How to Implement Safety Features in Half Wave Rectifier Designs?

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rectifier Safety Overview

Half wave rectifiers are fundamental components in power electronics, converting alternating current (AC) to pulsating direct current (DC). While these devices are essential in many applications, their implementation requires careful consideration of safety features to protect both the circuit and end-users. Safety in rectifier designs is paramount, as these components often handle high voltages and currents, which can pose significant risks if not properly managed.

One of the primary safety concerns in half wave rectifier designs is overvoltage protection. During operation, voltage spikes can occur due to various factors such as sudden load changes or power surges. These spikes can damage sensitive components downstream or create hazardous conditions. To mitigate this risk, designers often incorporate voltage clamping devices such as Zener diodes or metal oxide varistors (MOVs) in parallel with the load. These components act as a safety valve, conducting excess current when voltage exceeds a predetermined threshold.

Overcurrent protection is another critical safety feature in half wave rectifier designs. Excessive current flow can lead to component failure, overheating, and potential fire hazards. Fuses and circuit breakers are commonly used to interrupt the circuit in case of overcurrent conditions. More advanced designs may employ electronic current limiting circuits that can react faster than traditional fuses, providing better protection for sensitive loads.

Thermal management is a crucial aspect of rectifier safety. The rectification process inherently generates heat, which must be effectively dissipated to prevent component failure and maintain safe operating temperatures. Heat sinks, cooling fans, and proper component spacing are essential design considerations. In some cases, thermal sensors and shutdown circuits may be implemented to prevent operation under dangerously high temperatures.

Isolation is a key safety feature, particularly in applications where the rectifier interfaces between high-voltage and low-voltage circuits. Transformers or optocouplers can provide galvanic isolation, protecting users and low-voltage circuitry from potentially lethal high-voltage sources. This is especially important in medical equipment, power supplies, and industrial control systems where safety standards are stringent.

Electromagnetic interference (EMI) suppression is another important safety consideration. Half wave rectifiers can generate significant electromagnetic noise, which may interfere with other electronic devices or violate regulatory standards. EMI filters, proper shielding, and careful PCB layout techniques are employed to minimize electromagnetic emissions and ensure compliance with safety regulations.

Reverse polarity protection is often overlooked but is crucial for preventing damage caused by incorrect connection of power sources. This can be achieved through the use of diodes or more sophisticated electronic circuits that prevent current flow in the wrong direction.

In conclusion, implementing safety features in half wave rectifier designs requires a multifaceted approach addressing various potential hazards. By incorporating these safety measures, designers can create robust and reliable rectifier circuits that not only perform their intended function but also prioritize the safety of both the equipment and its users.

One of the primary safety concerns in half wave rectifier designs is overvoltage protection. During operation, voltage spikes can occur due to various factors such as sudden load changes or power surges. These spikes can damage sensitive components downstream or create hazardous conditions. To mitigate this risk, designers often incorporate voltage clamping devices such as Zener diodes or metal oxide varistors (MOVs) in parallel with the load. These components act as a safety valve, conducting excess current when voltage exceeds a predetermined threshold.

Overcurrent protection is another critical safety feature in half wave rectifier designs. Excessive current flow can lead to component failure, overheating, and potential fire hazards. Fuses and circuit breakers are commonly used to interrupt the circuit in case of overcurrent conditions. More advanced designs may employ electronic current limiting circuits that can react faster than traditional fuses, providing better protection for sensitive loads.

Thermal management is a crucial aspect of rectifier safety. The rectification process inherently generates heat, which must be effectively dissipated to prevent component failure and maintain safe operating temperatures. Heat sinks, cooling fans, and proper component spacing are essential design considerations. In some cases, thermal sensors and shutdown circuits may be implemented to prevent operation under dangerously high temperatures.

Isolation is a key safety feature, particularly in applications where the rectifier interfaces between high-voltage and low-voltage circuits. Transformers or optocouplers can provide galvanic isolation, protecting users and low-voltage circuitry from potentially lethal high-voltage sources. This is especially important in medical equipment, power supplies, and industrial control systems where safety standards are stringent.

Electromagnetic interference (EMI) suppression is another important safety consideration. Half wave rectifiers can generate significant electromagnetic noise, which may interfere with other electronic devices or violate regulatory standards. EMI filters, proper shielding, and careful PCB layout techniques are employed to minimize electromagnetic emissions and ensure compliance with safety regulations.

Reverse polarity protection is often overlooked but is crucial for preventing damage caused by incorrect connection of power sources. This can be achieved through the use of diodes or more sophisticated electronic circuits that prevent current flow in the wrong direction.

In conclusion, implementing safety features in half wave rectifier designs requires a multifaceted approach addressing various potential hazards. By incorporating these safety measures, designers can create robust and reliable rectifier circuits that not only perform their intended function but also prioritize the safety of both the equipment and its users.

Market Demand Analysis

The market demand for safety features in half wave rectifier designs has been steadily increasing due to growing concerns about electrical safety and regulatory requirements across various industries. This trend is particularly evident in consumer electronics, industrial equipment, and automotive sectors, where the need for reliable and safe power conversion is paramount.

In the consumer electronics market, the proliferation of smart devices and home appliances has led to a surge in demand for compact and efficient power supplies. Half wave rectifiers, being simple and cost-effective, are widely used in these applications. However, consumers are becoming increasingly aware of the potential risks associated with electrical devices, driving manufacturers to incorporate advanced safety features in their designs.

The industrial sector presents a significant market opportunity for enhanced half wave rectifier safety features. With the ongoing digital transformation and automation of industrial processes, there is a growing need for robust power conversion solutions that can withstand harsh environments and ensure uninterrupted operations. Safety features that protect against overcurrent, overvoltage, and thermal issues are highly valued in this segment.

In the automotive industry, the shift towards electric and hybrid vehicles has created a substantial demand for efficient and safe power conversion systems. Half wave rectifiers play a crucial role in various automotive applications, including battery charging, motor control, and auxiliary power systems. As vehicle electrification continues to accelerate, the market for safety-enhanced rectifier designs is expected to expand significantly.

The healthcare sector is another key market driver for safety features in half wave rectifier designs. Medical devices and equipment require highly reliable power supplies with stringent safety standards. The increasing adoption of portable and wearable medical devices further emphasizes the need for compact, efficient, and safe power conversion solutions.

Market analysis indicates that the global power electronics market, which includes rectifier technologies, is projected to grow at a compound annual growth rate (CAGR) of over 5% in the coming years. The safety features segment within this market is expected to outpace the overall growth rate, driven by regulatory pressures and consumer demand for safer electronic products.

Geographically, developed regions such as North America and Europe are leading the adoption of advanced safety features in electronic designs, including half wave rectifiers. However, emerging economies in Asia-Pacific and Latin America are showing rapid growth potential as they upgrade their industrial infrastructure and implement stricter safety regulations.

The market demand for safety features in half wave rectifier designs is also influenced by the broader trend of energy efficiency and sustainability. As governments and organizations worldwide push for reduced energy consumption, there is a growing emphasis on developing power conversion solutions that not only prioritize safety but also optimize energy usage.

In the consumer electronics market, the proliferation of smart devices and home appliances has led to a surge in demand for compact and efficient power supplies. Half wave rectifiers, being simple and cost-effective, are widely used in these applications. However, consumers are becoming increasingly aware of the potential risks associated with electrical devices, driving manufacturers to incorporate advanced safety features in their designs.

The industrial sector presents a significant market opportunity for enhanced half wave rectifier safety features. With the ongoing digital transformation and automation of industrial processes, there is a growing need for robust power conversion solutions that can withstand harsh environments and ensure uninterrupted operations. Safety features that protect against overcurrent, overvoltage, and thermal issues are highly valued in this segment.

In the automotive industry, the shift towards electric and hybrid vehicles has created a substantial demand for efficient and safe power conversion systems. Half wave rectifiers play a crucial role in various automotive applications, including battery charging, motor control, and auxiliary power systems. As vehicle electrification continues to accelerate, the market for safety-enhanced rectifier designs is expected to expand significantly.

The healthcare sector is another key market driver for safety features in half wave rectifier designs. Medical devices and equipment require highly reliable power supplies with stringent safety standards. The increasing adoption of portable and wearable medical devices further emphasizes the need for compact, efficient, and safe power conversion solutions.

Market analysis indicates that the global power electronics market, which includes rectifier technologies, is projected to grow at a compound annual growth rate (CAGR) of over 5% in the coming years. The safety features segment within this market is expected to outpace the overall growth rate, driven by regulatory pressures and consumer demand for safer electronic products.

Geographically, developed regions such as North America and Europe are leading the adoption of advanced safety features in electronic designs, including half wave rectifiers. However, emerging economies in Asia-Pacific and Latin America are showing rapid growth potential as they upgrade their industrial infrastructure and implement stricter safety regulations.

The market demand for safety features in half wave rectifier designs is also influenced by the broader trend of energy efficiency and sustainability. As governments and organizations worldwide push for reduced energy consumption, there is a growing emphasis on developing power conversion solutions that not only prioritize safety but also optimize energy usage.

Current Challenges

Half wave rectifier designs, while fundamental in power electronics, face several challenges in implementing robust safety features. One of the primary concerns is the inherent voltage ripple associated with these circuits. This ripple can lead to instability in the output voltage, potentially damaging sensitive components or causing erratic behavior in connected devices. Addressing this issue requires careful consideration of filtering techniques and component selection, which can increase complexity and cost.

Another significant challenge lies in the management of reverse voltage stress on the rectifying diode. During the negative half-cycle, the diode is subjected to reverse bias, which can lead to breakdown if not properly managed. This stress can be particularly problematic in high-voltage applications, necessitating the use of specialized diodes or additional protective circuitry, further complicating the design process.

Thermal management presents a substantial hurdle in implementing safety features for half wave rectifiers. The pulsating nature of the current flow leads to cyclic heating and cooling of components, particularly the rectifying diode. This thermal cycling can accelerate component degradation and potentially lead to premature failure. Designing effective heat dissipation mechanisms without significantly increasing the overall size of the circuit remains a challenge.

Electromagnetic interference (EMI) is another critical issue that designers must address. The abrupt current transitions inherent in half wave rectification can generate high-frequency noise, potentially interfering with nearby electronic systems. Mitigating EMI often requires additional filtering components and careful PCB layout considerations, which can conflict with size and cost constraints.

The efficiency of half wave rectifiers is inherently lower compared to full wave designs, presenting challenges in applications where power conservation is crucial. This lower efficiency not only impacts overall system performance but also contributes to increased heat generation, exacerbating thermal management issues. Balancing efficiency improvements with safety features often involves trade-offs that designers must carefully navigate.

Surge protection is another vital safety concern in half wave rectifier designs. Voltage spikes from the input source or load transients can damage the rectifying diode and other components. Implementing effective surge protection without compromising the basic functionality of the rectifier requires sophisticated design strategies and often additional components, increasing both cost and complexity.

Lastly, ensuring galvanic isolation between the input and output stages of the rectifier circuit poses a significant challenge, especially in applications requiring high safety standards. Achieving this isolation while maintaining circuit performance and adhering to regulatory requirements often necessitates the use of specialized transformers or optocouplers, adding to the design complexity and cost.

Another significant challenge lies in the management of reverse voltage stress on the rectifying diode. During the negative half-cycle, the diode is subjected to reverse bias, which can lead to breakdown if not properly managed. This stress can be particularly problematic in high-voltage applications, necessitating the use of specialized diodes or additional protective circuitry, further complicating the design process.

Thermal management presents a substantial hurdle in implementing safety features for half wave rectifiers. The pulsating nature of the current flow leads to cyclic heating and cooling of components, particularly the rectifying diode. This thermal cycling can accelerate component degradation and potentially lead to premature failure. Designing effective heat dissipation mechanisms without significantly increasing the overall size of the circuit remains a challenge.

Electromagnetic interference (EMI) is another critical issue that designers must address. The abrupt current transitions inherent in half wave rectification can generate high-frequency noise, potentially interfering with nearby electronic systems. Mitigating EMI often requires additional filtering components and careful PCB layout considerations, which can conflict with size and cost constraints.

The efficiency of half wave rectifiers is inherently lower compared to full wave designs, presenting challenges in applications where power conservation is crucial. This lower efficiency not only impacts overall system performance but also contributes to increased heat generation, exacerbating thermal management issues. Balancing efficiency improvements with safety features often involves trade-offs that designers must carefully navigate.

Surge protection is another vital safety concern in half wave rectifier designs. Voltage spikes from the input source or load transients can damage the rectifying diode and other components. Implementing effective surge protection without compromising the basic functionality of the rectifier requires sophisticated design strategies and often additional components, increasing both cost and complexity.

Lastly, ensuring galvanic isolation between the input and output stages of the rectifier circuit poses a significant challenge, especially in applications requiring high safety standards. Achieving this isolation while maintaining circuit performance and adhering to regulatory requirements often necessitates the use of specialized transformers or optocouplers, adding to the design complexity and cost.

Existing Safety Solutions

01 Overcurrent protection mechanisms

Half-wave rectifiers often incorporate overcurrent protection features to prevent damage from excessive current flow. These mechanisms may include fuses, circuit breakers, or current-limiting devices that automatically interrupt the circuit when current exceeds safe levels. This protection helps safeguard both the rectifier and connected components from potential harm due to current surges or short circuits.- Overcurrent protection mechanisms: Half-wave rectifiers often incorporate overcurrent protection features to prevent damage from excessive current flow. These mechanisms may include fuses, circuit breakers, or current-limiting devices that automatically disconnect or limit the current when it exceeds safe levels, protecting both the rectifier and connected components.

- Thermal management and heat dissipation: Safety features for half-wave rectifiers include thermal management systems to prevent overheating. These may involve heat sinks, cooling fans, or temperature sensors that monitor and regulate the rectifier's operating temperature, ensuring safe and efficient operation even under high-load conditions.

- Voltage regulation and surge protection: Half-wave rectifiers often incorporate voltage regulation and surge protection features to safeguard against voltage spikes and fluctuations. These may include voltage-clamping devices, transient voltage suppressors, or advanced control circuits that maintain stable output voltage and protect connected equipment from electrical surges.

- Isolation and insulation techniques: Safety features in half-wave rectifiers include proper isolation and insulation techniques to prevent electric shock and short circuits. These may involve the use of insulating materials, physical barriers between high-voltage components, and galvanic isolation methods to separate input and output circuits, ensuring user safety and equipment protection.

- Monitoring and fault detection systems: Advanced half-wave rectifiers may incorporate monitoring and fault detection systems as safety features. These can include sensors and diagnostic circuits that continuously monitor key parameters such as voltage, current, and temperature. In case of abnormal conditions or faults, these systems can trigger alarms, initiate shutdown procedures, or activate backup systems to prevent damage and ensure safe operation.

02 Thermal management and heat dissipation

Safety features in half-wave rectifiers often include thermal management solutions to prevent overheating. These may involve heat sinks, cooling fans, or thermal shutdown circuits that monitor temperature and shut off the device if it exceeds safe operating limits. Proper heat dissipation is crucial for maintaining the rectifier's efficiency and preventing component failure due to excessive heat.Expand Specific Solutions03 Voltage regulation and surge protection

Half-wave rectifiers may incorporate voltage regulation and surge protection features to ensure stable and safe output voltage. This can include voltage clamping devices, transient voltage suppressors, or feedback control circuits that adjust the output voltage to maintain it within acceptable limits. These features protect both the rectifier and connected devices from voltage spikes and fluctuations.Expand Specific Solutions04 Isolation and insulation techniques

Safety features in half-wave rectifiers often include electrical isolation and insulation techniques to prevent electric shock and reduce electromagnetic interference. This may involve the use of optocouplers, isolation transformers, or high-quality insulating materials. These measures help ensure user safety and compliance with electrical safety standards.Expand Specific Solutions05 Monitoring and fault detection systems

Advanced half-wave rectifiers may incorporate monitoring and fault detection systems as safety features. These can include sensors and microcontrollers that continuously monitor various parameters such as voltage, current, and temperature. In case of abnormal conditions or faults, these systems can trigger alarms, initiate protective measures, or safely shut down the rectifier to prevent damage or hazardous situations.Expand Specific Solutions

Key Industry Players

The implementation of safety features in half wave rectifier designs is currently in a growth phase, with increasing market demand driven by the rising focus on electrical safety across industries. The global market for safety-enhanced rectifiers is expanding, estimated to reach several billion dollars by 2025. Technologically, the field is advancing rapidly, with companies like ABB Group, Siemens Corp., and Toshiba Corp. leading innovation. These firms are developing sophisticated safety mechanisms, including overcurrent protection, thermal shutdown, and reverse voltage protection. State Grid Corp. of China and Huawei Technologies are also making significant strides in this area, particularly in integrating smart safety features with IoT capabilities. While the core technology is mature, ongoing research focuses on enhancing efficiency, reliability, and miniaturization of safety components in rectifier designs.

ABB Group

Technical Solution: ABB Group has developed advanced safety features for half wave rectifier designs, focusing on overcurrent and overvoltage protection. Their approach includes implementing fast-acting fuses and surge arresters to protect against sudden voltage spikes[1]. They have also integrated sophisticated monitoring systems that can detect abnormal current or voltage levels and trigger automatic shutdown mechanisms[3]. ABB's design incorporates thermal management solutions to prevent overheating, using temperature sensors and intelligent cooling systems[5]. Additionally, they have implemented isolation techniques to ensure electrical safety, including optocouplers for signal isolation and reinforced insulation for power components[7].

Strengths: Comprehensive protection against multiple failure modes, advanced monitoring capabilities, and robust thermal management. Weaknesses: Potentially higher cost due to advanced components, and increased complexity in circuit design.

Siemens Corp.

Technical Solution: Siemens Corp. has innovated in half wave rectifier safety by implementing a multi-layered protection approach. Their design incorporates smart current limiting circuits that can dynamically adjust to load conditions, preventing overcurrent situations[2]. Siemens has also developed a proprietary voltage clamping technology that effectively suppresses voltage transients without compromising efficiency[4]. Their rectifiers feature advanced EMI/RFI filtering to ensure electromagnetic compatibility and reduce interference[6]. Siemens has integrated self-diagnostic capabilities into their rectifiers, allowing for real-time monitoring and predictive maintenance[8]. Furthermore, they have implemented redundancy in critical components to enhance overall system reliability.

Strengths: Adaptive protection mechanisms, excellent EMC performance, and predictive maintenance capabilities. Weaknesses: Potentially higher initial cost and increased circuit complexity that may require specialized maintenance.

Core Safety Innovations

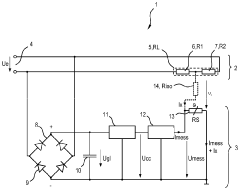

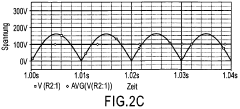

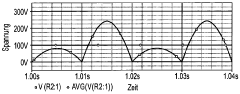

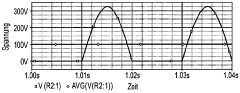

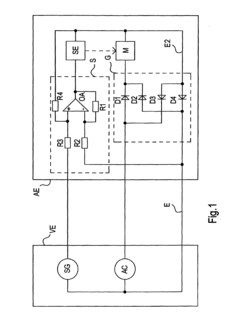

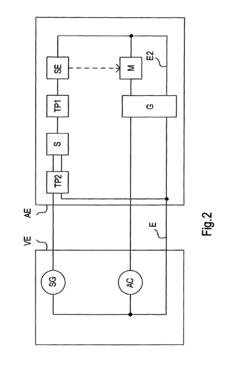

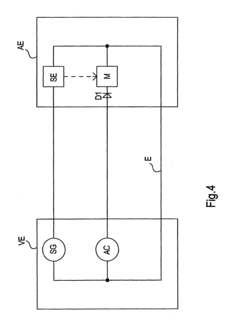

Electric circuit and household appliance

PatentWO2010000767A1

Innovation

- The implementation of a half-wave rectifier in the DC circuit, which can include a single diode or triac, reduces or eliminates the influence of AC currents on measurement accuracy by minimizing leakage currents, and the use of a low-pass filter further enhances measurement precision by filtering out ripple effects.

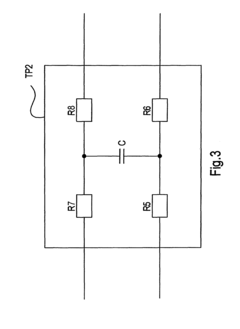

Drive device

PatentInactiveEP1848102A2

Innovation

- Implementing a full-wave rectifier using a subtractor with an operational amplifier and resistors to eliminate interference, and employing a second low-pass filter at the input of the subtractor to effectively dampen interference signals, along with a smaller smoothing capacitor for material savings.

Regulatory Compliance

Regulatory compliance is a critical aspect of implementing safety features in half wave rectifier designs. As these devices are widely used in various electronic applications, adherence to safety standards and regulations is paramount to ensure the protection of both users and equipment. The regulatory landscape for half wave rectifiers encompasses a range of standards set by international and regional bodies.

One of the primary regulatory frameworks governing half wave rectifier safety is the International Electrotechnical Commission (IEC) standards. These standards provide comprehensive guidelines for the design, testing, and implementation of safety features in electronic devices, including rectifiers. Specifically, IEC 61000 series addresses electromagnetic compatibility (EMC) requirements, which are crucial for ensuring that half wave rectifiers do not interfere with other electronic equipment or suffer from external electromagnetic disturbances.

In addition to IEC standards, manufacturers must also comply with regional regulations. In the European Union, the CE marking is mandatory for electronic products, including those incorporating half wave rectifiers. This certification ensures compliance with the EU's Low Voltage Directive (LVD) and Electromagnetic Compatibility Directive (EMCD). Similarly, in North America, Underwriters Laboratories (UL) standards play a significant role in safety certification, with UL 1012 specifically addressing power supplies, including rectifier circuits.

To meet these regulatory requirements, designers must incorporate various safety features into half wave rectifier designs. Overcurrent protection is a key element, often implemented through fuses or circuit breakers to prevent damage from excessive current flow. Overvoltage protection, such as transient voltage suppressors or metal oxide varistors, is essential to guard against voltage spikes that could compromise the rectifier's integrity.

Thermal management is another critical safety consideration in regulatory compliance. Proper heat dissipation techniques, including heat sinks and thermal cutoff devices, must be employed to prevent overheating and potential fire hazards. Additionally, isolation between input and output circuits is often required to protect against electric shock, typically achieved through transformer isolation or optocouplers.

Manufacturers must also consider electromagnetic interference (EMI) suppression techniques to comply with EMC regulations. This may involve the use of EMI filters, shielding, and proper PCB layout design to minimize radiated and conducted emissions. Furthermore, safety standards often mandate specific creepage and clearance distances between conductive parts to prevent arcing and ensure electrical isolation.

Documentation and labeling requirements form another crucial aspect of regulatory compliance. Clear and accurate product labeling, including safety warnings and electrical ratings, must be provided. Comprehensive technical documentation, including circuit diagrams, component specifications, and test results, is essential for demonstrating compliance during certification processes.

One of the primary regulatory frameworks governing half wave rectifier safety is the International Electrotechnical Commission (IEC) standards. These standards provide comprehensive guidelines for the design, testing, and implementation of safety features in electronic devices, including rectifiers. Specifically, IEC 61000 series addresses electromagnetic compatibility (EMC) requirements, which are crucial for ensuring that half wave rectifiers do not interfere with other electronic equipment or suffer from external electromagnetic disturbances.

In addition to IEC standards, manufacturers must also comply with regional regulations. In the European Union, the CE marking is mandatory for electronic products, including those incorporating half wave rectifiers. This certification ensures compliance with the EU's Low Voltage Directive (LVD) and Electromagnetic Compatibility Directive (EMCD). Similarly, in North America, Underwriters Laboratories (UL) standards play a significant role in safety certification, with UL 1012 specifically addressing power supplies, including rectifier circuits.

To meet these regulatory requirements, designers must incorporate various safety features into half wave rectifier designs. Overcurrent protection is a key element, often implemented through fuses or circuit breakers to prevent damage from excessive current flow. Overvoltage protection, such as transient voltage suppressors or metal oxide varistors, is essential to guard against voltage spikes that could compromise the rectifier's integrity.

Thermal management is another critical safety consideration in regulatory compliance. Proper heat dissipation techniques, including heat sinks and thermal cutoff devices, must be employed to prevent overheating and potential fire hazards. Additionally, isolation between input and output circuits is often required to protect against electric shock, typically achieved through transformer isolation or optocouplers.

Manufacturers must also consider electromagnetic interference (EMI) suppression techniques to comply with EMC regulations. This may involve the use of EMI filters, shielding, and proper PCB layout design to minimize radiated and conducted emissions. Furthermore, safety standards often mandate specific creepage and clearance distances between conductive parts to prevent arcing and ensure electrical isolation.

Documentation and labeling requirements form another crucial aspect of regulatory compliance. Clear and accurate product labeling, including safety warnings and electrical ratings, must be provided. Comprehensive technical documentation, including circuit diagrams, component specifications, and test results, is essential for demonstrating compliance during certification processes.

Risk Assessment Methods

Risk assessment is a critical component in implementing safety features for half wave rectifier designs. The process involves identifying potential hazards, evaluating their likelihood and potential impact, and developing strategies to mitigate risks. One common method is the Failure Mode and Effects Analysis (FMEA), which systematically examines potential failure modes in the rectifier design and their consequences.

Another approach is the Hazard and Operability Study (HAZOP), which focuses on identifying deviations from the intended design and operation of the rectifier. This method is particularly useful for complex systems where interactions between components can lead to unforeseen risks.

Quantitative risk assessment techniques, such as Fault Tree Analysis (FTA) and Event Tree Analysis (ETA), can provide numerical estimates of failure probabilities and potential consequences. These methods are valuable for prioritizing risk mitigation efforts and allocating resources effectively.

For electrical safety specifically, the IEC 61508 standard provides a framework for functional safety assessment in electronic systems. This standard outlines a systematic approach to risk reduction, including the concept of Safety Integrity Levels (SIL) for quantifying the required performance of safety functions.

When assessing electromagnetic compatibility (EMC) risks in half wave rectifier designs, methods such as the EMC Risk Analysis outlined in IEC 62430 can be employed. This approach considers both the emission of electromagnetic disturbances and the susceptibility of the device to external interference.

Thermal risk assessment is another crucial aspect, particularly for high-power applications. Techniques like Computational Fluid Dynamics (CFD) simulations and infrared thermography can be used to identify potential hotspots and thermal runaway scenarios in the rectifier design.

Software-based risk assessment tools, such as probabilistic risk assessment (PRA) software, can integrate multiple risk factors and provide a comprehensive view of the overall system safety. These tools often incorporate Monte Carlo simulations to account for uncertainties in risk parameters.

Lastly, iterative risk assessment throughout the design process is essential. This involves continuous monitoring and reassessment of risks as the design evolves, ensuring that safety features remain effective and new risks are promptly identified and addressed.

Another approach is the Hazard and Operability Study (HAZOP), which focuses on identifying deviations from the intended design and operation of the rectifier. This method is particularly useful for complex systems where interactions between components can lead to unforeseen risks.

Quantitative risk assessment techniques, such as Fault Tree Analysis (FTA) and Event Tree Analysis (ETA), can provide numerical estimates of failure probabilities and potential consequences. These methods are valuable for prioritizing risk mitigation efforts and allocating resources effectively.

For electrical safety specifically, the IEC 61508 standard provides a framework for functional safety assessment in electronic systems. This standard outlines a systematic approach to risk reduction, including the concept of Safety Integrity Levels (SIL) for quantifying the required performance of safety functions.

When assessing electromagnetic compatibility (EMC) risks in half wave rectifier designs, methods such as the EMC Risk Analysis outlined in IEC 62430 can be employed. This approach considers both the emission of electromagnetic disturbances and the susceptibility of the device to external interference.

Thermal risk assessment is another crucial aspect, particularly for high-power applications. Techniques like Computational Fluid Dynamics (CFD) simulations and infrared thermography can be used to identify potential hotspots and thermal runaway scenarios in the rectifier design.

Software-based risk assessment tools, such as probabilistic risk assessment (PRA) software, can integrate multiple risk factors and provide a comprehensive view of the overall system safety. These tools often incorporate Monte Carlo simulations to account for uncertainties in risk parameters.

Lastly, iterative risk assessment throughout the design process is essential. This involves continuous monitoring and reassessment of risks as the design evolves, ensuring that safety features remain effective and new risks are promptly identified and addressed.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!