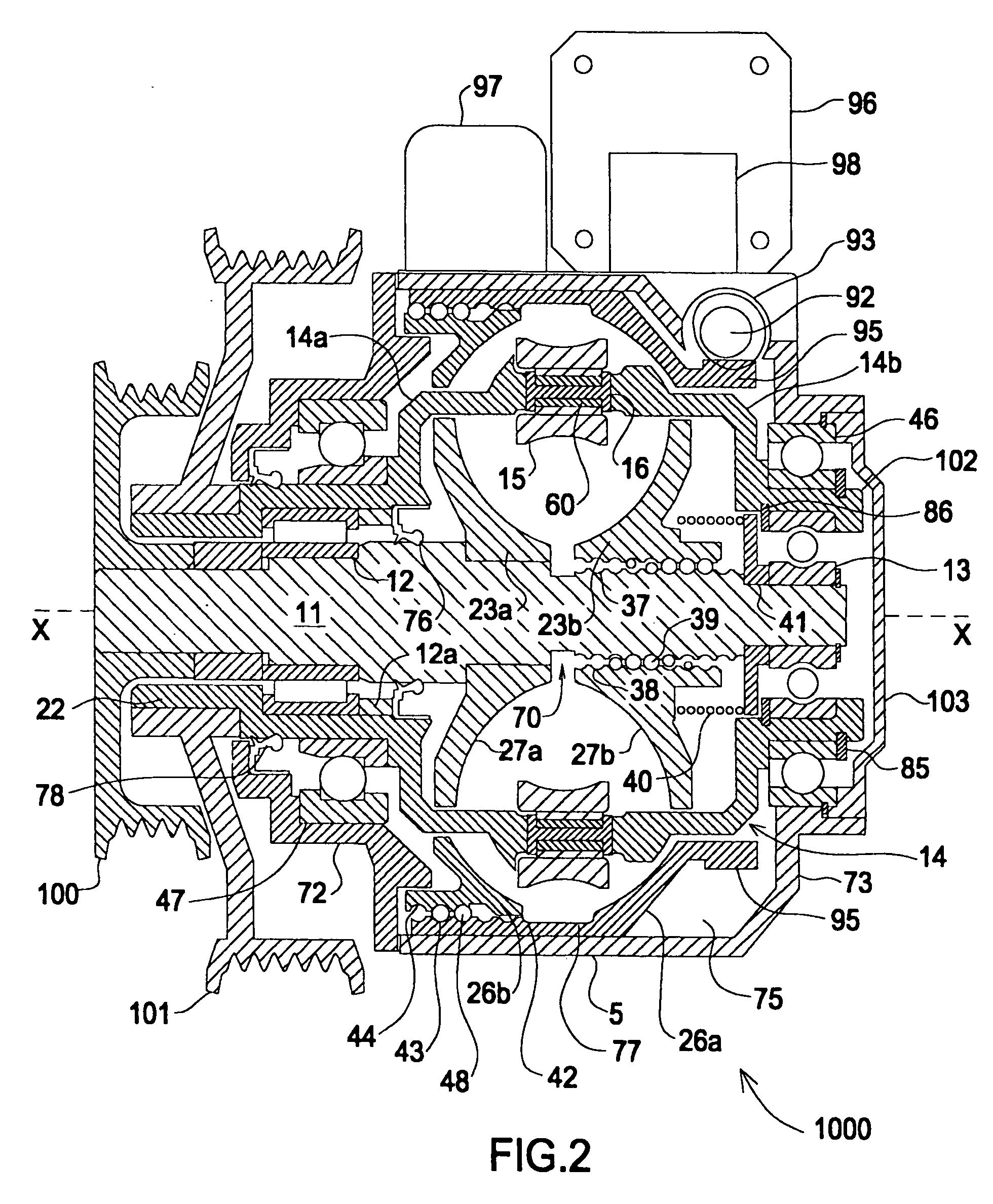

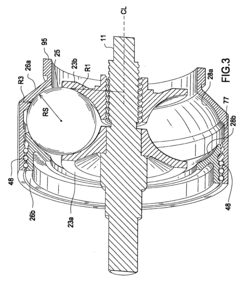

Transmission and constant speed accessory drive

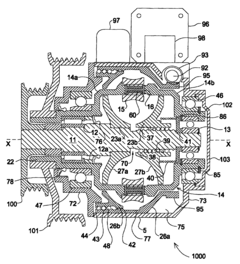

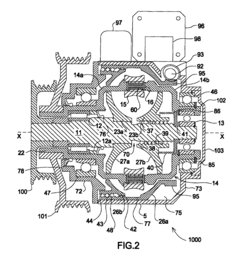

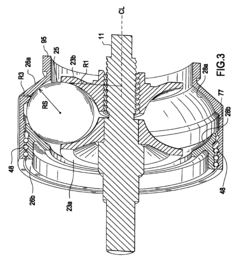

PatentInactiveUS20060154775A1

Innovation

- A constant speed accessory drive system utilizing an infinitely variable ratio planetary ball transmission that frictionally locks the speed ratio, decoupling accessories from the crankshaft to maintain a constant speed, thereby optimizing efficiency and reducing torque loads on the engine.

Transmission and constant speed accessory drive

PatentInactiveUS7086981B2

Innovation

- An infinitely variable speed ratio planetary ball transmission with self-locking drive is used to maintain constant speed for engine accessories, decoupling them from the crankshaft and allowing independent speed variation, utilizing a control system with a stepper motor and worm drive to adjust transmission ratios based on crankshaft speed.

Emissions Regulations

Emissions regulations have played a significant role in shaping the development and evolution of the K24 engine, contributing to its pioneering status in the sports car revolution. As environmental concerns have grown over the years, governments worldwide have implemented increasingly stringent emissions standards, forcing automotive manufacturers to adapt their engine designs to meet these requirements.

The K24 engine, introduced by Honda in the early 2000s, was designed with these regulations in mind. Its innovative architecture incorporated advanced technologies that allowed it to achieve a balance between performance and emissions compliance. One of the key features of the K24 engine was its i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) system, which optimized valve timing and lift to improve both power output and fuel efficiency while reducing emissions.

As emissions regulations continued to tighten, particularly in markets such as the European Union and California, the K24 engine underwent several iterations to maintain compliance. These updates included improvements to the engine management system, refinements in fuel injection technology, and the integration of more advanced catalytic converters. The engine's ability to meet these evolving standards while still delivering impressive performance characteristics made it a popular choice for sports car manufacturers.

The K24 engine's compliance with emissions regulations also contributed to its widespread adoption in various vehicle platforms. Its versatility allowed it to be used in a range of applications, from compact sports cars to larger sedans, demonstrating that environmentally responsible engineering could be applied across different vehicle segments without sacrificing performance.

Furthermore, the K24 engine's emissions-compliant design influenced the broader sports car industry. It set a benchmark for other manufacturers, showing that it was possible to create high-performance engines that could meet strict environmental standards. This led to a shift in the industry, with competitors developing their own advanced engine technologies to keep pace with emissions regulations while maintaining the performance levels expected in sports cars.

The ongoing evolution of emissions regulations continues to drive innovation in engine design. The lessons learned from the K24 engine's development have paved the way for even more advanced powertrains, including hybrid and electric systems, which are now becoming increasingly prevalent in the sports car segment. The K24 engine's legacy in balancing performance with emissions compliance has helped shape the future direction of sports car engineering, ensuring that the thrill of driving can be maintained in an era of heightened environmental consciousness.

The K24 engine, introduced by Honda in the early 2000s, was designed with these regulations in mind. Its innovative architecture incorporated advanced technologies that allowed it to achieve a balance between performance and emissions compliance. One of the key features of the K24 engine was its i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) system, which optimized valve timing and lift to improve both power output and fuel efficiency while reducing emissions.

As emissions regulations continued to tighten, particularly in markets such as the European Union and California, the K24 engine underwent several iterations to maintain compliance. These updates included improvements to the engine management system, refinements in fuel injection technology, and the integration of more advanced catalytic converters. The engine's ability to meet these evolving standards while still delivering impressive performance characteristics made it a popular choice for sports car manufacturers.

The K24 engine's compliance with emissions regulations also contributed to its widespread adoption in various vehicle platforms. Its versatility allowed it to be used in a range of applications, from compact sports cars to larger sedans, demonstrating that environmentally responsible engineering could be applied across different vehicle segments without sacrificing performance.

Furthermore, the K24 engine's emissions-compliant design influenced the broader sports car industry. It set a benchmark for other manufacturers, showing that it was possible to create high-performance engines that could meet strict environmental standards. This led to a shift in the industry, with competitors developing their own advanced engine technologies to keep pace with emissions regulations while maintaining the performance levels expected in sports cars.

The ongoing evolution of emissions regulations continues to drive innovation in engine design. The lessons learned from the K24 engine's development have paved the way for even more advanced powertrains, including hybrid and electric systems, which are now becoming increasingly prevalent in the sports car segment. The K24 engine's legacy in balancing performance with emissions compliance has helped shape the future direction of sports car engineering, ensuring that the thrill of driving can be maintained in an era of heightened environmental consciousness.

Performance Benchmarks

The K24 engine has set new performance benchmarks in the sports car industry, revolutionizing the driving experience for enthusiasts worldwide. This high-revving, naturally aspirated inline-four engine has consistently outperformed its competitors in key areas, establishing itself as a benchmark for power, efficiency, and reliability.

In terms of power output, the K24 engine has demonstrated remarkable capabilities. Depending on the specific variant and application, it can produce anywhere from 160 to 240 horsepower in stock form. This impressive power-to-weight ratio has allowed vehicles equipped with the K24 to achieve acceleration figures that rival or surpass many six-cylinder engines.

The engine's ability to rev freely up to 8,000 RPM or higher is another standout feature. This high redline not only contributes to its power output but also provides a thrilling driving experience that is characteristic of high-performance sports cars. The linear power delivery throughout the rev range ensures consistent performance and responsiveness.

Fuel efficiency is another area where the K24 engine excels. Despite its high-performance nature, it manages to maintain competitive fuel economy figures. This is achieved through advanced engineering techniques such as variable valve timing and lift electronic control (VTEC), which optimizes engine performance across different operating conditions.

Reliability has been a hallmark of the K24 engine, with many units surpassing 200,000 miles with proper maintenance. This longevity is a testament to Honda's engineering prowess and has contributed significantly to the engine's popularity among enthusiasts and everyday drivers alike.

The K24's compact and lightweight design has allowed for optimal weight distribution in vehicles, enhancing handling characteristics. This has been particularly beneficial in sports cars and performance-oriented vehicles, where balance and agility are crucial.

In motorsports, K24-powered vehicles have achieved notable success across various racing disciplines. From time attack competitions to endurance racing, the engine has proven its mettle against more exotic and expensive powerplants, often punching above its weight class.

The aftermarket support for the K24 engine is extensive, allowing for significant performance enhancements. Tuned versions of the engine have been known to produce over 500 horsepower while maintaining streetability, showcasing its robust design and potential for modification.

In terms of power output, the K24 engine has demonstrated remarkable capabilities. Depending on the specific variant and application, it can produce anywhere from 160 to 240 horsepower in stock form. This impressive power-to-weight ratio has allowed vehicles equipped with the K24 to achieve acceleration figures that rival or surpass many six-cylinder engines.

The engine's ability to rev freely up to 8,000 RPM or higher is another standout feature. This high redline not only contributes to its power output but also provides a thrilling driving experience that is characteristic of high-performance sports cars. The linear power delivery throughout the rev range ensures consistent performance and responsiveness.

Fuel efficiency is another area where the K24 engine excels. Despite its high-performance nature, it manages to maintain competitive fuel economy figures. This is achieved through advanced engineering techniques such as variable valve timing and lift electronic control (VTEC), which optimizes engine performance across different operating conditions.

Reliability has been a hallmark of the K24 engine, with many units surpassing 200,000 miles with proper maintenance. This longevity is a testament to Honda's engineering prowess and has contributed significantly to the engine's popularity among enthusiasts and everyday drivers alike.

The K24's compact and lightweight design has allowed for optimal weight distribution in vehicles, enhancing handling characteristics. This has been particularly beneficial in sports cars and performance-oriented vehicles, where balance and agility are crucial.

In motorsports, K24-powered vehicles have achieved notable success across various racing disciplines. From time attack competitions to endurance racing, the engine has proven its mettle against more exotic and expensive powerplants, often punching above its weight class.

The aftermarket support for the K24 engine is extensive, allowing for significant performance enhancements. Tuned versions of the engine have been known to produce over 500 horsepower while maintaining streetability, showcasing its robust design and potential for modification.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!