How to Perfect Gel Casting in Electrophoresis?

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gel Casting Evolution

Gel casting in electrophoresis has undergone significant evolution since its inception in the mid-20th century. The technique has progressed from rudimentary hand-poured gels to sophisticated automated systems, reflecting the broader advancements in molecular biology and biochemistry.

In the early days of electrophoresis, gel casting was a labor-intensive process. Scientists manually prepared and poured agarose or polyacrylamide gels, often resulting in inconsistent thickness and composition. This variability could lead to unreliable results and poor reproducibility across experiments. The introduction of vertical gel casting systems in the 1970s marked a significant improvement, allowing for more uniform gel thickness and easier handling.

The 1980s saw the development of pre-cast gels, which revolutionized the field by offering standardized, ready-to-use gel matrices. These pre-cast gels significantly reduced preparation time and improved consistency between experiments. However, they were initially limited in their range of concentrations and sizes.

The 1990s brought about the integration of computer-controlled systems in gel casting. This automation allowed for precise control over gel composition, thickness, and well formation. Gradient gels, which offer a range of pore sizes within a single gel, became more accessible and reproducible through these automated systems.

In the early 2000s, miniaturization trends led to the development of microfluidic electrophoresis systems. These devices integrated gel casting, sample loading, and separation into a single chip, dramatically reducing sample and reagent volumes while increasing throughput.

Recent advancements have focused on enhancing gel properties for specific applications. The introduction of high-resolution agarose gels has improved DNA fragment separation, while specialized acrylamide formulations have optimized protein separation. Additionally, the development of environmentally friendly and non-toxic gel alternatives has addressed safety concerns associated with traditional materials.

The latest innovations in gel casting technology include 3D-printed molds for custom gel shapes and sizes, as well as smart gel systems that can respond to external stimuli. These advancements are pushing the boundaries of what's possible in electrophoretic separations, enabling more complex and precise analyses.

Throughout its evolution, the focus of gel casting development has been on improving reproducibility, ease of use, and separation performance. From manual pouring to automated systems, and from standard formulations to application-specific gels, the field continues to advance, driven by the ever-increasing demands of molecular biology and biochemical research.

In the early days of electrophoresis, gel casting was a labor-intensive process. Scientists manually prepared and poured agarose or polyacrylamide gels, often resulting in inconsistent thickness and composition. This variability could lead to unreliable results and poor reproducibility across experiments. The introduction of vertical gel casting systems in the 1970s marked a significant improvement, allowing for more uniform gel thickness and easier handling.

The 1980s saw the development of pre-cast gels, which revolutionized the field by offering standardized, ready-to-use gel matrices. These pre-cast gels significantly reduced preparation time and improved consistency between experiments. However, they were initially limited in their range of concentrations and sizes.

The 1990s brought about the integration of computer-controlled systems in gel casting. This automation allowed for precise control over gel composition, thickness, and well formation. Gradient gels, which offer a range of pore sizes within a single gel, became more accessible and reproducible through these automated systems.

In the early 2000s, miniaturization trends led to the development of microfluidic electrophoresis systems. These devices integrated gel casting, sample loading, and separation into a single chip, dramatically reducing sample and reagent volumes while increasing throughput.

Recent advancements have focused on enhancing gel properties for specific applications. The introduction of high-resolution agarose gels has improved DNA fragment separation, while specialized acrylamide formulations have optimized protein separation. Additionally, the development of environmentally friendly and non-toxic gel alternatives has addressed safety concerns associated with traditional materials.

The latest innovations in gel casting technology include 3D-printed molds for custom gel shapes and sizes, as well as smart gel systems that can respond to external stimuli. These advancements are pushing the boundaries of what's possible in electrophoretic separations, enabling more complex and precise analyses.

Throughout its evolution, the focus of gel casting development has been on improving reproducibility, ease of use, and separation performance. From manual pouring to automated systems, and from standard formulations to application-specific gels, the field continues to advance, driven by the ever-increasing demands of molecular biology and biochemical research.

Market Analysis

The gel electrophoresis market has been experiencing steady growth due to increasing applications in molecular biology, genetics, and biochemistry research. The global market for electrophoresis equipment and supplies is projected to reach significant value in the coming years, driven by advancements in proteomics and genomics research, as well as the rising demand for personalized medicine.

Gel casting, a critical step in electrophoresis, plays a crucial role in determining the quality and reproducibility of results. As such, there is a growing demand for improved gel casting techniques and products that can enhance the overall performance of electrophoresis experiments. This demand is particularly strong in academic and research institutions, biotechnology companies, and pharmaceutical laboratories.

The market for gel casting products and solutions is characterized by a mix of established players and innovative startups. Major companies in the life sciences and laboratory equipment sectors offer a range of gel casting systems, from basic setups to advanced automated platforms. These products cater to various needs, from small-scale research projects to high-throughput industrial applications.

One of the key drivers of market growth is the increasing focus on precision and reproducibility in scientific research. Researchers and laboratories are seeking solutions that can minimize variability in gel casting, leading to more consistent and reliable results. This trend has spurred the development of new technologies and products aimed at perfecting the gel casting process.

Another significant factor influencing the market is the growing adoption of proteomics and genomics in drug discovery and development. As these fields continue to expand, the demand for high-quality electrophoresis gels and casting solutions is expected to rise. This is particularly evident in the pharmaceutical and biotechnology sectors, where accurate protein and nucleic acid analysis is crucial for drug development and quality control.

The market also sees a trend towards automation and integration of gel casting systems with other laboratory equipment. This shift is driven by the need for increased efficiency, reduced human error, and improved workflow in research and clinical settings. Automated gel casting systems that offer precise control over gel thickness, composition, and polymerization conditions are gaining traction among end-users.

Geographically, North America and Europe remain the largest markets for gel electrophoresis products, including gel casting solutions. However, the Asia-Pacific region is emerging as a rapidly growing market, fueled by increasing research and development activities in countries like China, Japan, and India. This regional growth is supported by rising government investments in life sciences research and the expansion of biotechnology and pharmaceutical industries.

In conclusion, the market for perfecting gel casting in electrophoresis is driven by the need for improved accuracy, reproducibility, and efficiency in molecular biology research. As the field of electrophoresis continues to evolve, there is significant potential for innovative solutions that address current challenges in gel casting, opening up opportunities for both established players and new entrants in the market.

Gel casting, a critical step in electrophoresis, plays a crucial role in determining the quality and reproducibility of results. As such, there is a growing demand for improved gel casting techniques and products that can enhance the overall performance of electrophoresis experiments. This demand is particularly strong in academic and research institutions, biotechnology companies, and pharmaceutical laboratories.

The market for gel casting products and solutions is characterized by a mix of established players and innovative startups. Major companies in the life sciences and laboratory equipment sectors offer a range of gel casting systems, from basic setups to advanced automated platforms. These products cater to various needs, from small-scale research projects to high-throughput industrial applications.

One of the key drivers of market growth is the increasing focus on precision and reproducibility in scientific research. Researchers and laboratories are seeking solutions that can minimize variability in gel casting, leading to more consistent and reliable results. This trend has spurred the development of new technologies and products aimed at perfecting the gel casting process.

Another significant factor influencing the market is the growing adoption of proteomics and genomics in drug discovery and development. As these fields continue to expand, the demand for high-quality electrophoresis gels and casting solutions is expected to rise. This is particularly evident in the pharmaceutical and biotechnology sectors, where accurate protein and nucleic acid analysis is crucial for drug development and quality control.

The market also sees a trend towards automation and integration of gel casting systems with other laboratory equipment. This shift is driven by the need for increased efficiency, reduced human error, and improved workflow in research and clinical settings. Automated gel casting systems that offer precise control over gel thickness, composition, and polymerization conditions are gaining traction among end-users.

Geographically, North America and Europe remain the largest markets for gel electrophoresis products, including gel casting solutions. However, the Asia-Pacific region is emerging as a rapidly growing market, fueled by increasing research and development activities in countries like China, Japan, and India. This regional growth is supported by rising government investments in life sciences research and the expansion of biotechnology and pharmaceutical industries.

In conclusion, the market for perfecting gel casting in electrophoresis is driven by the need for improved accuracy, reproducibility, and efficiency in molecular biology research. As the field of electrophoresis continues to evolve, there is significant potential for innovative solutions that address current challenges in gel casting, opening up opportunities for both established players and new entrants in the market.

Technical Challenges

Gel casting in electrophoresis faces several technical challenges that researchers and laboratory technicians must overcome to achieve optimal results. One of the primary issues is the formation of air bubbles during the gel preparation and pouring process. These bubbles can disrupt the uniform electric field and cause irregular migration patterns, leading to inaccurate results. Developing techniques to minimize bubble formation and effectively remove any trapped air is crucial for improving gel quality.

Another significant challenge is achieving consistent gel thickness across the entire casting area. Uneven gel thickness can result in non-uniform electric field distribution, causing distorted band patterns and compromising the accuracy of molecular weight estimations. This issue is particularly pronounced when casting large gels or when using glass plates that are not perfectly flat.

The polymerization process itself presents challenges in terms of timing and uniformity. Ensuring complete and uniform polymerization throughout the gel is essential for consistent pore size distribution. Factors such as temperature, catalyst concentration, and oxygen exposure can affect polymerization kinetics, potentially leading to regions of incomplete cross-linking or over-polymerization.

Gel adhesion to the supporting plates is another critical aspect that can impact electrophoresis performance. Poor adhesion can result in gel detachment during the run, causing leaks and compromising the integrity of the separation. Developing reliable methods to enhance gel-plate adhesion without introducing contaminants or affecting gel properties is an ongoing challenge.

The choice of buffer systems and their interaction with the gel matrix presents additional complexities. Different buffer compositions can affect the pH stability and conductivity of the gel, influencing separation efficiency and resolution. Optimizing buffer systems for specific applications while maintaining gel integrity throughout the electrophoresis run remains a technical hurdle.

Environmental factors, such as temperature fluctuations and humidity, can also impact gel casting quality. These variables can affect polymerization rates, gel drying, and overall structural integrity. Developing robust protocols that account for these environmental influences is essential for reproducible results across different laboratory conditions.

Lastly, the challenge of scaling gel casting processes for high-throughput applications without compromising quality or reproducibility is becoming increasingly important. Automating gel preparation and casting while maintaining precision and eliminating human error is a complex technical problem that requires innovative solutions in both hardware and methodology.

Another significant challenge is achieving consistent gel thickness across the entire casting area. Uneven gel thickness can result in non-uniform electric field distribution, causing distorted band patterns and compromising the accuracy of molecular weight estimations. This issue is particularly pronounced when casting large gels or when using glass plates that are not perfectly flat.

The polymerization process itself presents challenges in terms of timing and uniformity. Ensuring complete and uniform polymerization throughout the gel is essential for consistent pore size distribution. Factors such as temperature, catalyst concentration, and oxygen exposure can affect polymerization kinetics, potentially leading to regions of incomplete cross-linking or over-polymerization.

Gel adhesion to the supporting plates is another critical aspect that can impact electrophoresis performance. Poor adhesion can result in gel detachment during the run, causing leaks and compromising the integrity of the separation. Developing reliable methods to enhance gel-plate adhesion without introducing contaminants or affecting gel properties is an ongoing challenge.

The choice of buffer systems and their interaction with the gel matrix presents additional complexities. Different buffer compositions can affect the pH stability and conductivity of the gel, influencing separation efficiency and resolution. Optimizing buffer systems for specific applications while maintaining gel integrity throughout the electrophoresis run remains a technical hurdle.

Environmental factors, such as temperature fluctuations and humidity, can also impact gel casting quality. These variables can affect polymerization rates, gel drying, and overall structural integrity. Developing robust protocols that account for these environmental influences is essential for reproducible results across different laboratory conditions.

Lastly, the challenge of scaling gel casting processes for high-throughput applications without compromising quality or reproducibility is becoming increasingly important. Automating gel preparation and casting while maintaining precision and eliminating human error is a complex technical problem that requires innovative solutions in both hardware and methodology.

Current Gel Casting Methods

01 Gel casting techniques for improved product quality

Advanced gel casting methods are employed to enhance the quality and perfection of cast products. These techniques involve optimizing the gel composition, controlling the casting environment, and implementing precise curing processes to achieve superior surface finish, dimensional accuracy, and overall product integrity.- Gel casting techniques for improved product quality: Advanced gel casting methods are employed to enhance the quality and perfection of cast products. These techniques involve optimizing the gel composition, controlling the casting environment, and refining the curing process to achieve superior surface finish, dimensional accuracy, and overall product quality.

- Innovative mold designs for gel casting: Novel mold designs are developed to facilitate the gel casting process and improve the final product. These designs may include features for better distribution of the gel material, enhanced heat transfer, and easier demolding, resulting in more consistent and higher quality cast parts.

- Material formulations for optimized gel casting: Specialized material formulations are created to enhance the gel casting process. These formulations may include additives to improve flow characteristics, reduce shrinkage, increase strength, or provide other desirable properties to the final cast product.

- Post-processing techniques for gel cast products: Various post-processing methods are developed to further improve the quality of gel cast products. These techniques may include surface treatments, heat treatments, or finishing processes to enhance the mechanical properties, appearance, or functionality of the cast parts.

- Automation and process control in gel casting: Advanced automation and process control systems are implemented to improve the consistency and efficiency of gel casting operations. These systems may include real-time monitoring, adaptive control algorithms, and data-driven optimization to achieve more reliable and repeatable results in gel casting processes.

02 Innovative mold designs for gel casting

Novel mold designs are developed to facilitate the gel casting process and improve the final product quality. These designs may incorporate features such as specialized cooling channels, adjustable mold components, or advanced release mechanisms to ensure uniform gelation, prevent defects, and enhance the overall casting perfection.Expand Specific Solutions03 Material selection and formulation for optimal gel casting

Careful selection and formulation of materials used in gel casting contribute to achieving perfection in the final product. This includes developing specialized gel compositions, incorporating additives to enhance specific properties, and optimizing the balance between gelation time, viscosity, and curing characteristics.Expand Specific Solutions04 Post-processing techniques for gel cast products

Various post-processing methods are employed to further improve the quality and perfection of gel cast products. These techniques may include surface treatments, heat treatments, or finishing processes to enhance mechanical properties, surface finish, and overall product performance.Expand Specific Solutions05 Quality control and monitoring systems for gel casting

Advanced quality control and monitoring systems are implemented to ensure consistency and perfection in gel casting processes. These systems may involve real-time monitoring of process parameters, automated inspection techniques, or data analytics to identify and correct potential issues during the casting process.Expand Specific Solutions

Industry Leaders

The gel casting electrophoresis market is in a mature stage, with established players and standardized techniques. The global market size for electrophoresis equipment and supplies is estimated to be around $1.8 billion, growing steadily. Key players like Bio-Rad Laboratories, Life Technologies, and EMD Millipore dominate the market with advanced technologies and comprehensive product portfolios. These companies have developed sophisticated gel casting systems and reagents, improving the precision and efficiency of electrophoresis. Smaller companies such as Sage Science and Expedeon are also contributing to innovation in the field. The technology is well-established, but ongoing research focuses on enhancing resolution, speed, and automation of gel casting processes.

Bio-Rad Laboratories, Inc.

Technical Solution: Bio-Rad has developed advanced gel casting systems for electrophoresis, focusing on precision and reproducibility. Their technology includes the Mini-PROTEAN Tetra Handcast Systems, which allow for simultaneous casting of up to four gels[1]. They have also introduced the TGX Stain-Free FastCast acrylamide solutions, enabling rapid gel polymerization in under 30 minutes[2]. Bio-Rad's gel casting technology incorporates innovative features such as leak-free sealing mechanisms and adjustable spacer plates for variable gel thicknesses[3]. Their systems are designed to minimize air bubbles and ensure even polymerization, resulting in high-quality, consistent gels for optimal electrophoresis results.

Strengths: High precision and reproducibility, rapid gel polymerization, versatile casting options. Weaknesses: Higher cost compared to basic systems, may require specialized consumables.

Life Technologies Corp.

Technical Solution: Life Technologies (now part of Thermo Fisher Scientific) has developed the E-Gel system, a revolutionary approach to gel electrophoresis. This system utilizes pre-cast agarose gels with integrated electrodes, eliminating the need for traditional gel casting[4]. The E-Gel technology incorporates a buffer-free design, where the running buffer is pre-packaged within the cassette[5]. This approach significantly reduces hands-on time and potential errors associated with manual gel casting. The company has also introduced the E-Gel Power Snap Electrophoresis Device, which allows for real-time monitoring of DNA migration during electrophoresis[6]. This technology enables researchers to optimize run times and improve overall efficiency in nucleic acid analysis.

Strengths: Eliminates manual gel casting, reduces hands-on time, improves consistency. Weaknesses: Limited customization options, higher per-gel cost compared to self-cast gels.

Key Innovations

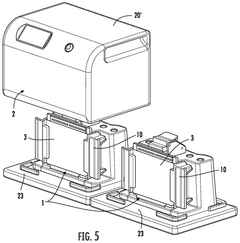

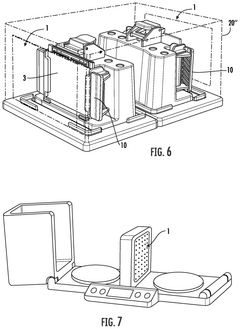

System And Method For Photopolymerizing Electrophoretic Gels

PatentPendingUS20240309195A1

Innovation

- A UV-Vis curing light source is used in conjunction with an acrylamide formulation containing lithium phenyl-2, 4, 6-trimethylbenzoyl-phosphinate as a photoinitiator, allowing for the simultaneous photopolymerization of resolving and stacking gels in a single step, reducing preparation time and chemical usage.

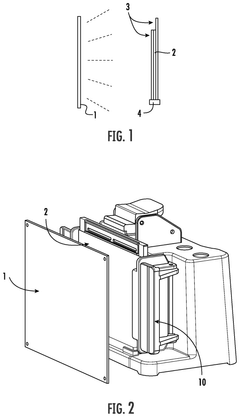

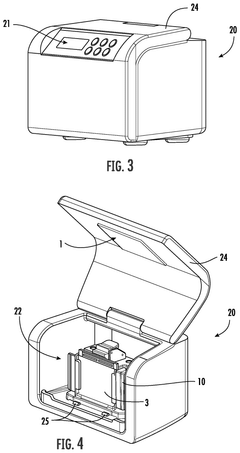

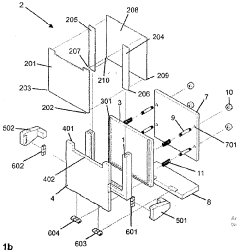

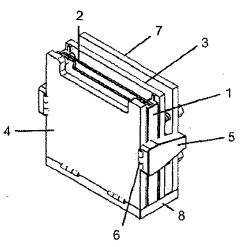

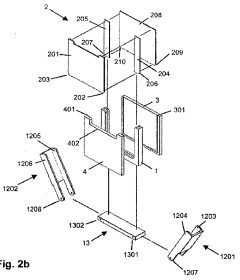

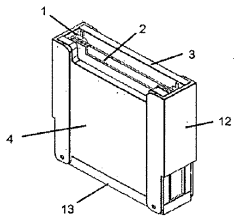

Gasket and casting stand system for sealing and casting of electrophoresis gels.

PatentActiveIN201721044503A

Innovation

- A gasket system with radiused inside corners and tapered inner edges, combined with a gel casting stand that applies increased pressure using clamps and a spring assembly, allowing for leak-proof sealing of gels of varying thickness and accommodating thicker combs without leakage.

Quality Control Measures

Quality control measures are essential for ensuring the reliability and reproducibility of gel electrophoresis results. A comprehensive quality control program for gel casting in electrophoresis should encompass several key aspects. Firstly, it is crucial to maintain strict control over the purity and quality of reagents used in gel preparation. This includes regular testing of acrylamide solutions, buffer components, and polymerization catalysts to ensure they meet specified standards.

The preparation environment plays a significant role in gel quality. Implementing clean room practices or dedicated gel casting areas can minimize contamination risks. Temperature and humidity control in these areas is vital, as these factors can affect gel polymerization and overall quality. Standardized protocols for gel preparation should be established and rigorously followed, including precise measurements of reagents and consistent mixing techniques.

Equipment calibration is another critical aspect of quality control. Regular maintenance and calibration of pipettes, balances, and pH meters used in gel preparation ensure accurate measurements. The use of calibrated spacers and combs for gel casting contributes to consistent gel thickness and well formation.

Implementing a system for batch tracking of prepared gels allows for traceability and easier troubleshooting if issues arise. This can include recording lot numbers of reagents used, preparation dates, and the technician responsible for each batch. Visual inspection of cast gels before use is essential to identify any obvious defects such as bubbles, uneven polymerization, or contamination.

Performance testing of prepared gels should be conducted regularly. This can involve running standard samples or molecular weight markers to verify expected migration patterns and resolution. Documenting and analyzing these results over time can help identify trends or shifts in gel performance.

Training and competency assessment of personnel involved in gel casting is crucial for maintaining quality standards. Regular refresher training and proficiency testing can help ensure that all staff members are following proper procedures consistently.

Finally, implementing a robust documentation system for all quality control measures, including standard operating procedures, equipment logs, and quality control test results, is essential for maintaining a traceable and auditable quality assurance program. Regular review and updating of these procedures based on new technologies or identified issues help in continuous improvement of the gel casting process.

The preparation environment plays a significant role in gel quality. Implementing clean room practices or dedicated gel casting areas can minimize contamination risks. Temperature and humidity control in these areas is vital, as these factors can affect gel polymerization and overall quality. Standardized protocols for gel preparation should be established and rigorously followed, including precise measurements of reagents and consistent mixing techniques.

Equipment calibration is another critical aspect of quality control. Regular maintenance and calibration of pipettes, balances, and pH meters used in gel preparation ensure accurate measurements. The use of calibrated spacers and combs for gel casting contributes to consistent gel thickness and well formation.

Implementing a system for batch tracking of prepared gels allows for traceability and easier troubleshooting if issues arise. This can include recording lot numbers of reagents used, preparation dates, and the technician responsible for each batch. Visual inspection of cast gels before use is essential to identify any obvious defects such as bubbles, uneven polymerization, or contamination.

Performance testing of prepared gels should be conducted regularly. This can involve running standard samples or molecular weight markers to verify expected migration patterns and resolution. Documenting and analyzing these results over time can help identify trends or shifts in gel performance.

Training and competency assessment of personnel involved in gel casting is crucial for maintaining quality standards. Regular refresher training and proficiency testing can help ensure that all staff members are following proper procedures consistently.

Finally, implementing a robust documentation system for all quality control measures, including standard operating procedures, equipment logs, and quality control test results, is essential for maintaining a traceable and auditable quality assurance program. Regular review and updating of these procedures based on new technologies or identified issues help in continuous improvement of the gel casting process.

Environmental Considerations

Environmental considerations play a crucial role in perfecting gel casting for electrophoresis. The process involves the use of various chemicals and materials that can have significant environmental impacts if not properly managed. One of the primary concerns is the disposal of used gels and buffers, which often contain toxic substances such as acrylamide and ethidium bromide. These chemicals can pose serious risks to aquatic ecosystems if released into water systems without proper treatment.

To address this issue, many laboratories have implemented comprehensive waste management protocols. These include the use of specialized waste containers for gel materials and the implementation of on-site treatment systems to neutralize or degrade harmful chemicals before disposal. Additionally, there is a growing trend towards the use of more environmentally friendly alternatives to traditional staining agents, such as SYBR Safe and GelRed, which are less toxic and easier to dispose of safely.

The energy consumption associated with electrophoresis equipment is another environmental consideration. Modern gel casting and electrophoresis systems are being designed with improved energy efficiency, incorporating features such as LED illumination and low-power cooling systems. This not only reduces the carbon footprint of laboratory operations but also contributes to cost savings in the long run.

Water usage is a significant factor in gel casting and electrophoresis. The process requires substantial amounts of purified water for gel preparation, buffer solutions, and equipment cleaning. To minimize water consumption, some laboratories have implemented water recycling systems and adopted more efficient cleaning protocols. The use of pre-cast gels has also gained popularity, as it reduces the need for on-site gel preparation and associated water usage.

The choice of materials used in gel casting equipment and consumables also has environmental implications. There is an increasing focus on developing biodegradable or recyclable alternatives to traditional plastic-based gel trays and combs. Some manufacturers are exploring the use of bio-based plastics or even plant-derived materials for these components, aiming to reduce the overall environmental impact of the electrophoresis process.

Lastly, the storage and transportation of electrophoresis materials and equipment present additional environmental challenges. Proper insulation and temperature control are essential to prevent degradation of sensitive reagents, which could lead to waste and the need for frequent replacements. Optimizing packaging and logistics can help reduce the carbon footprint associated with the distribution of electrophoresis supplies, contributing to a more sustainable laboratory practice overall.

To address this issue, many laboratories have implemented comprehensive waste management protocols. These include the use of specialized waste containers for gel materials and the implementation of on-site treatment systems to neutralize or degrade harmful chemicals before disposal. Additionally, there is a growing trend towards the use of more environmentally friendly alternatives to traditional staining agents, such as SYBR Safe and GelRed, which are less toxic and easier to dispose of safely.

The energy consumption associated with electrophoresis equipment is another environmental consideration. Modern gel casting and electrophoresis systems are being designed with improved energy efficiency, incorporating features such as LED illumination and low-power cooling systems. This not only reduces the carbon footprint of laboratory operations but also contributes to cost savings in the long run.

Water usage is a significant factor in gel casting and electrophoresis. The process requires substantial amounts of purified water for gel preparation, buffer solutions, and equipment cleaning. To minimize water consumption, some laboratories have implemented water recycling systems and adopted more efficient cleaning protocols. The use of pre-cast gels has also gained popularity, as it reduces the need for on-site gel preparation and associated water usage.

The choice of materials used in gel casting equipment and consumables also has environmental implications. There is an increasing focus on developing biodegradable or recyclable alternatives to traditional plastic-based gel trays and combs. Some manufacturers are exploring the use of bio-based plastics or even plant-derived materials for these components, aiming to reduce the overall environmental impact of the electrophoresis process.

Lastly, the storage and transportation of electrophoresis materials and equipment present additional environmental challenges. Proper insulation and temperature control are essential to prevent degradation of sensitive reagents, which could lead to waste and the need for frequent replacements. Optimizing packaging and logistics can help reduce the carbon footprint associated with the distribution of electrophoresis supplies, contributing to a more sustainable laboratory practice overall.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!