How to Address Electromagnetic Interference in Half Wave Rectifiers?

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EMI in Half Wave Rectifiers: Background and Objectives

Electromagnetic interference (EMI) in half wave rectifiers has been a persistent challenge in electrical engineering since the early days of power electronics. The evolution of this technology has been driven by the increasing demand for efficient and compact power conversion systems across various industries. As electronic devices become more sophisticated and miniaturized, the need to address EMI issues in half wave rectifiers has become paramount.

The primary objective of this technical research is to comprehensively explore the current state of EMI mitigation techniques in half wave rectifiers and identify potential innovative solutions. By examining the historical development and current trends, we aim to provide a solid foundation for future advancements in this field.

Half wave rectifiers, despite their simplicity, play a crucial role in numerous applications, including power supplies, battery chargers, and signal processing circuits. However, their operation inherently generates electromagnetic disturbances that can interfere with nearby electronic systems. This interference can manifest as noise in audio equipment, degradation of signal quality in communication systems, or even malfunction of sensitive medical devices.

The technological progression in addressing EMI in half wave rectifiers has seen several key milestones. Early approaches focused on passive filtering techniques, such as the use of capacitors and inductors to suppress high-frequency noise. As the understanding of EMI mechanisms improved, more sophisticated methods emerged, including active EMI cancellation and spread spectrum techniques.

Recent years have witnessed a shift towards integrated solutions, where EMI mitigation is considered at the design stage of power electronic systems. This holistic approach has led to the development of advanced semiconductor materials and novel circuit topologies that inherently produce less electromagnetic noise.

The global push for energy efficiency and the rapid growth of renewable energy systems have further intensified the need for effective EMI control in power conversion devices. As half wave rectifiers find applications in solar inverters and electric vehicle chargers, the importance of addressing EMI issues has transcended beyond traditional electronics into the realm of sustainable technologies.

Looking ahead, the technical goals for EMI mitigation in half wave rectifiers are multifaceted. They include developing more effective shielding techniques, improving the prediction and modeling of EMI generation and propagation, and creating intelligent, adaptive EMI suppression systems that can respond to changing operational conditions in real-time.

The primary objective of this technical research is to comprehensively explore the current state of EMI mitigation techniques in half wave rectifiers and identify potential innovative solutions. By examining the historical development and current trends, we aim to provide a solid foundation for future advancements in this field.

Half wave rectifiers, despite their simplicity, play a crucial role in numerous applications, including power supplies, battery chargers, and signal processing circuits. However, their operation inherently generates electromagnetic disturbances that can interfere with nearby electronic systems. This interference can manifest as noise in audio equipment, degradation of signal quality in communication systems, or even malfunction of sensitive medical devices.

The technological progression in addressing EMI in half wave rectifiers has seen several key milestones. Early approaches focused on passive filtering techniques, such as the use of capacitors and inductors to suppress high-frequency noise. As the understanding of EMI mechanisms improved, more sophisticated methods emerged, including active EMI cancellation and spread spectrum techniques.

Recent years have witnessed a shift towards integrated solutions, where EMI mitigation is considered at the design stage of power electronic systems. This holistic approach has led to the development of advanced semiconductor materials and novel circuit topologies that inherently produce less electromagnetic noise.

The global push for energy efficiency and the rapid growth of renewable energy systems have further intensified the need for effective EMI control in power conversion devices. As half wave rectifiers find applications in solar inverters and electric vehicle chargers, the importance of addressing EMI issues has transcended beyond traditional electronics into the realm of sustainable technologies.

Looking ahead, the technical goals for EMI mitigation in half wave rectifiers are multifaceted. They include developing more effective shielding techniques, improving the prediction and modeling of EMI generation and propagation, and creating intelligent, adaptive EMI suppression systems that can respond to changing operational conditions in real-time.

Market Demand for EMI-Resistant Rectifiers

The market demand for EMI-resistant rectifiers has been steadily increasing due to the growing complexity of electronic systems and the need for reliable power conversion in various industries. As electronic devices become more compact and operate at higher frequencies, the risk of electromagnetic interference (EMI) becomes more pronounced, particularly in half-wave rectifier circuits.

In the automotive sector, the shift towards electric and hybrid vehicles has created a significant demand for EMI-resistant rectifiers. These components are crucial for maintaining the integrity of sensitive electronic systems in vehicles, including advanced driver assistance systems (ADAS) and infotainment units. The automotive industry's stringent electromagnetic compatibility (EMC) standards have further fueled the need for robust EMI mitigation solutions in rectifier designs.

The telecommunications industry represents another major market for EMI-resistant rectifiers. With the ongoing rollout of 5G networks and the increasing density of wireless communication infrastructure, the demand for reliable power conversion components that can operate in high-frequency environments without causing interference has surged. Base stations and network equipment require rectifiers that can maintain signal integrity while efficiently converting power.

In the industrial automation sector, the adoption of Industry 4.0 technologies has led to a greater emphasis on EMI-resistant power components. Factory floors with numerous interconnected devices and sensors require rectifiers that can operate without disrupting sensitive measurement and control systems. This has created a niche market for specialized EMI-resistant rectifiers designed for harsh industrial environments.

The consumer electronics market has also contributed to the demand for EMI-resistant rectifiers. As smartphones, tablets, and wearable devices incorporate more features and operate at higher speeds, manufacturers are seeking power conversion solutions that minimize electromagnetic emissions and ensure compliance with regulatory standards.

The medical device industry presents a unique and growing market for EMI-resistant rectifiers. Life-critical equipment such as pacemakers, defibrillators, and diagnostic imaging systems require exceptionally reliable power conversion components that can operate without interference in hospital environments where multiple electronic devices coexist.

Market analysts project that the global demand for EMI-resistant rectifiers will continue to grow at a compound annual growth rate (CAGR) of 6-8% over the next five years. This growth is driven by the increasing integration of electronic systems across industries and the tightening of EMC regulations worldwide. As a result, manufacturers are investing in research and development to create innovative rectifier designs that offer superior EMI suppression capabilities while maintaining high efficiency and compact form factors.

In the automotive sector, the shift towards electric and hybrid vehicles has created a significant demand for EMI-resistant rectifiers. These components are crucial for maintaining the integrity of sensitive electronic systems in vehicles, including advanced driver assistance systems (ADAS) and infotainment units. The automotive industry's stringent electromagnetic compatibility (EMC) standards have further fueled the need for robust EMI mitigation solutions in rectifier designs.

The telecommunications industry represents another major market for EMI-resistant rectifiers. With the ongoing rollout of 5G networks and the increasing density of wireless communication infrastructure, the demand for reliable power conversion components that can operate in high-frequency environments without causing interference has surged. Base stations and network equipment require rectifiers that can maintain signal integrity while efficiently converting power.

In the industrial automation sector, the adoption of Industry 4.0 technologies has led to a greater emphasis on EMI-resistant power components. Factory floors with numerous interconnected devices and sensors require rectifiers that can operate without disrupting sensitive measurement and control systems. This has created a niche market for specialized EMI-resistant rectifiers designed for harsh industrial environments.

The consumer electronics market has also contributed to the demand for EMI-resistant rectifiers. As smartphones, tablets, and wearable devices incorporate more features and operate at higher speeds, manufacturers are seeking power conversion solutions that minimize electromagnetic emissions and ensure compliance with regulatory standards.

The medical device industry presents a unique and growing market for EMI-resistant rectifiers. Life-critical equipment such as pacemakers, defibrillators, and diagnostic imaging systems require exceptionally reliable power conversion components that can operate without interference in hospital environments where multiple electronic devices coexist.

Market analysts project that the global demand for EMI-resistant rectifiers will continue to grow at a compound annual growth rate (CAGR) of 6-8% over the next five years. This growth is driven by the increasing integration of electronic systems across industries and the tightening of EMC regulations worldwide. As a result, manufacturers are investing in research and development to create innovative rectifier designs that offer superior EMI suppression capabilities while maintaining high efficiency and compact form factors.

Current EMI Challenges in Half Wave Rectifiers

Half wave rectifiers, while essential in power electronics, face significant challenges related to electromagnetic interference (EMI). These challenges stem from the inherent nature of the rectification process and can have far-reaching impacts on the performance and reliability of electronic systems.

One of the primary EMI challenges in half wave rectifiers is the generation of high-frequency harmonics. The abrupt switching action during rectification creates sharp current transitions, resulting in a rich spectrum of harmonic frequencies. These harmonics can propagate through the power supply system, causing interference with nearby electronic devices and potentially violating electromagnetic compatibility (EMC) standards.

Another critical issue is the asymmetrical current flow characteristic of half wave rectifiers. This asymmetry leads to an unbalanced load on the power source, which can introduce low-frequency noise and fluctuations in the power supply. Such disturbances can manifest as visible flicker in lighting systems or audible noise in audio equipment, degrading the overall quality of the power supply.

The pulsating nature of the rectified output in half wave rectifiers also contributes to EMI problems. The large ripple content in the output voltage can couple into sensitive circuits, causing unwanted modulation or noise in analog signals. This is particularly problematic in applications requiring high signal integrity, such as medical equipment or precision measurement devices.

Furthermore, the discontinuous current draw of half wave rectifiers can lead to voltage spikes and transients on the input side. These rapid voltage changes can create electromagnetic emissions that radiate into the surrounding environment, potentially interfering with wireless communications or other sensitive electronic systems in the vicinity.

The physical layout and component selection in half wave rectifier circuits also play crucial roles in EMI generation and propagation. Improper PCB design, such as inadequate ground planes or long trace loops, can exacerbate EMI issues by creating unintended antennas that radiate electromagnetic energy. Similarly, the choice of rectifying diodes with slow reverse recovery characteristics can lead to additional high-frequency noise during switching transitions.

Addressing these EMI challenges in half wave rectifiers requires a multifaceted approach. Implementing proper filtering techniques, such as input and output EMI filters, can help attenuate both conducted and radiated emissions. Careful circuit layout and component selection, including the use of fast-recovery diodes and appropriate bypass capacitors, can significantly reduce EMI generation at the source.

In conclusion, the current EMI challenges in half wave rectifiers encompass a range of issues from harmonic generation and asymmetrical current flow to pulsating outputs and layout-related problems. Overcoming these challenges is crucial for ensuring the reliable operation of electronic systems and compliance with increasingly stringent EMC regulations.

One of the primary EMI challenges in half wave rectifiers is the generation of high-frequency harmonics. The abrupt switching action during rectification creates sharp current transitions, resulting in a rich spectrum of harmonic frequencies. These harmonics can propagate through the power supply system, causing interference with nearby electronic devices and potentially violating electromagnetic compatibility (EMC) standards.

Another critical issue is the asymmetrical current flow characteristic of half wave rectifiers. This asymmetry leads to an unbalanced load on the power source, which can introduce low-frequency noise and fluctuations in the power supply. Such disturbances can manifest as visible flicker in lighting systems or audible noise in audio equipment, degrading the overall quality of the power supply.

The pulsating nature of the rectified output in half wave rectifiers also contributes to EMI problems. The large ripple content in the output voltage can couple into sensitive circuits, causing unwanted modulation or noise in analog signals. This is particularly problematic in applications requiring high signal integrity, such as medical equipment or precision measurement devices.

Furthermore, the discontinuous current draw of half wave rectifiers can lead to voltage spikes and transients on the input side. These rapid voltage changes can create electromagnetic emissions that radiate into the surrounding environment, potentially interfering with wireless communications or other sensitive electronic systems in the vicinity.

The physical layout and component selection in half wave rectifier circuits also play crucial roles in EMI generation and propagation. Improper PCB design, such as inadequate ground planes or long trace loops, can exacerbate EMI issues by creating unintended antennas that radiate electromagnetic energy. Similarly, the choice of rectifying diodes with slow reverse recovery characteristics can lead to additional high-frequency noise during switching transitions.

Addressing these EMI challenges in half wave rectifiers requires a multifaceted approach. Implementing proper filtering techniques, such as input and output EMI filters, can help attenuate both conducted and radiated emissions. Careful circuit layout and component selection, including the use of fast-recovery diodes and appropriate bypass capacitors, can significantly reduce EMI generation at the source.

In conclusion, the current EMI challenges in half wave rectifiers encompass a range of issues from harmonic generation and asymmetrical current flow to pulsating outputs and layout-related problems. Overcoming these challenges is crucial for ensuring the reliable operation of electronic systems and compliance with increasingly stringent EMC regulations.

Existing EMI Suppression Solutions

01 EMI reduction techniques in half-wave rectifiers

Various techniques are employed to reduce electromagnetic interference (EMI) in half-wave rectifiers. These include the use of filtering components, shielding, and circuit design optimization. Such methods help to minimize the emission of electromagnetic noise and improve the overall performance of the rectifier circuit.- EMI reduction techniques in half-wave rectifiers: Various techniques are employed to reduce electromagnetic interference (EMI) in half-wave rectifiers. These include the use of filtering components, shielding, and circuit design optimization. Such methods help to minimize the emission of electromagnetic noise and improve the overall performance of the rectifier circuit.

- Soft-switching and resonant techniques: Soft-switching and resonant techniques are implemented in half-wave rectifier designs to reduce EMI. These methods involve controlling the switching transitions to minimize abrupt changes in current and voltage, thereby reducing high-frequency noise emissions. Resonant circuits can also be used to shape the waveforms and reduce harmonic content.

- EMI suppression in power supply applications: Half-wave rectifiers used in power supply applications often require specific EMI suppression techniques. These may include the use of common-mode chokes, Y-capacitors, and specialized PCB layouts. Such measures help to comply with electromagnetic compatibility (EMC) standards and ensure proper operation of the power supply in various electronic devices.

- Integration of EMI reduction features: Modern half-wave rectifier designs often integrate EMI reduction features directly into the semiconductor devices or modules. This can include on-chip filtering, controlled slew rates, and optimized package designs. Such integration helps to minimize external component count and improve overall EMI performance.

- EMI analysis and modeling for half-wave rectifiers: Advanced analysis and modeling techniques are used to predict and mitigate EMI in half-wave rectifier circuits. This includes the use of electromagnetic simulation software, frequency domain analysis, and behavioral modeling. These methods allow designers to optimize EMI performance before physical prototyping, reducing development time and costs.

02 Soft-switching and resonant techniques

Soft-switching and resonant techniques are implemented in half-wave rectifiers to reduce EMI. These methods involve controlling the switching transitions to minimize abrupt changes in current and voltage, thereby reducing high-frequency noise emissions. Resonant circuits can also be used to shape the waveforms and reduce harmonic content.Expand Specific Solutions03 EMI suppression in power supply applications

Half-wave rectifiers used in power supply applications often require specific EMI suppression techniques. These may include the use of common-mode chokes, Y-capacitors, and specialized PCB layouts. Such measures help to comply with electromagnetic compatibility (EMC) standards and ensure proper operation of the power supply in various electronic devices.Expand Specific Solutions04 Integration of EMI reduction features in IC designs

Integrated circuit (IC) designs for half-wave rectifiers incorporate built-in EMI reduction features. These may include on-chip filtering, spread spectrum techniques, and advanced packaging solutions. Such integrated approaches help to minimize EMI at the source and reduce the need for external components.Expand Specific Solutions05 EMI analysis and modeling for half-wave rectifiers

Advanced analysis and modeling techniques are used to study and predict EMI behavior in half-wave rectifiers. These methods include electromagnetic simulation, frequency domain analysis, and time-domain reflectometry. Such tools help designers optimize circuit layouts and component selection to minimize EMI issues in the final product.Expand Specific Solutions

Key Players in EMI-Resistant Rectifier Industry

The electromagnetic interference (EMI) mitigation in half wave rectifiers market is in a growth phase, driven by increasing demand for efficient power electronics across various industries. The global market size is expanding, fueled by the rising adoption of electronic devices and stringent EMI regulations. Technologically, the field is advancing rapidly, with companies like Samsung Electronics, Delta Electronics, and Renesas Electronics leading innovation. These firms are developing sophisticated EMI suppression techniques, integrating advanced materials and design methodologies. Other key players such as Robert Bosch GmbH and NEC Corp. are also contributing significantly to the technological maturity of EMI solutions in rectifier circuits, focusing on miniaturization and improved performance.

NEC Corp.

Technical Solution: NEC Corp. has developed a comprehensive EMI suppression strategy for half-wave rectifiers used in their electronic systems and components. Their approach combines advanced circuit design techniques with specialized EMI suppression components. NEC utilizes a multi-layer PCB design with dedicated ground planes and careful component placement to minimize EMI generation and propagation[2]. They have also implemented digital control techniques in their power supply designs, allowing for precise timing control of switching events to reduce EMI[4]. Additionally, NEC has developed proprietary EMI absorption sheets made of magnetic composite materials that can be applied directly to circuit boards or components to suppress high-frequency noise[6]. These sheets are particularly effective in addressing EMI issues in compact electronic devices where traditional filtering methods may be impractical.

Strengths: Holistic approach combining circuit design, digital control, and specialized materials. Effective solutions for compact electronic devices. Weaknesses: May require redesign of existing circuits to fully implement EMI suppression techniques. Specialized materials could increase overall product cost.

Renesas Electronics Corp.

Technical Solution: Renesas Electronics Corp. has developed a proprietary EMI reduction technology for half-wave rectifiers in their microcontroller and power management ICs. Their approach focuses on integrated solutions that combine advanced circuit design with on-chip EMI suppression techniques. Renesas utilizes spread spectrum clock generation (SSCG) to reduce EMI by spreading the energy of clock harmonics over a wider frequency range[2]. They have also implemented adaptive voltage positioning (AVP) in their power management ICs, which helps to reduce voltage overshoot and undershoot, thereby minimizing EMI generation[4]. Furthermore, Renesas has developed specialized EMI-hardened I/O cells and package designs that incorporate built-in EMI filtering elements[6].

Strengths: Highly integrated solutions reducing overall system complexity. On-chip EMI suppression techniques offer space-saving advantages. Weaknesses: May be less flexible for customization in specific applications. Potentially higher cost for specialized ICs with built-in EMI suppression.

Core EMI Mitigation Innovations

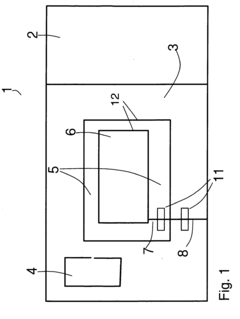

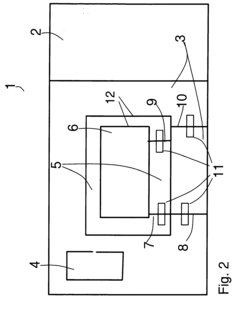

Electronic circuit and method for reducing EMC malfunctions in this circuit

PatentInactiveEP1931189A2

Innovation

- The electronic circuit design features a first conductive surface at a single potential partially surrounding a second conductive surface of the same potential, with strategically placed separation points connected to real impedances that convert RF energy into heat, ensuring the impedance values match the characteristic impedance or its double, and additional separation points are introduced to prevent standing waves and current flow through resistors.

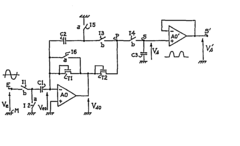

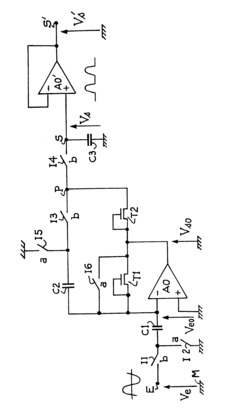

One-way rectifier with switched capacitors

PatentInactiveEP0146431A1

Innovation

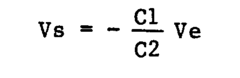

- A circuit with switched capacitors, operational amplifiers, and field-effect transistors is designed, where capacitors and transistors are connected in specific phases to isolate and rectify alternating voltage, using a third capacitor to output the rectified voltage and a unity gain amplifier to maintain it without discharge, optimized for integration in MOS technology.

EMC Standards and Regulations

Electromagnetic Compatibility (EMC) standards and regulations play a crucial role in addressing electromagnetic interference (EMI) in half wave rectifiers and other electronic devices. These standards ensure that electronic equipment operates without causing or experiencing undue electromagnetic disturbances.

The International Electrotechnical Commission (IEC) has established several key standards relevant to EMI in power electronics. IEC 61000-3-2 specifically addresses harmonic current emissions limits for equipment with input current up to 16A per phase. This standard is particularly relevant for half wave rectifiers, which are known to generate significant harmonic distortion.

In the United States, the Federal Communications Commission (FCC) regulates EMI through Part 15 of its rules. These regulations set limits on the amount of electromagnetic energy that can be radiated by electronic devices, including those incorporating half wave rectifiers. Compliance with FCC Part 15 is mandatory for many consumer and industrial electronic products.

The European Union's EMC Directive (2014/30/EU) provides a regulatory framework for EMC within the EU market. This directive requires manufacturers to ensure their products meet essential EMC requirements before they can be sold in the EU. For half wave rectifiers, this often involves implementing EMI mitigation techniques to comply with harmonized standards.

CISPR (Comité International Spécial des Perturbations Radioélectriques) publications, particularly CISPR 11 and CISPR 22, provide limits and methods of measurement for electromagnetic disturbances from industrial, scientific, and medical equipment. These standards are often referenced in national and international regulations for EMC compliance.

Military and aerospace applications have their own stringent EMC standards. MIL-STD-461 in the United States and DEF STAN 59-411 in the UK provide detailed requirements for the control of EMI characteristics of subsystems and equipment. These standards often influence commercial practices in high-reliability applications.

Compliance with EMC standards typically requires a combination of design techniques and testing. For half wave rectifiers, this may involve implementing EMI filters, proper shielding, and careful PCB layout. Testing procedures often include conducted and radiated emissions measurements in specialized EMC chambers.

As technology evolves, EMC standards are regularly updated to address new challenges. For instance, the increasing use of high-frequency switching in power electronics has led to more stringent regulations in the higher frequency bands. Manufacturers and designers must stay informed about these evolving standards to ensure ongoing compliance.

The International Electrotechnical Commission (IEC) has established several key standards relevant to EMI in power electronics. IEC 61000-3-2 specifically addresses harmonic current emissions limits for equipment with input current up to 16A per phase. This standard is particularly relevant for half wave rectifiers, which are known to generate significant harmonic distortion.

In the United States, the Federal Communications Commission (FCC) regulates EMI through Part 15 of its rules. These regulations set limits on the amount of electromagnetic energy that can be radiated by electronic devices, including those incorporating half wave rectifiers. Compliance with FCC Part 15 is mandatory for many consumer and industrial electronic products.

The European Union's EMC Directive (2014/30/EU) provides a regulatory framework for EMC within the EU market. This directive requires manufacturers to ensure their products meet essential EMC requirements before they can be sold in the EU. For half wave rectifiers, this often involves implementing EMI mitigation techniques to comply with harmonized standards.

CISPR (Comité International Spécial des Perturbations Radioélectriques) publications, particularly CISPR 11 and CISPR 22, provide limits and methods of measurement for electromagnetic disturbances from industrial, scientific, and medical equipment. These standards are often referenced in national and international regulations for EMC compliance.

Military and aerospace applications have their own stringent EMC standards. MIL-STD-461 in the United States and DEF STAN 59-411 in the UK provide detailed requirements for the control of EMI characteristics of subsystems and equipment. These standards often influence commercial practices in high-reliability applications.

Compliance with EMC standards typically requires a combination of design techniques and testing. For half wave rectifiers, this may involve implementing EMI filters, proper shielding, and careful PCB layout. Testing procedures often include conducted and radiated emissions measurements in specialized EMC chambers.

As technology evolves, EMC standards are regularly updated to address new challenges. For instance, the increasing use of high-frequency switching in power electronics has led to more stringent regulations in the higher frequency bands. Manufacturers and designers must stay informed about these evolving standards to ensure ongoing compliance.

Economic Impact of EMI Reduction

The reduction of electromagnetic interference (EMI) in half wave rectifiers has significant economic implications across various industries. By addressing EMI issues, companies can improve product performance, reduce costs associated with compliance and recalls, and enhance their competitive position in the market.

In the consumer electronics sector, EMI reduction leads to improved device functionality and reliability. This translates to fewer customer complaints, reduced warranty claims, and increased brand loyalty. For manufacturers, the ability to produce low-EMI products can be a key differentiator, potentially commanding premium prices and expanding market share.

In industrial applications, EMI reduction in power systems using half wave rectifiers can result in substantial cost savings. Improved electromagnetic compatibility reduces downtime, extends equipment lifespan, and minimizes the need for shielding and filtering components. This leads to lower operational costs and increased productivity for businesses across manufacturing, energy, and automation sectors.

The automotive industry stands to benefit significantly from EMI reduction in vehicle electrical systems. As cars become more electronically sophisticated, managing EMI is crucial for ensuring safety, reliability, and compliance with stringent regulations. Manufacturers who excel in EMI reduction can reduce recall risks, improve vehicle performance, and potentially gain a competitive edge in the rapidly evolving electric vehicle market.

In the telecommunications sector, EMI reduction in power supplies and signal processing equipment can lead to improved signal quality, increased data transmission rates, and enhanced network reliability. This translates to better service quality for end-users and potential cost savings for network operators through reduced maintenance and upgrade requirements.

The medical device industry also sees substantial economic benefits from EMI reduction. Improved electromagnetic compatibility in diagnostic and therapeutic equipment enhances patient safety, reduces the risk of device malfunctions, and simplifies regulatory compliance processes. This can lead to faster time-to-market for new devices and reduced liability risks for manufacturers.

From a broader economic perspective, advancements in EMI reduction techniques for half wave rectifiers can stimulate innovation and create new market opportunities. Companies specializing in EMI solutions may experience growth, potentially creating jobs and driving economic development in the electronics and engineering sectors.

In the consumer electronics sector, EMI reduction leads to improved device functionality and reliability. This translates to fewer customer complaints, reduced warranty claims, and increased brand loyalty. For manufacturers, the ability to produce low-EMI products can be a key differentiator, potentially commanding premium prices and expanding market share.

In industrial applications, EMI reduction in power systems using half wave rectifiers can result in substantial cost savings. Improved electromagnetic compatibility reduces downtime, extends equipment lifespan, and minimizes the need for shielding and filtering components. This leads to lower operational costs and increased productivity for businesses across manufacturing, energy, and automation sectors.

The automotive industry stands to benefit significantly from EMI reduction in vehicle electrical systems. As cars become more electronically sophisticated, managing EMI is crucial for ensuring safety, reliability, and compliance with stringent regulations. Manufacturers who excel in EMI reduction can reduce recall risks, improve vehicle performance, and potentially gain a competitive edge in the rapidly evolving electric vehicle market.

In the telecommunications sector, EMI reduction in power supplies and signal processing equipment can lead to improved signal quality, increased data transmission rates, and enhanced network reliability. This translates to better service quality for end-users and potential cost savings for network operators through reduced maintenance and upgrade requirements.

The medical device industry also sees substantial economic benefits from EMI reduction. Improved electromagnetic compatibility in diagnostic and therapeutic equipment enhances patient safety, reduces the risk of device malfunctions, and simplifies regulatory compliance processes. This can lead to faster time-to-market for new devices and reduced liability risks for manufacturers.

From a broader economic perspective, advancements in EMI reduction techniques for half wave rectifiers can stimulate innovation and create new market opportunities. Companies specializing in EMI solutions may experience growth, potentially creating jobs and driving economic development in the electronics and engineering sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!