K24 Engine Contributions to Future Vehicle Technologies

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Background and Objectives

The K24 engine, developed by Honda, represents a significant milestone in automotive engineering. This 2.4-liter inline-four cylinder engine has been a cornerstone of Honda's powertrain lineup since its introduction in the early 2000s. Known for its reliability, efficiency, and performance, the K24 has undergone several iterations and improvements over the years, adapting to changing market demands and technological advancements.

The evolution of the K24 engine reflects broader trends in the automotive industry, including the push for improved fuel efficiency, reduced emissions, and enhanced performance. As global regulations become increasingly stringent, the K24 has been at the forefront of Honda's efforts to balance these often-competing demands. Its development has incorporated various technologies such as variable valve timing, direct injection, and lightweight materials to achieve these goals.

Looking towards the future, the K24 engine serves as a platform for exploring new technologies that will shape the next generation of vehicles. The objectives for its continued development align closely with the automotive industry's major trends: electrification, connectivity, and autonomous driving. While the K24 is primarily a combustion engine, its future iterations are expected to play a crucial role in hybrid powertrains, serving as a bridge between traditional combustion technology and fully electric vehicles.

One of the key objectives for the K24 engine's future development is to further improve its efficiency and reduce emissions without compromising performance. This involves exploring advanced combustion techniques, such as lean-burn technology and homogeneous charge compression ignition (HCCI). Additionally, there is a focus on integrating the K24 with electric motors in various hybrid configurations, ranging from mild hybrids to plug-in hybrid electric vehicles (PHEVs).

Another important goal is to enhance the K24's compatibility with future vehicle technologies. This includes improving its integration with advanced driver assistance systems (ADAS) and ensuring seamless operation with next-generation vehicle control units. The engine's electronic control systems are being developed to support increased connectivity and over-the-air updates, allowing for continuous optimization of performance and efficiency throughout the vehicle's lifecycle.

As the automotive industry moves towards more sustainable practices, the K24 engine's development also aims to incorporate more environmentally friendly materials and manufacturing processes. This includes exploring the use of recycled materials, reducing the overall environmental impact of engine production, and designing for easier recyclability at the end of the engine's life cycle.

The evolution of the K24 engine reflects broader trends in the automotive industry, including the push for improved fuel efficiency, reduced emissions, and enhanced performance. As global regulations become increasingly stringent, the K24 has been at the forefront of Honda's efforts to balance these often-competing demands. Its development has incorporated various technologies such as variable valve timing, direct injection, and lightweight materials to achieve these goals.

Looking towards the future, the K24 engine serves as a platform for exploring new technologies that will shape the next generation of vehicles. The objectives for its continued development align closely with the automotive industry's major trends: electrification, connectivity, and autonomous driving. While the K24 is primarily a combustion engine, its future iterations are expected to play a crucial role in hybrid powertrains, serving as a bridge between traditional combustion technology and fully electric vehicles.

One of the key objectives for the K24 engine's future development is to further improve its efficiency and reduce emissions without compromising performance. This involves exploring advanced combustion techniques, such as lean-burn technology and homogeneous charge compression ignition (HCCI). Additionally, there is a focus on integrating the K24 with electric motors in various hybrid configurations, ranging from mild hybrids to plug-in hybrid electric vehicles (PHEVs).

Another important goal is to enhance the K24's compatibility with future vehicle technologies. This includes improving its integration with advanced driver assistance systems (ADAS) and ensuring seamless operation with next-generation vehicle control units. The engine's electronic control systems are being developed to support increased connectivity and over-the-air updates, allowing for continuous optimization of performance and efficiency throughout the vehicle's lifecycle.

As the automotive industry moves towards more sustainable practices, the K24 engine's development also aims to incorporate more environmentally friendly materials and manufacturing processes. This includes exploring the use of recycled materials, reducing the overall environmental impact of engine production, and designing for easier recyclability at the end of the engine's life cycle.

Market Demand Analysis for K24-Powered Vehicles

The market demand for K24-powered vehicles has shown significant growth potential in recent years, driven by a combination of technological advancements, changing consumer preferences, and evolving regulatory landscapes. The K24 engine, known for its balance of performance and efficiency, has positioned itself as a versatile powerplant capable of meeting diverse market needs.

In the passenger vehicle segment, there is a growing demand for vehicles that offer a blend of power and fuel economy. The K24 engine's ability to deliver responsive performance while maintaining competitive fuel efficiency has made it an attractive option for manufacturers looking to meet stringent emissions standards without compromising on driving dynamics. This has led to increased adoption in mid-size sedans, compact SUVs, and crossover vehicles, which continue to dominate sales charts in many global markets.

The commercial vehicle sector has also shown interest in K24-powered solutions, particularly in light-duty trucks and vans. The engine's durability and torque characteristics make it suitable for applications that require reliable performance under varying load conditions. Fleet operators are increasingly considering K24-equipped vehicles as they seek to balance operational costs with environmental responsibilities.

Market research indicates that regions with stringent emissions regulations, such as Europe and parts of Asia, are likely to see the highest demand growth for K24-powered vehicles. These markets are characterized by consumers who prioritize fuel efficiency and environmental impact alongside performance metrics. North America, while traditionally favoring larger displacement engines, is showing a gradual shift towards more efficient powertrains, presenting an opportunity for K24 expansion.

The aftermarket and performance tuning sectors have also contributed to the demand for K24 engines. The engine's robust design and potential for modification have made it popular among enthusiasts, leading to a thriving ecosystem of aftermarket parts and services. This secondary market not only drives direct sales but also enhances the engine's reputation and desirability in stock form.

Looking ahead, the market for K24-powered vehicles is expected to evolve in response to emerging trends in electrification and hybridization. There is growing interest in hybrid powertrains that combine the K24 engine with electric motors, offering improved fuel economy and reduced emissions while maintaining the reliability and range of conventional powertrains. This hybrid approach could extend the market relevance of the K24 engine as the automotive industry transitions towards full electrification.

However, the long-term market demand for K24-powered vehicles will likely face challenges from the accelerating shift towards electric vehicles. As battery technology improves and charging infrastructure expands, consumer preferences may increasingly favor fully electric solutions. Manufacturers and suppliers in the K24 ecosystem will need to adapt their strategies to remain competitive in this changing landscape.

In the passenger vehicle segment, there is a growing demand for vehicles that offer a blend of power and fuel economy. The K24 engine's ability to deliver responsive performance while maintaining competitive fuel efficiency has made it an attractive option for manufacturers looking to meet stringent emissions standards without compromising on driving dynamics. This has led to increased adoption in mid-size sedans, compact SUVs, and crossover vehicles, which continue to dominate sales charts in many global markets.

The commercial vehicle sector has also shown interest in K24-powered solutions, particularly in light-duty trucks and vans. The engine's durability and torque characteristics make it suitable for applications that require reliable performance under varying load conditions. Fleet operators are increasingly considering K24-equipped vehicles as they seek to balance operational costs with environmental responsibilities.

Market research indicates that regions with stringent emissions regulations, such as Europe and parts of Asia, are likely to see the highest demand growth for K24-powered vehicles. These markets are characterized by consumers who prioritize fuel efficiency and environmental impact alongside performance metrics. North America, while traditionally favoring larger displacement engines, is showing a gradual shift towards more efficient powertrains, presenting an opportunity for K24 expansion.

The aftermarket and performance tuning sectors have also contributed to the demand for K24 engines. The engine's robust design and potential for modification have made it popular among enthusiasts, leading to a thriving ecosystem of aftermarket parts and services. This secondary market not only drives direct sales but also enhances the engine's reputation and desirability in stock form.

Looking ahead, the market for K24-powered vehicles is expected to evolve in response to emerging trends in electrification and hybridization. There is growing interest in hybrid powertrains that combine the K24 engine with electric motors, offering improved fuel economy and reduced emissions while maintaining the reliability and range of conventional powertrains. This hybrid approach could extend the market relevance of the K24 engine as the automotive industry transitions towards full electrification.

However, the long-term market demand for K24-powered vehicles will likely face challenges from the accelerating shift towards electric vehicles. As battery technology improves and charging infrastructure expands, consumer preferences may increasingly favor fully electric solutions. Manufacturers and suppliers in the K24 ecosystem will need to adapt their strategies to remain competitive in this changing landscape.

K24 Engine Current Status and Challenges

The K24 engine, a prominent player in Honda's powertrain lineup, currently faces several challenges and opportunities in the rapidly evolving automotive landscape. As vehicle technologies advance towards electrification and increased efficiency, the K24 engine must adapt to remain relevant and competitive.

One of the primary challenges for the K24 engine is meeting increasingly stringent emissions regulations worldwide. While the engine has undergone several iterations to improve its efficiency and reduce emissions, further enhancements are necessary to comply with future standards. This includes optimizing combustion processes, reducing friction losses, and implementing advanced aftertreatment systems.

Fuel efficiency remains a critical focus area for the K24 engine. As consumers and regulators demand better fuel economy, the engine must continue to evolve to deliver improved performance while consuming less fuel. This challenge is compounded by the need to maintain or enhance power output and drivability, which often conflicts with efficiency goals.

The rise of hybrid and electric powertrains presents both a challenge and an opportunity for the K24 engine. While pure electric vehicles are gaining market share, hybrid systems still rely on efficient internal combustion engines. The K24 engine must be adapted to work seamlessly in hybrid configurations, potentially serving as a range extender or part of a plug-in hybrid system.

Durability and reliability continue to be crucial factors in the K24 engine's success. As vehicles are expected to last longer and operate under various conditions, the engine must maintain its reputation for robustness while incorporating new technologies and materials.

Manufacturing and cost considerations pose additional challenges. As new technologies are integrated, production processes must be updated to maintain efficiency and keep costs competitive. This includes exploring new materials and manufacturing techniques that can enhance performance without significantly increasing production expenses.

The K24 engine also faces competition from alternative engine designs, such as smaller turbocharged engines that offer similar power with potentially better efficiency. To remain competitive, the K24 must leverage its strengths while addressing areas where rival engines may have an advantage.

Lastly, the engine must adapt to changing consumer preferences and market trends. This includes meeting demands for increased connectivity, reduced noise and vibration, and seamless integration with advanced driver assistance systems. The K24 engine's control systems and overall design must evolve to support these features while maintaining its core performance characteristics.

One of the primary challenges for the K24 engine is meeting increasingly stringent emissions regulations worldwide. While the engine has undergone several iterations to improve its efficiency and reduce emissions, further enhancements are necessary to comply with future standards. This includes optimizing combustion processes, reducing friction losses, and implementing advanced aftertreatment systems.

Fuel efficiency remains a critical focus area for the K24 engine. As consumers and regulators demand better fuel economy, the engine must continue to evolve to deliver improved performance while consuming less fuel. This challenge is compounded by the need to maintain or enhance power output and drivability, which often conflicts with efficiency goals.

The rise of hybrid and electric powertrains presents both a challenge and an opportunity for the K24 engine. While pure electric vehicles are gaining market share, hybrid systems still rely on efficient internal combustion engines. The K24 engine must be adapted to work seamlessly in hybrid configurations, potentially serving as a range extender or part of a plug-in hybrid system.

Durability and reliability continue to be crucial factors in the K24 engine's success. As vehicles are expected to last longer and operate under various conditions, the engine must maintain its reputation for robustness while incorporating new technologies and materials.

Manufacturing and cost considerations pose additional challenges. As new technologies are integrated, production processes must be updated to maintain efficiency and keep costs competitive. This includes exploring new materials and manufacturing techniques that can enhance performance without significantly increasing production expenses.

The K24 engine also faces competition from alternative engine designs, such as smaller turbocharged engines that offer similar power with potentially better efficiency. To remain competitive, the K24 must leverage its strengths while addressing areas where rival engines may have an advantage.

Lastly, the engine must adapt to changing consumer preferences and market trends. This includes meeting demands for increased connectivity, reduced noise and vibration, and seamless integration with advanced driver assistance systems. The K24 engine's control systems and overall design must evolve to support these features while maintaining its core performance characteristics.

Current K24 Engine Solutions

01 Engine design and structure

The K24 engine is a 2.4-liter inline-four engine known for its compact design and efficient performance. It features a lightweight aluminum block and cylinder head, dual overhead camshafts, and i-VTEC technology for improved power and fuel efficiency. The engine's design allows for easy integration into various vehicle models and applications.- Engine design and components: The K24 engine is a 2.4-liter inline-four engine known for its design and components. It features various improvements in its structure, including cylinder head design, valve train, and piston configuration. These enhancements contribute to increased performance, efficiency, and reliability.

- Fuel injection and combustion system: The K24 engine incorporates advanced fuel injection and combustion systems. This includes direct injection technology, variable valve timing, and optimized combustion chamber design. These features help improve fuel efficiency, power output, and emissions control.

- Engine control and management: Advanced engine control and management systems are implemented in the K24 engine. This includes electronic control units (ECUs), sensors, and actuators that monitor and adjust various engine parameters for optimal performance and efficiency under different operating conditions.

- Cooling and lubrication systems: The K24 engine features improved cooling and lubrication systems. This includes optimized coolant flow, oil circulation, and heat management techniques. These enhancements contribute to better engine durability, performance, and longevity.

- Engine accessories and integration: Various accessories and integration features are incorporated into the K24 engine design. This includes components such as alternators, power steering pumps, and air conditioning compressors. The integration of these accessories is optimized for space efficiency and overall engine performance.

02 Fuel injection and combustion system

The K24 engine utilizes advanced fuel injection and combustion systems to optimize performance and emissions. This includes direct fuel injection technology, variable valve timing, and precise fuel metering for improved combustion efficiency. The engine's combustion chamber design and piston geometry contribute to better fuel atomization and combustion characteristics.Expand Specific Solutions03 Engine control and management

Advanced engine control systems are employed in the K24 engine to manage various parameters such as fuel injection timing, ignition timing, and valve timing. These systems utilize sensors and electronic control units to optimize engine performance, fuel efficiency, and emissions across different operating conditions. The engine management system also incorporates diagnostic features for improved reliability and maintenance.Expand Specific Solutions04 Engine cooling and lubrication

The K24 engine features efficient cooling and lubrication systems to maintain optimal operating temperatures and reduce friction. This includes a high-capacity water pump, strategically placed coolant passages, and an oil cooler for improved heat dissipation. The engine's lubrication system is designed to provide consistent oil flow to critical components, enhancing durability and performance.Expand Specific Solutions05 Engine accessories and integration

Various accessories and components are integrated into the K24 engine design to enhance its functionality and adaptability. This includes components such as alternators, power steering pumps, and air conditioning compressors. The engine's compact design allows for efficient packaging and integration with transmission systems and other vehicle components, making it suitable for a wide range of applications.Expand Specific Solutions

Key Players in K24 Engine Development

The K24 Engine technology landscape is characterized by intense competition among established automotive manufacturers and emerging players. The industry is in a transitional phase, with a growing focus on future vehicle technologies. The market size for advanced engine technologies is expanding rapidly, driven by increasing demand for fuel-efficient and environmentally friendly vehicles. Companies like Hyundai Motor, Toyota, and GM are at the forefront of K24 Engine development, leveraging their extensive R&D capabilities and market presence. Emerging players such as Geely and Chery are also making significant strides, particularly in the Chinese market. The technology's maturity varies, with some companies like Hyundai KEFICO and Aisin AW specializing in specific components, while others focus on integrated systems.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai's K24 engine technology focuses on improving efficiency and reducing emissions for future vehicles. The company has developed a Continuously Variable Valve Duration (CVVD) system for the K24 engine, which optimizes valve timing for different driving conditions[1]. This innovation allows for a 4% increase in performance, 5% improvement in fuel efficiency, and a 12% reduction in emissions[2]. Hyundai is also exploring the integration of mild hybrid systems with the K24 engine to further enhance fuel economy and reduce environmental impact. The company is investing in advanced materials and manufacturing processes to reduce engine weight and improve thermal efficiency, contributing to overall vehicle performance and sustainability[3].

Strengths: Innovative CVVD technology, improved fuel efficiency, and reduced emissions. Weaknesses: Potential complexity in manufacturing and maintenance of advanced systems.

Toyota Motor Corp.

Technical Solution: Toyota's approach to future vehicle technologies involving the K24 engine focuses on hybridization and electrification. The company is developing a new generation of hybrid powertrains that incorporate the K24 engine, aiming to achieve higher thermal efficiency and lower emissions. Toyota's engineers are working on advanced combustion techniques, such as lean-burn technology and high compression ratios, to maximize the engine's efficiency[4]. Additionally, Toyota is exploring the use of hydrogen as a fuel in modified K24 engines, potentially offering a clean alternative to traditional gasoline[5]. The company is also investing in artificial intelligence and machine learning to optimize engine performance and fuel consumption in real-time driving conditions[6].

Strengths: Strong hybrid technology integration, exploration of alternative fuels. Weaknesses: Potential high costs associated with advanced technology development.

Key K24 Engine Innovations

Internal combustion engine system with novel alternative fuel injection system and method thereof

PatentPendingIN202441006619A

Innovation

- A novel alternative fuel injection system that incorporates intelligent sensors and real-time control algorithms, designed to optimize combustion processes within internal combustion engines, allowing for the seamless integration of various alternative fuels and adapting to diverse driving conditions, thereby enhancing efficiency and reducing emissions.

Energy management method and system for model predictive control of hybrid electric vehicle

PatentActiveCN118182439A

Innovation

- A multi-feature deep neural network prediction speed model is used, combined with multivariate data for online model prediction control, and the optimal reference trajectory of the battery SOC is designed through a real-time prediction error adjustment mechanism and network connection technology to optimize the power distribution of the motor and engine.

Environmental Impact of K24 Engine

The K24 engine, known for its reliability and efficiency, has made significant contributions to reducing the environmental impact of vehicles. This engine's design incorporates several features that align with the growing emphasis on sustainability in the automotive industry. One of the key environmental benefits of the K24 engine is its improved fuel efficiency compared to its predecessors. By optimizing combustion processes and reducing internal friction, the K24 engine achieves better fuel economy, which directly translates to lower carbon dioxide emissions per mile driven.

The engine's lightweight construction also plays a crucial role in its environmental performance. By utilizing advanced materials and design techniques, the overall weight of the engine is reduced, contributing to improved vehicle efficiency and reduced fuel consumption. This weight reduction not only benefits fuel economy but also potentially extends the lifespan of other vehicle components, reducing the overall environmental impact associated with manufacturing and replacing parts.

Another notable aspect of the K24 engine's environmental impact is its compliance with stringent emission standards. The engine incorporates advanced emission control technologies, such as improved catalytic converters and precise fuel injection systems, which effectively reduce harmful pollutants like nitrogen oxides (NOx) and particulate matter. This compliance ensures that vehicles equipped with the K24 engine meet or exceed regulatory requirements in various markets, contributing to improved air quality in urban areas.

The K24 engine's durability and longevity also factor into its overall environmental impact. With proper maintenance, these engines are known to have extended service lives, reducing the frequency of engine replacements and the associated environmental costs of manufacturing new engines. This longevity not only benefits individual vehicle owners but also contributes to a reduction in the automotive industry's overall resource consumption and waste generation.

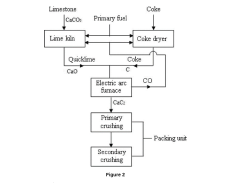

In terms of manufacturing, the production processes for the K24 engine have been optimized to reduce energy consumption and minimize waste. Advanced manufacturing techniques and lean production principles have been implemented to improve efficiency and reduce the environmental footprint of engine production. Additionally, the use of recyclable materials in certain engine components contributes to the circular economy, allowing for more sustainable end-of-life management of these engines.

Looking towards the future, the K24 engine serves as a platform for ongoing environmental improvements. Its adaptability to hybrid powertrains and potential for further efficiency enhancements through software updates and minor hardware modifications positions it as a bridge technology in the transition towards more sustainable transportation solutions. As automotive technologies continue to evolve, the lessons learned from the K24 engine's development and implementation will undoubtedly inform the design of even more environmentally friendly propulsion systems in the years to come.

The engine's lightweight construction also plays a crucial role in its environmental performance. By utilizing advanced materials and design techniques, the overall weight of the engine is reduced, contributing to improved vehicle efficiency and reduced fuel consumption. This weight reduction not only benefits fuel economy but also potentially extends the lifespan of other vehicle components, reducing the overall environmental impact associated with manufacturing and replacing parts.

Another notable aspect of the K24 engine's environmental impact is its compliance with stringent emission standards. The engine incorporates advanced emission control technologies, such as improved catalytic converters and precise fuel injection systems, which effectively reduce harmful pollutants like nitrogen oxides (NOx) and particulate matter. This compliance ensures that vehicles equipped with the K24 engine meet or exceed regulatory requirements in various markets, contributing to improved air quality in urban areas.

The K24 engine's durability and longevity also factor into its overall environmental impact. With proper maintenance, these engines are known to have extended service lives, reducing the frequency of engine replacements and the associated environmental costs of manufacturing new engines. This longevity not only benefits individual vehicle owners but also contributes to a reduction in the automotive industry's overall resource consumption and waste generation.

In terms of manufacturing, the production processes for the K24 engine have been optimized to reduce energy consumption and minimize waste. Advanced manufacturing techniques and lean production principles have been implemented to improve efficiency and reduce the environmental footprint of engine production. Additionally, the use of recyclable materials in certain engine components contributes to the circular economy, allowing for more sustainable end-of-life management of these engines.

Looking towards the future, the K24 engine serves as a platform for ongoing environmental improvements. Its adaptability to hybrid powertrains and potential for further efficiency enhancements through software updates and minor hardware modifications positions it as a bridge technology in the transition towards more sustainable transportation solutions. As automotive technologies continue to evolve, the lessons learned from the K24 engine's development and implementation will undoubtedly inform the design of even more environmentally friendly propulsion systems in the years to come.

K24 Integration with Hybrid Systems

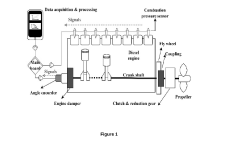

The integration of the K24 engine with hybrid systems represents a significant advancement in automotive technology, combining the efficiency of electric powertrains with the reliability and range of internal combustion engines. This integration leverages the K24's robust design and adaptability to create a synergistic powertrain that addresses the growing demand for fuel-efficient and environmentally friendly vehicles.

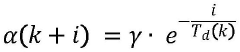

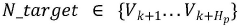

In hybrid configurations, the K24 engine typically serves as the primary power source, working in tandem with one or more electric motors. This arrangement allows for optimal power distribution, with the electric motors providing instant torque for low-speed operations and acceleration, while the K24 engine efficiently handles sustained high-speed driving and recharging of the hybrid battery system.

One of the key advantages of integrating the K24 with hybrid systems is its compatibility with various hybrid architectures. In parallel hybrid setups, the K24 can directly power the wheels alongside the electric motor, offering seamless power transitions and improved fuel economy. In series hybrid configurations, the K24 acts as a generator, charging the battery pack and providing electricity to the electric drive motors, which solely propel the vehicle.

The K24's variable valve timing and lift electronic control (VTEC) system plays a crucial role in its hybrid integration. This technology allows for precise control of engine performance, optimizing power output and fuel efficiency based on driving conditions and hybrid system demands. When coupled with advanced hybrid control units, the K24 can operate in its most efficient range, further enhancing overall system performance.

Moreover, the integration of the K24 with hybrid systems has led to the development of innovative energy recovery mechanisms. During deceleration and braking, the electric motors can function as generators, converting kinetic energy into electrical energy to recharge the hybrid battery. This regenerative braking system, working in conjunction with the K24's efficient operation, significantly improves the vehicle's overall energy utilization.

The K24's durability and reliability make it an ideal candidate for hybrid applications, where frequent start-stop cycles and varying load conditions are common. Its robust construction ensures longevity and consistent performance, even under the demanding conditions of hybrid operation. Additionally, the K24's compact design allows for flexible packaging solutions, enabling automakers to optimize vehicle layout and weight distribution in hybrid models.

As hybrid technologies continue to evolve, the K24 engine's integration capabilities are expected to expand further. Future developments may include more advanced thermal management systems, improved combustion strategies, and enhanced electronic control units that can better harmonize the operation of the K24 with electric powertrains. These advancements will likely result in even greater efficiency gains and reduced emissions, solidifying the K24's role in the transition towards more sustainable transportation solutions.

In hybrid configurations, the K24 engine typically serves as the primary power source, working in tandem with one or more electric motors. This arrangement allows for optimal power distribution, with the electric motors providing instant torque for low-speed operations and acceleration, while the K24 engine efficiently handles sustained high-speed driving and recharging of the hybrid battery system.

One of the key advantages of integrating the K24 with hybrid systems is its compatibility with various hybrid architectures. In parallel hybrid setups, the K24 can directly power the wheels alongside the electric motor, offering seamless power transitions and improved fuel economy. In series hybrid configurations, the K24 acts as a generator, charging the battery pack and providing electricity to the electric drive motors, which solely propel the vehicle.

The K24's variable valve timing and lift electronic control (VTEC) system plays a crucial role in its hybrid integration. This technology allows for precise control of engine performance, optimizing power output and fuel efficiency based on driving conditions and hybrid system demands. When coupled with advanced hybrid control units, the K24 can operate in its most efficient range, further enhancing overall system performance.

Moreover, the integration of the K24 with hybrid systems has led to the development of innovative energy recovery mechanisms. During deceleration and braking, the electric motors can function as generators, converting kinetic energy into electrical energy to recharge the hybrid battery. This regenerative braking system, working in conjunction with the K24's efficient operation, significantly improves the vehicle's overall energy utilization.

The K24's durability and reliability make it an ideal candidate for hybrid applications, where frequent start-stop cycles and varying load conditions are common. Its robust construction ensures longevity and consistent performance, even under the demanding conditions of hybrid operation. Additionally, the K24's compact design allows for flexible packaging solutions, enabling automakers to optimize vehicle layout and weight distribution in hybrid models.

As hybrid technologies continue to evolve, the K24 engine's integration capabilities are expected to expand further. Future developments may include more advanced thermal management systems, improved combustion strategies, and enhanced electronic control units that can better harmonize the operation of the K24 with electric powertrains. These advancements will likely result in even greater efficiency gains and reduced emissions, solidifying the K24's role in the transition towards more sustainable transportation solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!