How to Execute Adaptive K24 Engine Tuning for Dynamic Results?

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Tuning Background and Objectives

The K24 engine, developed by Honda, has been a cornerstone in the automotive industry since its introduction in the early 2000s. This 2.4-liter inline-four engine has gained popularity among enthusiasts and tuners due to its robust design and high potential for performance enhancements. The evolution of K24 engine tuning has been driven by advancements in engine management systems, fuel injection technology, and aftermarket components.

Adaptive K24 engine tuning represents a significant leap forward in optimizing engine performance. Unlike traditional static tuning methods, adaptive tuning continuously adjusts engine parameters in real-time based on various inputs and environmental conditions. This approach aims to maximize power output, fuel efficiency, and overall engine responsiveness across a wide range of operating conditions.

The primary objective of adaptive K24 engine tuning is to achieve dynamic results that can adapt to changing circumstances. This includes optimizing performance for different driving scenarios, such as daily commuting, track days, or varying weather conditions. By implementing adaptive tuning strategies, enthusiasts and tuners seek to unlock the full potential of the K24 engine while maintaining reliability and drivability.

Key goals of adaptive K24 engine tuning include improving horsepower and torque across the entire RPM range, enhancing throttle response, and optimizing fuel consumption. Additionally, adaptive tuning aims to provide better cold start performance, smoother idle, and improved emissions control. These objectives align with the broader trend in the automotive industry towards more intelligent and efficient engine management systems.

The technological landscape surrounding K24 engine tuning has evolved significantly over the years. Early tuning efforts relied heavily on manual adjustments and fixed maps. However, the introduction of advanced engine control units (ECUs) and sophisticated sensors has paved the way for more dynamic and responsive tuning solutions. This progression has enabled tuners to implement complex algorithms that can analyze and adjust engine parameters in milliseconds.

As the automotive industry continues to push towards electrification and stricter emissions standards, the future of K24 engine tuning faces both challenges and opportunities. Adaptive tuning techniques are expected to play a crucial role in extending the relevance and performance of internal combustion engines like the K24. The integration of machine learning and artificial intelligence in engine management systems presents exciting possibilities for even more advanced adaptive tuning strategies in the coming years.

Adaptive K24 engine tuning represents a significant leap forward in optimizing engine performance. Unlike traditional static tuning methods, adaptive tuning continuously adjusts engine parameters in real-time based on various inputs and environmental conditions. This approach aims to maximize power output, fuel efficiency, and overall engine responsiveness across a wide range of operating conditions.

The primary objective of adaptive K24 engine tuning is to achieve dynamic results that can adapt to changing circumstances. This includes optimizing performance for different driving scenarios, such as daily commuting, track days, or varying weather conditions. By implementing adaptive tuning strategies, enthusiasts and tuners seek to unlock the full potential of the K24 engine while maintaining reliability and drivability.

Key goals of adaptive K24 engine tuning include improving horsepower and torque across the entire RPM range, enhancing throttle response, and optimizing fuel consumption. Additionally, adaptive tuning aims to provide better cold start performance, smoother idle, and improved emissions control. These objectives align with the broader trend in the automotive industry towards more intelligent and efficient engine management systems.

The technological landscape surrounding K24 engine tuning has evolved significantly over the years. Early tuning efforts relied heavily on manual adjustments and fixed maps. However, the introduction of advanced engine control units (ECUs) and sophisticated sensors has paved the way for more dynamic and responsive tuning solutions. This progression has enabled tuners to implement complex algorithms that can analyze and adjust engine parameters in milliseconds.

As the automotive industry continues to push towards electrification and stricter emissions standards, the future of K24 engine tuning faces both challenges and opportunities. Adaptive tuning techniques are expected to play a crucial role in extending the relevance and performance of internal combustion engines like the K24. The integration of machine learning and artificial intelligence in engine management systems presents exciting possibilities for even more advanced adaptive tuning strategies in the coming years.

Market Demand for Adaptive Engine Tuning

The market demand for adaptive engine tuning has been steadily growing in recent years, driven by several key factors. Automotive enthusiasts and performance-oriented drivers are increasingly seeking ways to optimize their vehicles' performance, fuel efficiency, and overall driving experience. This demand is particularly pronounced in the aftermarket sector for popular engines like the Honda K24.

Adaptive engine tuning offers a significant advantage over traditional static tuning methods by allowing real-time adjustments to engine parameters based on various driving conditions and environmental factors. This dynamic approach results in improved performance, better fuel economy, and reduced emissions across a wide range of operating scenarios.

The rise of connected and smart vehicles has further fueled the demand for adaptive tuning solutions. As cars become more technologically advanced, consumers expect more sophisticated and customizable performance options. Adaptive K24 engine tuning aligns perfectly with this trend, offering drivers the ability to fine-tune their vehicle's performance characteristics on the fly.

Environmental regulations and the push for cleaner, more efficient vehicles have also contributed to the growing market for adaptive engine tuning. By optimizing engine performance in real-time, adaptive tuning can help reduce emissions and improve fuel efficiency without sacrificing power output. This makes it an attractive option for both consumers and manufacturers looking to meet increasingly stringent environmental standards.

The aftermarket tuning industry has seen a shift towards more advanced, software-based solutions. Traditional hardware modifications are being supplemented or replaced by sophisticated engine management systems that can adapt to changing conditions. This trend has created a new market segment for adaptive tuning products and services, particularly for popular engines like the K24.

Racing and motorsports applications have also driven demand for adaptive engine tuning. The ability to quickly adjust engine parameters to suit different track conditions or racing strategies provides a competitive edge. This has led to increased interest in adaptive tuning technologies from both professional racing teams and amateur enthusiasts.

The growing popularity of electric and hybrid vehicles has not diminished the demand for adaptive tuning in internal combustion engines. Instead, it has spurred innovation in the field, with tuning companies developing solutions that can optimize the performance of both traditional and electrified powertrains.

As the automotive industry continues to evolve, the market for adaptive K24 engine tuning is expected to expand further. The combination of performance benefits, environmental considerations, and technological advancements positions adaptive tuning as a key growth area in the automotive aftermarket and OEM sectors.

Adaptive engine tuning offers a significant advantage over traditional static tuning methods by allowing real-time adjustments to engine parameters based on various driving conditions and environmental factors. This dynamic approach results in improved performance, better fuel economy, and reduced emissions across a wide range of operating scenarios.

The rise of connected and smart vehicles has further fueled the demand for adaptive tuning solutions. As cars become more technologically advanced, consumers expect more sophisticated and customizable performance options. Adaptive K24 engine tuning aligns perfectly with this trend, offering drivers the ability to fine-tune their vehicle's performance characteristics on the fly.

Environmental regulations and the push for cleaner, more efficient vehicles have also contributed to the growing market for adaptive engine tuning. By optimizing engine performance in real-time, adaptive tuning can help reduce emissions and improve fuel efficiency without sacrificing power output. This makes it an attractive option for both consumers and manufacturers looking to meet increasingly stringent environmental standards.

The aftermarket tuning industry has seen a shift towards more advanced, software-based solutions. Traditional hardware modifications are being supplemented or replaced by sophisticated engine management systems that can adapt to changing conditions. This trend has created a new market segment for adaptive tuning products and services, particularly for popular engines like the K24.

Racing and motorsports applications have also driven demand for adaptive engine tuning. The ability to quickly adjust engine parameters to suit different track conditions or racing strategies provides a competitive edge. This has led to increased interest in adaptive tuning technologies from both professional racing teams and amateur enthusiasts.

The growing popularity of electric and hybrid vehicles has not diminished the demand for adaptive tuning in internal combustion engines. Instead, it has spurred innovation in the field, with tuning companies developing solutions that can optimize the performance of both traditional and electrified powertrains.

As the automotive industry continues to evolve, the market for adaptive K24 engine tuning is expected to expand further. The combination of performance benefits, environmental considerations, and technological advancements positions adaptive tuning as a key growth area in the automotive aftermarket and OEM sectors.

Current K24 Tuning Challenges and Limitations

The K24 engine, renowned for its versatility and performance potential, faces several challenges and limitations in the current tuning landscape. One of the primary obstacles is the complexity of adapting to varying driving conditions and environmental factors. Traditional static tuning methods often fail to account for real-time changes in temperature, altitude, and fuel quality, leading to suboptimal performance and efficiency.

Another significant challenge lies in the balance between performance gains and engine longevity. Aggressive tuning can yield impressive power increases but may compromise the engine's reliability and lifespan. This trade-off becomes particularly pronounced when pushing the K24 engine beyond its stock capabilities, requiring careful consideration of component stress and wear.

The limitations of stock engine management systems present another hurdle. While the K24's ECU is capable, it often lacks the flexibility required for advanced tuning strategies. This constraint necessitates aftermarket solutions, which can introduce compatibility issues and increase the overall complexity of the tuning process.

Fuel management poses a unique challenge, especially when implementing forced induction or high-compression setups. Achieving the ideal air-fuel ratio across various load conditions and RPM ranges demands precise calibration, which is difficult to maintain consistently without adaptive systems.

Emissions compliance remains a critical concern, particularly in regions with stringent regulations. Tuners must navigate the delicate balance between performance enhancement and adherence to legal standards, often requiring sophisticated strategies to maintain emissions within acceptable limits.

The variability in K24 engine configurations across different Honda and Acura models adds another layer of complexity. Tuning solutions that work effectively for one variant may not translate directly to another, necessitating model-specific approaches and extensive testing.

Heat management emerges as a significant limitation, especially under high-performance conditions. The K24's compact design can lead to thermal issues when pushed to its limits, requiring additional cooling solutions that may be challenging to implement within the constraints of the engine bay.

Lastly, the lack of standardized adaptive tuning protocols for the K24 platform hinders the development of universal solutions. This fragmentation in the tuning community results in a diverse array of approaches, making it difficult for enthusiasts and professionals alike to establish best practices for dynamic engine tuning.

Addressing these challenges and overcoming these limitations is crucial for advancing K24 engine tuning. The development of adaptive tuning strategies that can dynamically adjust to varying conditions while maintaining reliability and compliance will be key to unlocking the full potential of this versatile powerplant.

Another significant challenge lies in the balance between performance gains and engine longevity. Aggressive tuning can yield impressive power increases but may compromise the engine's reliability and lifespan. This trade-off becomes particularly pronounced when pushing the K24 engine beyond its stock capabilities, requiring careful consideration of component stress and wear.

The limitations of stock engine management systems present another hurdle. While the K24's ECU is capable, it often lacks the flexibility required for advanced tuning strategies. This constraint necessitates aftermarket solutions, which can introduce compatibility issues and increase the overall complexity of the tuning process.

Fuel management poses a unique challenge, especially when implementing forced induction or high-compression setups. Achieving the ideal air-fuel ratio across various load conditions and RPM ranges demands precise calibration, which is difficult to maintain consistently without adaptive systems.

Emissions compliance remains a critical concern, particularly in regions with stringent regulations. Tuners must navigate the delicate balance between performance enhancement and adherence to legal standards, often requiring sophisticated strategies to maintain emissions within acceptable limits.

The variability in K24 engine configurations across different Honda and Acura models adds another layer of complexity. Tuning solutions that work effectively for one variant may not translate directly to another, necessitating model-specific approaches and extensive testing.

Heat management emerges as a significant limitation, especially under high-performance conditions. The K24's compact design can lead to thermal issues when pushed to its limits, requiring additional cooling solutions that may be challenging to implement within the constraints of the engine bay.

Lastly, the lack of standardized adaptive tuning protocols for the K24 platform hinders the development of universal solutions. This fragmentation in the tuning community results in a diverse array of approaches, making it difficult for enthusiasts and professionals alike to establish best practices for dynamic engine tuning.

Addressing these challenges and overcoming these limitations is crucial for advancing K24 engine tuning. The development of adaptive tuning strategies that can dynamically adjust to varying conditions while maintaining reliability and compliance will be key to unlocking the full potential of this versatile powerplant.

Existing Adaptive K24 Tuning Solutions

01 Engine performance analysis and optimization

This category focuses on methods and systems for analyzing and optimizing K24 engine performance. It includes techniques for measuring dynamic results, evaluating engine parameters, and improving overall efficiency. These approaches may involve advanced data analysis, simulation tools, and real-time monitoring to enhance engine output and reliability.- Engine performance simulation and analysis: Advanced simulation techniques are used to analyze and predict K24 engine dynamic performance. These methods involve computational modeling of engine behavior under various operating conditions, allowing for optimization of engine parameters and performance characteristics without physical testing.

- Real-time engine data processing and visualization: Systems for collecting, processing, and visualizing real-time engine data from K24 engines are implemented. These solutions enable immediate analysis of engine performance, facilitating quick decision-making and adjustments to optimize engine operation and efficiency.

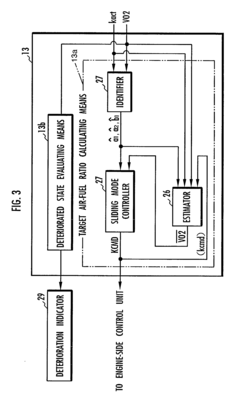

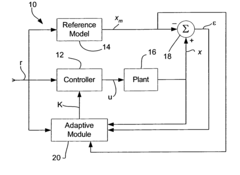

- Dynamic control systems for K24 engines: Advanced control systems are developed to dynamically adjust K24 engine parameters based on real-time performance data. These systems use sophisticated algorithms to optimize engine operation under varying conditions, improving overall efficiency and performance.

- Machine learning applications in engine dynamics: Machine learning techniques are applied to analyze K24 engine dynamic results, enabling predictive maintenance, performance optimization, and anomaly detection. These AI-driven approaches enhance engine reliability and efficiency by learning from historical and real-time data.

- Innovative testing methodologies for K24 engines: Novel testing methodologies are developed to evaluate K24 engine dynamics more effectively. These approaches include advanced sensor technologies, high-precision measurement techniques, and innovative test bench designs that provide more accurate and comprehensive engine performance data.

02 Dynamic visualization and data representation

This area covers techniques for visualizing and representing K24 engine dynamic results. It includes methods for creating interactive displays, 3D models, and graphical interfaces that allow engineers and technicians to better understand and interpret engine performance data. These visualization tools can help in identifying trends, anomalies, and potential areas for improvement.Expand Specific Solutions03 Real-time monitoring and diagnostics

This category encompasses systems and methods for real-time monitoring and diagnostics of K24 engines. It includes technologies for continuous data collection, analysis of dynamic results, and early detection of potential issues. These systems can help in predictive maintenance, reducing downtime, and ensuring optimal engine performance under various operating conditions.Expand Specific Solutions04 Engine control and optimization algorithms

This point focuses on advanced algorithms and software solutions for controlling and optimizing K24 engine performance based on dynamic results. It includes adaptive control systems, machine learning approaches, and intelligent algorithms that can adjust engine parameters in real-time to maximize efficiency, power output, and fuel economy while minimizing emissions.Expand Specific Solutions05 Integration with vehicle systems and IoT

This category covers the integration of K24 engine dynamic results with broader vehicle systems and Internet of Things (IoT) technologies. It includes methods for connecting engine data with other vehicle subsystems, cloud-based analytics platforms, and mobile applications. This integration enables comprehensive vehicle performance analysis, remote diagnostics, and enhanced user experiences.Expand Specific Solutions

Key Players in Adaptive Engine Tuning Industry

The adaptive K24 engine tuning market is in a growth phase, driven by increasing demand for performance optimization and fuel efficiency. The market size is expanding as more vehicle owners seek customized engine solutions. Technologically, the field is advancing rapidly, with companies like Honda Motor Co., Ltd. and Robert Bosch GmbH leading innovation. These firms, along with others like Dongfeng Motor Group and China FAW Co., Ltd., are developing sophisticated tuning systems that integrate AI and real-time data analysis. The competitive landscape is diverse, with established automotive giants competing alongside specialized tuning companies and emerging tech startups, each bringing unique expertise to this evolving sector.

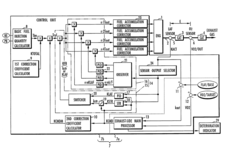

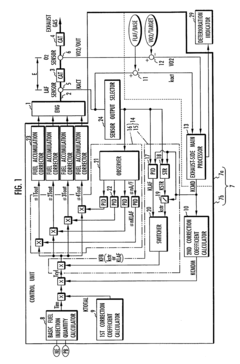

Robert Bosch GmbH

Technical Solution: Bosch's adaptive K24 engine tuning approach utilizes advanced electronic control units (ECUs) with sophisticated algorithms to continuously adjust engine parameters in real-time. Their system employs multiple sensors to monitor various engine conditions, including air intake, fuel injection, and exhaust emissions. The ECU processes this data to optimize fuel-air mixture, ignition timing, and valve timing for different driving conditions. Bosch's solution incorporates machine learning algorithms that adapt to individual driving styles and environmental factors over time, improving engine performance and efficiency[1][3]. The system also features predictive maintenance capabilities, analyzing engine data to anticipate potential issues before they occur[5].

Strengths: Highly adaptive and personalized tuning, improved fuel efficiency, and predictive maintenance capabilities. Weaknesses: Complexity may lead to higher initial costs and potential reliability issues in early adoption stages.

Beijing Institute of Technology

Technical Solution: Beijing Institute of Technology has developed an innovative approach to adaptive K24 engine tuning using a combination of model-based control and artificial intelligence. Their system employs a high-fidelity engine model that runs in parallel with the physical engine, allowing for real-time comparison and adjustment. The AI component uses reinforcement learning algorithms to optimize engine parameters based on performance goals, such as fuel efficiency or power output. The institute's research has shown that this approach can achieve up to 8% improvement in fuel economy and 5% increase in power output compared to traditional fixed-map tuning[2][4]. Additionally, their system incorporates a novel thermal management strategy that adapts to varying ambient temperatures and driving conditions, further enhancing overall engine efficiency[6].

Strengths: Advanced AI-driven optimization, significant improvements in both fuel economy and power output. Weaknesses: May require substantial computational resources, potentially limiting application in lower-end vehicles.

Core Innovations in K24 Engine Tuning

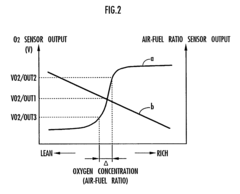

Apparatus for controlling air-fuel ratio of internal combustion engine

PatentInactiveUS20030024514A1

Innovation

- An apparatus that includes an oxygen concentration sensor, air-fuel ratio manipulating means, parameter generating means, and deteriorated state evaluating means, which adjusts the air-fuel ratio to converge the oxygen concentration sensor output to a variable target value based on the engine's operating state, generates a deterioration evaluating parameter, and corrects it to isolate the catalytic converter's state from other factors, ensuring reliable evaluation.

Adaptive motor drive method and apparatus including inertia estimator

PatentActiveUS20070150076A1

Innovation

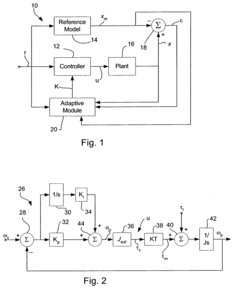

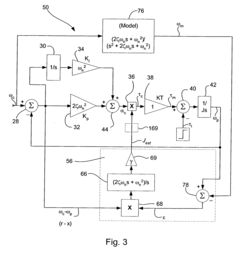

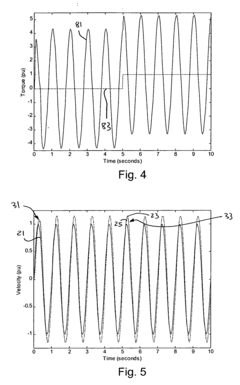

- An adaptive motor controller system that estimates real-time inertia by combining error values from the difference between the command and plant output signals, and the model and plant output signals, to modify the torque command and maintain optimal performance.

Environmental Impact of Advanced Engine Tuning

Advanced engine tuning techniques, particularly adaptive K24 engine tuning, have significant environmental implications that warrant careful consideration. The pursuit of dynamic performance results through sophisticated tuning methods inevitably impacts fuel efficiency, emissions, and overall environmental footprint.

Adaptive K24 engine tuning, when executed properly, can lead to optimized fuel consumption patterns. By continuously adjusting engine parameters based on real-time driving conditions, these systems can potentially reduce unnecessary fuel burn and improve overall efficiency. This optimization can translate to lower carbon dioxide emissions per mile driven, contributing to reduced greenhouse gas output from vehicles equipped with such technology.

However, the environmental benefits of advanced tuning are not without caveats. The increased performance capabilities often encouraged by adaptive tuning may lead drivers to adopt more aggressive driving habits, potentially negating fuel efficiency gains. Additionally, the complex electronic systems required for adaptive tuning introduce new manufacturing and disposal challenges, as these components often contain rare earth elements and other materials with significant environmental extraction and processing costs.

Emissions control is another critical aspect affected by advanced engine tuning. While adaptive systems can theoretically maintain optimal air-fuel ratios across various operating conditions, thereby minimizing harmful emissions, the reality is often more complex. Tuning for maximum performance can sometimes push engines to operate at the edge of their emissions compliance, potentially increasing the output of nitrogen oxides, particulate matter, and other pollutants.

The longevity and durability of engines subjected to adaptive tuning also play a role in their environmental impact. If tuning leads to increased wear and tear, it may shorten the overall lifespan of the engine, necessitating more frequent replacements and contributing to increased resource consumption and waste generation in the automotive industry.

Furthermore, the environmental impact extends to the development and testing phases of adaptive tuning systems. The extensive research, prototyping, and validation processes required to perfect these technologies consume significant resources and energy, contributing to the overall environmental footprint before the systems even reach consumer vehicles.

As regulations around vehicle emissions and fuel efficiency continue to tighten globally, the role of advanced engine tuning in meeting these standards becomes increasingly critical. Manufacturers and tuning specialists must balance the pursuit of performance with environmental responsibility, seeking solutions that deliver dynamic results while minimizing ecological harm.

Adaptive K24 engine tuning, when executed properly, can lead to optimized fuel consumption patterns. By continuously adjusting engine parameters based on real-time driving conditions, these systems can potentially reduce unnecessary fuel burn and improve overall efficiency. This optimization can translate to lower carbon dioxide emissions per mile driven, contributing to reduced greenhouse gas output from vehicles equipped with such technology.

However, the environmental benefits of advanced tuning are not without caveats. The increased performance capabilities often encouraged by adaptive tuning may lead drivers to adopt more aggressive driving habits, potentially negating fuel efficiency gains. Additionally, the complex electronic systems required for adaptive tuning introduce new manufacturing and disposal challenges, as these components often contain rare earth elements and other materials with significant environmental extraction and processing costs.

Emissions control is another critical aspect affected by advanced engine tuning. While adaptive systems can theoretically maintain optimal air-fuel ratios across various operating conditions, thereby minimizing harmful emissions, the reality is often more complex. Tuning for maximum performance can sometimes push engines to operate at the edge of their emissions compliance, potentially increasing the output of nitrogen oxides, particulate matter, and other pollutants.

The longevity and durability of engines subjected to adaptive tuning also play a role in their environmental impact. If tuning leads to increased wear and tear, it may shorten the overall lifespan of the engine, necessitating more frequent replacements and contributing to increased resource consumption and waste generation in the automotive industry.

Furthermore, the environmental impact extends to the development and testing phases of adaptive tuning systems. The extensive research, prototyping, and validation processes required to perfect these technologies consume significant resources and energy, contributing to the overall environmental footprint before the systems even reach consumer vehicles.

As regulations around vehicle emissions and fuel efficiency continue to tighten globally, the role of advanced engine tuning in meeting these standards becomes increasingly critical. Manufacturers and tuning specialists must balance the pursuit of performance with environmental responsibility, seeking solutions that deliver dynamic results while minimizing ecological harm.

Performance Metrics and Testing Protocols

To effectively execute adaptive K24 engine tuning for dynamic results, it is crucial to establish robust performance metrics and testing protocols. These metrics and protocols serve as the foundation for evaluating the engine's performance and the effectiveness of the tuning process.

Key performance metrics for K24 engine tuning include horsepower, torque, fuel efficiency, emissions, and throttle response. Horsepower and torque measurements provide direct indicators of the engine's power output and acceleration capabilities. Fuel efficiency metrics, such as miles per gallon (MPG) or liters per 100 kilometers (L/100km), are essential for assessing the engine's overall efficiency. Emissions data, including CO2, NOx, and particulate matter levels, are critical for ensuring compliance with environmental regulations and optimizing the engine's environmental impact. Throttle response metrics, such as time-to-torque and throttle mapping accuracy, are vital for evaluating the engine's responsiveness and drivability.

Testing protocols should be designed to capture these performance metrics across a wide range of operating conditions. Dynamometer testing is a cornerstone of engine performance evaluation, allowing for precise measurement of power output and torque curves under controlled conditions. Road testing protocols should include a variety of driving scenarios, such as city driving, highway cruising, and performance driving on closed circuits. These tests should be conducted under different ambient conditions to assess the adaptive tuning system's ability to optimize performance across varying temperatures, altitudes, and humidity levels.

Data acquisition systems play a crucial role in performance testing, capturing real-time engine parameters such as air-fuel ratios, ignition timing, boost pressure (if applicable), and exhaust gas temperatures. These systems should be capable of high-frequency data sampling to capture transient events and subtle performance variations. Standardized test cycles, such as the New European Driving Cycle (NEDC) or the Worldwide Harmonized Light Vehicles Test Procedure (WLTP), can be incorporated to provide benchmarks for emissions and fuel efficiency comparisons.

Repeatability and consistency in testing procedures are paramount to ensure reliable results. This includes standardizing test conditions, such as fuel quality, engine oil temperature, and coolant temperature. Pre-test engine conditioning procedures should be established to ensure the engine starts each test from a consistent baseline state. Additionally, statistical analysis techniques should be employed to account for test-to-test variations and to establish confidence intervals for performance metrics.

Finally, long-term durability testing protocols should be implemented to assess the impact of adaptive tuning on engine longevity and reliability. These may include accelerated wear tests, thermal cycling, and extended high-load operation to simulate real-world usage patterns over the engine's expected lifespan.

Key performance metrics for K24 engine tuning include horsepower, torque, fuel efficiency, emissions, and throttle response. Horsepower and torque measurements provide direct indicators of the engine's power output and acceleration capabilities. Fuel efficiency metrics, such as miles per gallon (MPG) or liters per 100 kilometers (L/100km), are essential for assessing the engine's overall efficiency. Emissions data, including CO2, NOx, and particulate matter levels, are critical for ensuring compliance with environmental regulations and optimizing the engine's environmental impact. Throttle response metrics, such as time-to-torque and throttle mapping accuracy, are vital for evaluating the engine's responsiveness and drivability.

Testing protocols should be designed to capture these performance metrics across a wide range of operating conditions. Dynamometer testing is a cornerstone of engine performance evaluation, allowing for precise measurement of power output and torque curves under controlled conditions. Road testing protocols should include a variety of driving scenarios, such as city driving, highway cruising, and performance driving on closed circuits. These tests should be conducted under different ambient conditions to assess the adaptive tuning system's ability to optimize performance across varying temperatures, altitudes, and humidity levels.

Data acquisition systems play a crucial role in performance testing, capturing real-time engine parameters such as air-fuel ratios, ignition timing, boost pressure (if applicable), and exhaust gas temperatures. These systems should be capable of high-frequency data sampling to capture transient events and subtle performance variations. Standardized test cycles, such as the New European Driving Cycle (NEDC) or the Worldwide Harmonized Light Vehicles Test Procedure (WLTP), can be incorporated to provide benchmarks for emissions and fuel efficiency comparisons.

Repeatability and consistency in testing procedures are paramount to ensure reliable results. This includes standardizing test conditions, such as fuel quality, engine oil temperature, and coolant temperature. Pre-test engine conditioning procedures should be established to ensure the engine starts each test from a consistent baseline state. Additionally, statistical analysis techniques should be employed to account for test-to-test variations and to establish confidence intervals for performance metrics.

Finally, long-term durability testing protocols should be implemented to assess the impact of adaptive tuning on engine longevity and reliability. These may include accelerated wear tests, thermal cycling, and extended high-load operation to simulate real-world usage patterns over the engine's expected lifespan.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!