How to Optimize Voltage Regulation in Half Wave Rectifiers?

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Half Wave Rectification Background and Objectives

Half-wave rectification, a fundamental process in power electronics, has been a cornerstone of voltage regulation since the early days of electrical engineering. This technique, which converts alternating current (AC) to pulsating direct current (DC), has evolved significantly over the past century. The primary objective of half-wave rectification is to provide a unidirectional current flow, essential for powering various electronic devices and systems.

The development of half-wave rectifiers can be traced back to the invention of the vacuum tube diode in the early 1900s. As semiconductor technology advanced, solid-state diodes replaced vacuum tubes, leading to more efficient and compact rectifier designs. This progression has been driven by the ever-increasing demand for more precise and stable voltage regulation in a wide range of applications, from consumer electronics to industrial power systems.

In recent years, the focus has shifted towards optimizing voltage regulation in half-wave rectifiers. This emphasis stems from the growing need for energy-efficient power conversion and the proliferation of sensitive electronic devices that require stable power supplies. The main goals of optimization include reducing ripple voltage, improving power factor, minimizing harmonic distortion, and enhancing overall efficiency.

The challenges in optimizing voltage regulation in half-wave rectifiers are multifaceted. One primary concern is the inherent pulsating nature of the output, which can lead to significant ripple in the DC voltage. This ripple can cause unwanted noise and potential damage to connected devices. Additionally, half-wave rectifiers typically have a poor power factor, which results in inefficient power transfer and increased energy costs.

Another critical objective is to address the limitations of traditional passive filtering methods. While capacitor and inductor-based filters have been widely used to smooth the output voltage, they often fall short in meeting the stringent requirements of modern electronic systems. This has led to the exploration of more advanced techniques, including active filtering and digital control strategies.

The pursuit of optimization also extends to improving the rectifier's response to varying load conditions and input voltage fluctuations. Achieving stable voltage regulation across a wide range of operating conditions is crucial for enhancing the reliability and performance of power supply systems. This goal has spurred research into adaptive control mechanisms and intelligent power management techniques.

As we delve deeper into the technical aspects of half-wave rectification, it becomes clear that the path to optimization involves a multidisciplinary approach. This encompasses advancements in semiconductor materials, circuit design innovations, and the integration of sophisticated control algorithms. The ultimate aim is to develop half-wave rectifier systems that can deliver highly regulated, efficient, and reliable power conversion, meeting the evolving needs of modern technology.

The development of half-wave rectifiers can be traced back to the invention of the vacuum tube diode in the early 1900s. As semiconductor technology advanced, solid-state diodes replaced vacuum tubes, leading to more efficient and compact rectifier designs. This progression has been driven by the ever-increasing demand for more precise and stable voltage regulation in a wide range of applications, from consumer electronics to industrial power systems.

In recent years, the focus has shifted towards optimizing voltage regulation in half-wave rectifiers. This emphasis stems from the growing need for energy-efficient power conversion and the proliferation of sensitive electronic devices that require stable power supplies. The main goals of optimization include reducing ripple voltage, improving power factor, minimizing harmonic distortion, and enhancing overall efficiency.

The challenges in optimizing voltage regulation in half-wave rectifiers are multifaceted. One primary concern is the inherent pulsating nature of the output, which can lead to significant ripple in the DC voltage. This ripple can cause unwanted noise and potential damage to connected devices. Additionally, half-wave rectifiers typically have a poor power factor, which results in inefficient power transfer and increased energy costs.

Another critical objective is to address the limitations of traditional passive filtering methods. While capacitor and inductor-based filters have been widely used to smooth the output voltage, they often fall short in meeting the stringent requirements of modern electronic systems. This has led to the exploration of more advanced techniques, including active filtering and digital control strategies.

The pursuit of optimization also extends to improving the rectifier's response to varying load conditions and input voltage fluctuations. Achieving stable voltage regulation across a wide range of operating conditions is crucial for enhancing the reliability and performance of power supply systems. This goal has spurred research into adaptive control mechanisms and intelligent power management techniques.

As we delve deeper into the technical aspects of half-wave rectification, it becomes clear that the path to optimization involves a multidisciplinary approach. This encompasses advancements in semiconductor materials, circuit design innovations, and the integration of sophisticated control algorithms. The ultimate aim is to develop half-wave rectifier systems that can deliver highly regulated, efficient, and reliable power conversion, meeting the evolving needs of modern technology.

Market Demand Analysis for Voltage Regulation

The market demand for voltage regulation in half wave rectifiers has been steadily growing, driven by the increasing need for efficient power management across various industries. This demand is particularly pronounced in sectors such as consumer electronics, automotive, industrial automation, and renewable energy systems, where precise voltage control is crucial for optimal performance and longevity of electronic devices.

In the consumer electronics sector, the proliferation of smartphones, tablets, and other portable devices has created a significant market for compact and efficient voltage regulation solutions. These devices require stable power supply to ensure consistent performance and extend battery life, making advanced voltage regulation techniques in half wave rectifiers highly desirable.

The automotive industry represents another major market for voltage regulation technologies. With the rise of electric and hybrid vehicles, there is an increased focus on power management systems that can efficiently handle the varying voltage requirements of different vehicle components. Half wave rectifiers with optimized voltage regulation play a crucial role in maintaining stable power supply for critical automotive systems.

Industrial automation is yet another sector driving the demand for improved voltage regulation in half wave rectifiers. As manufacturing processes become more sophisticated and reliant on precision electronics, the need for stable and reliable power supply becomes paramount. Voltage regulation technologies that can withstand harsh industrial environments while maintaining consistent output are highly sought after in this market.

The renewable energy sector, particularly solar and wind power systems, also contributes significantly to the market demand for voltage regulation solutions. These systems often generate variable voltages that need to be regulated for grid integration or local consumption. Half wave rectifiers with advanced voltage regulation capabilities are essential components in power conversion systems for renewable energy applications.

Market analysis indicates that the global voltage regulator market, which includes half wave rectifier technologies, is expected to grow substantially in the coming years. This growth is attributed to the increasing adoption of electronic devices across various industries and the rising demand for energy-efficient power management solutions.

Furthermore, the trend towards miniaturization and increased power density in electronic devices is driving the need for more sophisticated voltage regulation techniques. This presents opportunities for innovations in half wave rectifier designs that can deliver improved efficiency and performance in smaller form factors.

As the Internet of Things (IoT) continues to expand, the demand for voltage regulation in low-power devices is also on the rise. This emerging market segment requires voltage regulation solutions that can operate efficiently at very low power levels, presenting new challenges and opportunities for half wave rectifier optimization.

In the consumer electronics sector, the proliferation of smartphones, tablets, and other portable devices has created a significant market for compact and efficient voltage regulation solutions. These devices require stable power supply to ensure consistent performance and extend battery life, making advanced voltage regulation techniques in half wave rectifiers highly desirable.

The automotive industry represents another major market for voltage regulation technologies. With the rise of electric and hybrid vehicles, there is an increased focus on power management systems that can efficiently handle the varying voltage requirements of different vehicle components. Half wave rectifiers with optimized voltage regulation play a crucial role in maintaining stable power supply for critical automotive systems.

Industrial automation is yet another sector driving the demand for improved voltage regulation in half wave rectifiers. As manufacturing processes become more sophisticated and reliant on precision electronics, the need for stable and reliable power supply becomes paramount. Voltage regulation technologies that can withstand harsh industrial environments while maintaining consistent output are highly sought after in this market.

The renewable energy sector, particularly solar and wind power systems, also contributes significantly to the market demand for voltage regulation solutions. These systems often generate variable voltages that need to be regulated for grid integration or local consumption. Half wave rectifiers with advanced voltage regulation capabilities are essential components in power conversion systems for renewable energy applications.

Market analysis indicates that the global voltage regulator market, which includes half wave rectifier technologies, is expected to grow substantially in the coming years. This growth is attributed to the increasing adoption of electronic devices across various industries and the rising demand for energy-efficient power management solutions.

Furthermore, the trend towards miniaturization and increased power density in electronic devices is driving the need for more sophisticated voltage regulation techniques. This presents opportunities for innovations in half wave rectifier designs that can deliver improved efficiency and performance in smaller form factors.

As the Internet of Things (IoT) continues to expand, the demand for voltage regulation in low-power devices is also on the rise. This emerging market segment requires voltage regulation solutions that can operate efficiently at very low power levels, presenting new challenges and opportunities for half wave rectifier optimization.

Current Challenges in Half Wave Rectifier Voltage Regulation

Half wave rectifiers, while simple and cost-effective, face several significant challenges in achieving optimal voltage regulation. One of the primary issues is the inherent ripple in the output voltage, which results from the rectifier's operation on only one half of the AC input cycle. This ripple can lead to inconsistent power delivery and potential damage to sensitive electronic components.

Another major challenge is the low efficiency of half wave rectifiers. Since they only utilize half of the input waveform, a substantial portion of the available power is wasted. This inefficiency not only increases energy costs but also necessitates more robust cooling solutions to manage the heat generated by the wasted power.

The non-linear nature of the rectification process introduces harmonic distortion into the power system. These harmonics can cause electromagnetic interference (EMI) and reduce the overall power quality. Managing and mitigating these harmonics presents a significant technical hurdle in the design and implementation of half wave rectifier systems.

Voltage drop across the rectifying diode is another critical issue. This drop, typically around 0.7V for silicon diodes, becomes particularly problematic in low-voltage applications where it can represent a significant percentage of the desired output voltage. Minimizing this voltage drop while maintaining rectification efficiency is a delicate balance that engineers must strike.

Temperature sensitivity of the rectifying components poses yet another challenge. As diodes and other semiconductor devices are affected by temperature changes, their performance characteristics can vary, leading to inconsistencies in voltage regulation across different operating conditions.

The limited current handling capacity of half wave rectifiers is also a concern, especially in applications requiring higher power output. This limitation often necessitates the use of multiple rectifiers in parallel or the selection of more complex rectification topologies, adding to system complexity and cost.

Lastly, the pulsating nature of the output from half wave rectifiers can cause stress on filtering components, such as capacitors. These components must be carefully selected and sized to handle the high peak currents and voltages associated with the rectification process, while still providing adequate smoothing of the output voltage.

Another major challenge is the low efficiency of half wave rectifiers. Since they only utilize half of the input waveform, a substantial portion of the available power is wasted. This inefficiency not only increases energy costs but also necessitates more robust cooling solutions to manage the heat generated by the wasted power.

The non-linear nature of the rectification process introduces harmonic distortion into the power system. These harmonics can cause electromagnetic interference (EMI) and reduce the overall power quality. Managing and mitigating these harmonics presents a significant technical hurdle in the design and implementation of half wave rectifier systems.

Voltage drop across the rectifying diode is another critical issue. This drop, typically around 0.7V for silicon diodes, becomes particularly problematic in low-voltage applications where it can represent a significant percentage of the desired output voltage. Minimizing this voltage drop while maintaining rectification efficiency is a delicate balance that engineers must strike.

Temperature sensitivity of the rectifying components poses yet another challenge. As diodes and other semiconductor devices are affected by temperature changes, their performance characteristics can vary, leading to inconsistencies in voltage regulation across different operating conditions.

The limited current handling capacity of half wave rectifiers is also a concern, especially in applications requiring higher power output. This limitation often necessitates the use of multiple rectifiers in parallel or the selection of more complex rectification topologies, adding to system complexity and cost.

Lastly, the pulsating nature of the output from half wave rectifiers can cause stress on filtering components, such as capacitors. These components must be carefully selected and sized to handle the high peak currents and voltages associated with the rectification process, while still providing adequate smoothing of the output voltage.

Existing Voltage Regulation Solutions for Half Wave Rectifiers

01 Use of capacitors for voltage regulation

Half-wave rectifiers can be improved by incorporating capacitors to smooth out voltage fluctuations. This technique helps maintain a more stable output voltage by storing energy during the conductive half-cycle and releasing it during the non-conductive half-cycle, effectively reducing ripple and improving overall voltage regulation.- Use of capacitors for voltage regulation: Half-wave rectifiers can employ capacitors to smooth out voltage fluctuations and improve regulation. The capacitor charges during the positive half-cycle and discharges during the negative half-cycle, helping to maintain a more stable output voltage. This technique is often used in simple power supply designs.

- Feedback control mechanisms: Implementing feedback control systems in half-wave rectifiers can significantly enhance voltage regulation. These systems continuously monitor the output voltage and adjust the rectifier's operation to maintain a stable voltage level. This approach is particularly useful in applications requiring precise voltage control.

- Transformer-based voltage regulation: Utilizing transformers in conjunction with half-wave rectifiers can provide improved voltage regulation. The transformer can be designed with multiple taps or windings to allow for voltage adjustment, helping to compensate for input voltage variations and load changes.

- Semiconductor-based voltage regulators: Incorporating semiconductor devices such as Zener diodes or voltage regulator ICs can enhance the voltage regulation of half-wave rectifier circuits. These components can maintain a constant output voltage despite variations in input voltage or load current, offering improved stability and efficiency.

- Switched-mode regulation techniques: Applying switched-mode regulation techniques to half-wave rectifier circuits can result in more efficient and precise voltage regulation. These methods involve rapidly switching the rectifier on and off to control the output voltage, often utilizing pulse-width modulation (PWM) to achieve the desired regulation.

02 Implementation of feedback control systems

Feedback control systems can be integrated into half-wave rectifier circuits to enhance voltage regulation. These systems continuously monitor the output voltage and adjust the rectifier's operation to maintain a constant voltage level, compensating for variations in input voltage or load conditions.Expand Specific Solutions03 Use of voltage regulator ICs

Specialized voltage regulator integrated circuits (ICs) can be employed in conjunction with half-wave rectifiers to improve voltage regulation. These ICs provide precise control over the output voltage, often incorporating features such as current limiting and thermal protection to enhance overall performance and reliability.Expand Specific Solutions04 Transformer-based voltage regulation

Transformers can be utilized in half-wave rectifier circuits to achieve better voltage regulation. By selecting appropriate transformer ratios and incorporating tap-changing mechanisms, the output voltage can be adjusted to compensate for input voltage variations or load changes, resulting in improved voltage stability.Expand Specific Solutions05 Active power factor correction techniques

Implementing active power factor correction (PFC) techniques in half-wave rectifier circuits can significantly improve voltage regulation. PFC circuits shape the input current waveform to match the voltage waveform, reducing harmonic distortion and improving overall power quality, which in turn leads to better voltage regulation.Expand Specific Solutions

Key Players in Power Electronics Industry

The optimization of voltage regulation in half wave rectifiers is a mature technology within the power electronics industry, currently in a stable growth phase. The market for this technology is substantial, driven by increasing demand for efficient power conversion in various applications. Major players like TE Connectivity, Littelfuse, and Panasonic Holdings are at the forefront, leveraging their extensive experience in electronic components. These companies, along with others such as Sanken Electric and Renesas Electronics, are continuously innovating to improve efficiency and reduce power losses. The technology's maturity is evident in the widespread adoption across industries, with ongoing research focused on incremental improvements rather than disruptive changes.

Littelfuse, Inc.

Technical Solution: Littelfuse has developed advanced voltage regulation solutions for half-wave rectifiers, focusing on improving efficiency and reducing power losses. Their approach involves implementing high-performance TVS (Transient Voltage Suppression) diodes in parallel with the rectifier diode. This configuration helps to clamp voltage spikes and protect sensitive components downstream. Additionally, Littelfuse has introduced smart fuse technology that integrates with the rectifier circuit to provide overcurrent protection and voltage regulation in a single package. The company has also explored the use of SiC (Silicon Carbide) diodes in half-wave rectifiers to minimize reverse recovery losses and improve overall system efficiency[1][3].

Strengths: Comprehensive protection against voltage spikes and overcurrent events. Integration of multiple functions in a single package reduces component count. Use of advanced materials like SiC improves efficiency. Weaknesses: Potentially higher cost compared to basic solutions. May require more complex circuit design and implementation.

Panasonic Holdings Corp.

Technical Solution: Panasonic has developed a novel approach to optimize voltage regulation in half-wave rectifiers by implementing a hybrid control system. This system combines traditional analog control with digital signal processing to achieve more precise and adaptive voltage regulation. Their solution incorporates a microcontroller that continuously monitors the output voltage and adjusts the rectifier's operation in real-time. Panasonic's technology also features an advanced feedback loop that compensates for load variations and input voltage fluctuations, ensuring stable output even under challenging conditions. Furthermore, they have integrated power factor correction (PFC) techniques into their half-wave rectifier designs, significantly improving overall power quality and efficiency[2][5].

Strengths: High precision voltage regulation through adaptive control. Improved power quality with integrated PFC. Robust performance under varying load and input conditions. Weaknesses: Increased complexity and cost due to the incorporation of digital control elements. May require more power for the control circuitry.

Core Innovations in Half Wave Rectifier Design

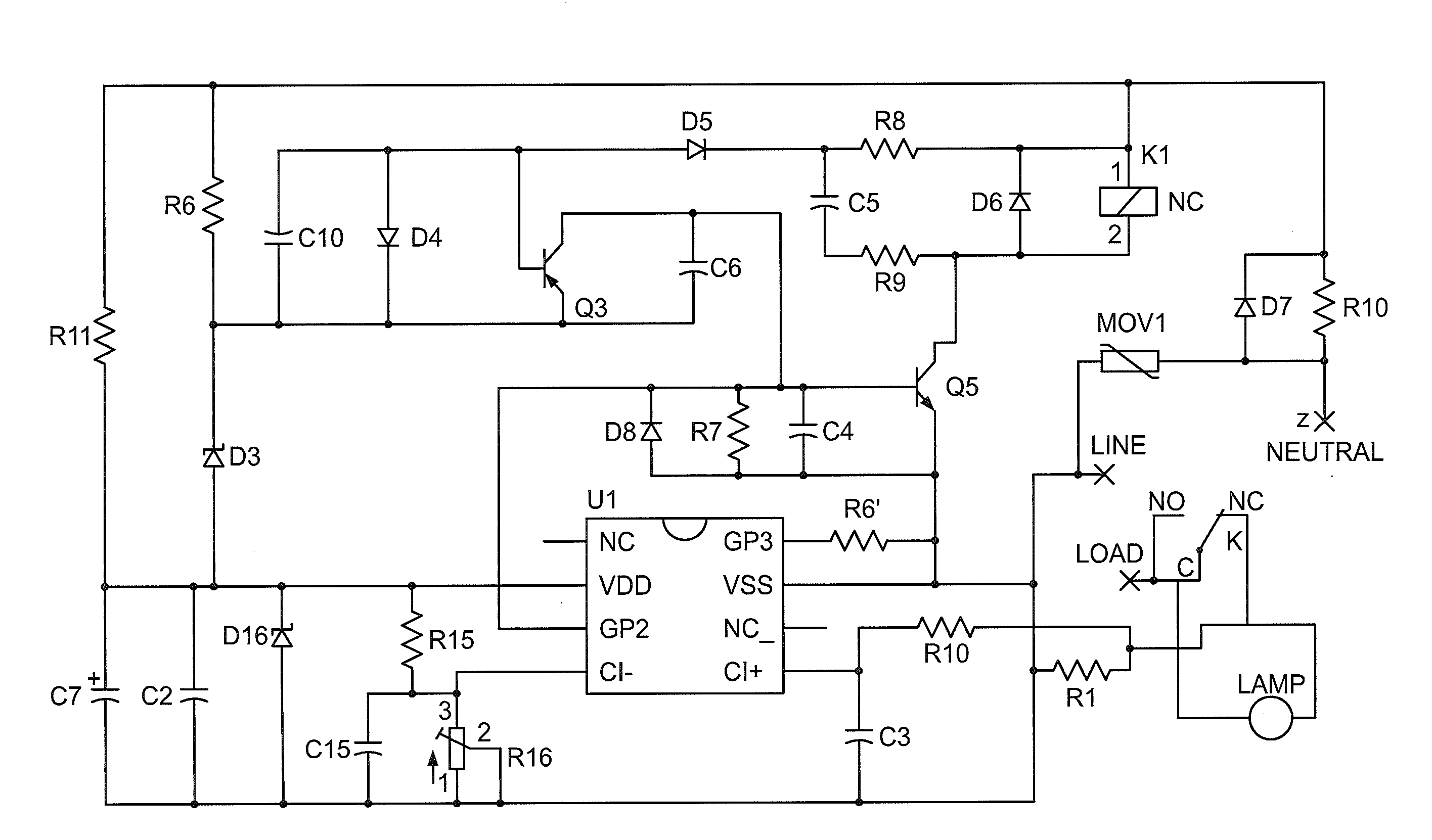

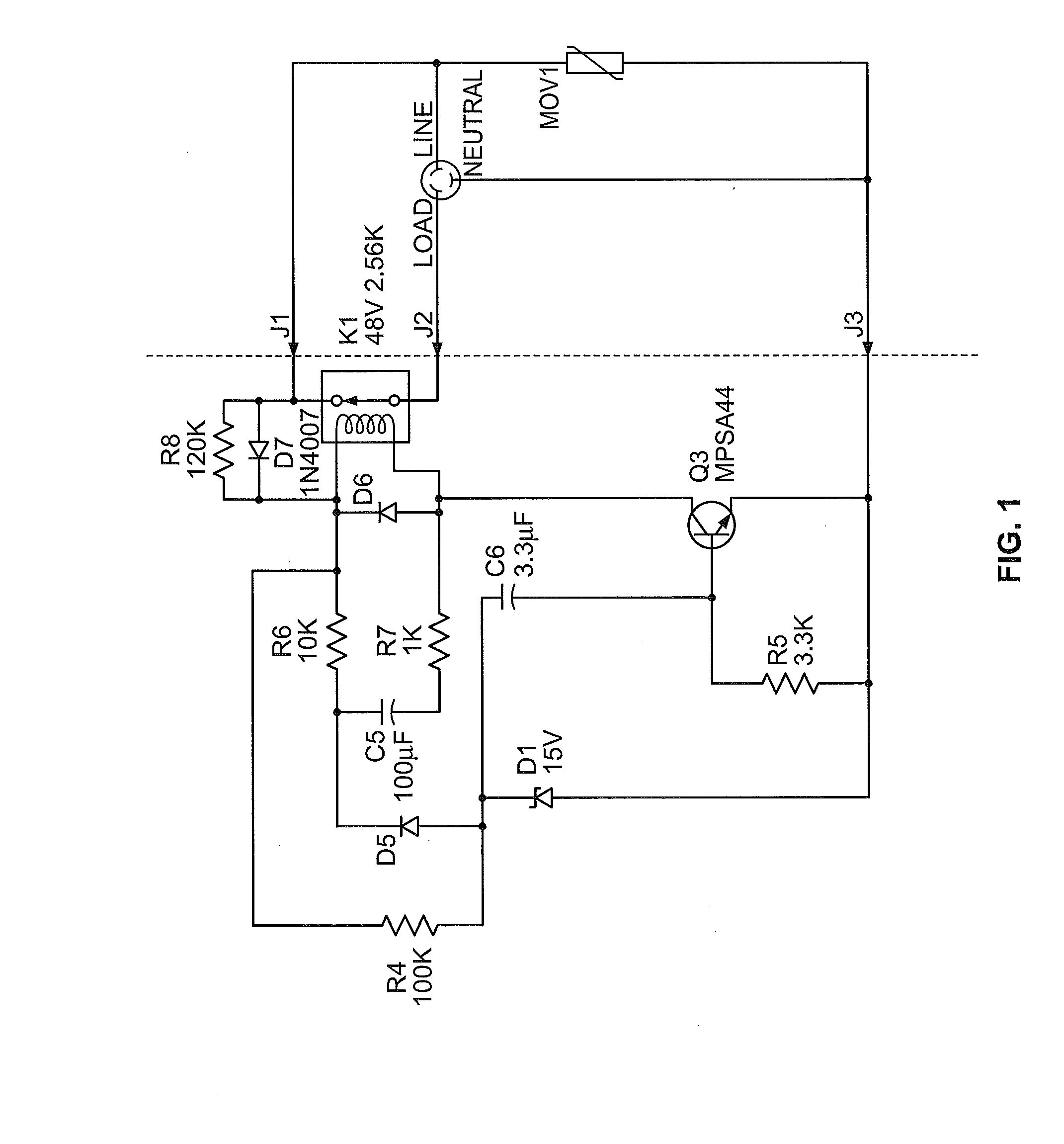

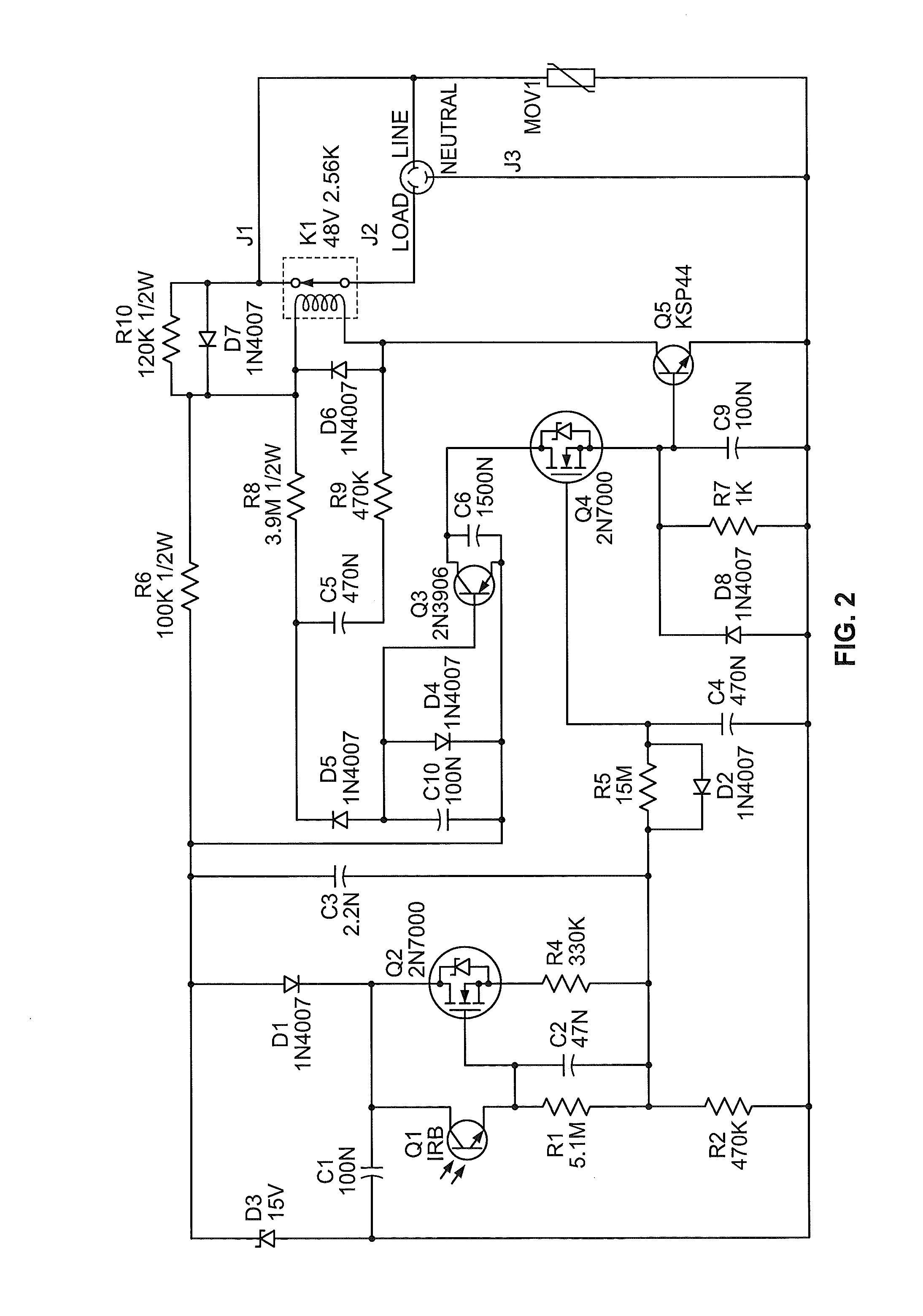

Controller Circuit Including a Switch Mode Power Converter and Automatic Recloser Using the Same

PatentInactiveUS20120019971A1

Innovation

- A switch mode power converter circuit using an electromagnetic relay, current sense circuit, and micro-controller to control AC power delivery, eliminating the need for heat sinks and reducing component count, enabling efficient and cost-effective power conversion.

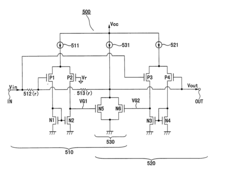

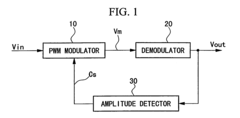

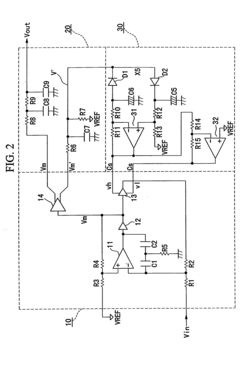

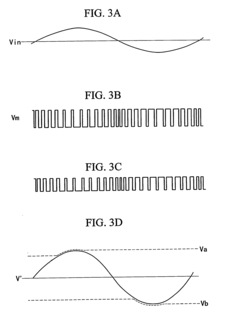

Device for amplitude adjustment and rectification made with MOS technology

PatentInactiveUS20050185433A1

Innovation

- The development of amplitude adjustment devices using PWM modulators, demodulators, and amplitude detectors with field-effect transistors, and full-wave rectifiers configured with inversion amplifiers and output sections, allowing for continuous gain variation and integration as ICs without external diodes.

Efficiency and Power Loss Considerations

Efficiency and power loss considerations are crucial aspects in optimizing voltage regulation for half-wave rectifiers. These factors directly impact the overall performance and reliability of the rectifier circuit, making them essential areas of focus for engineers and designers.

One of the primary concerns in half-wave rectification is the inherent inefficiency of the process. Since only one half of the AC cycle is utilized, a significant portion of the input power is wasted. This inefficiency leads to increased power consumption and heat generation, which can negatively affect the longevity and reliability of the circuit components.

To address these issues, several strategies can be employed to improve efficiency and reduce power losses. One approach is to implement a more efficient diode selection process. By choosing diodes with lower forward voltage drops and faster switching times, the conduction losses can be minimized. Additionally, the use of Schottky diodes, which have lower forward voltage drops compared to conventional silicon diodes, can further enhance efficiency.

Another important consideration is the design of the filter circuit. A well-designed filter can help smooth out the rectified waveform, reducing ripple and improving the overall quality of the output voltage. However, it is essential to strike a balance between filtering effectiveness and power loss. Oversized filter components may introduce unnecessary losses, while undersized components may fail to adequately smooth the output.

The choice of transformer in the rectifier circuit also plays a crucial role in efficiency and power loss considerations. A properly sized transformer with low core losses and appropriate winding resistance can significantly improve overall system efficiency. Furthermore, the use of high-frequency transformers can reduce the size and weight of the circuit while potentially improving efficiency.

Heat management is another critical aspect of optimizing voltage regulation in half-wave rectifiers. Excessive heat generation not only reduces efficiency but also accelerates component degradation. Implementing effective thermal management techniques, such as heat sinks and proper component placement, can help dissipate heat and maintain optimal operating temperatures.

Advanced control techniques, such as pulse-width modulation (PWM) and synchronous rectification, can be employed to further enhance efficiency and reduce power losses. These methods allow for more precise control of the rectification process, minimizing switching losses and improving overall performance.

By carefully considering these efficiency and power loss factors, engineers can develop optimized half-wave rectifier designs that deliver improved voltage regulation while minimizing energy waste and heat generation. This approach not only enhances the performance of the rectifier circuit but also contributes to the overall sustainability and cost-effectiveness of the power supply system.

One of the primary concerns in half-wave rectification is the inherent inefficiency of the process. Since only one half of the AC cycle is utilized, a significant portion of the input power is wasted. This inefficiency leads to increased power consumption and heat generation, which can negatively affect the longevity and reliability of the circuit components.

To address these issues, several strategies can be employed to improve efficiency and reduce power losses. One approach is to implement a more efficient diode selection process. By choosing diodes with lower forward voltage drops and faster switching times, the conduction losses can be minimized. Additionally, the use of Schottky diodes, which have lower forward voltage drops compared to conventional silicon diodes, can further enhance efficiency.

Another important consideration is the design of the filter circuit. A well-designed filter can help smooth out the rectified waveform, reducing ripple and improving the overall quality of the output voltage. However, it is essential to strike a balance between filtering effectiveness and power loss. Oversized filter components may introduce unnecessary losses, while undersized components may fail to adequately smooth the output.

The choice of transformer in the rectifier circuit also plays a crucial role in efficiency and power loss considerations. A properly sized transformer with low core losses and appropriate winding resistance can significantly improve overall system efficiency. Furthermore, the use of high-frequency transformers can reduce the size and weight of the circuit while potentially improving efficiency.

Heat management is another critical aspect of optimizing voltage regulation in half-wave rectifiers. Excessive heat generation not only reduces efficiency but also accelerates component degradation. Implementing effective thermal management techniques, such as heat sinks and proper component placement, can help dissipate heat and maintain optimal operating temperatures.

Advanced control techniques, such as pulse-width modulation (PWM) and synchronous rectification, can be employed to further enhance efficiency and reduce power losses. These methods allow for more precise control of the rectification process, minimizing switching losses and improving overall performance.

By carefully considering these efficiency and power loss factors, engineers can develop optimized half-wave rectifier designs that deliver improved voltage regulation while minimizing energy waste and heat generation. This approach not only enhances the performance of the rectifier circuit but also contributes to the overall sustainability and cost-effectiveness of the power supply system.

Electromagnetic Compatibility and Noise Reduction Strategies

Electromagnetic compatibility (EMC) and noise reduction are critical aspects of optimizing voltage regulation in half-wave rectifiers. These strategies aim to minimize electromagnetic interference (EMI) and improve the overall performance of the rectifier circuit. One key approach is the implementation of proper shielding techniques. By enclosing the rectifier circuit in a conductive enclosure, external electromagnetic fields can be effectively blocked, reducing their impact on the voltage regulation process.

Another important strategy is the use of filtering components. Capacitors and inductors can be strategically placed in the circuit to attenuate high-frequency noise and smooth out voltage fluctuations. Low-pass filters are particularly effective in reducing high-frequency harmonics generated by the rectification process. Additionally, ferrite beads can be employed to suppress common-mode noise on power lines and signal traces.

Proper PCB layout design is crucial for EMC and noise reduction. Implementing a ground plane helps minimize ground loop currents and provides a low-impedance return path for high-frequency signals. Careful routing of traces, with attention to minimizing loop areas and separating sensitive analog signals from noisy digital lines, can significantly reduce EMI.

Component selection also plays a vital role in EMC performance. Choosing low-noise components, such as precision voltage references and low-dropout regulators, can help maintain stable voltage levels and reduce noise injection into the system. Furthermore, the use of snubber circuits across rectifying diodes can help suppress voltage spikes and ringing, improving overall EMC performance.

Implementing proper grounding techniques is essential for effective noise reduction. Star grounding, where all ground connections converge at a single point, can help prevent ground loops and minimize noise coupling between different circuit sections. Additionally, the use of separate analog and digital grounds, connected at a single point, can further improve noise isolation.

Lastly, employing spread spectrum techniques can help distribute EMI energy across a wider frequency range, reducing peak emissions and improving overall EMC performance. This approach can be particularly effective in meeting stringent regulatory requirements for electromagnetic emissions.

By implementing these electromagnetic compatibility and noise reduction strategies, designers can significantly improve the voltage regulation performance of half-wave rectifiers, ensuring stable and reliable operation in various applications.

Another important strategy is the use of filtering components. Capacitors and inductors can be strategically placed in the circuit to attenuate high-frequency noise and smooth out voltage fluctuations. Low-pass filters are particularly effective in reducing high-frequency harmonics generated by the rectification process. Additionally, ferrite beads can be employed to suppress common-mode noise on power lines and signal traces.

Proper PCB layout design is crucial for EMC and noise reduction. Implementing a ground plane helps minimize ground loop currents and provides a low-impedance return path for high-frequency signals. Careful routing of traces, with attention to minimizing loop areas and separating sensitive analog signals from noisy digital lines, can significantly reduce EMI.

Component selection also plays a vital role in EMC performance. Choosing low-noise components, such as precision voltage references and low-dropout regulators, can help maintain stable voltage levels and reduce noise injection into the system. Furthermore, the use of snubber circuits across rectifying diodes can help suppress voltage spikes and ringing, improving overall EMC performance.

Implementing proper grounding techniques is essential for effective noise reduction. Star grounding, where all ground connections converge at a single point, can help prevent ground loops and minimize noise coupling between different circuit sections. Additionally, the use of separate analog and digital grounds, connected at a single point, can further improve noise isolation.

Lastly, employing spread spectrum techniques can help distribute EMI energy across a wider frequency range, reducing peak emissions and improving overall EMC performance. This approach can be particularly effective in meeting stringent regulatory requirements for electromagnetic emissions.

By implementing these electromagnetic compatibility and noise reduction strategies, designers can significantly improve the voltage regulation performance of half-wave rectifiers, ensuring stable and reliable operation in various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!