How to Meet Increasing Half Wave Rectifier Demand?

JUL 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Half Wave Rectifier Evolution and Objectives

Half wave rectifiers have played a crucial role in the evolution of power electronics since their inception in the early 20th century. Initially developed for radio applications, these devices have undergone significant transformations to meet the growing demands of various industries. The evolution of half wave rectifiers can be traced through several key stages, each marked by technological advancements and expanding applications.

In the 1920s and 1930s, vacuum tube diodes were the primary components used in half wave rectifiers. These early rectifiers were bulky, inefficient, and limited in their power handling capabilities. However, they laid the foundation for future developments in AC to DC conversion technologies. The advent of solid-state electronics in the 1950s brought about a revolutionary change in rectifier design, with the introduction of semiconductor diodes.

The transition to semiconductor technology significantly improved the efficiency, reliability, and miniaturization of half wave rectifiers. Silicon diodes, in particular, became the standard for most applications due to their superior performance characteristics. This shift enabled the widespread adoption of half wave rectifiers in consumer electronics, industrial equipment, and power supply systems.

As technology progressed, the demand for more efficient and higher-power rectification solutions continued to grow. This led to the development of advanced semiconductor materials and device structures, such as Schottky diodes and fast recovery diodes. These innovations allowed for higher switching speeds, lower forward voltage drops, and improved thermal management, further expanding the capabilities of half wave rectifiers.

In recent years, the increasing focus on energy efficiency and power density has driven further advancements in half wave rectifier technology. The integration of rectifiers with other power electronic components, such as power factor correction circuits and voltage regulators, has become more common. This trend towards integrated solutions has enabled more compact and efficient power conversion systems.

Looking ahead, the objectives for half wave rectifier development are centered around meeting the increasing demand for high-performance, energy-efficient, and cost-effective solutions. Key goals include improving power density to enable smaller form factors, enhancing efficiency to reduce energy losses, and developing more robust designs capable of withstanding harsh operating conditions. Additionally, there is a growing emphasis on sustainability, driving research into eco-friendly materials and manufacturing processes for rectifier components.

Another important objective is to address the challenges posed by emerging applications, such as electric vehicles, renewable energy systems, and 5G infrastructure. These applications require rectifiers capable of handling higher voltages and currents while maintaining high efficiency across a wide range of operating conditions. Meeting these demands will likely involve innovations in semiconductor materials, device architectures, and thermal management techniques.

In the 1920s and 1930s, vacuum tube diodes were the primary components used in half wave rectifiers. These early rectifiers were bulky, inefficient, and limited in their power handling capabilities. However, they laid the foundation for future developments in AC to DC conversion technologies. The advent of solid-state electronics in the 1950s brought about a revolutionary change in rectifier design, with the introduction of semiconductor diodes.

The transition to semiconductor technology significantly improved the efficiency, reliability, and miniaturization of half wave rectifiers. Silicon diodes, in particular, became the standard for most applications due to their superior performance characteristics. This shift enabled the widespread adoption of half wave rectifiers in consumer electronics, industrial equipment, and power supply systems.

As technology progressed, the demand for more efficient and higher-power rectification solutions continued to grow. This led to the development of advanced semiconductor materials and device structures, such as Schottky diodes and fast recovery diodes. These innovations allowed for higher switching speeds, lower forward voltage drops, and improved thermal management, further expanding the capabilities of half wave rectifiers.

In recent years, the increasing focus on energy efficiency and power density has driven further advancements in half wave rectifier technology. The integration of rectifiers with other power electronic components, such as power factor correction circuits and voltage regulators, has become more common. This trend towards integrated solutions has enabled more compact and efficient power conversion systems.

Looking ahead, the objectives for half wave rectifier development are centered around meeting the increasing demand for high-performance, energy-efficient, and cost-effective solutions. Key goals include improving power density to enable smaller form factors, enhancing efficiency to reduce energy losses, and developing more robust designs capable of withstanding harsh operating conditions. Additionally, there is a growing emphasis on sustainability, driving research into eco-friendly materials and manufacturing processes for rectifier components.

Another important objective is to address the challenges posed by emerging applications, such as electric vehicles, renewable energy systems, and 5G infrastructure. These applications require rectifiers capable of handling higher voltages and currents while maintaining high efficiency across a wide range of operating conditions. Meeting these demands will likely involve innovations in semiconductor materials, device architectures, and thermal management techniques.

Market Analysis for Half Wave Rectifiers

The global market for half wave rectifiers has been experiencing significant growth in recent years, driven by the increasing demand for power electronics across various industries. This surge in demand is primarily attributed to the rapid expansion of renewable energy systems, electric vehicles, and consumer electronics sectors. The market size for half wave rectifiers is expected to reach substantial figures by 2025, with a compound annual growth rate (CAGR) outpacing many other electronic components.

One of the key factors contributing to this market growth is the rising adoption of renewable energy sources, particularly solar and wind power. Half wave rectifiers play a crucial role in converting the alternating current (AC) generated by these sources into direct current (DC) for storage and distribution. As countries worldwide push for cleaner energy solutions, the demand for efficient power conversion technologies, including half wave rectifiers, continues to rise.

The automotive industry, especially the electric vehicle (EV) segment, is another major driver of the half wave rectifier market. With the global shift towards electrification, the need for power conversion and management systems in EVs has skyrocketed. Half wave rectifiers are essential components in EV charging infrastructure and on-board power management systems, further fueling market growth.

Consumer electronics, including smartphones, laptops, and home appliances, represent another significant market segment for half wave rectifiers. The increasing complexity and power requirements of these devices necessitate more sophisticated power management solutions, driving the demand for efficient rectification technologies.

Geographically, Asia-Pacific dominates the half wave rectifier market, with China and India leading in terms of production and consumption. This regional dominance is attributed to the presence of major electronics manufacturing hubs and the rapid industrialization in these countries. North America and Europe follow closely, driven by technological advancements and the growing adoption of renewable energy systems.

Despite the overall positive outlook, the market faces challenges such as price volatility of raw materials and the emergence of more advanced rectification technologies. However, ongoing research and development efforts are focused on improving the efficiency and reliability of half wave rectifiers, potentially opening new avenues for market growth.

In conclusion, the market analysis for half wave rectifiers reveals a robust growth trajectory, underpinned by the expanding applications in renewable energy, automotive, and consumer electronics sectors. As industries continue to evolve and demand for efficient power conversion solutions increases, the half wave rectifier market is poised for sustained growth in the coming years.

One of the key factors contributing to this market growth is the rising adoption of renewable energy sources, particularly solar and wind power. Half wave rectifiers play a crucial role in converting the alternating current (AC) generated by these sources into direct current (DC) for storage and distribution. As countries worldwide push for cleaner energy solutions, the demand for efficient power conversion technologies, including half wave rectifiers, continues to rise.

The automotive industry, especially the electric vehicle (EV) segment, is another major driver of the half wave rectifier market. With the global shift towards electrification, the need for power conversion and management systems in EVs has skyrocketed. Half wave rectifiers are essential components in EV charging infrastructure and on-board power management systems, further fueling market growth.

Consumer electronics, including smartphones, laptops, and home appliances, represent another significant market segment for half wave rectifiers. The increasing complexity and power requirements of these devices necessitate more sophisticated power management solutions, driving the demand for efficient rectification technologies.

Geographically, Asia-Pacific dominates the half wave rectifier market, with China and India leading in terms of production and consumption. This regional dominance is attributed to the presence of major electronics manufacturing hubs and the rapid industrialization in these countries. North America and Europe follow closely, driven by technological advancements and the growing adoption of renewable energy systems.

Despite the overall positive outlook, the market faces challenges such as price volatility of raw materials and the emergence of more advanced rectification technologies. However, ongoing research and development efforts are focused on improving the efficiency and reliability of half wave rectifiers, potentially opening new avenues for market growth.

In conclusion, the market analysis for half wave rectifiers reveals a robust growth trajectory, underpinned by the expanding applications in renewable energy, automotive, and consumer electronics sectors. As industries continue to evolve and demand for efficient power conversion solutions increases, the half wave rectifier market is poised for sustained growth in the coming years.

Current Challenges in Half Wave Rectification

Half wave rectification, while a fundamental technique in power electronics, faces several challenges in meeting the increasing demand for efficient and reliable power conversion. One of the primary issues is the inherent inefficiency of the process. Half wave rectifiers only utilize one half of the AC cycle, resulting in significant power loss and a lower overall efficiency compared to full wave rectification methods. This inefficiency becomes more pronounced as power requirements increase, leading to higher energy costs and increased heat generation.

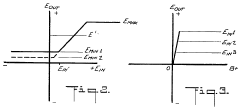

Another challenge lies in the quality of the output waveform. Half wave rectifiers produce a pulsating DC output with a significant ripple component. This ripple can cause unwanted noise and interference in sensitive electronic systems, necessitating additional filtering and smoothing circuits. As demand for cleaner power sources grows, particularly in applications such as medical equipment and precision instrumentation, the limitations of half wave rectification become more apparent.

The increasing miniaturization of electronic devices presents another hurdle for half wave rectifiers. The need for larger filtering components to smooth out the pulsating DC output conflicts with the trend towards smaller, more compact designs. This size constraint often forces engineers to make trade-offs between power quality and device dimensions, limiting the applicability of half wave rectification in modern, space-sensitive applications.

Thermal management is also a significant concern. The inefficiency of half wave rectification leads to increased heat generation, which can be particularly problematic in high-power applications or densely packed electronic assemblies. This heat not only reduces the overall system efficiency but also poses reliability risks and may necessitate additional cooling solutions, further complicating design and increasing costs.

Moreover, the growing emphasis on energy efficiency and environmental sustainability poses challenges for half wave rectification technology. As regulations and market demands push for more energy-efficient solutions, the inherent limitations of half wave rectifiers in terms of power utilization become increasingly problematic. This pressure is driving the need for more advanced rectification techniques that can offer higher efficiency and better power quality.

The rise of renewable energy sources and smart grid technologies also presents challenges for traditional half wave rectification. These new power systems often require more sophisticated power conversion and management capabilities, including bidirectional power flow and precise control over power factor and harmonics. Half wave rectifiers, with their simplistic operation, struggle to meet these advanced requirements without significant modifications or additional circuitry.

Lastly, the increasing prevalence of high-frequency applications in areas such as wireless power transfer and switch-mode power supplies pushes the boundaries of conventional half wave rectifier designs. At higher frequencies, issues such as switching losses, electromagnetic interference, and component limitations become more pronounced, necessitating innovative approaches to rectifier design and implementation.

Another challenge lies in the quality of the output waveform. Half wave rectifiers produce a pulsating DC output with a significant ripple component. This ripple can cause unwanted noise and interference in sensitive electronic systems, necessitating additional filtering and smoothing circuits. As demand for cleaner power sources grows, particularly in applications such as medical equipment and precision instrumentation, the limitations of half wave rectification become more apparent.

The increasing miniaturization of electronic devices presents another hurdle for half wave rectifiers. The need for larger filtering components to smooth out the pulsating DC output conflicts with the trend towards smaller, more compact designs. This size constraint often forces engineers to make trade-offs between power quality and device dimensions, limiting the applicability of half wave rectification in modern, space-sensitive applications.

Thermal management is also a significant concern. The inefficiency of half wave rectification leads to increased heat generation, which can be particularly problematic in high-power applications or densely packed electronic assemblies. This heat not only reduces the overall system efficiency but also poses reliability risks and may necessitate additional cooling solutions, further complicating design and increasing costs.

Moreover, the growing emphasis on energy efficiency and environmental sustainability poses challenges for half wave rectification technology. As regulations and market demands push for more energy-efficient solutions, the inherent limitations of half wave rectifiers in terms of power utilization become increasingly problematic. This pressure is driving the need for more advanced rectification techniques that can offer higher efficiency and better power quality.

The rise of renewable energy sources and smart grid technologies also presents challenges for traditional half wave rectification. These new power systems often require more sophisticated power conversion and management capabilities, including bidirectional power flow and precise control over power factor and harmonics. Half wave rectifiers, with their simplistic operation, struggle to meet these advanced requirements without significant modifications or additional circuitry.

Lastly, the increasing prevalence of high-frequency applications in areas such as wireless power transfer and switch-mode power supplies pushes the boundaries of conventional half wave rectifier designs. At higher frequencies, issues such as switching losses, electromagnetic interference, and component limitations become more pronounced, necessitating innovative approaches to rectifier design and implementation.

Existing Half Wave Rectifier Solutions

01 Circuit design and components

Half wave rectifiers typically consist of a diode and a transformer. The diode allows current to flow in only one direction, effectively converting AC to pulsating DC. The transformer is used to step up or step down the voltage as needed. Various circuit configurations and component selections can be employed to optimize performance and efficiency.- Circuit design and components: Half wave rectifiers typically consist of a diode and a transformer. The diode allows current to flow in only one direction, effectively converting AC to pulsating DC. The transformer is used to step up or step down the voltage as needed. Various circuit configurations and component selections can be employed to optimize performance for specific applications.

- Efficiency improvements: Techniques to improve the efficiency of half wave rectifiers include using high-speed switching diodes, implementing snubber circuits to reduce switching losses, and optimizing the transformer design. Advanced control methods and feedback systems can also be employed to enhance overall performance and reduce power losses.

- Applications in power supplies: Half wave rectifiers are commonly used in various power supply applications, including low-power electronic devices, battery chargers, and some industrial equipment. They can be integrated into more complex power supply designs, such as voltage regulators and DC-DC converters, to provide stable and controlled output voltages.

- Protection and safety features: To enhance reliability and safety, half wave rectifier circuits often incorporate protection features such as overvoltage protection, overcurrent protection, and thermal shutdown mechanisms. These features help prevent damage to the rectifier and connected equipment in case of fault conditions or abnormal operating scenarios.

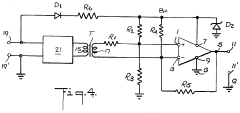

- Miniaturization and integration: Advancements in semiconductor technology have led to the development of compact and integrated half wave rectifier solutions. These include system-on-chip designs that incorporate the rectifier, control circuitry, and protection features in a single package. Such integrated solutions offer benefits in terms of size reduction, improved reliability, and simplified circuit design.

02 Voltage regulation and smoothing

To improve the output of half wave rectifiers, voltage regulation and smoothing techniques are often employed. This can involve the use of capacitors to reduce ripple, voltage regulators to maintain a steady output, and filters to remove unwanted harmonics. These enhancements help to produce a more stable and usable DC output.Expand Specific Solutions03 Applications in power supplies

Half wave rectifiers are commonly used in various power supply applications. They can be found in low-power adapters, battery chargers, and some electronic devices. In these applications, the rectifier converts AC mains power to DC for use by the device. The simplicity of the half wave rectifier makes it suitable for certain low-cost or low-power scenarios.Expand Specific Solutions04 Efficiency improvements

Researchers and engineers have developed various methods to improve the efficiency of half wave rectifiers. These improvements may include the use of advanced semiconductor materials, optimized circuit layouts, and innovative cooling solutions. Some designs incorporate synchronous rectification or other techniques to reduce power losses and increase overall system efficiency.Expand Specific Solutions05 Integration with other circuits

Half wave rectifiers are often integrated with other circuits to create more complex power management systems. This can include combination with voltage multipliers, control circuits, or protection mechanisms. Such integrations allow for more versatile and robust power supply designs, adapting the basic half wave rectifier concept to a wide range of applications and requirements.Expand Specific Solutions

Key Players in Rectifier Industry

The half wave rectifier market is experiencing increasing demand, driven by growth in power electronics and renewable energy sectors. The industry is in a mature stage, with established players and proven technologies, but still sees innovation in efficiency and miniaturization. Market size is expanding, particularly in emerging economies adopting more electronic devices. Technologically, companies like Shin-Etsu Chemical, Yamaha Corp, and HOYA Corp are leading advancements in semiconductor materials and components crucial for rectifier performance. Universities such as Technical University of Denmark and South China University of Technology contribute to research and development, pushing the boundaries of rectifier technology and applications.

State Grid Corp. of China

Technical Solution: State Grid has addressed the increasing half-wave rectifier demand by developing smart grid technologies that incorporate advanced rectification systems. Their approach focuses on large-scale power distribution networks, utilizing high-voltage direct current (HVDC) transmission systems with efficient half-wave rectifiers[4]. State Grid's rectifiers employ thyristor-based designs for high power handling capabilities, achieving conversion efficiencies of up to 97% in HVDC applications[5]. The company has also implemented adaptive control strategies to manage harmonic distortion and improve power quality in grid-connected rectifier systems[6].

Strengths: Large-scale implementation, high power handling, grid integration. Weaknesses: Complex control systems, high infrastructure requirements.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed advanced half-wave rectifier solutions to meet increasing demand, focusing on high-efficiency power conversion for 5G base stations and data centers. Their approach integrates silicon carbide (SiC) technology, which offers higher switching frequencies and lower power losses compared to traditional silicon-based rectifiers[1]. Huawei's rectifiers achieve up to 98% efficiency, reducing energy consumption in large-scale applications[2]. The company has also implemented digital control algorithms to optimize rectifier performance under varying load conditions, enhancing overall system reliability and power quality[3].

Strengths: High efficiency, advanced SiC technology, digital control optimization. Weaknesses: Potentially higher initial costs, reliance on specialized components.

Core Innovations in Half Wave Rectification

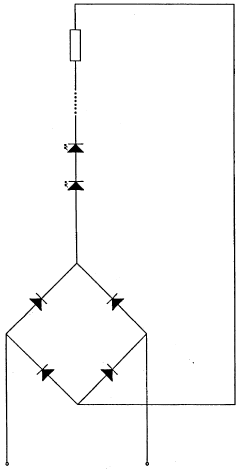

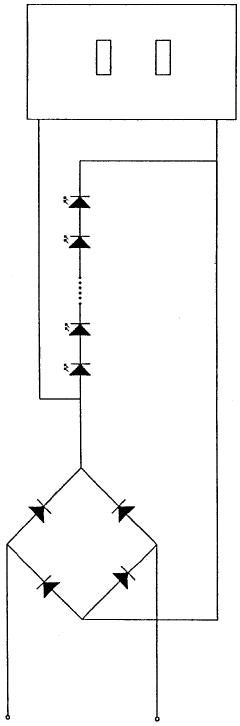

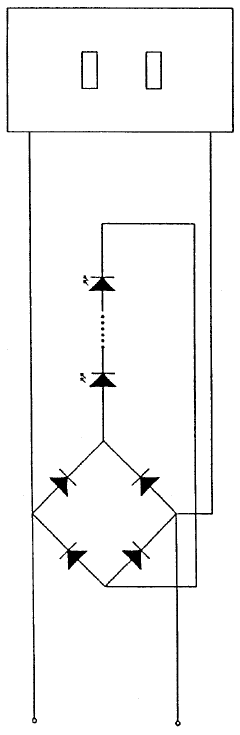

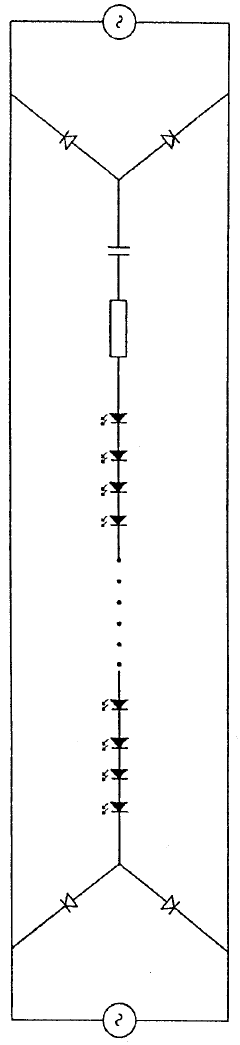

Improved light string and method of assembling thereof

PatentInactiveCA2542227A1

Innovation

- The implementation of a light string design that incorporates multiple double half wave rectification circuits with impedance devices and diodes, along with a compact resistor arrangement, allows for efficient voltage and current supply to each LED series block, reducing power consumption and production costs while enabling the connection of a large number of LEDs.

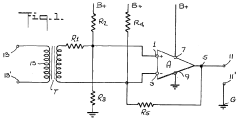

Half-wave rectifier circuit

PatentInactiveUS3936720A

Innovation

- A high-gain differential amplifier-based half-wave rectifier circuit operating from a single power supply, eliminating the need for voltage regulation and reducing temperature dependence, with resistor ratios optimized to minimize errors and achieve minimal output voltage drop.

Supply Chain Analysis for Rectifier Components

The supply chain for rectifier components plays a crucial role in meeting the increasing demand for half wave rectifiers. A comprehensive analysis of the supply chain reveals several key factors that impact the availability and production of these essential components.

Raw material sourcing is a primary concern in the rectifier supply chain. Silicon, the fundamental material for semiconductor diodes, requires a stable and reliable supply. The global silicon market has experienced fluctuations in recent years, with occasional shortages affecting production capacity. Diversifying silicon sources and establishing long-term contracts with multiple suppliers can help mitigate supply risks.

Component manufacturing represents another critical link in the supply chain. The production of rectifier diodes involves complex processes, including wafer fabrication, assembly, and testing. Manufacturers must continuously optimize these processes to increase yield and reduce production costs. Investing in advanced manufacturing technologies and automation can significantly enhance production efficiency and output.

Distribution networks play a vital role in ensuring timely delivery of rectifier components to end-users. Efficient logistics and inventory management systems are essential for maintaining an adequate supply of components while minimizing storage costs. Implementing just-in-time delivery strategies and leveraging data analytics for demand forecasting can help streamline the distribution process.

Quality control measures throughout the supply chain are crucial for maintaining the reliability and performance of rectifier components. Implementing rigorous testing protocols at various stages of production and distribution helps identify and address potential issues before they reach end-users. Collaboration between suppliers, manufacturers, and distributors is essential for maintaining consistent quality standards across the supply chain.

The global nature of the rectifier component supply chain introduces additional complexities, including geopolitical risks and trade regulations. Diversifying manufacturing locations and establishing regional supply hubs can help mitigate these risks and ensure a more resilient supply chain. Additionally, staying informed about changing trade policies and regulations is crucial for maintaining smooth operations across international borders.

Sustainability considerations are becoming increasingly important in the rectifier component supply chain. Implementing eco-friendly manufacturing processes, reducing waste, and exploring recycling options for end-of-life components can help address environmental concerns and meet growing customer demands for sustainable products.

By addressing these key aspects of the supply chain, manufacturers and suppliers can work towards meeting the increasing demand for half wave rectifiers while maintaining product quality, reliability, and cost-effectiveness.

Raw material sourcing is a primary concern in the rectifier supply chain. Silicon, the fundamental material for semiconductor diodes, requires a stable and reliable supply. The global silicon market has experienced fluctuations in recent years, with occasional shortages affecting production capacity. Diversifying silicon sources and establishing long-term contracts with multiple suppliers can help mitigate supply risks.

Component manufacturing represents another critical link in the supply chain. The production of rectifier diodes involves complex processes, including wafer fabrication, assembly, and testing. Manufacturers must continuously optimize these processes to increase yield and reduce production costs. Investing in advanced manufacturing technologies and automation can significantly enhance production efficiency and output.

Distribution networks play a vital role in ensuring timely delivery of rectifier components to end-users. Efficient logistics and inventory management systems are essential for maintaining an adequate supply of components while minimizing storage costs. Implementing just-in-time delivery strategies and leveraging data analytics for demand forecasting can help streamline the distribution process.

Quality control measures throughout the supply chain are crucial for maintaining the reliability and performance of rectifier components. Implementing rigorous testing protocols at various stages of production and distribution helps identify and address potential issues before they reach end-users. Collaboration between suppliers, manufacturers, and distributors is essential for maintaining consistent quality standards across the supply chain.

The global nature of the rectifier component supply chain introduces additional complexities, including geopolitical risks and trade regulations. Diversifying manufacturing locations and establishing regional supply hubs can help mitigate these risks and ensure a more resilient supply chain. Additionally, staying informed about changing trade policies and regulations is crucial for maintaining smooth operations across international borders.

Sustainability considerations are becoming increasingly important in the rectifier component supply chain. Implementing eco-friendly manufacturing processes, reducing waste, and exploring recycling options for end-of-life components can help address environmental concerns and meet growing customer demands for sustainable products.

By addressing these key aspects of the supply chain, manufacturers and suppliers can work towards meeting the increasing demand for half wave rectifiers while maintaining product quality, reliability, and cost-effectiveness.

Energy Efficiency Considerations in Rectification

Energy efficiency is a critical consideration in the design and implementation of rectification systems, particularly as the demand for half-wave rectifiers continues to increase. The conversion of alternating current (AC) to direct current (DC) inherently involves some energy loss, and improving the efficiency of this process is crucial for reducing power consumption and heat generation.

One of the primary approaches to enhancing energy efficiency in rectification is the use of advanced semiconductor materials. Silicon carbide (SiC) and gallium nitride (GaN) have emerged as promising alternatives to traditional silicon-based devices. These wide-bandgap semiconductors offer lower on-resistance and faster switching speeds, resulting in reduced conduction and switching losses. Implementing SiC or GaN diodes in half-wave rectifier circuits can significantly improve overall system efficiency.

Circuit topology optimization is another key factor in improving energy efficiency. By carefully designing the rectifier circuit layout and component placement, parasitic inductances and capacitances can be minimized, reducing energy losses due to electromagnetic interference and stray currents. Advanced printed circuit board (PCB) design techniques, such as the use of multi-layer boards with dedicated power and ground planes, can further enhance efficiency by improving thermal management and reducing electrical noise.

Thermal management plays a crucial role in maintaining high energy efficiency in rectification systems. As rectifiers handle significant power levels, effective heat dissipation is essential to prevent performance degradation and component failure. Implementing advanced cooling solutions, such as heat sinks with optimized fin designs or active cooling systems, can help maintain lower operating temperatures and improve overall system efficiency.

The integration of smart control systems and power management techniques can also contribute to improved energy efficiency. Implementing adaptive control algorithms that adjust rectifier operation based on load conditions can optimize performance across a wide range of operating scenarios. Additionally, incorporating power factor correction (PFC) circuits can minimize reactive power consumption and improve overall system efficiency by ensuring that the current waveform closely matches the voltage waveform.

As the demand for half-wave rectifiers continues to grow, particularly in applications such as renewable energy systems and electric vehicle charging, the focus on energy efficiency becomes increasingly important. Research into novel materials, such as graphene-based devices and organic semiconductors, holds promise for future improvements in rectification efficiency. Furthermore, the development of advanced simulation and modeling tools enables designers to optimize rectifier performance and energy efficiency before physical prototyping, accelerating the development of more efficient solutions.

In conclusion, addressing energy efficiency in rectification requires a multifaceted approach, combining advancements in materials science, circuit design, thermal management, and control systems. By focusing on these areas, manufacturers can develop half-wave rectifiers that meet the increasing demand while minimizing energy losses and environmental impact.

One of the primary approaches to enhancing energy efficiency in rectification is the use of advanced semiconductor materials. Silicon carbide (SiC) and gallium nitride (GaN) have emerged as promising alternatives to traditional silicon-based devices. These wide-bandgap semiconductors offer lower on-resistance and faster switching speeds, resulting in reduced conduction and switching losses. Implementing SiC or GaN diodes in half-wave rectifier circuits can significantly improve overall system efficiency.

Circuit topology optimization is another key factor in improving energy efficiency. By carefully designing the rectifier circuit layout and component placement, parasitic inductances and capacitances can be minimized, reducing energy losses due to electromagnetic interference and stray currents. Advanced printed circuit board (PCB) design techniques, such as the use of multi-layer boards with dedicated power and ground planes, can further enhance efficiency by improving thermal management and reducing electrical noise.

Thermal management plays a crucial role in maintaining high energy efficiency in rectification systems. As rectifiers handle significant power levels, effective heat dissipation is essential to prevent performance degradation and component failure. Implementing advanced cooling solutions, such as heat sinks with optimized fin designs or active cooling systems, can help maintain lower operating temperatures and improve overall system efficiency.

The integration of smart control systems and power management techniques can also contribute to improved energy efficiency. Implementing adaptive control algorithms that adjust rectifier operation based on load conditions can optimize performance across a wide range of operating scenarios. Additionally, incorporating power factor correction (PFC) circuits can minimize reactive power consumption and improve overall system efficiency by ensuring that the current waveform closely matches the voltage waveform.

As the demand for half-wave rectifiers continues to grow, particularly in applications such as renewable energy systems and electric vehicle charging, the focus on energy efficiency becomes increasingly important. Research into novel materials, such as graphene-based devices and organic semiconductors, holds promise for future improvements in rectification efficiency. Furthermore, the development of advanced simulation and modeling tools enables designers to optimize rectifier performance and energy efficiency before physical prototyping, accelerating the development of more efficient solutions.

In conclusion, addressing energy efficiency in rectification requires a multifaceted approach, combining advancements in materials science, circuit design, thermal management, and control systems. By focusing on these areas, manufacturers can develop half-wave rectifiers that meet the increasing demand while minimizing energy losses and environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!