How to Achieve Precision in Half Wave Rectifier Outputs?

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Half Wave Rectification Background and Objectives

Half wave rectification is a fundamental process in electrical engineering that converts alternating current (AC) to pulsating direct current (DC). This technique has been a cornerstone in power electronics since the early 20th century, with its origins tracing back to the invention of the vacuum tube diode by John Ambrose Fleming in 1904. The primary objective of half wave rectification is to extract the positive or negative half of an AC waveform, effectively creating a unidirectional current flow.

As technology has advanced, the demand for more precise and efficient rectification methods has grown significantly. In modern applications, ranging from power supplies to signal processing, the accuracy of half wave rectifier outputs has become increasingly critical. The pursuit of precision in half wave rectification is driven by the need for cleaner power conversion, reduced harmonic distortion, and improved overall system efficiency.

The evolution of half wave rectification technology has been marked by several key developments. Initially, vacuum tube diodes were used for rectification, but these were later replaced by solid-state semiconductor diodes in the mid-20th century. This transition brought about significant improvements in efficiency, reliability, and miniaturization. Further advancements in semiconductor technology, including the introduction of fast recovery diodes and Schottky diodes, have continued to enhance the performance of half wave rectifiers.

In recent years, the focus has shifted towards achieving greater precision in half wave rectifier outputs. This trend is driven by the increasing complexity of electronic systems and the stringent requirements of modern applications. Precision in half wave rectification is crucial for minimizing ripple voltage, reducing power loss, and ensuring stable DC output. These factors are particularly important in sensitive applications such as medical equipment, high-fidelity audio systems, and precision measurement devices.

The current technological landscape presents both challenges and opportunities in the quest for precision half wave rectification. Key areas of focus include improving diode characteristics, enhancing filtering techniques, and implementing advanced control strategies. Additionally, the integration of digital control and feedback mechanisms is opening new avenues for achieving unprecedented levels of precision in rectifier outputs.

As we look towards the future, the objectives for half wave rectification technology are centered on further improving accuracy, efficiency, and adaptability. This includes developing more sophisticated rectifier circuits that can dynamically adjust to varying load conditions, minimizing voltage drops across rectifying elements, and reducing electromagnetic interference. The ultimate goal is to create half wave rectifier systems that can deliver near-ideal DC outputs with minimal distortion and maximum energy efficiency.

As technology has advanced, the demand for more precise and efficient rectification methods has grown significantly. In modern applications, ranging from power supplies to signal processing, the accuracy of half wave rectifier outputs has become increasingly critical. The pursuit of precision in half wave rectification is driven by the need for cleaner power conversion, reduced harmonic distortion, and improved overall system efficiency.

The evolution of half wave rectification technology has been marked by several key developments. Initially, vacuum tube diodes were used for rectification, but these were later replaced by solid-state semiconductor diodes in the mid-20th century. This transition brought about significant improvements in efficiency, reliability, and miniaturization. Further advancements in semiconductor technology, including the introduction of fast recovery diodes and Schottky diodes, have continued to enhance the performance of half wave rectifiers.

In recent years, the focus has shifted towards achieving greater precision in half wave rectifier outputs. This trend is driven by the increasing complexity of electronic systems and the stringent requirements of modern applications. Precision in half wave rectification is crucial for minimizing ripple voltage, reducing power loss, and ensuring stable DC output. These factors are particularly important in sensitive applications such as medical equipment, high-fidelity audio systems, and precision measurement devices.

The current technological landscape presents both challenges and opportunities in the quest for precision half wave rectification. Key areas of focus include improving diode characteristics, enhancing filtering techniques, and implementing advanced control strategies. Additionally, the integration of digital control and feedback mechanisms is opening new avenues for achieving unprecedented levels of precision in rectifier outputs.

As we look towards the future, the objectives for half wave rectification technology are centered on further improving accuracy, efficiency, and adaptability. This includes developing more sophisticated rectifier circuits that can dynamically adjust to varying load conditions, minimizing voltage drops across rectifying elements, and reducing electromagnetic interference. The ultimate goal is to create half wave rectifier systems that can deliver near-ideal DC outputs with minimal distortion and maximum energy efficiency.

Market Demand for Precision Rectification

The market demand for precision rectification has been steadily growing across various industries, driven by the increasing need for accurate and reliable power conversion in electronic devices and systems. Half-wave rectifiers, while simple in design, play a crucial role in many applications where precise DC voltage is required from an AC input source.

In the consumer electronics sector, the demand for high-quality audio equipment has led to a surge in the need for precision rectification. Audiophiles and professional sound engineers require clean, low-noise power supplies for their amplifiers and audio processing units. This has created a niche market for precision half-wave rectifiers that can deliver stable, ripple-free DC voltage, essential for maintaining signal integrity and minimizing distortion in audio systems.

The automotive industry has also become a significant driver of demand for precision rectification. With the rapid advancement of electric and hybrid vehicles, there is an increasing need for efficient and accurate power conversion systems. Precision half-wave rectifiers are utilized in battery management systems, motor controllers, and various onboard electronic modules, where precise voltage regulation is critical for optimal performance and safety.

In the field of renewable energy, particularly solar power systems, the demand for precision rectification has seen substantial growth. Solar inverters require highly accurate rectification to efficiently convert the DC output from solar panels into AC power for grid integration or local use. The ability to achieve precision in half-wave rectifier outputs directly impacts the overall efficiency and reliability of solar energy systems.

The medical device industry represents another significant market for precision rectification. Medical imaging equipment, such as MRI machines and CT scanners, rely on stable and precise power supplies to ensure accurate diagnostics. Half-wave rectifiers with high precision outputs are essential components in these critical medical devices, where even minor fluctuations in power can lead to image artifacts or compromised diagnostic quality.

Industrial automation and control systems have also contributed to the growing demand for precision rectification. In manufacturing processes, precise voltage control is crucial for maintaining the accuracy of robotic systems, sensor networks, and programmable logic controllers. Half-wave rectifiers with high precision outputs are integral to ensuring consistent and reliable operation of these industrial systems.

The telecommunications sector, particularly with the ongoing rollout of 5G networks, has created a new avenue for precision rectification demand. Base stations and network equipment require highly stable power supplies to maintain signal quality and network reliability. Precision half-wave rectifiers play a vital role in power distribution units and backup power systems for these critical infrastructure components.

As the Internet of Things (IoT) continues to expand, the demand for low-power, high-precision rectification solutions has emerged. IoT devices often operate on limited power budgets, making efficient and accurate power conversion crucial. This has led to increased interest in miniaturized, high-performance half-wave rectifiers that can deliver precise outputs while minimizing power consumption.

In the consumer electronics sector, the demand for high-quality audio equipment has led to a surge in the need for precision rectification. Audiophiles and professional sound engineers require clean, low-noise power supplies for their amplifiers and audio processing units. This has created a niche market for precision half-wave rectifiers that can deliver stable, ripple-free DC voltage, essential for maintaining signal integrity and minimizing distortion in audio systems.

The automotive industry has also become a significant driver of demand for precision rectification. With the rapid advancement of electric and hybrid vehicles, there is an increasing need for efficient and accurate power conversion systems. Precision half-wave rectifiers are utilized in battery management systems, motor controllers, and various onboard electronic modules, where precise voltage regulation is critical for optimal performance and safety.

In the field of renewable energy, particularly solar power systems, the demand for precision rectification has seen substantial growth. Solar inverters require highly accurate rectification to efficiently convert the DC output from solar panels into AC power for grid integration or local use. The ability to achieve precision in half-wave rectifier outputs directly impacts the overall efficiency and reliability of solar energy systems.

The medical device industry represents another significant market for precision rectification. Medical imaging equipment, such as MRI machines and CT scanners, rely on stable and precise power supplies to ensure accurate diagnostics. Half-wave rectifiers with high precision outputs are essential components in these critical medical devices, where even minor fluctuations in power can lead to image artifacts or compromised diagnostic quality.

Industrial automation and control systems have also contributed to the growing demand for precision rectification. In manufacturing processes, precise voltage control is crucial for maintaining the accuracy of robotic systems, sensor networks, and programmable logic controllers. Half-wave rectifiers with high precision outputs are integral to ensuring consistent and reliable operation of these industrial systems.

The telecommunications sector, particularly with the ongoing rollout of 5G networks, has created a new avenue for precision rectification demand. Base stations and network equipment require highly stable power supplies to maintain signal quality and network reliability. Precision half-wave rectifiers play a vital role in power distribution units and backup power systems for these critical infrastructure components.

As the Internet of Things (IoT) continues to expand, the demand for low-power, high-precision rectification solutions has emerged. IoT devices often operate on limited power budgets, making efficient and accurate power conversion crucial. This has led to increased interest in miniaturized, high-performance half-wave rectifiers that can deliver precise outputs while minimizing power consumption.

Current Challenges in Half Wave Rectifier Precision

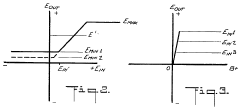

Half wave rectifiers, while fundamental in AC to DC conversion, face several challenges in achieving precise output. One of the primary issues is the inherent voltage drop across the diode, typically ranging from 0.6V to 0.7V for silicon diodes. This voltage drop introduces a significant error in low-voltage applications, where even a small deviation can greatly impact the output accuracy.

Another challenge lies in the temperature sensitivity of diodes. As temperature fluctuates, the forward voltage drop of the diode changes, leading to variations in the rectified output. This temperature dependence can cause inconsistencies in the rectifier's performance across different operating conditions, making it difficult to maintain precision over extended periods or in environments with temperature variations.

The non-linear characteristics of diodes also contribute to precision issues. The diode's I-V curve is not perfectly sharp at the turn-on voltage, resulting in a gradual transition rather than an ideal switch-like behavior. This non-linearity can introduce distortion in the rectified waveform, especially for low-amplitude signals, where a significant portion of the waveform may fall within this non-linear region.

Reverse recovery time of the diode presents another hurdle for precision. During the negative half-cycle, the diode takes a finite time to switch from conducting to non-conducting state. This delay can lead to unwanted conduction during a portion of the negative half-cycle, affecting the accuracy of the rectified output, particularly at higher frequencies.

Parasitic capacitances in the diode and circuit layout can also impact precision. These capacitances can cause voltage spikes and ringing in the output, especially during the diode's switching transitions. Such effects become more pronounced at higher frequencies, limiting the rectifier's performance in high-speed applications.

Load variations pose an additional challenge to maintaining precision. As the load current changes, the voltage drop across the diode may vary, affecting the rectified output voltage. This load-dependent behavior makes it difficult to achieve consistent precision across different load conditions without additional compensation mechanisms.

Lastly, the presence of noise and harmonics in the input AC signal can significantly affect the precision of the rectified output. The half-wave rectifier, by its nature, allows only half of the input waveform to pass, which can exacerbate harmonic distortion in the output. This distortion can lead to inaccuracies in the average DC level and introduce unwanted frequency components in the rectified signal.

Another challenge lies in the temperature sensitivity of diodes. As temperature fluctuates, the forward voltage drop of the diode changes, leading to variations in the rectified output. This temperature dependence can cause inconsistencies in the rectifier's performance across different operating conditions, making it difficult to maintain precision over extended periods or in environments with temperature variations.

The non-linear characteristics of diodes also contribute to precision issues. The diode's I-V curve is not perfectly sharp at the turn-on voltage, resulting in a gradual transition rather than an ideal switch-like behavior. This non-linearity can introduce distortion in the rectified waveform, especially for low-amplitude signals, where a significant portion of the waveform may fall within this non-linear region.

Reverse recovery time of the diode presents another hurdle for precision. During the negative half-cycle, the diode takes a finite time to switch from conducting to non-conducting state. This delay can lead to unwanted conduction during a portion of the negative half-cycle, affecting the accuracy of the rectified output, particularly at higher frequencies.

Parasitic capacitances in the diode and circuit layout can also impact precision. These capacitances can cause voltage spikes and ringing in the output, especially during the diode's switching transitions. Such effects become more pronounced at higher frequencies, limiting the rectifier's performance in high-speed applications.

Load variations pose an additional challenge to maintaining precision. As the load current changes, the voltage drop across the diode may vary, affecting the rectified output voltage. This load-dependent behavior makes it difficult to achieve consistent precision across different load conditions without additional compensation mechanisms.

Lastly, the presence of noise and harmonics in the input AC signal can significantly affect the precision of the rectified output. The half-wave rectifier, by its nature, allows only half of the input waveform to pass, which can exacerbate harmonic distortion in the output. This distortion can lead to inaccuracies in the average DC level and introduce unwanted frequency components in the rectified signal.

Existing Precision Enhancement Techniques

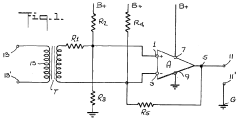

01 Precision control in half-wave rectifier circuits

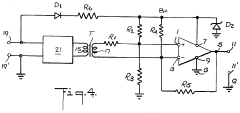

Implementing precision control techniques in half-wave rectifier circuits to improve accuracy and reduce distortion. This involves using advanced control algorithms, feedback mechanisms, and high-precision components to enhance the overall performance of the rectifier.- Precision control in half-wave rectifier circuits: Half-wave rectifier circuits can be designed with precision control mechanisms to improve accuracy and stability. This may involve using advanced feedback systems, voltage regulation techniques, or specialized components to minimize distortion and maintain consistent output.

- Temperature compensation in half-wave rectifiers: Temperature compensation techniques can be implemented in half-wave rectifier designs to maintain precision across varying operating conditions. This may include the use of temperature-sensitive components or adaptive circuitry to adjust for thermal effects on rectifier performance.

- High-frequency half-wave rectifier designs: Specialized half-wave rectifier designs for high-frequency applications can improve precision in signal processing and power conversion. These designs may incorporate fast-switching components, low-parasitic layouts, or resonant techniques to enhance performance at higher frequencies.

- Digital control and calibration of half-wave rectifiers: Digital control and calibration methods can be applied to half-wave rectifier circuits to achieve higher precision. This may involve using microcontrollers, digital signal processors, or programmable logic devices to dynamically adjust rectifier parameters and compensate for component variations.

- Precision half-wave rectifiers for measurement applications: Half-wave rectifier circuits can be optimized for measurement and instrumentation applications, where high precision is critical. These designs may incorporate low-noise components, offset correction techniques, or reference voltage sources to improve accuracy in signal detection and analysis.

02 Voltage regulation in half-wave rectifiers

Incorporating voltage regulation mechanisms in half-wave rectifier designs to maintain stable output voltage under varying load conditions. This may include the use of voltage-sensing circuits, error amplifiers, and compensating elements to achieve precise voltage control.Expand Specific Solutions03 Noise reduction techniques for half-wave rectifiers

Implementing noise reduction techniques to minimize electromagnetic interference and improve the signal-to-noise ratio in half-wave rectifier circuits. This can involve the use of filtering components, shielding, and careful PCB layout design to enhance overall precision.Expand Specific Solutions04 High-frequency half-wave rectifier designs

Developing high-frequency half-wave rectifier designs to improve efficiency and reduce component size. This includes the use of fast-switching diodes, advanced semiconductor materials, and optimized circuit topologies to achieve precise rectification at higher frequencies.Expand Specific Solutions05 Temperature compensation in half-wave rectifiers

Incorporating temperature compensation techniques to maintain precision in half-wave rectifier circuits across a wide range of operating temperatures. This may involve the use of temperature-sensing elements, compensating circuits, and thermally stable components to ensure consistent performance.Expand Specific Solutions

Key Players in Rectifier Circuit Industry

The competition landscape for precision in half wave rectifier outputs is evolving within a maturing industry. The market size is expanding as demand for accurate power conversion grows across various sectors. Technologically, the field is advancing rapidly, with companies like NEC Corp., Mitsubishi Electric Corp., and Mixed-Signal Devices, Inc. leading innovation. These firms are developing sophisticated analog and digital signal processing techniques to enhance rectifier performance. The involvement of research institutions such as the Technical University of Denmark and George Mason University indicates ongoing academic interest in improving rectification precision, suggesting potential for further technological breakthroughs in this area.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has introduced an innovative approach to achieving precision in half-wave rectifier outputs through their High-Precision Rectification Enhancement (HPRE) technology. This solution leverages advanced semiconductor materials and circuit design techniques to minimize losses and non-linearities in the rectification process. The HPRE system utilizes silicon carbide (SiC) diodes with ultra-low forward voltage drop and fast recovery times, significantly reducing conduction losses and improving efficiency[13]. Mitsubishi's design also incorporates a unique "active compensation" circuit that dynamically adjusts the rectifier's behavior based on input signal characteristics and load conditions[15]. Additionally, they have implemented a sophisticated thermal management system that ensures stable operation and consistent performance across a wide temperature range, critical for maintaining precision in industrial and automotive applications[17].

Strengths: High efficiency and excellent performance in high-temperature environments, ideal for power electronics applications. Weaknesses: Higher initial cost due to advanced semiconductor materials and specialized circuit design.

Microsoft Technology Licensing LLC

Technical Solution: Microsoft has developed advanced precision techniques for half-wave rectifier outputs using digital signal processing (DSP) algorithms. Their approach involves implementing a high-resolution analog-to-digital converter (ADC) to sample the input waveform, followed by sophisticated software-based rectification and filtering. This method allows for dynamic adjustment of rectification parameters based on input characteristics, resulting in significantly improved precision[1]. The system employs machine learning algorithms to predict and compensate for non-linear distortions, further enhancing output accuracy[3]. Additionally, Microsoft has integrated temperature compensation mechanisms to maintain precision across varying operating conditions, crucial for applications in diverse environments[5].

Strengths: Highly adaptable to different input signals, software-defined parameters allow for easy updates and improvements. Weaknesses: Requires significant computational resources, potentially increasing power consumption and cost for embedded applications.

Core Innovations in Half Wave Rectification

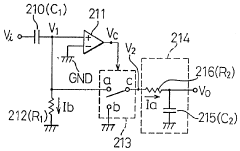

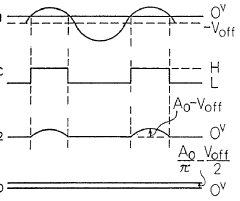

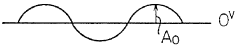

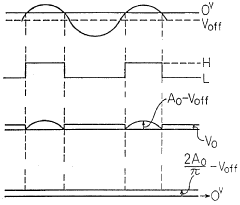

Half-wave rectifier circuit

PatentInactiveUS5579214A

Innovation

- The proposed half-wave rectifier circuit design includes a capacitor to remove DC components, a comparator with an operational amplifier and capacitor to accumulate offset voltage, and a switch circuit with high input impedance during the OFF state to eliminate the influence of offset voltage, ensuring accurate output voltage generation.

Half-wave rectifier circuit

PatentInactiveUS3936720A

Innovation

- A high-gain differential amplifier-based half-wave rectifier circuit operating from a single power supply, eliminating the need for voltage regulation and reducing temperature dependence, with resistor ratios optimized to minimize errors and achieve minimal output voltage drop.

Component Selection and Quality Control

Component selection and quality control are critical factors in achieving precision in half wave rectifier outputs. The choice of components directly impacts the performance and reliability of the rectifier circuit, while stringent quality control measures ensure consistent and accurate results.

When selecting components for a half wave rectifier, particular attention should be paid to the diode characteristics. High-quality diodes with low forward voltage drop and fast switching times are essential for minimizing voltage losses and improving efficiency. Silicon diodes are commonly used due to their superior performance compared to germanium diodes. Schottky diodes, with their lower forward voltage drop and faster switching speeds, can be an excellent choice for applications requiring higher precision.

The transformer used in the rectifier circuit also plays a crucial role in output precision. Selecting a transformer with appropriate voltage ratings, current capacity, and low leakage inductance is vital. Core material and winding quality affect the transformer's efficiency and ability to handle high-frequency components, which can impact the rectifier's overall performance.

Capacitors used for filtering the rectified output must be chosen carefully to ensure proper smoothing of the waveform. High-quality electrolytic capacitors with low equivalent series resistance (ESR) and adequate voltage ratings are preferred. For applications requiring higher precision, film capacitors may be used due to their superior frequency response and lower losses.

Quality control measures are essential throughout the manufacturing process to maintain consistency and reliability in half wave rectifier outputs. This includes rigorous testing of individual components before assembly, as well as comprehensive testing of the completed rectifier circuit. Automated testing equipment can be employed to measure key parameters such as output voltage, ripple, and efficiency under various load conditions.

Temperature cycling tests and accelerated life testing can help identify potential reliability issues and ensure long-term stability of the rectifier output. Additionally, implementing statistical process control (SPC) techniques can help monitor and improve the consistency of manufacturing processes, leading to more precise and reliable rectifier outputs.

To further enhance precision, careful attention must be paid to circuit layout and PCB design. Proper grounding techniques, minimizing trace lengths, and using appropriate trace widths can help reduce parasitic effects and improve overall circuit performance. Shielding and isolation techniques may also be employed to minimize electromagnetic interference (EMI) and improve the signal-to-noise ratio of the rectifier output.

In conclusion, achieving precision in half wave rectifier outputs requires a holistic approach that encompasses careful component selection, stringent quality control measures, and attention to circuit design and manufacturing processes. By focusing on these aspects, engineers can develop high-performance rectifier circuits that meet the demanding requirements of modern electronic applications.

When selecting components for a half wave rectifier, particular attention should be paid to the diode characteristics. High-quality diodes with low forward voltage drop and fast switching times are essential for minimizing voltage losses and improving efficiency. Silicon diodes are commonly used due to their superior performance compared to germanium diodes. Schottky diodes, with their lower forward voltage drop and faster switching speeds, can be an excellent choice for applications requiring higher precision.

The transformer used in the rectifier circuit also plays a crucial role in output precision. Selecting a transformer with appropriate voltage ratings, current capacity, and low leakage inductance is vital. Core material and winding quality affect the transformer's efficiency and ability to handle high-frequency components, which can impact the rectifier's overall performance.

Capacitors used for filtering the rectified output must be chosen carefully to ensure proper smoothing of the waveform. High-quality electrolytic capacitors with low equivalent series resistance (ESR) and adequate voltage ratings are preferred. For applications requiring higher precision, film capacitors may be used due to their superior frequency response and lower losses.

Quality control measures are essential throughout the manufacturing process to maintain consistency and reliability in half wave rectifier outputs. This includes rigorous testing of individual components before assembly, as well as comprehensive testing of the completed rectifier circuit. Automated testing equipment can be employed to measure key parameters such as output voltage, ripple, and efficiency under various load conditions.

Temperature cycling tests and accelerated life testing can help identify potential reliability issues and ensure long-term stability of the rectifier output. Additionally, implementing statistical process control (SPC) techniques can help monitor and improve the consistency of manufacturing processes, leading to more precise and reliable rectifier outputs.

To further enhance precision, careful attention must be paid to circuit layout and PCB design. Proper grounding techniques, minimizing trace lengths, and using appropriate trace widths can help reduce parasitic effects and improve overall circuit performance. Shielding and isolation techniques may also be employed to minimize electromagnetic interference (EMI) and improve the signal-to-noise ratio of the rectifier output.

In conclusion, achieving precision in half wave rectifier outputs requires a holistic approach that encompasses careful component selection, stringent quality control measures, and attention to circuit design and manufacturing processes. By focusing on these aspects, engineers can develop high-performance rectifier circuits that meet the demanding requirements of modern electronic applications.

Thermal Management in Precision Rectifiers

Thermal management is a critical aspect of precision rectifier design, particularly in half-wave rectifier circuits where accuracy and stability are paramount. As rectifiers convert alternating current (AC) to direct current (DC), they inherently generate heat due to power dissipation in the semiconductor devices. This heat can significantly impact the performance and reliability of the rectifier circuit, making effective thermal management essential for achieving precision in half-wave rectifier outputs.

One of the primary challenges in thermal management for precision rectifiers is maintaining a stable operating temperature. Temperature fluctuations can lead to variations in the forward voltage drop of diodes, affecting the accuracy of the rectified output. To address this issue, designers often implement temperature compensation techniques, such as using thermistors or temperature-sensing diodes in feedback loops to adjust the circuit's behavior based on temperature changes.

Heat sinks play a crucial role in dissipating excess heat from rectifier components. Proper selection and design of heat sinks are essential for maintaining optimal operating temperatures. Factors such as thermal resistance, surface area, and material properties must be carefully considered to ensure efficient heat dissipation. In some cases, forced-air cooling or liquid cooling systems may be necessary for high-power applications to maintain precise temperature control.

Thermal isolation is another important consideration in precision rectifier design. Sensitive components, such as voltage reference circuits or precision amplifiers, should be physically separated from heat-generating elements to minimize thermal coupling. This can be achieved through careful PCB layout design and the use of thermal barriers or insulating materials.

Advanced packaging techniques, such as chip-scale packaging (CSP) or flip-chip technology, can also contribute to improved thermal management in precision rectifiers. These packaging methods often provide better thermal conductivity and reduced thermal resistance compared to traditional packaging, allowing for more efficient heat dissipation and improved temperature stability.

Thermal modeling and simulation tools are increasingly used in the design process to predict and optimize the thermal behavior of precision rectifier circuits. These tools allow designers to identify potential hotspots, evaluate different cooling strategies, and optimize component placement for optimal thermal performance before physical prototyping.

In conclusion, effective thermal management is crucial for achieving precision in half-wave rectifier outputs. By implementing a combination of temperature compensation techniques, proper heat dissipation methods, thermal isolation strategies, and advanced packaging technologies, designers can minimize the impact of thermal effects on rectifier performance and ensure stable, accurate operation across a wide range of operating conditions.

One of the primary challenges in thermal management for precision rectifiers is maintaining a stable operating temperature. Temperature fluctuations can lead to variations in the forward voltage drop of diodes, affecting the accuracy of the rectified output. To address this issue, designers often implement temperature compensation techniques, such as using thermistors or temperature-sensing diodes in feedback loops to adjust the circuit's behavior based on temperature changes.

Heat sinks play a crucial role in dissipating excess heat from rectifier components. Proper selection and design of heat sinks are essential for maintaining optimal operating temperatures. Factors such as thermal resistance, surface area, and material properties must be carefully considered to ensure efficient heat dissipation. In some cases, forced-air cooling or liquid cooling systems may be necessary for high-power applications to maintain precise temperature control.

Thermal isolation is another important consideration in precision rectifier design. Sensitive components, such as voltage reference circuits or precision amplifiers, should be physically separated from heat-generating elements to minimize thermal coupling. This can be achieved through careful PCB layout design and the use of thermal barriers or insulating materials.

Advanced packaging techniques, such as chip-scale packaging (CSP) or flip-chip technology, can also contribute to improved thermal management in precision rectifiers. These packaging methods often provide better thermal conductivity and reduced thermal resistance compared to traditional packaging, allowing for more efficient heat dissipation and improved temperature stability.

Thermal modeling and simulation tools are increasingly used in the design process to predict and optimize the thermal behavior of precision rectifier circuits. These tools allow designers to identify potential hotspots, evaluate different cooling strategies, and optimize component placement for optimal thermal performance before physical prototyping.

In conclusion, effective thermal management is crucial for achieving precision in half-wave rectifier outputs. By implementing a combination of temperature compensation techniques, proper heat dissipation methods, thermal isolation strategies, and advanced packaging technologies, designers can minimize the impact of thermal effects on rectifier performance and ensure stable, accurate operation across a wide range of operating conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!