How to Prevent Overheating in Half Wave Rectifiers?

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rectifier Overheating Background and Objectives

Half-wave rectifiers are fundamental components in power electronics, widely used for converting alternating current (AC) to pulsating direct current (DC). The evolution of rectifier technology has been closely tied to the development of power electronics and semiconductor devices. Over the past century, rectifiers have progressed from vacuum tube diodes to modern solid-state devices, significantly improving efficiency and reliability.

The primary objective in addressing overheating issues in half-wave rectifiers is to enhance their thermal management capabilities, thereby improving overall performance and longevity. This goal aligns with the broader industry trends of miniaturization, increased power density, and improved energy efficiency in electronic systems.

Overheating in half-wave rectifiers occurs due to power dissipation during the rectification process. As current flows through the rectifying element, typically a diode, it encounters resistance, resulting in heat generation. This heat, if not properly managed, can lead to reduced efficiency, component degradation, and even catastrophic failure.

The technical evolution in this field has focused on several key areas. First, the development of more efficient semiconductor materials and device structures has reduced the forward voltage drop and reverse leakage current in rectifying diodes, minimizing heat generation at the source. Second, advancements in thermal management techniques, including improved heat sink designs and thermal interface materials, have enhanced heat dissipation capabilities.

Current trends in rectifier technology are moving towards higher frequency operation, which allows for smaller passive components but also introduces new thermal challenges due to increased switching losses. Additionally, there is a growing emphasis on wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), which offer superior thermal properties and higher breakdown voltages compared to traditional silicon-based devices.

The market demand for more efficient and reliable rectifiers is driven by various factors, including the proliferation of power electronics in consumer devices, industrial equipment, and renewable energy systems. As these applications become more compact and power-dense, the need for effective thermal management in rectifiers becomes increasingly critical.

Looking forward, the objectives for preventing overheating in half-wave rectifiers include developing novel cooling techniques, such as integrated microfluidic channels or phase-change materials, optimizing circuit topologies to distribute heat more evenly, and exploring advanced materials with enhanced thermal conductivity. Additionally, there is a focus on intelligent thermal management systems that can dynamically adjust operating parameters based on real-time temperature monitoring.

The primary objective in addressing overheating issues in half-wave rectifiers is to enhance their thermal management capabilities, thereby improving overall performance and longevity. This goal aligns with the broader industry trends of miniaturization, increased power density, and improved energy efficiency in electronic systems.

Overheating in half-wave rectifiers occurs due to power dissipation during the rectification process. As current flows through the rectifying element, typically a diode, it encounters resistance, resulting in heat generation. This heat, if not properly managed, can lead to reduced efficiency, component degradation, and even catastrophic failure.

The technical evolution in this field has focused on several key areas. First, the development of more efficient semiconductor materials and device structures has reduced the forward voltage drop and reverse leakage current in rectifying diodes, minimizing heat generation at the source. Second, advancements in thermal management techniques, including improved heat sink designs and thermal interface materials, have enhanced heat dissipation capabilities.

Current trends in rectifier technology are moving towards higher frequency operation, which allows for smaller passive components but also introduces new thermal challenges due to increased switching losses. Additionally, there is a growing emphasis on wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), which offer superior thermal properties and higher breakdown voltages compared to traditional silicon-based devices.

The market demand for more efficient and reliable rectifiers is driven by various factors, including the proliferation of power electronics in consumer devices, industrial equipment, and renewable energy systems. As these applications become more compact and power-dense, the need for effective thermal management in rectifiers becomes increasingly critical.

Looking forward, the objectives for preventing overheating in half-wave rectifiers include developing novel cooling techniques, such as integrated microfluidic channels or phase-change materials, optimizing circuit topologies to distribute heat more evenly, and exploring advanced materials with enhanced thermal conductivity. Additionally, there is a focus on intelligent thermal management systems that can dynamically adjust operating parameters based on real-time temperature monitoring.

Market Demand for Efficient Power Supplies

The demand for efficient power supplies has been steadily increasing across various industries, driven by the growing need for energy-efficient solutions and the proliferation of electronic devices. Half-wave rectifiers, as fundamental components in power supply systems, play a crucial role in this market. However, the issue of overheating in these rectifiers has become a significant concern, prompting manufacturers and consumers alike to seek more reliable and efficient alternatives.

In the consumer electronics sector, the surge in portable devices and smart home appliances has created a substantial market for compact, high-performance power supplies. These devices require stable power sources that can operate efficiently without generating excessive heat, making the prevention of overheating in half-wave rectifiers a critical factor in product design and consumer satisfaction.

The industrial sector also demonstrates a strong demand for improved power supply solutions. Manufacturing equipment, automation systems, and industrial control devices rely heavily on stable power sources. Overheating issues in rectifiers can lead to production downtime, increased maintenance costs, and potential safety hazards. As industries continue to adopt more sophisticated and power-intensive technologies, the need for rectifiers that can handle higher loads without overheating becomes increasingly important.

The automotive industry represents another significant market segment driving the demand for efficient power supplies. With the rapid growth of electric and hybrid vehicles, the requirements for high-performance, reliable power conversion systems have intensified. Rectifiers that can operate efficiently under varying load conditions and temperature ranges are essential for ensuring the longevity and reliability of vehicle electrical systems.

In the renewable energy sector, the expansion of solar and wind power installations has created a substantial market for power conversion technologies. Efficient rectifiers are crucial components in inverters and charge controllers used in these systems. The ability to prevent overheating in half-wave rectifiers directly impacts the overall efficiency and reliability of renewable energy installations, making it a key consideration for manufacturers and system integrators.

The telecommunications industry, with its ongoing expansion of 5G networks and data centers, presents another significant market opportunity. These infrastructure projects require robust power supply systems that can operate continuously under high-load conditions. Rectifiers that can maintain efficiency and prevent overheating are essential for ensuring the reliability and uptime of critical communication networks.

As energy efficiency regulations become more stringent worldwide, there is an increasing emphasis on developing power supply solutions that meet or exceed these standards. This regulatory environment further drives the demand for innovative approaches to prevent overheating in half-wave rectifiers, as manufacturers seek to comply with efficiency requirements while maintaining competitive pricing and performance.

In the consumer electronics sector, the surge in portable devices and smart home appliances has created a substantial market for compact, high-performance power supplies. These devices require stable power sources that can operate efficiently without generating excessive heat, making the prevention of overheating in half-wave rectifiers a critical factor in product design and consumer satisfaction.

The industrial sector also demonstrates a strong demand for improved power supply solutions. Manufacturing equipment, automation systems, and industrial control devices rely heavily on stable power sources. Overheating issues in rectifiers can lead to production downtime, increased maintenance costs, and potential safety hazards. As industries continue to adopt more sophisticated and power-intensive technologies, the need for rectifiers that can handle higher loads without overheating becomes increasingly important.

The automotive industry represents another significant market segment driving the demand for efficient power supplies. With the rapid growth of electric and hybrid vehicles, the requirements for high-performance, reliable power conversion systems have intensified. Rectifiers that can operate efficiently under varying load conditions and temperature ranges are essential for ensuring the longevity and reliability of vehicle electrical systems.

In the renewable energy sector, the expansion of solar and wind power installations has created a substantial market for power conversion technologies. Efficient rectifiers are crucial components in inverters and charge controllers used in these systems. The ability to prevent overheating in half-wave rectifiers directly impacts the overall efficiency and reliability of renewable energy installations, making it a key consideration for manufacturers and system integrators.

The telecommunications industry, with its ongoing expansion of 5G networks and data centers, presents another significant market opportunity. These infrastructure projects require robust power supply systems that can operate continuously under high-load conditions. Rectifiers that can maintain efficiency and prevent overheating are essential for ensuring the reliability and uptime of critical communication networks.

As energy efficiency regulations become more stringent worldwide, there is an increasing emphasis on developing power supply solutions that meet or exceed these standards. This regulatory environment further drives the demand for innovative approaches to prevent overheating in half-wave rectifiers, as manufacturers seek to comply with efficiency requirements while maintaining competitive pricing and performance.

Current Challenges in Half Wave Rectifier Cooling

Half wave rectifiers, while essential in many electronic applications, face significant challenges in thermal management. The primary issue stems from the inherent inefficiency of the rectification process, where only half of the AC waveform is utilized. This results in substantial power dissipation and heat generation within the rectifying components, particularly the diode.

One of the main challenges is the localized heating of the diode junction. During the conduction phase, the diode experiences a voltage drop and current flow, leading to power dissipation in the form of heat. This heat is concentrated in a small area, potentially causing thermal runaway if not adequately managed. The problem is exacerbated in high-power applications where large currents are involved.

Another significant challenge is the pulsating nature of the rectified current. The intermittent conduction of the diode creates thermal cycling, subjecting components to repeated heating and cooling cycles. This thermal stress can lead to fatigue and premature failure of both the diode and surrounding components, including capacitors and transformers.

The design of effective heat sinks presents another hurdle. Traditional heat sink designs may not be optimal for the unique thermal profile of half wave rectifiers. The pulsating heat generation requires heat sinks that can quickly absorb and dissipate heat bursts, while also maintaining overall temperature stability. This demands innovative approaches to heat sink geometry and material selection.

Furthermore, the compact nature of modern electronic devices poses spatial constraints for implementing robust cooling solutions. As devices become smaller and more densely packed, there is less room for conventional cooling methods such as large heat sinks or forced air cooling. This limitation necessitates the development of more efficient and compact cooling techniques.

The environmental impact of cooling solutions is an emerging concern. Traditional cooling methods often rely on materials or processes that may not be environmentally friendly. There is a growing need for sustainable cooling solutions that minimize energy consumption and use eco-friendly materials, without compromising on thermal performance.

Lastly, the cost-effectiveness of cooling solutions remains a persistent challenge. Implementing advanced cooling techniques often incurs additional costs, which can be significant in mass-produced consumer electronics. Striking a balance between effective thermal management and cost-efficiency is crucial for the commercial viability of products incorporating half wave rectifiers.

One of the main challenges is the localized heating of the diode junction. During the conduction phase, the diode experiences a voltage drop and current flow, leading to power dissipation in the form of heat. This heat is concentrated in a small area, potentially causing thermal runaway if not adequately managed. The problem is exacerbated in high-power applications where large currents are involved.

Another significant challenge is the pulsating nature of the rectified current. The intermittent conduction of the diode creates thermal cycling, subjecting components to repeated heating and cooling cycles. This thermal stress can lead to fatigue and premature failure of both the diode and surrounding components, including capacitors and transformers.

The design of effective heat sinks presents another hurdle. Traditional heat sink designs may not be optimal for the unique thermal profile of half wave rectifiers. The pulsating heat generation requires heat sinks that can quickly absorb and dissipate heat bursts, while also maintaining overall temperature stability. This demands innovative approaches to heat sink geometry and material selection.

Furthermore, the compact nature of modern electronic devices poses spatial constraints for implementing robust cooling solutions. As devices become smaller and more densely packed, there is less room for conventional cooling methods such as large heat sinks or forced air cooling. This limitation necessitates the development of more efficient and compact cooling techniques.

The environmental impact of cooling solutions is an emerging concern. Traditional cooling methods often rely on materials or processes that may not be environmentally friendly. There is a growing need for sustainable cooling solutions that minimize energy consumption and use eco-friendly materials, without compromising on thermal performance.

Lastly, the cost-effectiveness of cooling solutions remains a persistent challenge. Implementing advanced cooling techniques often incurs additional costs, which can be significant in mass-produced consumer electronics. Striking a balance between effective thermal management and cost-efficiency is crucial for the commercial viability of products incorporating half wave rectifiers.

Existing Overheating Prevention Techniques

01 Improved cooling mechanisms

Various cooling mechanisms can be implemented to address overheating in half-wave rectifiers. These include heat sinks, cooling fans, and improved thermal management systems. By enhancing heat dissipation, these solutions help maintain optimal operating temperatures and prevent damage to the rectifier components.- Improved cooling mechanisms: Implementing enhanced cooling systems in half-wave rectifiers to dissipate heat more effectively. This can include heat sinks, fans, or liquid cooling solutions to prevent overheating and maintain optimal performance.

- Advanced circuit design: Developing sophisticated circuit designs that minimize heat generation in half-wave rectifiers. This may involve optimizing component placement, using more efficient semiconductors, or implementing advanced control algorithms to reduce power dissipation.

- Thermal management materials: Utilizing high-performance thermal management materials in the construction of half-wave rectifiers. These materials can include thermally conductive polymers, ceramics, or advanced metal alloys that help to distribute and dissipate heat more efficiently.

- Power regulation and control: Implementing intelligent power regulation and control systems to manage the current flow through half-wave rectifiers. This can include adaptive power management, current limiting features, or dynamic load balancing to prevent excessive heat buildup.

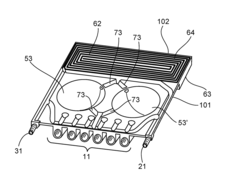

- Modular and scalable designs: Developing modular and scalable half-wave rectifier designs that allow for better heat distribution and easier maintenance. This approach can include separating heat-generating components, using multiple smaller rectifiers instead of a single large one, or implementing easily replaceable modules for improved thermal management.

02 Circuit design optimization

Optimizing the circuit design of half-wave rectifiers can help reduce heat generation. This may involve using more efficient components, improving current distribution, and implementing better voltage regulation techniques. Such optimizations can lead to reduced power losses and improved overall performance.Expand Specific Solutions03 Advanced semiconductor materials

Utilizing advanced semiconductor materials in half-wave rectifiers can improve their thermal performance. Materials with better thermal conductivity and lower resistance can help dissipate heat more effectively, reducing the risk of overheating and improving overall efficiency.Expand Specific Solutions04 Intelligent temperature monitoring and control

Implementing intelligent temperature monitoring and control systems can help prevent overheating in half-wave rectifiers. These systems can include temperature sensors, microcontrollers, and adaptive cooling mechanisms that adjust based on real-time temperature readings, ensuring optimal performance and longevity of the rectifier.Expand Specific Solutions05 Power management techniques

Employing advanced power management techniques can help reduce heat generation in half-wave rectifiers. This may include implementing soft-start mechanisms, current limiting features, and dynamic power adjustment based on load conditions. These techniques can help optimize power consumption and minimize thermal stress on the rectifier components.Expand Specific Solutions

Key Players in Power Electronics Industry

The market for half wave rectifier overheating prevention technology is in a mature stage, with established players and well-understood solutions. The global power electronics market, which includes rectifiers, is projected to reach $40 billion by 2027. Companies like Infineon Technologies, ROHM, and Fuji Electric are at the forefront of developing advanced semiconductor solutions to address thermal management in rectifiers. These firms have invested heavily in R&D to improve efficiency and reduce heat generation in power conversion devices. Smaller players like Cosel and Eichenauer Heizelemente are also contributing innovative approaches to thermal design and materials. The technology's maturity is evident in the wide range of commercial products available, from basic heat sinks to sophisticated integrated cooling systems.

Infineon Technologies AG

Technical Solution: Infineon Technologies AG has developed advanced thermal management solutions for half-wave rectifiers to prevent overheating. Their approach includes the use of high-performance semiconductor materials, such as silicon carbide (SiC), which offers superior thermal conductivity and lower power losses compared to traditional silicon-based devices[1]. Infineon's rectifiers incorporate intelligent thermal design with optimized heat spreading techniques and integrated temperature sensors for real-time monitoring[2]. Additionally, they have implemented advanced packaging technologies that enhance heat dissipation, such as copper clip technology and thermally enhanced leadframes[3]. These innovations collectively contribute to improved thermal performance and reliability in high-power applications.

Strengths: Superior thermal management, high efficiency, and reliability in demanding applications. Weaknesses: Potentially higher cost compared to traditional silicon-based solutions, may require specialized design considerations.

Panasonic Holdings Corp.

Technical Solution: Panasonic Holdings Corp. has developed a comprehensive strategy to prevent overheating in half-wave rectifiers, focusing on both component-level and system-level solutions. At the component level, they have introduced high-efficiency rectifier diodes with optimized doping profiles and junction structures to minimize power losses[13]. Panasonic's approach also includes the use of advanced thermal management materials, such as high thermal conductivity ceramics and specialized thermal interface materials[14]. At the system level, they have implemented intelligent power management systems that dynamically adjust rectifier operation based on load conditions and temperature feedback. Additionally, Panasonic has developed compact, high-efficiency cooling solutions, including miniaturized heat pipes and vapor chambers, to enhance heat dissipation in confined spaces[15].

Strengths: Comprehensive approach addressing both component and system-level thermal management, suitable for various application scales. Weaknesses: May require integration of multiple technologies, potentially increasing complexity and cost.

Innovative Cooling Solutions for Rectifiers

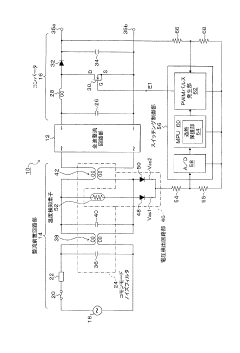

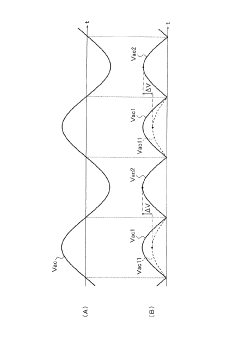

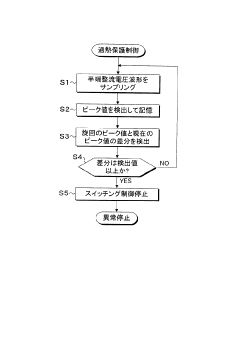

Stabilized power supply device

PatentActiveJP2019083670A

Innovation

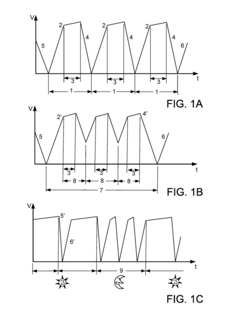

- A stabilized power supply device that includes a voltage detection circuit and a temperature detection element in the pre-rectification circuit, detecting half-wave rectified voltage waveforms to identify overheating and performing protective operations by comparing peak values to a variable threshold, using a temperature sensing element with a positive temperature characteristic to thermally couple with circuit components.

Medical device heaters and methods

PatentActiveUS20170189600A1

Innovation

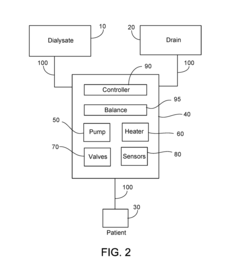

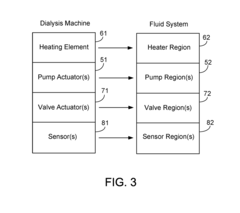

- A medical device with a heater and a heating control unit that monitors zero crossings of the mains voltage and switches heating elements on or off, controlling power through the ratio of half cycles, allowing operation at different voltages and reducing electromagnetic irradiation and power loss, with optional synchronous or alternating operation of multiple heating elements to maintain consistent power.

Regulatory Standards for Electronic Cooling

Regulatory standards for electronic cooling play a crucial role in ensuring the safe and efficient operation of half wave rectifiers and other electronic devices. These standards are established by various international and national organizations to address the potential risks associated with overheating and to promote the development of reliable cooling solutions.

The International Electrotechnical Commission (IEC) has developed several standards that are relevant to electronic cooling, including IEC 60068-2-1 and IEC 60068-2-2, which specify environmental testing procedures for electronic equipment, including temperature tests. These standards provide guidelines for manufacturers to assess the thermal performance of their devices under various operating conditions.

In the United States, the Underwriters Laboratories (UL) has established UL 60950-1, which covers the safety of information technology equipment, including requirements for temperature limits and cooling systems. This standard is widely recognized and adopted by manufacturers worldwide.

The European Union's Restriction of Hazardous Substances (RoHS) directive, while primarily focused on limiting the use of certain hazardous materials in electronic equipment, also indirectly impacts cooling solutions by promoting the use of more environmentally friendly materials in heat sinks and other thermal management components.

For specific applications in the automotive industry, where half wave rectifiers are commonly used, standards such as ISO 16750-4 provide guidelines for environmental conditions and testing for electrical and electronic equipment in road vehicles. This standard includes specifications for temperature cycling and thermal shock tests.

The implementation of these regulatory standards often requires manufacturers to conduct thorough thermal analysis and testing of their products. This may involve the use of computational fluid dynamics (CFD) simulations, thermal imaging, and physical prototyping to ensure compliance with the prescribed temperature limits and cooling performance requirements.

Adherence to these standards not only ensures the safety and reliability of electronic devices but also promotes innovation in cooling technologies. Manufacturers are continually challenged to develop more efficient and compact cooling solutions that meet or exceed regulatory requirements while addressing the increasing power densities of modern electronic components.

As technology advances, regulatory bodies regularly update their standards to keep pace with new developments and emerging challenges in electronic cooling. This ongoing process involves collaboration between industry experts, researchers, and regulatory authorities to establish benchmarks that balance safety, performance, and environmental considerations.

The International Electrotechnical Commission (IEC) has developed several standards that are relevant to electronic cooling, including IEC 60068-2-1 and IEC 60068-2-2, which specify environmental testing procedures for electronic equipment, including temperature tests. These standards provide guidelines for manufacturers to assess the thermal performance of their devices under various operating conditions.

In the United States, the Underwriters Laboratories (UL) has established UL 60950-1, which covers the safety of information technology equipment, including requirements for temperature limits and cooling systems. This standard is widely recognized and adopted by manufacturers worldwide.

The European Union's Restriction of Hazardous Substances (RoHS) directive, while primarily focused on limiting the use of certain hazardous materials in electronic equipment, also indirectly impacts cooling solutions by promoting the use of more environmentally friendly materials in heat sinks and other thermal management components.

For specific applications in the automotive industry, where half wave rectifiers are commonly used, standards such as ISO 16750-4 provide guidelines for environmental conditions and testing for electrical and electronic equipment in road vehicles. This standard includes specifications for temperature cycling and thermal shock tests.

The implementation of these regulatory standards often requires manufacturers to conduct thorough thermal analysis and testing of their products. This may involve the use of computational fluid dynamics (CFD) simulations, thermal imaging, and physical prototyping to ensure compliance with the prescribed temperature limits and cooling performance requirements.

Adherence to these standards not only ensures the safety and reliability of electronic devices but also promotes innovation in cooling technologies. Manufacturers are continually challenged to develop more efficient and compact cooling solutions that meet or exceed regulatory requirements while addressing the increasing power densities of modern electronic components.

As technology advances, regulatory bodies regularly update their standards to keep pace with new developments and emerging challenges in electronic cooling. This ongoing process involves collaboration between industry experts, researchers, and regulatory authorities to establish benchmarks that balance safety, performance, and environmental considerations.

Environmental Impact of Cooling Technologies

The environmental impact of cooling technologies used in half wave rectifiers is a critical consideration in the broader context of electronic device sustainability. As the demand for efficient power conversion systems grows, so does the need for effective cooling solutions that minimize ecological footprints. Traditional cooling methods often rely on materials and processes that can have significant environmental consequences.

Air cooling, a common approach in half wave rectifiers, generally has a lower environmental impact compared to liquid cooling systems. However, the energy consumption required to power fans and heat sinks can contribute to increased carbon emissions if the electricity source is not renewable. Furthermore, the production of aluminum heat sinks involves energy-intensive processes and mining activities that can lead to habitat disruption and resource depletion.

Liquid cooling systems, while more efficient in heat dissipation, introduce additional environmental concerns. The use of coolants, particularly those containing harmful chemicals, poses risks of contamination if leaks occur. The disposal of these coolants at the end of the device's life cycle requires careful management to prevent soil and water pollution. Additionally, the manufacturing of complex liquid cooling components often involves more resource-intensive processes compared to simpler air cooling solutions.

Passive cooling techniques, such as those utilizing phase change materials or advanced thermal management designs, offer promising alternatives with potentially lower environmental impacts. These methods can reduce or eliminate the need for energy-consuming active cooling components. However, the production of specialized materials for passive cooling may involve complex chemical processes that need to be carefully assessed for their environmental implications.

The lifecycle assessment of cooling technologies must also consider the end-of-life disposal and recyclability of components. Many cooling systems contain metals and plastics that can be recycled, but the separation and processing of these materials require energy and resources. Designing cooling systems with easily separable and recyclable components can significantly reduce their overall environmental impact.

Emerging technologies in the field of cooling, such as thermoelectric cooling and graphene-based heat spreaders, offer potential for more environmentally friendly solutions. These technologies may reduce the reliance on traditional cooling methods and their associated environmental drawbacks. However, the environmental impact of producing and implementing these new technologies at scale must be thoroughly evaluated to ensure they offer a net positive effect on sustainability.

In conclusion, the environmental impact of cooling technologies in half wave rectifiers extends beyond their operational efficiency. A holistic approach considering material sourcing, manufacturing processes, energy consumption during use, and end-of-life management is essential for developing truly sustainable cooling solutions in electronic power systems.

Air cooling, a common approach in half wave rectifiers, generally has a lower environmental impact compared to liquid cooling systems. However, the energy consumption required to power fans and heat sinks can contribute to increased carbon emissions if the electricity source is not renewable. Furthermore, the production of aluminum heat sinks involves energy-intensive processes and mining activities that can lead to habitat disruption and resource depletion.

Liquid cooling systems, while more efficient in heat dissipation, introduce additional environmental concerns. The use of coolants, particularly those containing harmful chemicals, poses risks of contamination if leaks occur. The disposal of these coolants at the end of the device's life cycle requires careful management to prevent soil and water pollution. Additionally, the manufacturing of complex liquid cooling components often involves more resource-intensive processes compared to simpler air cooling solutions.

Passive cooling techniques, such as those utilizing phase change materials or advanced thermal management designs, offer promising alternatives with potentially lower environmental impacts. These methods can reduce or eliminate the need for energy-consuming active cooling components. However, the production of specialized materials for passive cooling may involve complex chemical processes that need to be carefully assessed for their environmental implications.

The lifecycle assessment of cooling technologies must also consider the end-of-life disposal and recyclability of components. Many cooling systems contain metals and plastics that can be recycled, but the separation and processing of these materials require energy and resources. Designing cooling systems with easily separable and recyclable components can significantly reduce their overall environmental impact.

Emerging technologies in the field of cooling, such as thermoelectric cooling and graphene-based heat spreaders, offer potential for more environmentally friendly solutions. These technologies may reduce the reliance on traditional cooling methods and their associated environmental drawbacks. However, the environmental impact of producing and implementing these new technologies at scale must be thoroughly evaluated to ensure they offer a net positive effect on sustainability.

In conclusion, the environmental impact of cooling technologies in half wave rectifiers extends beyond their operational efficiency. A holistic approach considering material sourcing, manufacturing processes, energy consumption during use, and end-of-life management is essential for developing truly sustainable cooling solutions in electronic power systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!